Patents

Literature

109 results about "Compartment (ship)" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A compartment is a portion of the space within a ship defined vertically between decks and horizontally between bulkheads. It is analogous to a room within a building, and may provide watertight subdivision of the ship's hull important in retaining buoyancy if the hull is damaged. Subdivision of a ship's hull into watertight compartments is called compartmentation.

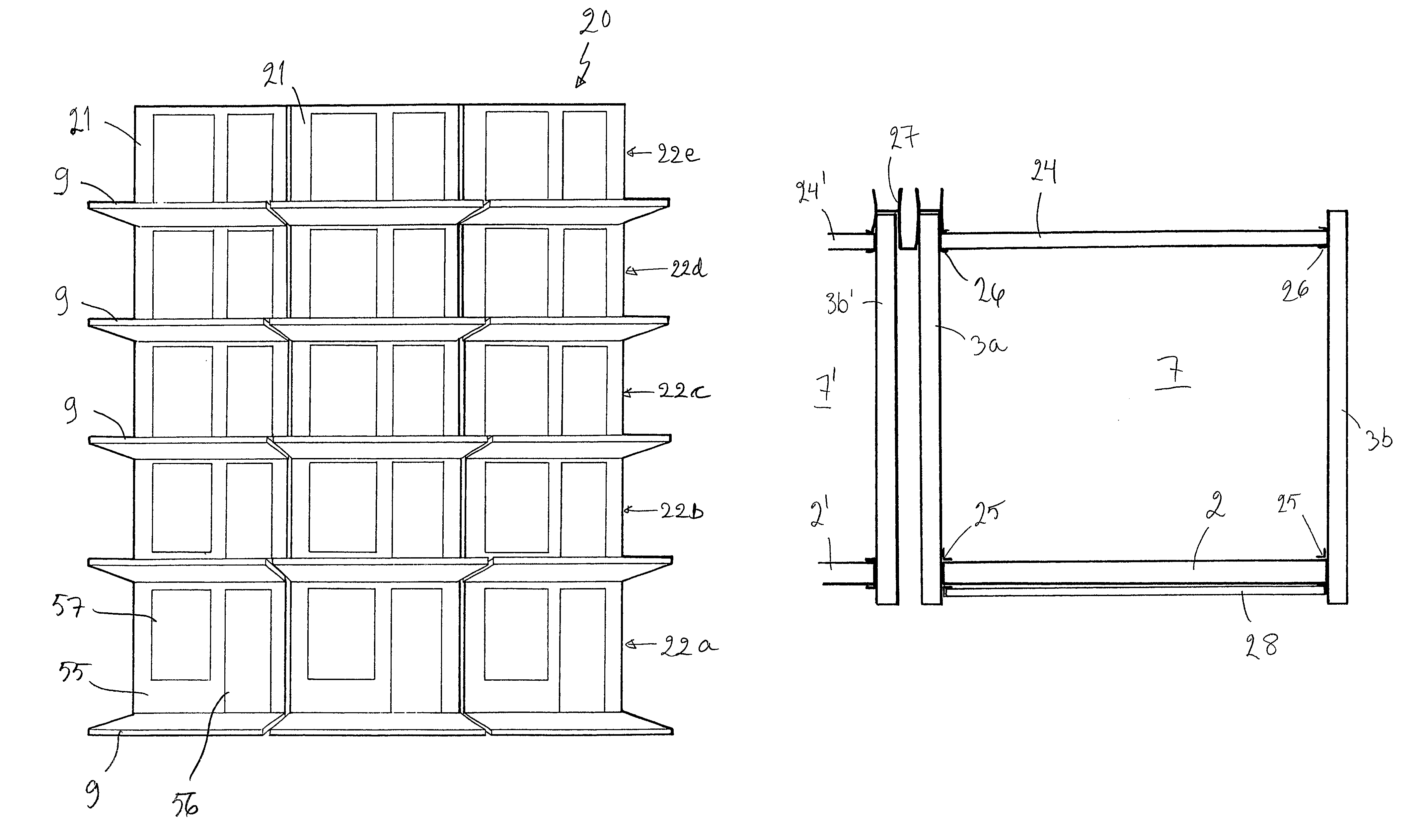

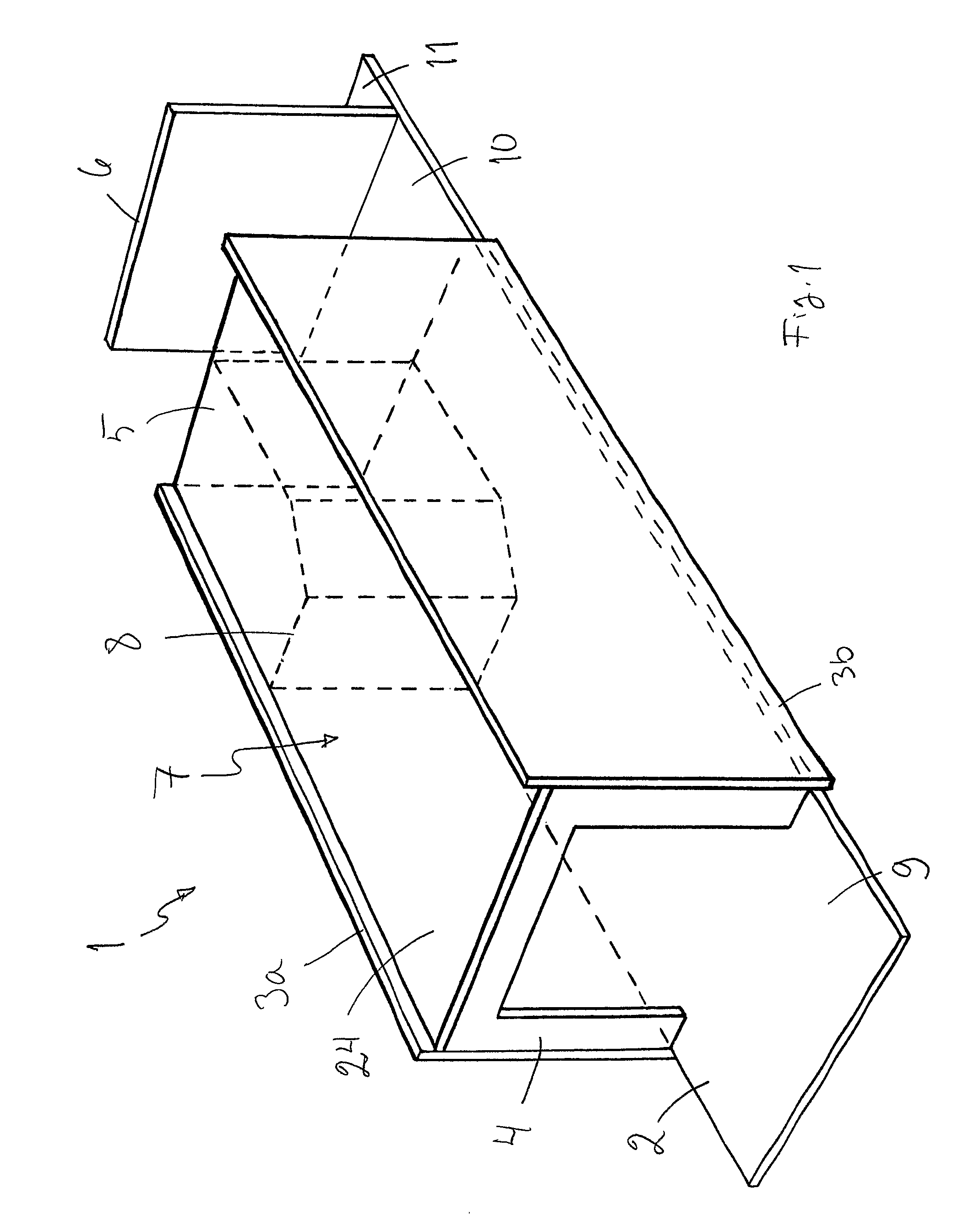

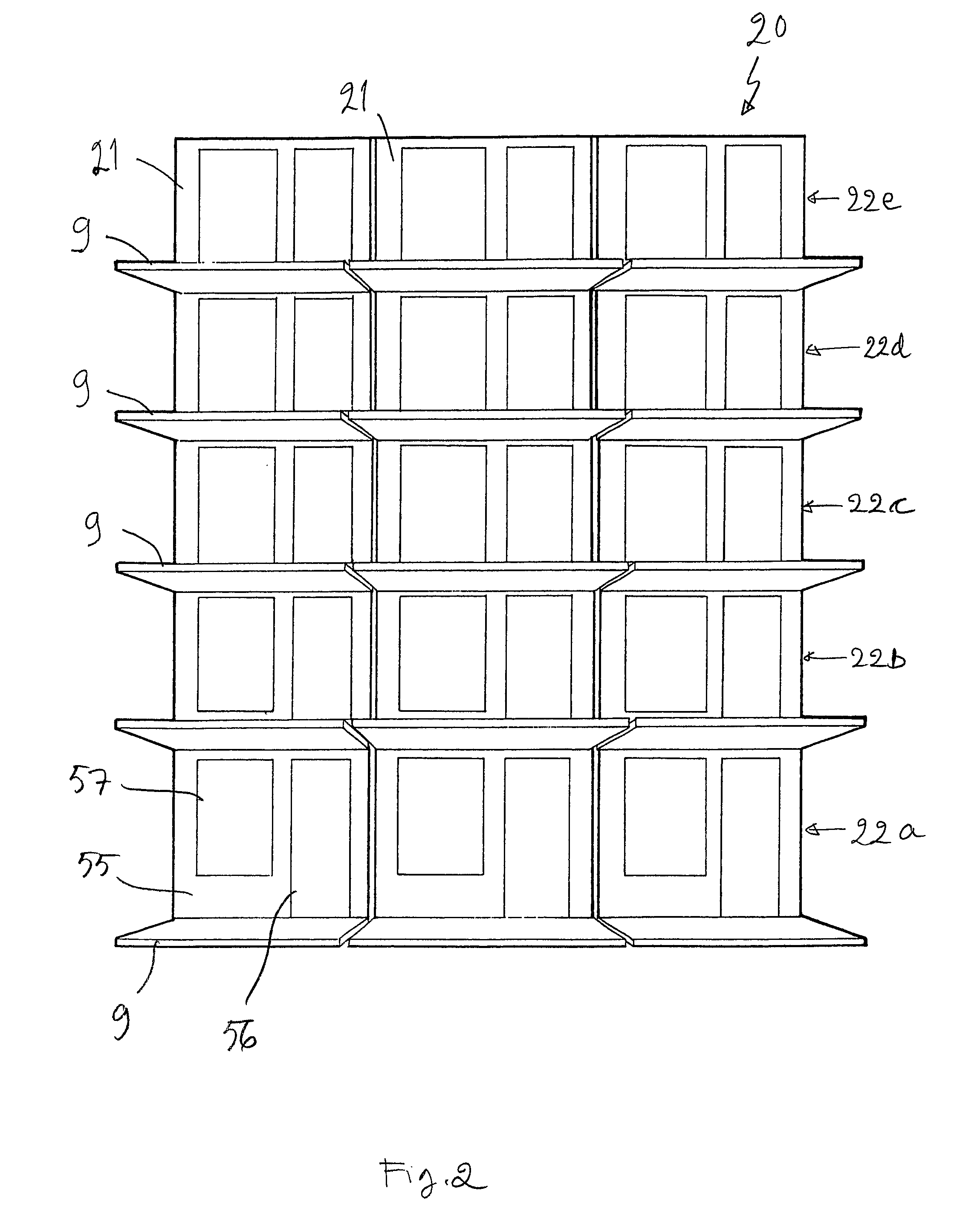

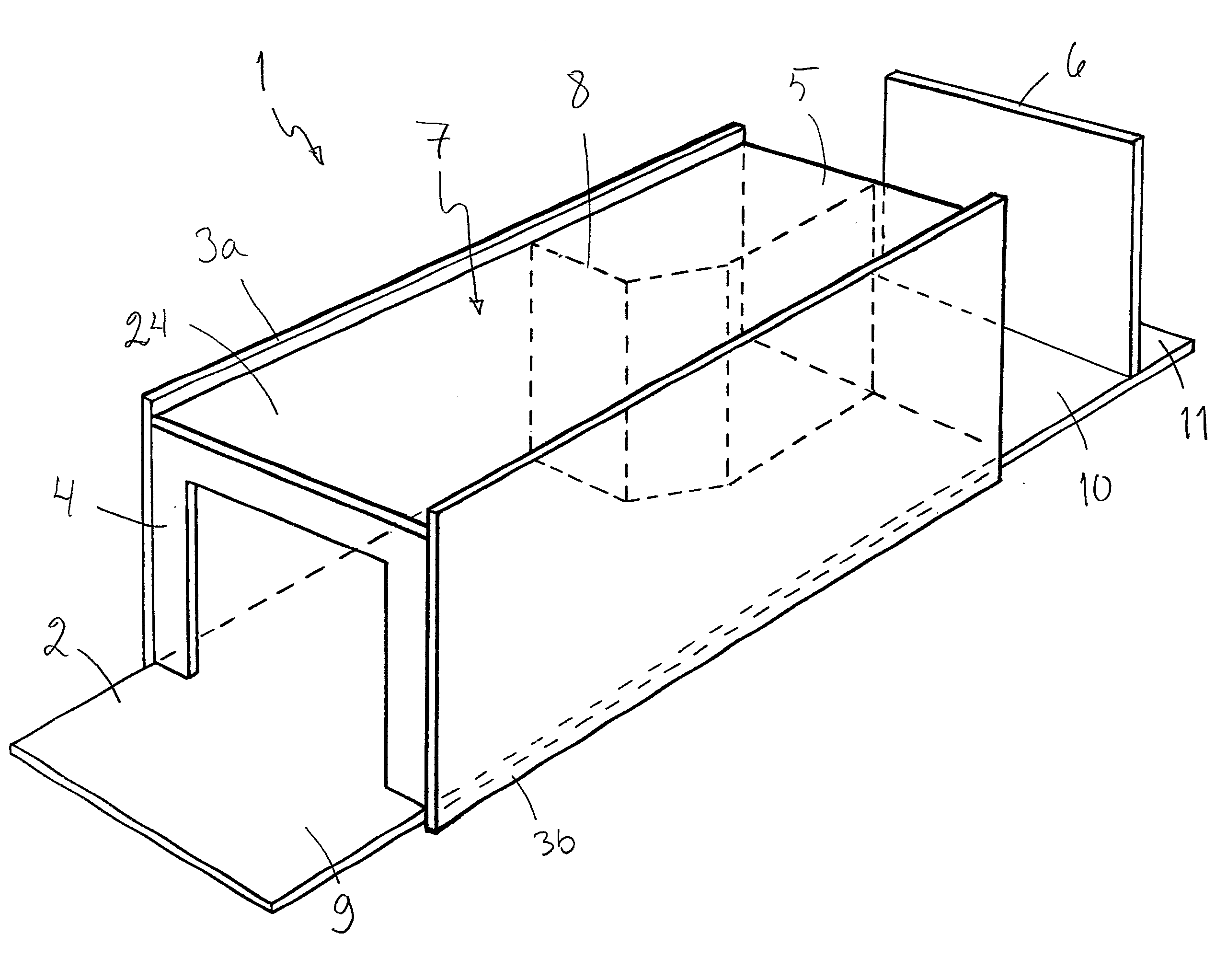

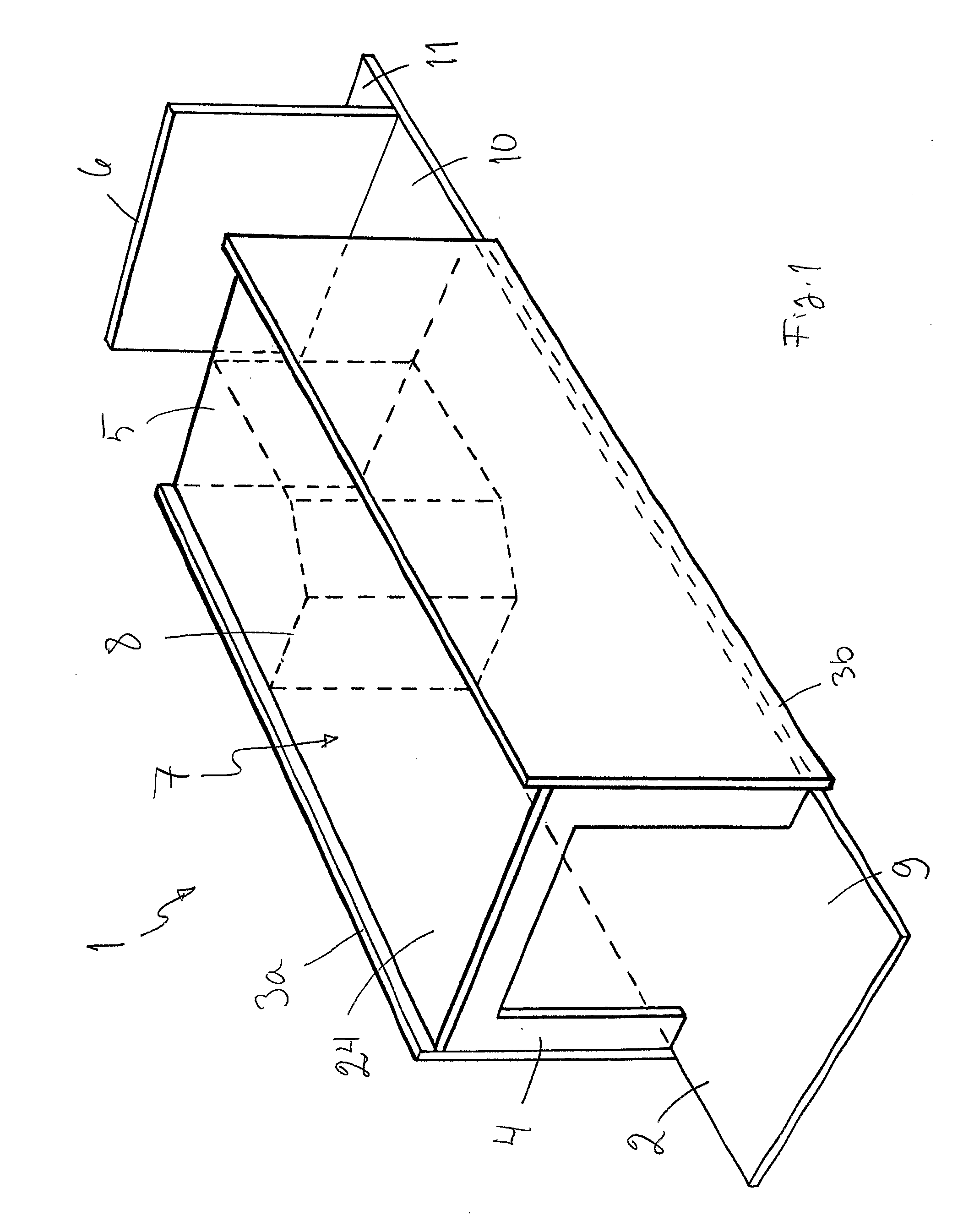

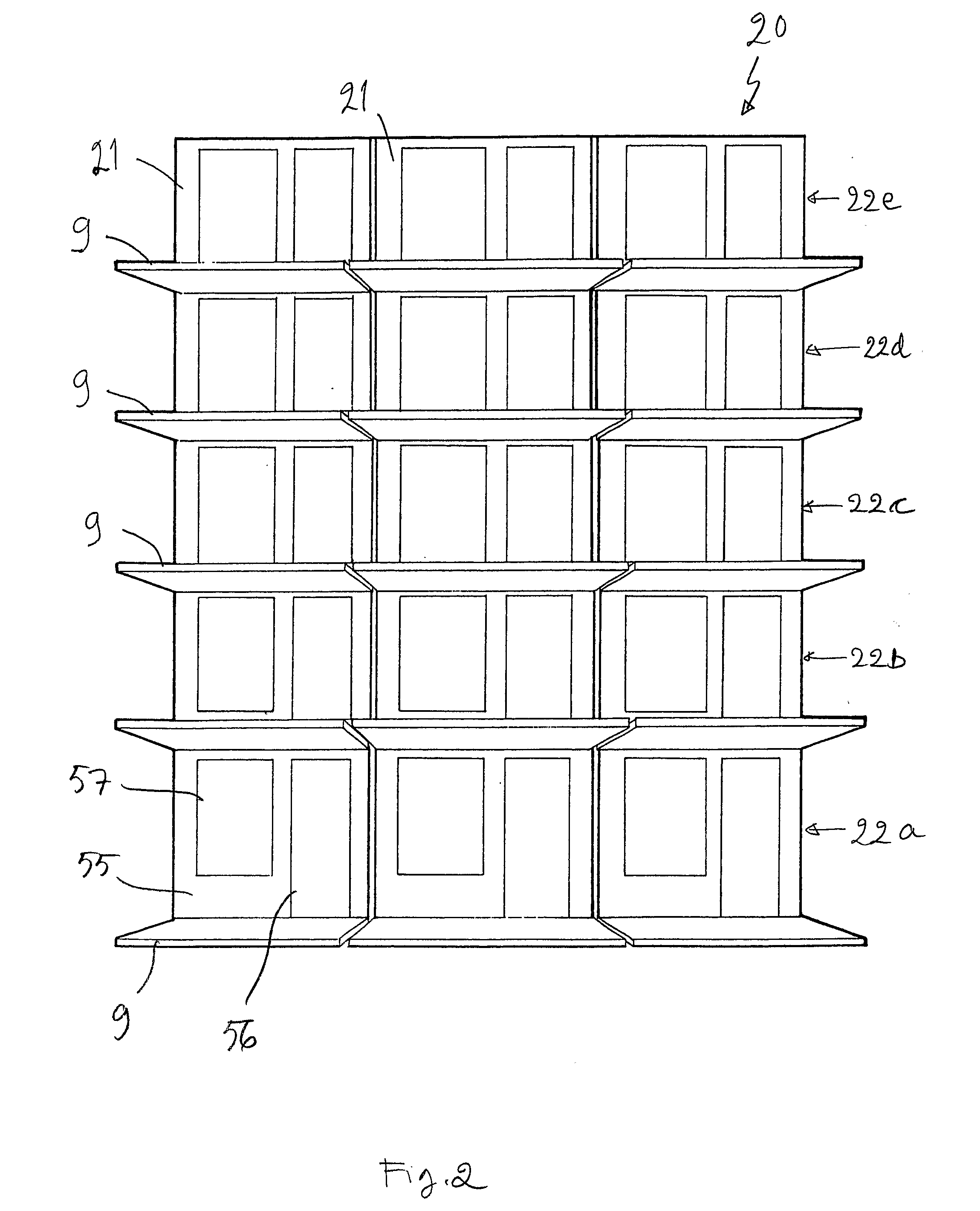

Room arrangement, ship, building and method for constructing a room arrangement

ActiveUS7921609B2Simple structureRapidly, economically and simplyWallsPublic buildingsApartmentBuilding construction

