Double-sided preassembling method for bulkhead guide rails on large container ship and bulkhead

A technology for container ships and compartments, which is applied to ship accessories, transportation and packaging, and load handling devices, etc. It can solve the problems of long backlog time of the tire position of the general group, affect the loading progress of the dock, and low construction efficiency, so as to improve the efficiency of ship construction , reduce the difficulty of operation, and improve the efficiency of pre-installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below we will further elaborate on the patent application of the present invention in conjunction with the accompanying drawings and specific embodiments, in order to understand the composition, structure and working mode of the patent of the present invention more clearly, but this cannot limit the scope of protection of the present invention. .

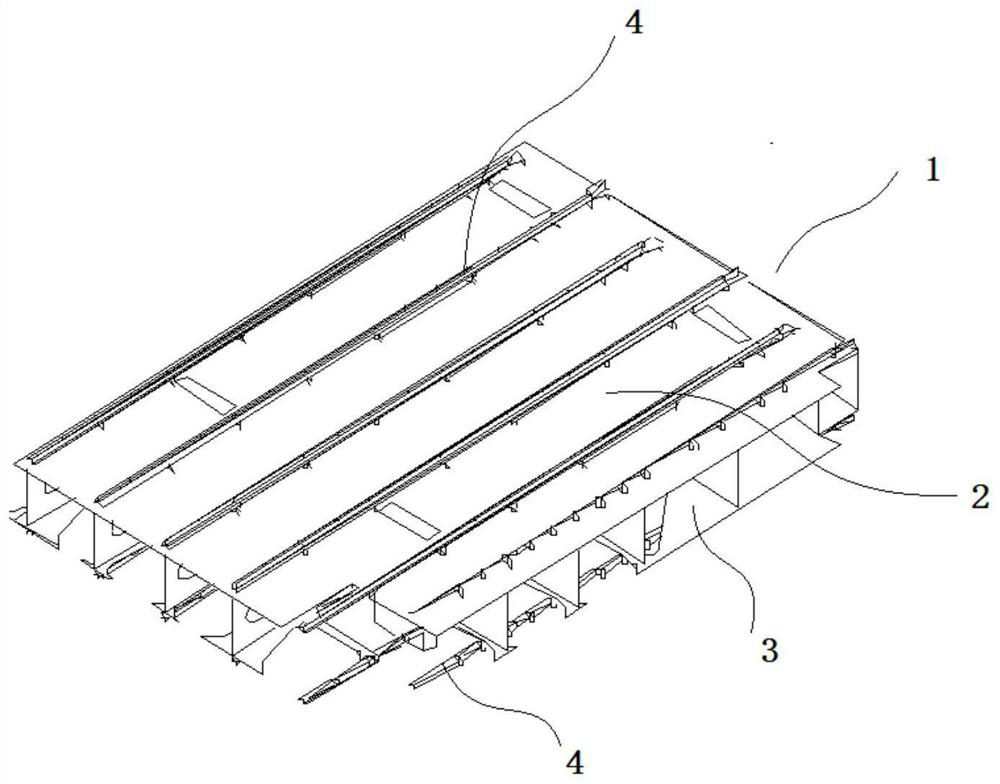

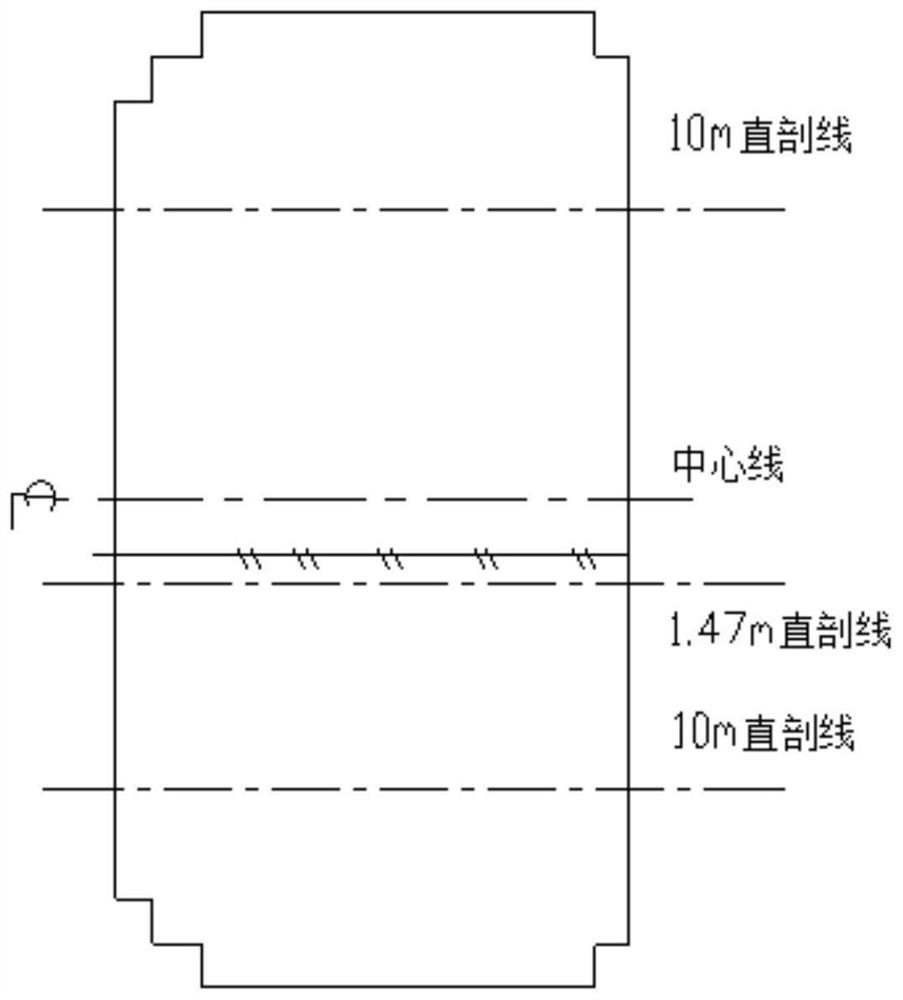

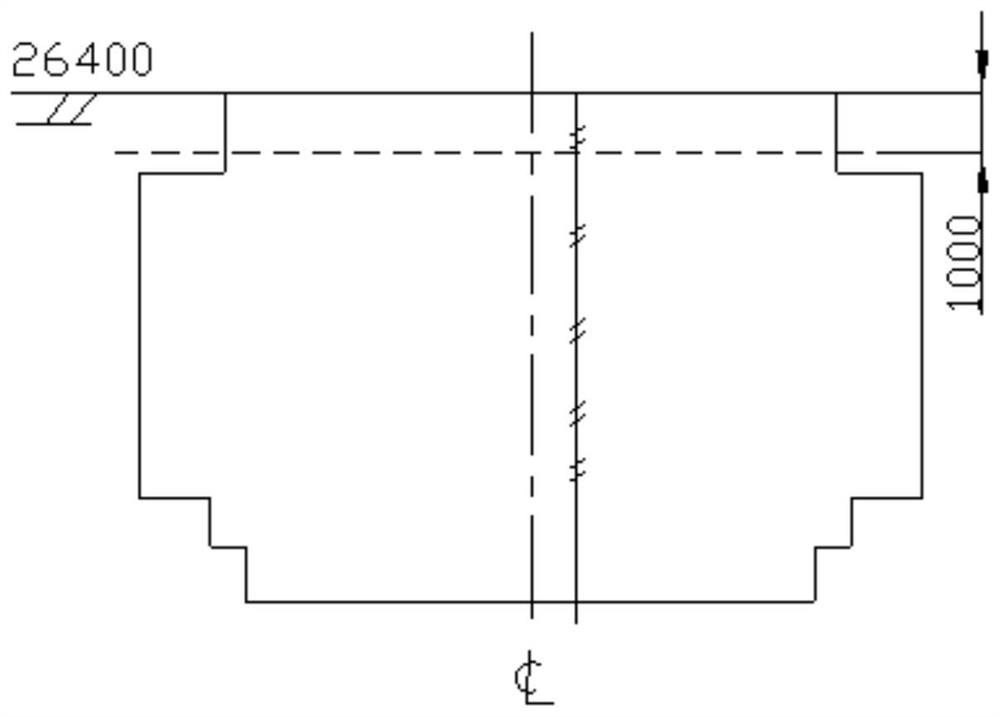

[0024] The invention provides a double-sided pre-installation method for a compartment guide rail on a large container ship. Such as figure 1 As shown, the compartments applied on large container ships are divided into watertight compartments and non-watertight compartments. The method of the present invention is mainly applied to non-watertight compartments. , respectively fixed on the rear wall and front wall on both sides of the frame, one end face of the compartment is a hatch enclosure panel, the guide rail frames are respectively installed on the outside of the front wall and rear wall, and the compartment guide rails ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com