Owner:STX FINLAND OY +1

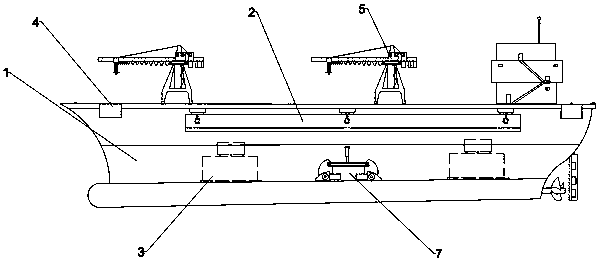

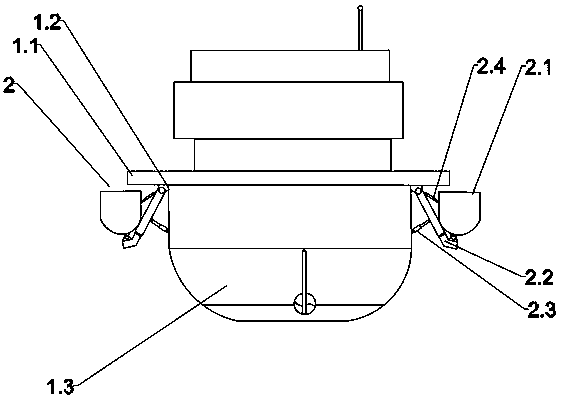

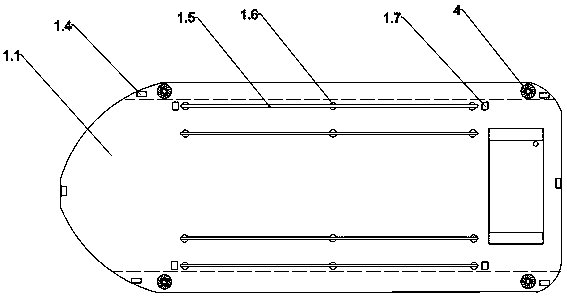

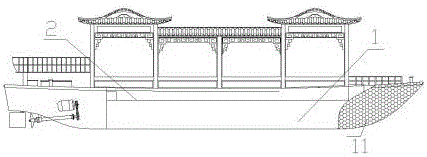

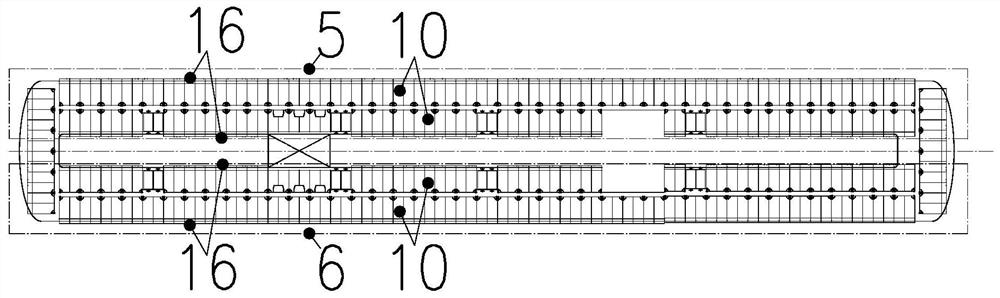

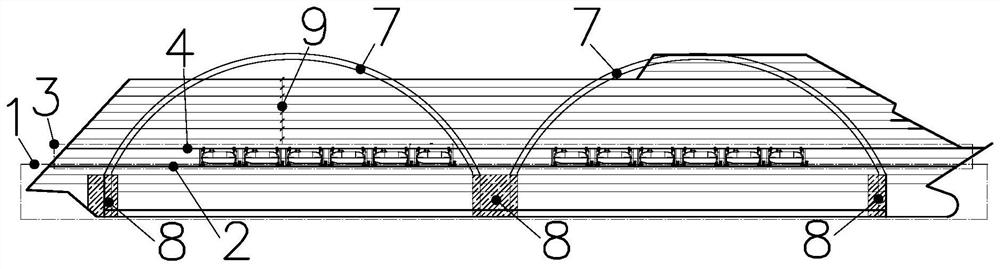

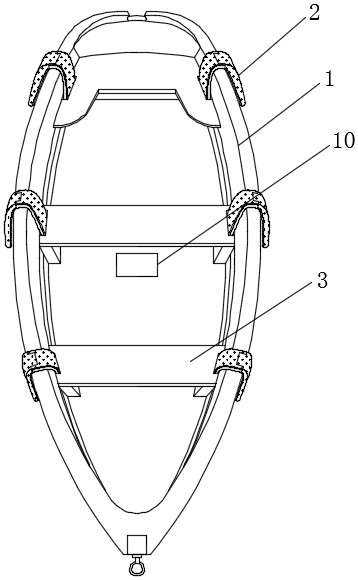

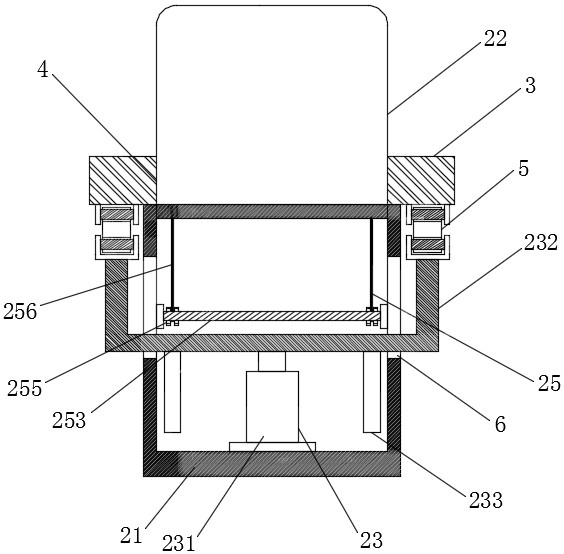

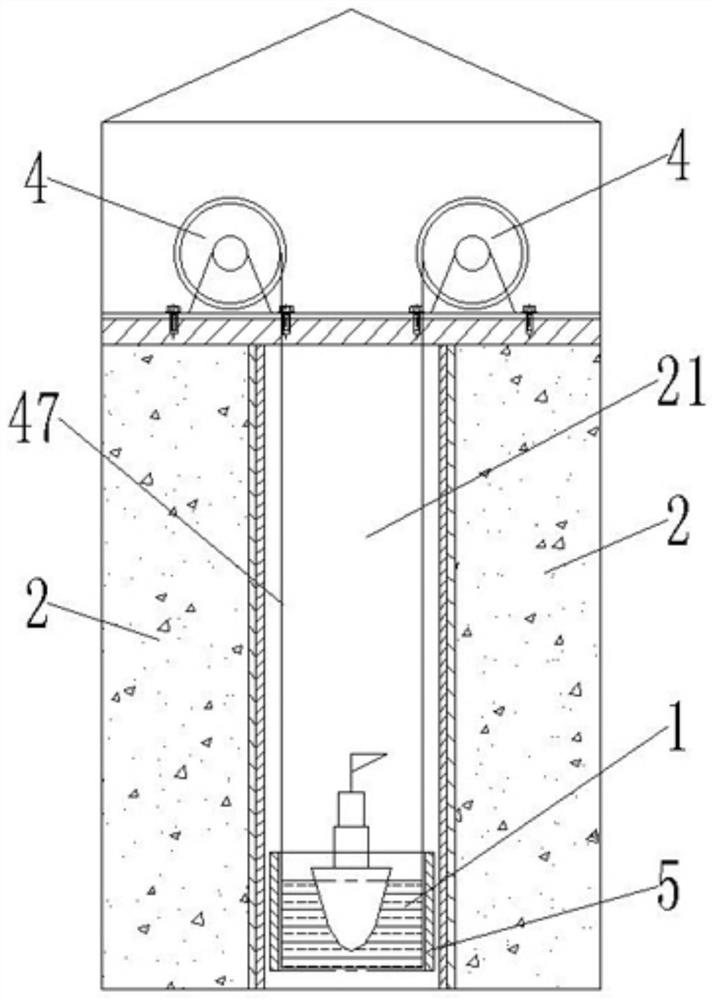

Multifunctional lifting ship balance system and working method thereof

InactiveCN109466717AAutomatically adjusts for tiltPrevent rolloverVessel safetyVessel movement reduction by jets/propellersBalance waterMultiple function

The invention provides a multifunctional lifting ship balance system and a working method thereof. The system comprises a ship body, balance water channels, a tuning balance water tank, lift fans, a self-balance crane, dual-water-spraying balance devices and a PLC system; the balance water channels are arranged at ship boards at the two sides of the ship body, the tuning balance water tank is arranged inside a ship compartment, the tuning balance water tank comprises a main water tank and an auxiliary water tank, the lift fans are arranged on decks at the periphery of the ship body, a fixing balancing weight and a variable balancing weight water tank device are arranged on a balance arm of the self-balance crane, and the dual-water-spraying balance devices are arranged at the bottoms of the two sides of the ship boards. By means of gravity and buoyancy of the balance water channels, the gravity of the tuning balance water tank, lifting force of the fans and thrust of a dual-water-spraying water pump, the balance torque of the ship body is supplied, the balance force of the crane can be automatically adjusted through the variable weighing water tank, the dual-water-spraying balancedevice can supply forward or backward thrust during ship navigation, when cargos are lifted, upwards thrust can be provided by turning by 90 degrees, and various operation functions can be achieved.

Owner:GUANGXI NANNING SHENGQIAN TECH DEV CO LTD

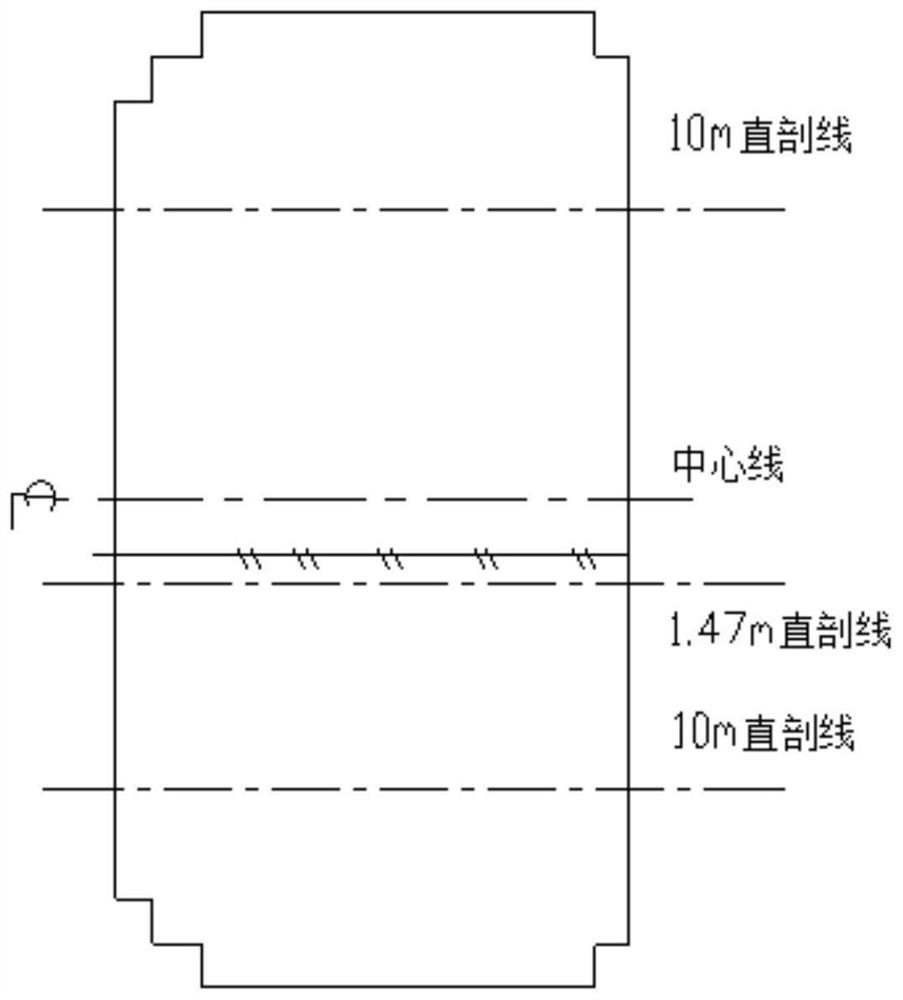

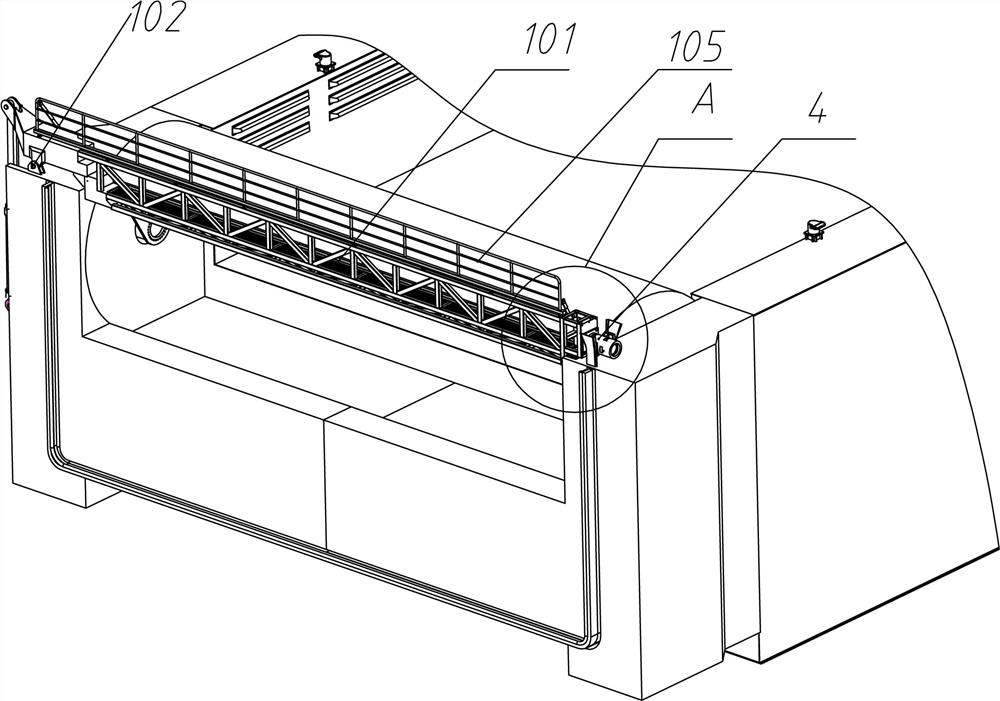

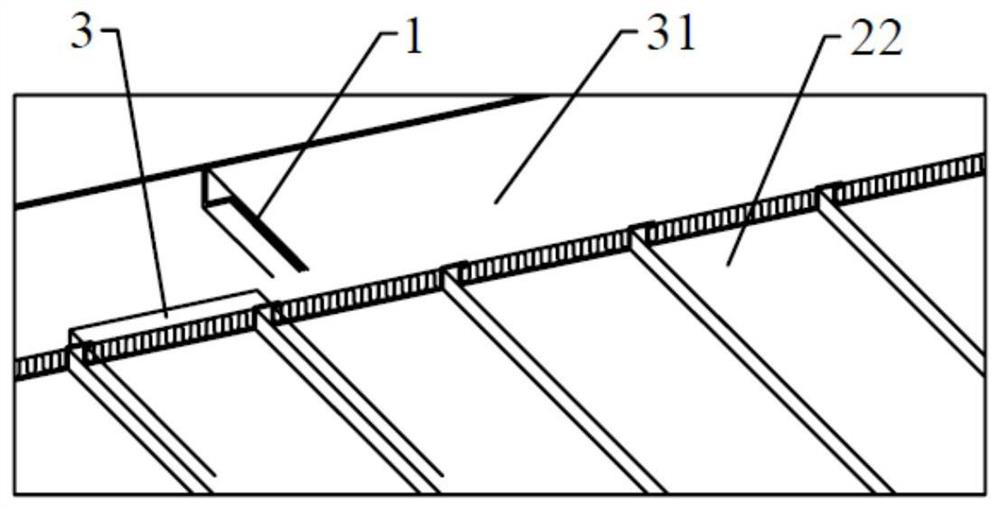

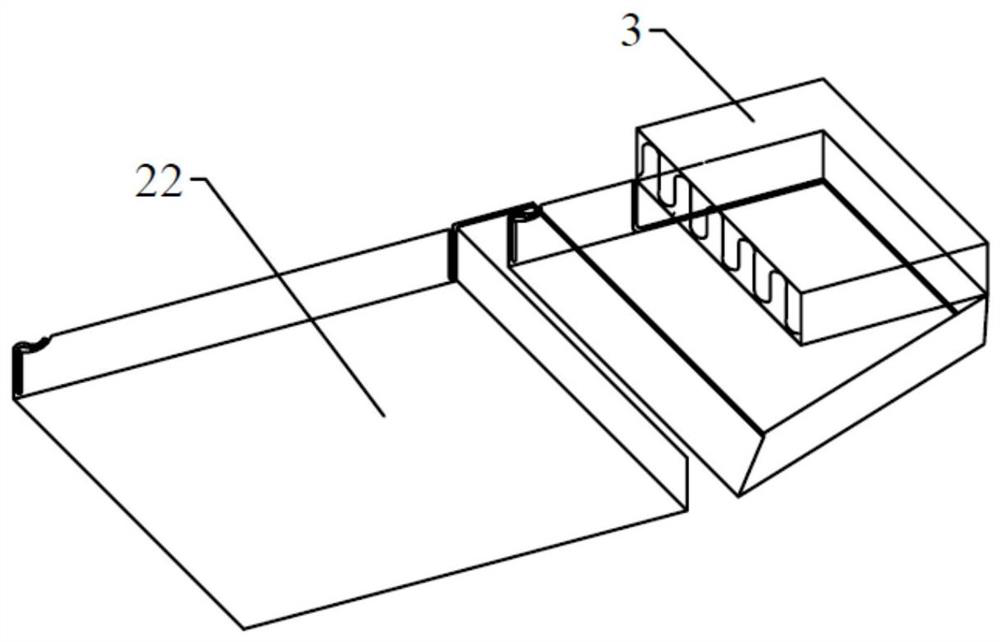

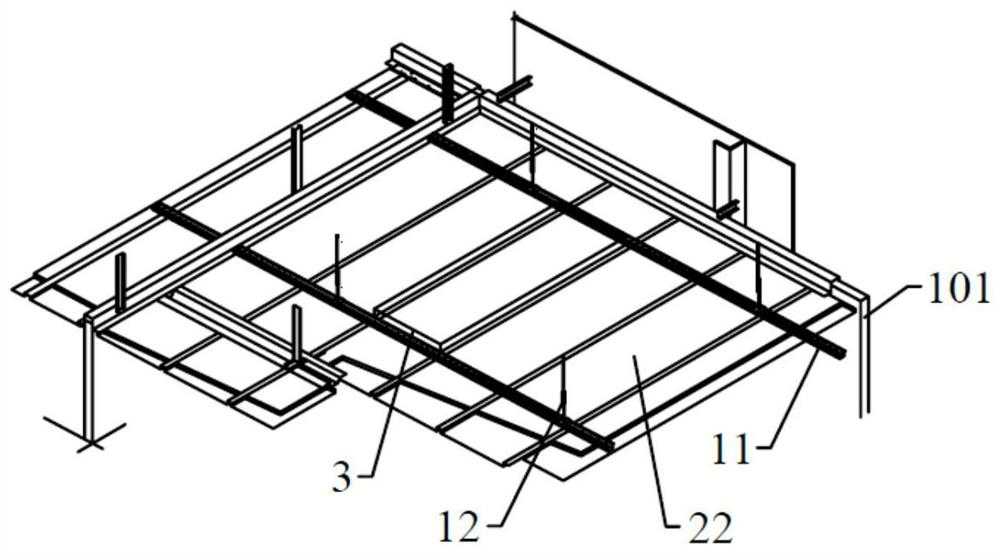

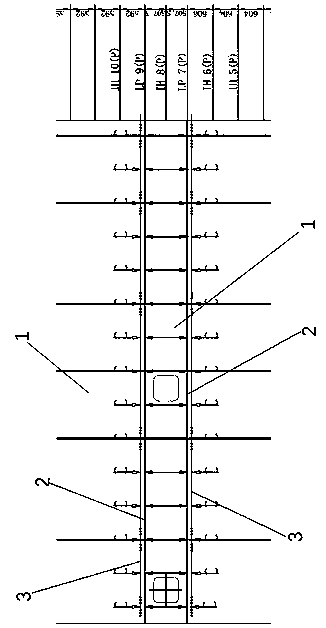

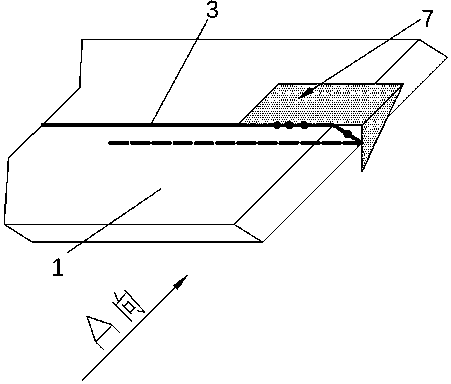

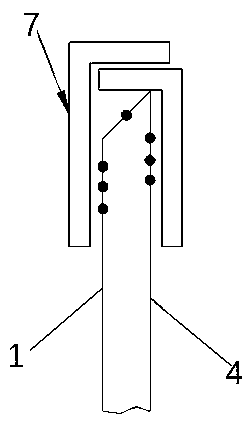

Double-sided preassembling method for bulkhead guide rails on large container ship and bulkhead

The invention relates to a double-sided preassembling method for a bulkhead guide rail on a large container ship. The bulkhead is a non-watertight bulkhead, the bulkhead is of a hollowed-out frame structure, and the installation precision of the bulkhead guide rail installed on the two faces is smaller than 7 mm. The method comprises the following steps: firstly, mounting a guide rail bracket on a horizontal jig frame of a compartment of the container ship; measuring levelness at a bay rib position datum line by taking one surface on which the guide rail bracket is mounted as a rear wall, and marking each hard gear of the bay by a punching point; then, the bay is adjusted to be horizontal again after the bay is turned over, the levelness of the guide rail frame located on the rear wall after installation is ensured, and the reference rib position line, the rear wall guide rail frame and the front wall guide rail frame to be installed are parallel to one another; therefore, the installation reference is determined, and the double-sided guide rail bracket is positioned and preassembled according to the found installation reference. The method is easy to operate, wherein guide rail preassembling can be completed in advance, the total assembling stage time is shortened, so that the pressure of a total assembling site is relieved, the building period in a dock is shortened, and the ship building efficiency is improved.

Owner:HUDONG ZHONGHUA SHIPBUILDINGGROUP

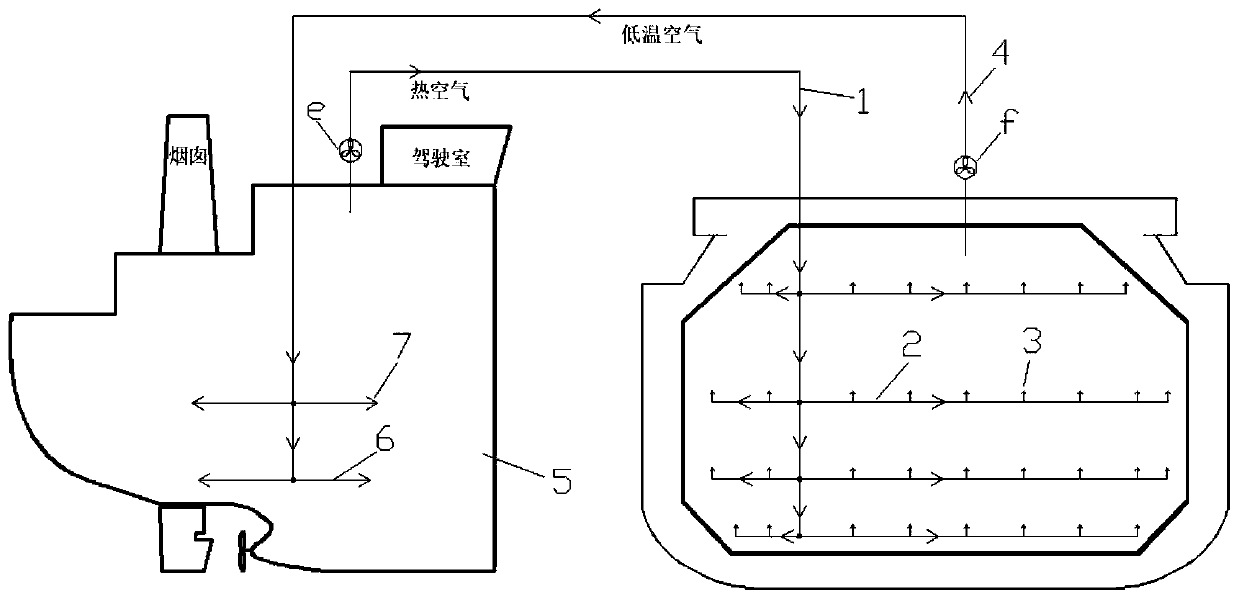

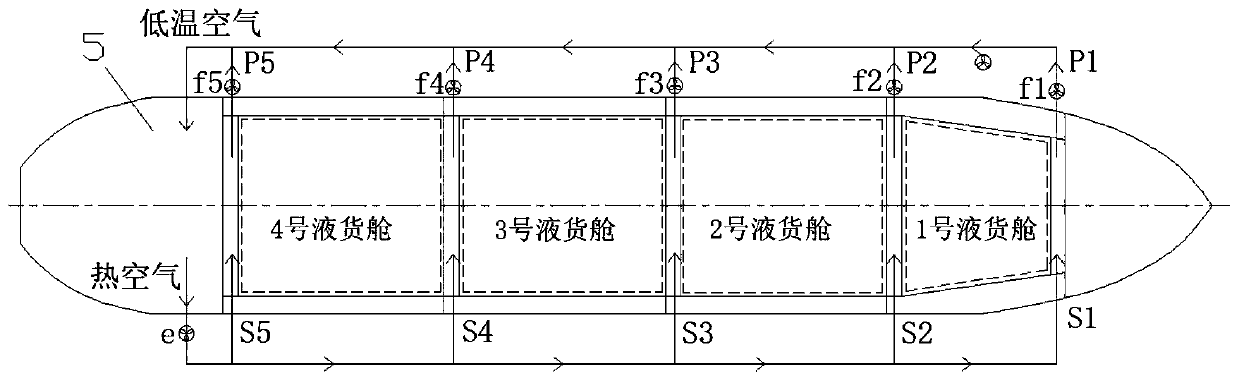

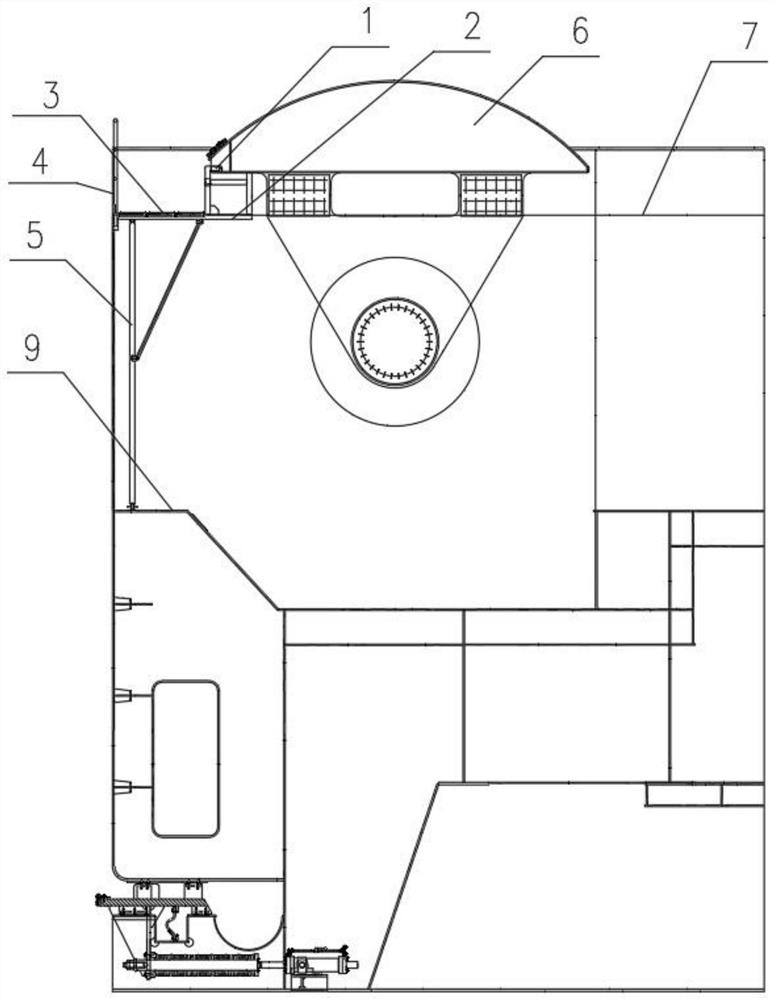

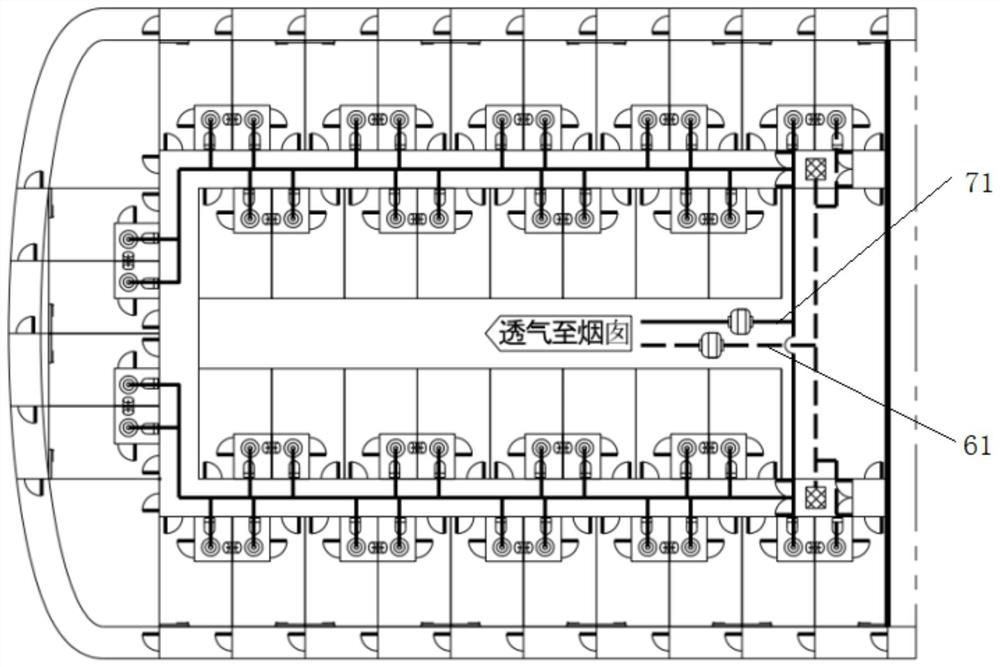

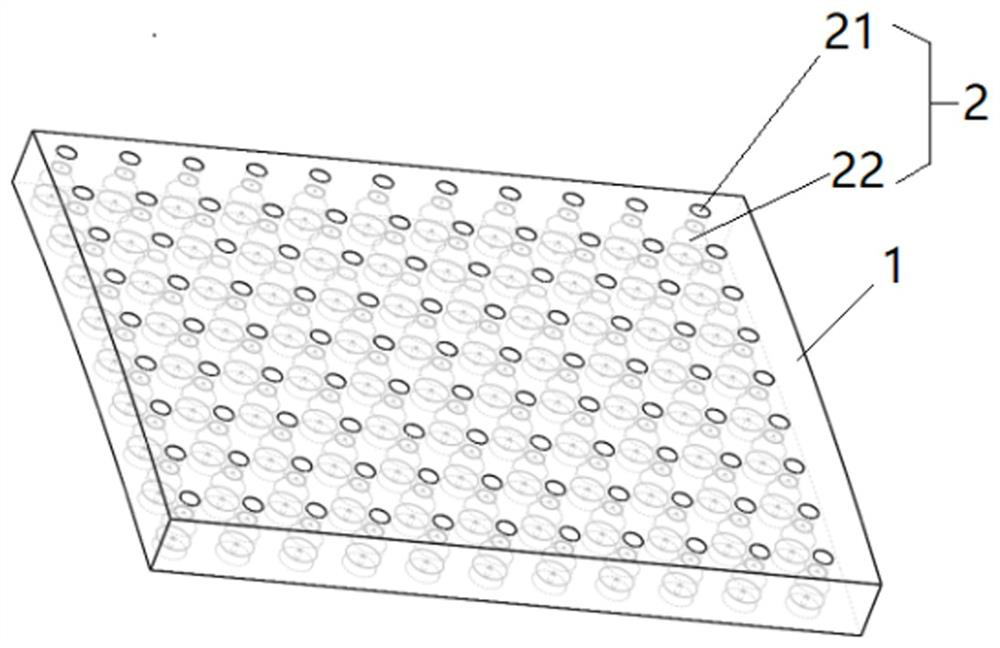

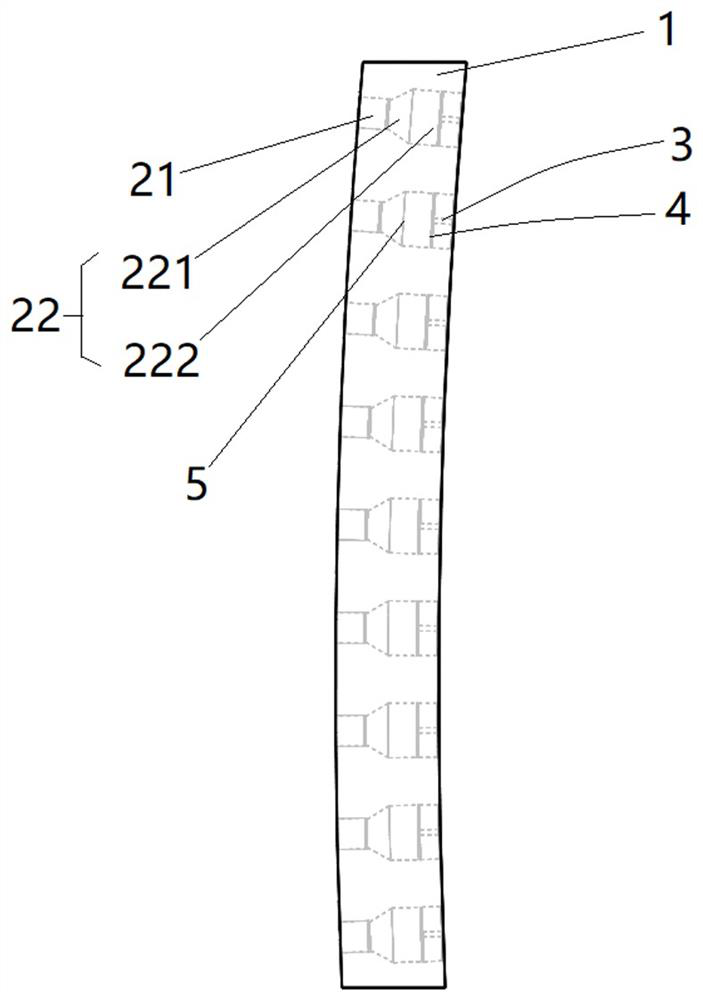

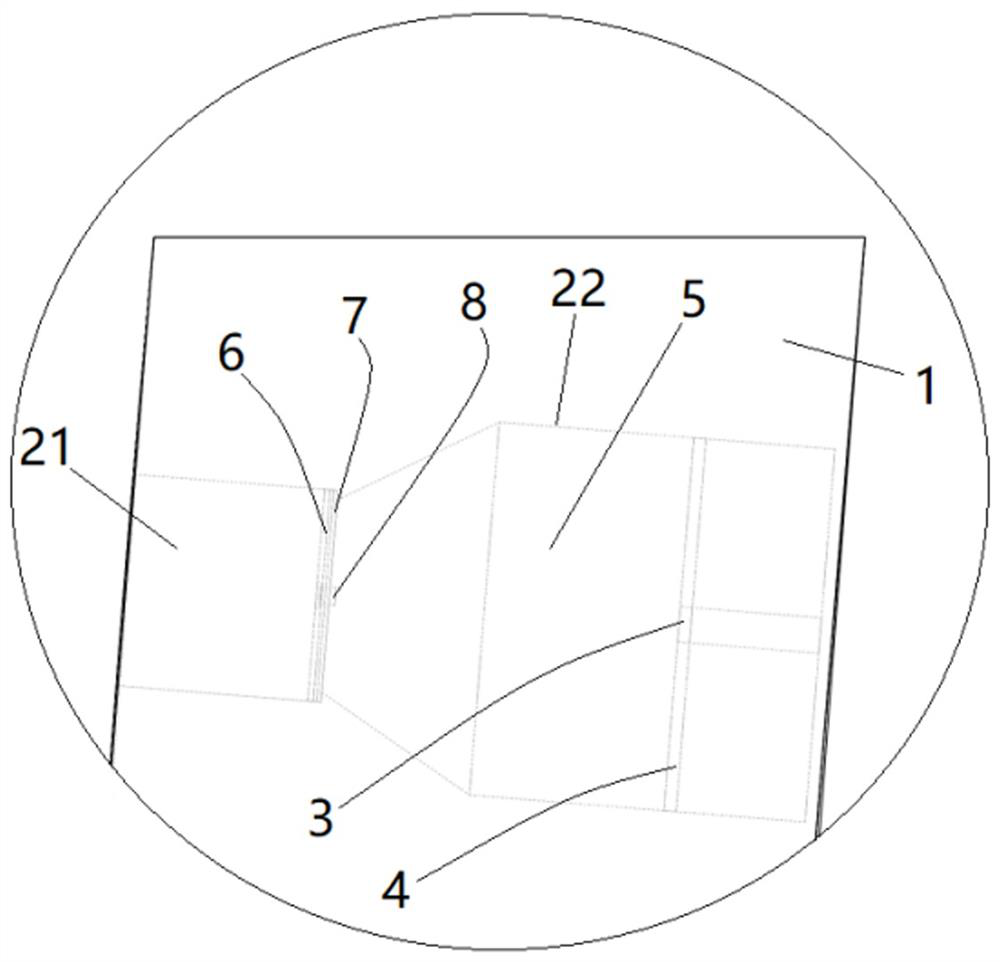

Dry compartment heat preservation system utilizing LNG ship engine room hot air

PendingCN111232178AGuaranteed StrengthMeet temperature requirementsHull interior subdivisionAuxillariesMarine engineeringHeat conservation

The invention discloses a dry compartment heat preservation system utilizing LNG ship engine room hot air. The system mainly comprises a dry compartment part and an engine room part. Hot air from theengine room enters the dry compartment through the air heater and the pipeline, releases heat, becomes low-temperature air, then returns to the engine room of the ship through the air cooler and the pipeline, absorbs the heat in the engine room and becomes hot air, and thus a cycle is formed. On the premise that no extra heat source is consumed in the dry compartment, it can be guaranteed that thedry compartment can meet the temperature requirement specified by relevant specifications of the ship, the low-grade heat source in the air of the marine engine room can be utilized, the energy utilization rate of the ship can be increased, and in addition, the temperature in the engine room can be reduced. The design method is simple, convenient to operate and high in economical efficiency, andhas great practical application value.

Owner:QINGDAO UNIV OF SCI & TECH

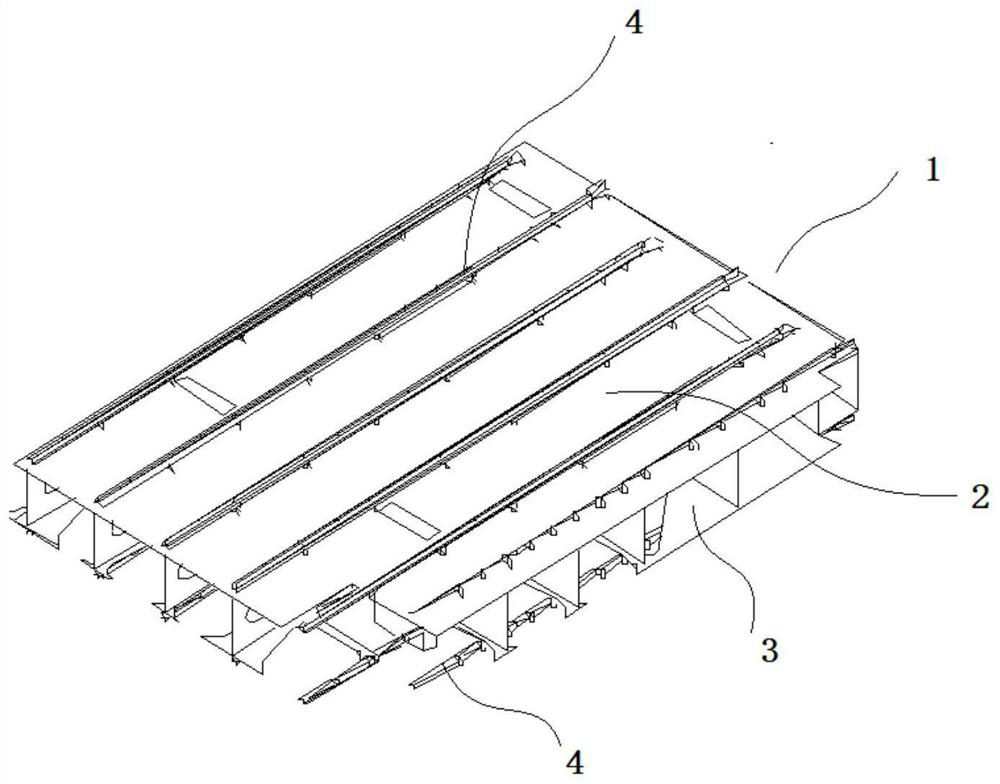

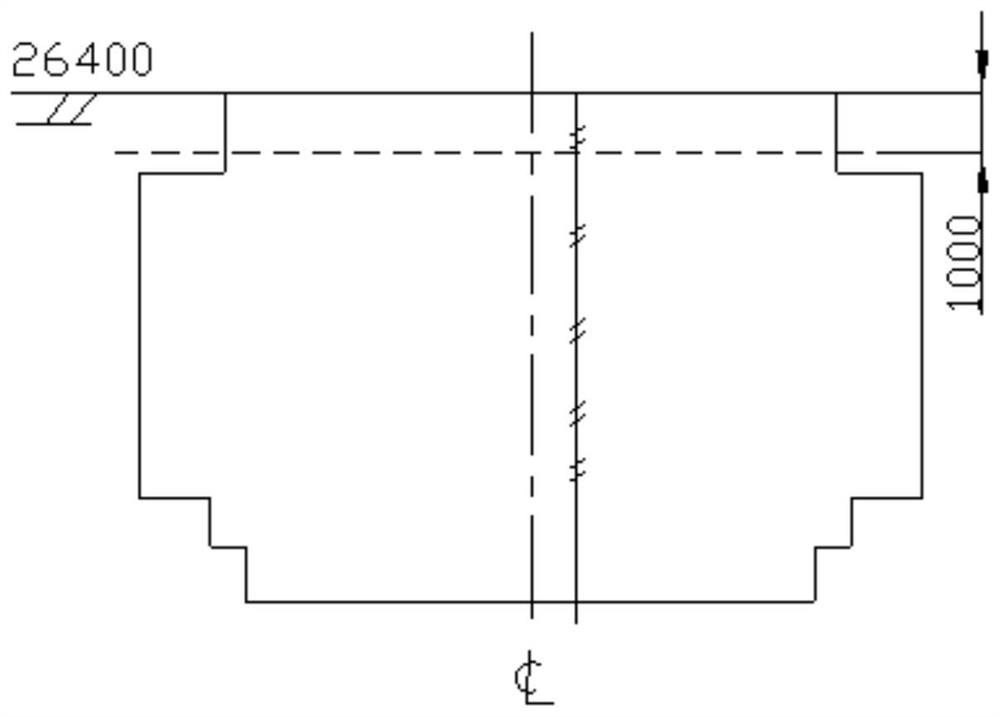

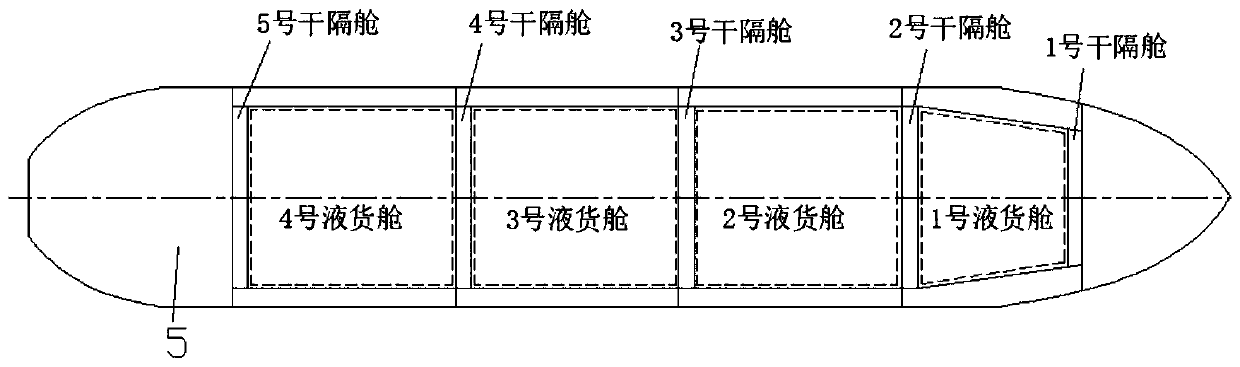

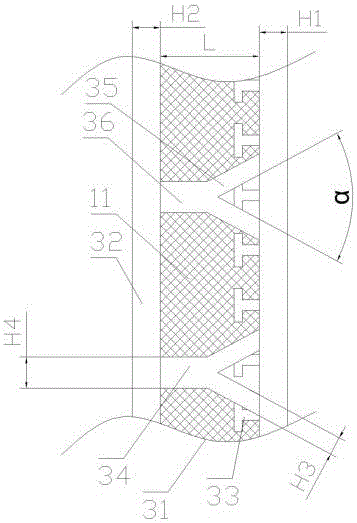

Cargo compartment section division design method and cargo compartment sections of 80,000-cubic-level film type LNG (Liquefied Natural Gas) ship

PendingCN113772042AImprove outfitting integrityReduce in quantityVessel designingFor bulk goodsBilgeMechanical engineering

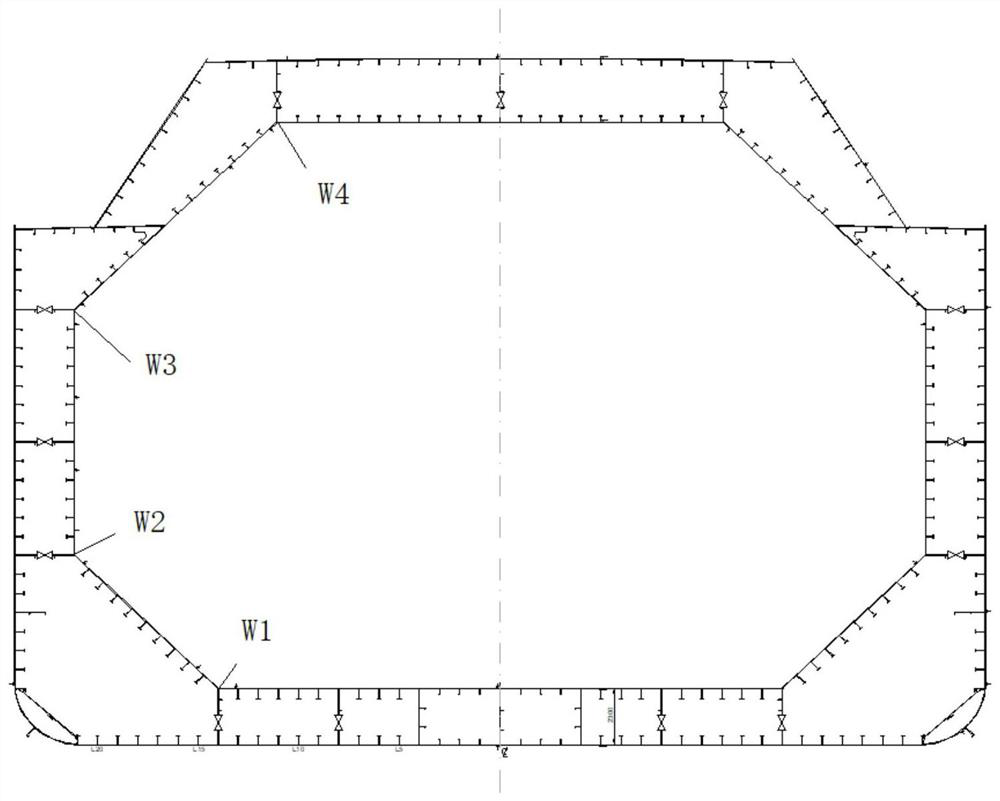

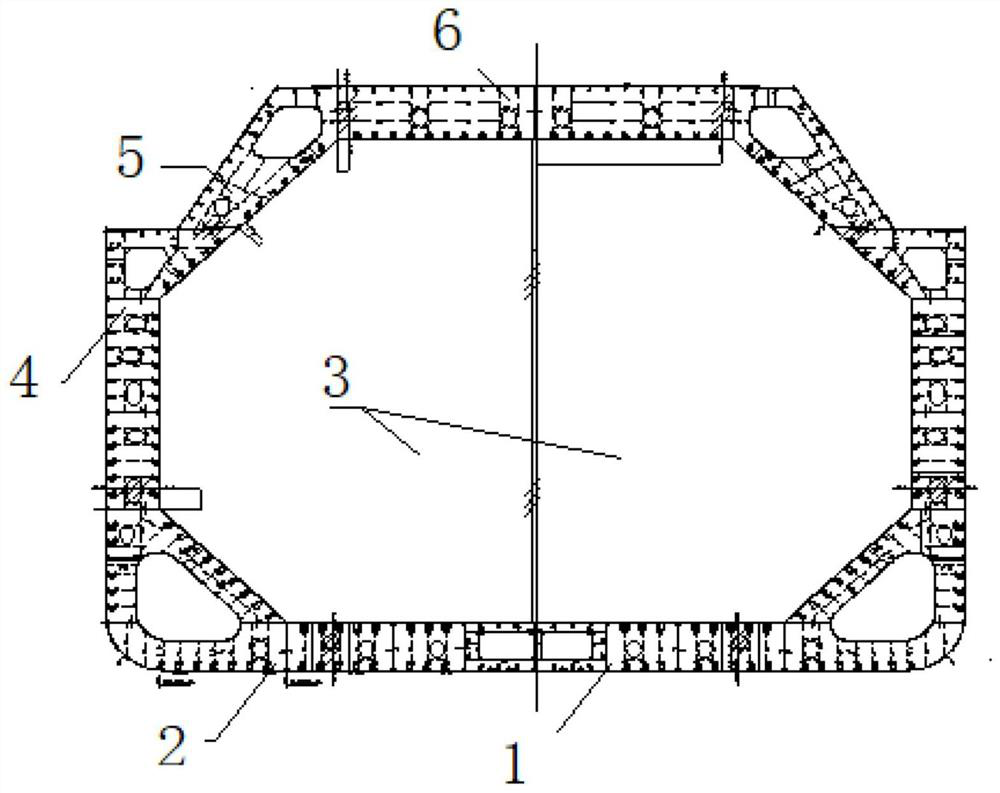

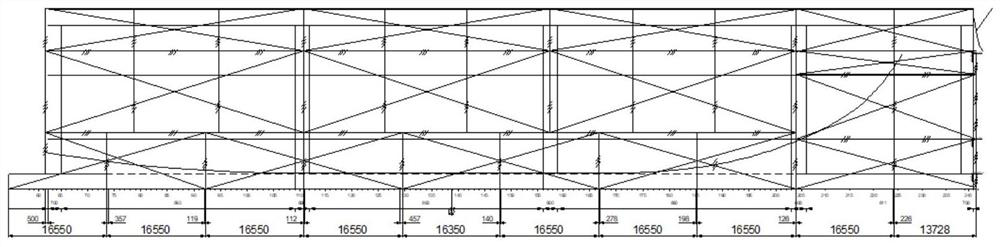

The invention relates to a cargo compartment sectioning design method for a 80,000-cubic-level film type LNG (liquefied natural gas) ship, a cargo compartment is divided into four compartments including a bottom and bilge section, a side section, a bulkhead and a deck section. The method comprises a cargo compartment bottom and bilge section dividing form, a cargo compartment side section dividing form, a cargo compartment bottom and bilge section dividing form, a cargo compartment bottom and bilge section dividing form, a cargo compartment side section dividing form, a cargo compartment bottom and bilge section dividing form and a cargo compartment bottom and bilge section dividing form. A cargo compartment division form and a cargo compartment deck subsection division form are adopted, each of the four cabins is longitudinally divided into three ring sections. Meanwhile, it is guaranteed that the full-width block of the deck is complete, a low-temperature pipe system on the deck is installed in the total assembly stage in advance, and meanwhile ship body key nodes W4 on the inner wall of the cargo compartment are divided into subsection internal nodes; the invention further relates to a cargo compartment section designed and built based on the method. According to the method disclosed by the invention, the cargo compartment is divided and designed in sections, so that high efficiency and high quality of ship construction are ensured, the construction is completed on schedule, Meanwhile, the construction period is shortened and the coating PSPC standard is met.

Owner:HUDONG ZHONGHUA SHIPBUILDINGGROUP

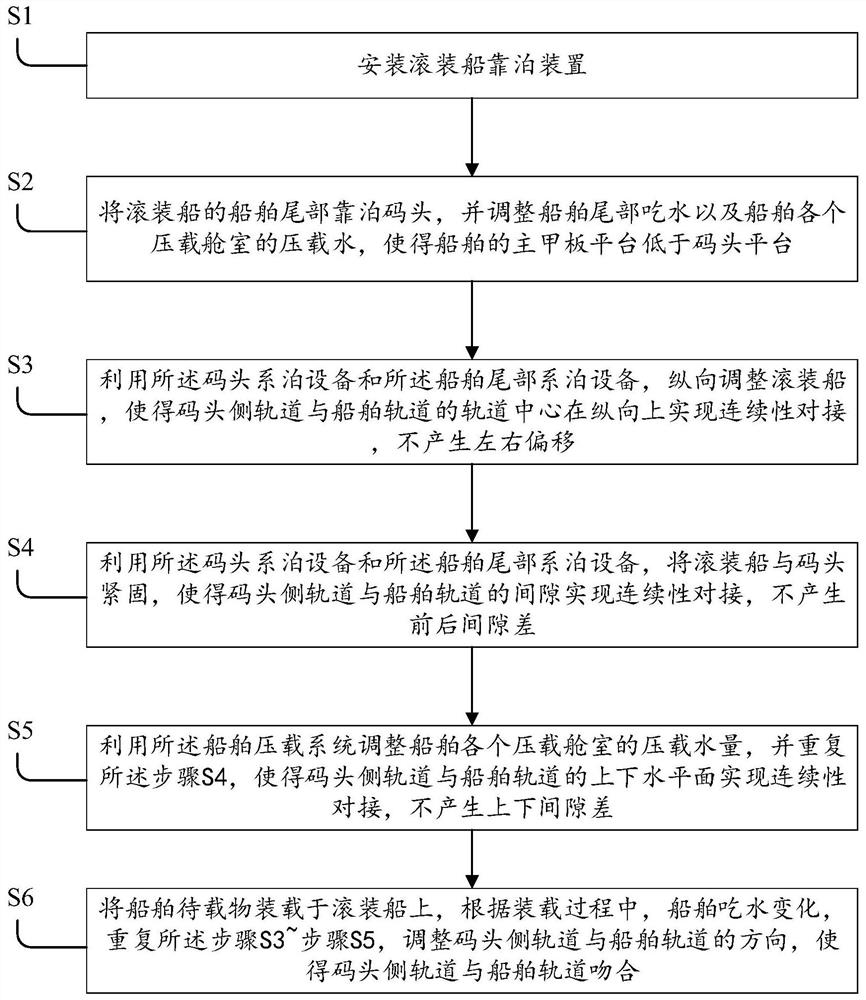

Mooring method of roll-on roll-off ship

ActiveCN112278195ALow costThe operation method is simple and convenientSlipwaysClimate change adaptationButt jointBallast tank

The invention relates to the technical field of ships and discloses a roll-on roll-off ship berthing method which comprises the following steps of mounting a roll-on roll-off ship berthing device; berthing the tail part of the roll-on roll-off ship to a wharf, and adjusting the draft of the tail part of the ship and ballast water of each ballast compartment of the ship; the roll-on roll-off ship being longitudinally adjusted so that continuous butt joint of the wharf side rail and the rail center of the ship rail is achieved in the longitudinal direction; the roll-on roll-off ship and the wharf being fastened so that continuous butt joint of a gap between the wharf side rail and the ship rail is achieved; adjusting the ballast water quantity of each ballast compartment of the ship so thatcontinuous butt joint of the wharf side track and the upper and lower horizontal planes of the ship track is realized; a ship to be loaded being loaded on the roll-on roll-off ship, and the directionsof the wharf side rail and the ship rail being adjusted according to the ship draught change in the loading process so that the wharf side rail is matched with the ship rail. According to the method,a problem of fitting of connection between the wharf side rail and the ship rail can be well solved, and fitting precision is improved.

Owner:CSSC HUANGPU WENCHONG SHIPBUILDING COMPANY

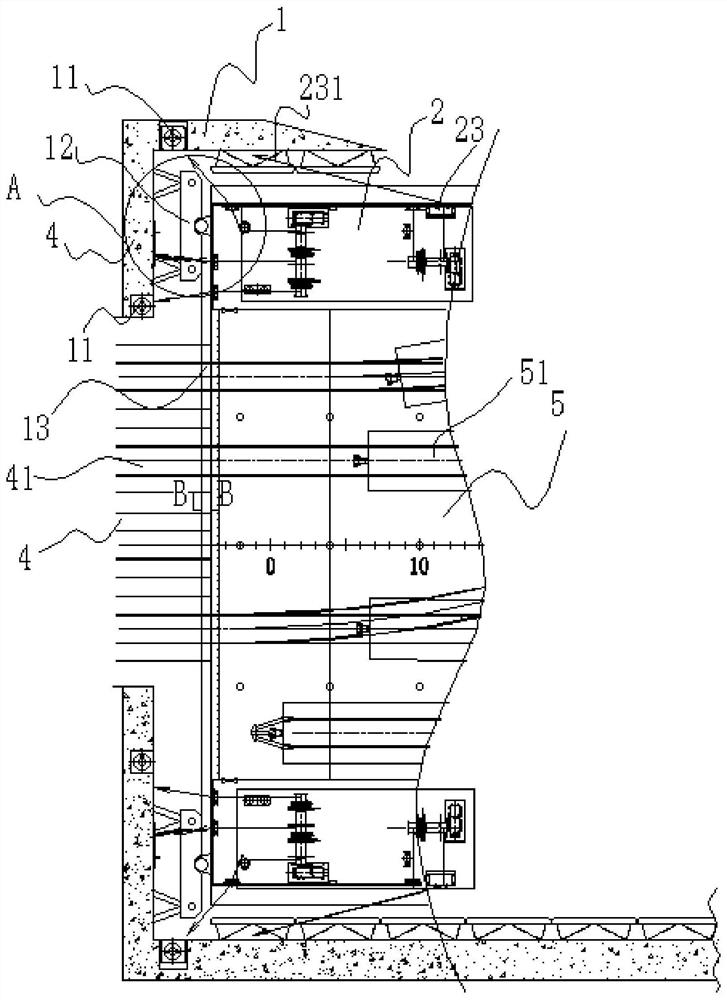

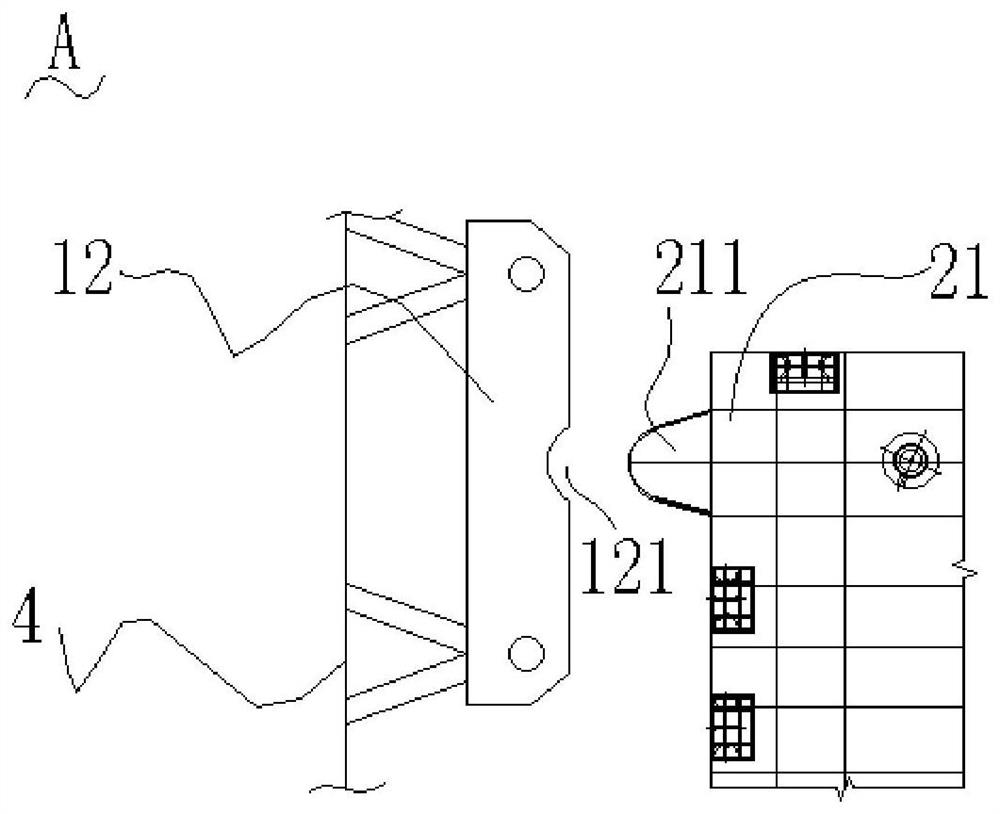

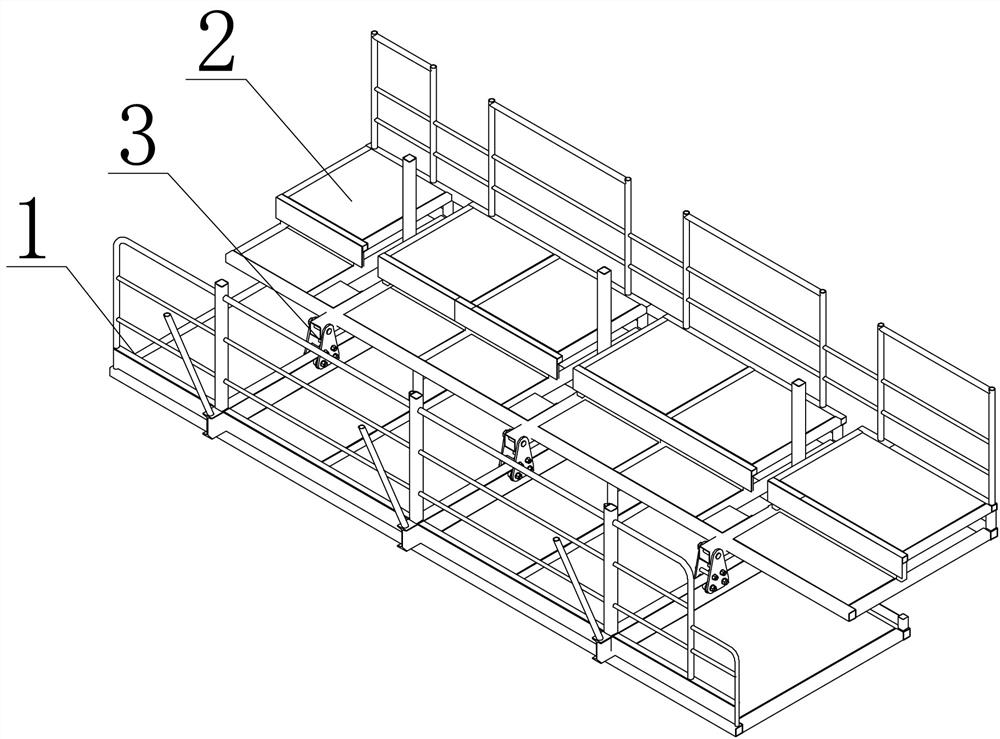

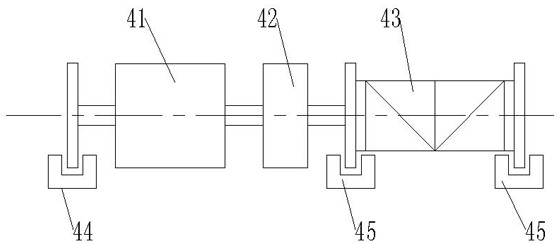

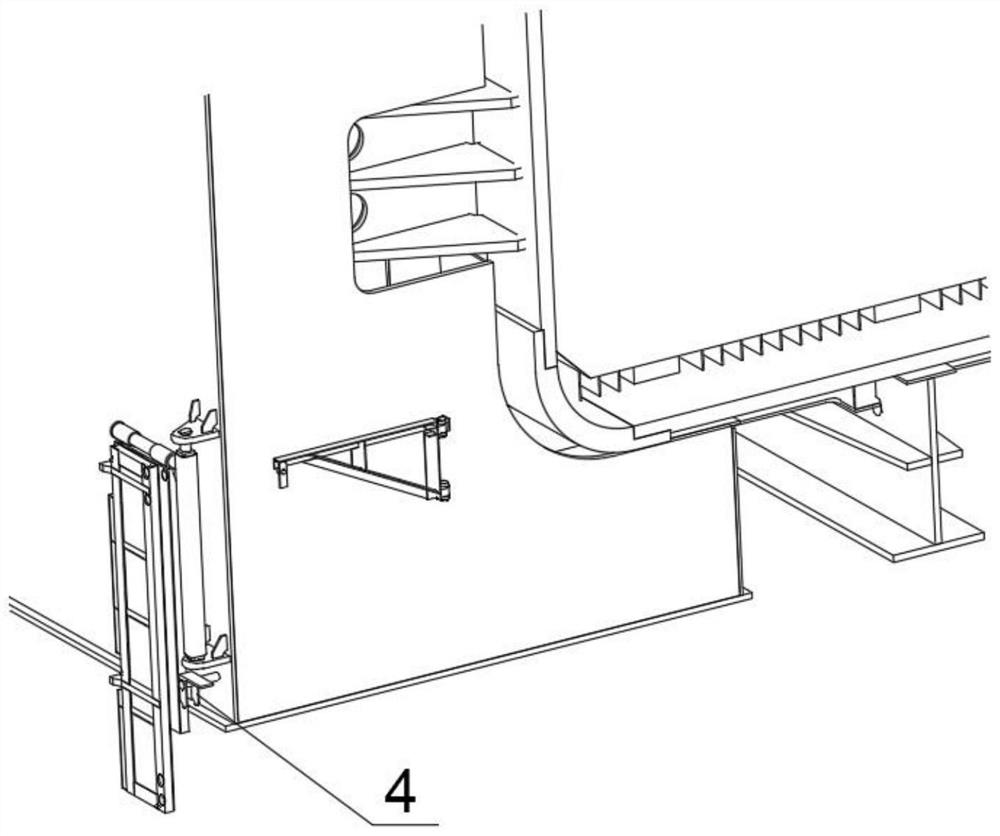

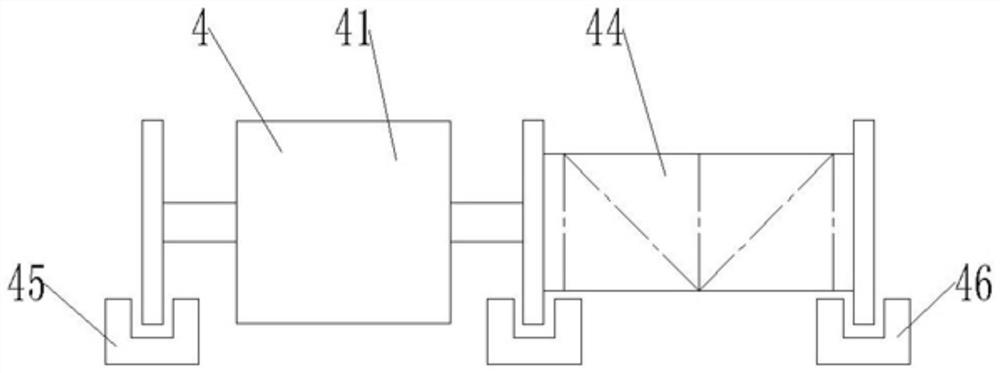

Quick push-pull platform for maintenance of clearance seal C-shaped water stop rubber of ship lift and using method

PendingCN112726549ADoes not affect operation and navigationReduce downtimeInclined ship-liftingVertical ship-liftingWater stopMarine engineering

The invention discloses a quick push-and-pull platform for maintenance of clearance seal C-shaped water stop rubber of a ship lift and a using method, and solves the problems that the platform is difficult to erect and the erection time is long during maintenance of the clearance seal C-shaped water stop rubber, so that the maintenance process is simplified, and the maintenance efficiency is improved. The platform comprises a fixing platform used for supporting the whole platform, and the fixing platform is fixedly installed at the bottom end of a ship compartment head structure of the ship lift and located under C-shaped water stop rubber. A movable platform is supported on the fixed platform in a sliding mode through a reverse walking wheel set and a riding wheel set. The reverse walking wheel set is fixed to the end of the movable platform and is in sliding fit with the fixed platform. The riding wheel set is fixed to the bottom end of the movable platform and supported on the top of the fixed platform in a sliding mode. And a bolt locking mechanism is arranged between the fixed platform and the movable platform.

Owner:CHINA THREE GORGES CORPORATION +2

Ship superstructure and LNG dual-fuel bulk cargo ship comprising same

InactiveCN112758243AEnsure safetyReduce casualtiesPropulsion based emission reductionVessel superstructuresBulk cargoLiquid tank

The invention discloses a ship superstructure and an LNG dual-fuel bulk cargo ship comprising the same, LNG liquid tanks are arranged on one side or two sides of the ship superstructure, the ship superstructure comprises a building main body and an escape channel arranged in the building main body, the escape channel extends in the plane and height directions, and the escape channel is arranged in the building main body. The building main body is provided with a main body fire-resistant side face arranged close to the LNG liquid tank, at least one part of the escape channel extends close to the main body fire-resistant side face, and the escape channel and the main body fire-resistant side face are separated through a main body compartment. According to the ship superstructure, the compartment is additionally arranged between the escape channel and the LNG liquid tank in the ship superstructure, so that when a danger occurs, the escape channel is always isolated from the LNG liquid tank, the safety of an escape route is ensured, and the probability of casualties is reduced.

Owner:上海外高桥造船海洋工程有限公司

Room Arrangement, Ship, Building and Method for Constructing a Room Arrangement

Owner:STX FINLAND OY +1

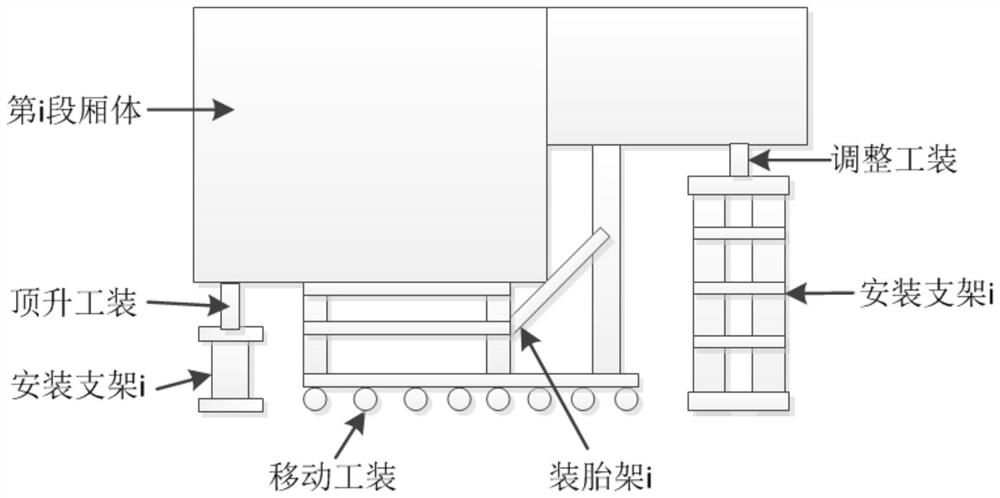

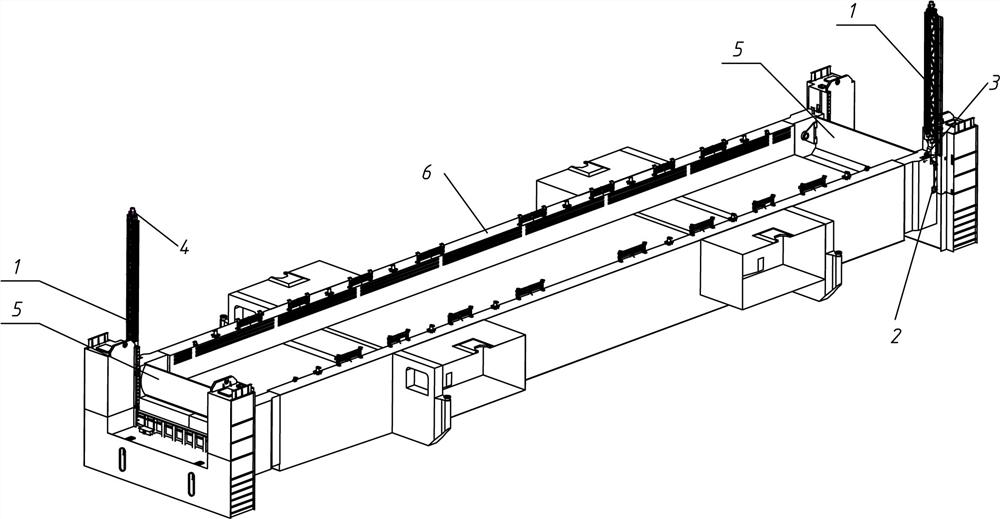

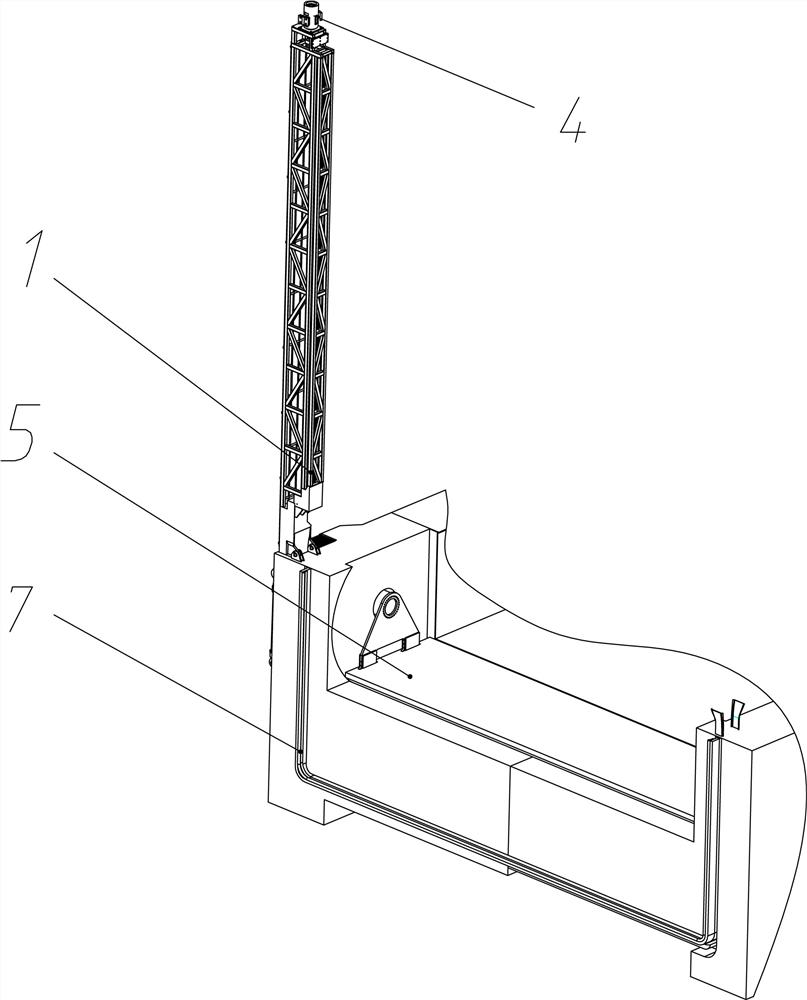

Method for assembling ship reception chamber of ship lift

ActiveCN112900406AShorten the hoisting and assembling timeVertical ship-liftingMarine engineeringCompartment (ship)

Owner:杭州国电机械设计研究院有限公司

Anti-sinking system for ship

PendingCN106828820AAvoid shipwreck situationHas flame retardant propertiesHull bulkheadsVessel safetyMarine engineeringBuoyancy

The invention specifically relates to an anti-sinking system for a ship. The anti-sinking system for the ship comprises a buoyancy device arranged in a watertight compartment under a deck and is characterized in that the buoyancy device is formed by filling the watertight compartment by using flame-retardant polyurethane foam; the density of the flame-retardant polyurethane foam is less than that of the water; and the buoyancy generated by the flame-retardant polyurethane foam in the watertight compartment in the water is larger than the total weight of the ship. The anti-sinking system for the ship further comprises anti-collision structures arranged on ship sides of the ship; and the anti-collision structures comprise composite clamping plates which are used for manufacturing the ship sides, wherein the composite clamping plates comprise steel plates, which are arranged on two sides outside the clamping plates, and flame-retardant polyurethane foams, which are filled between the two steel plates. The invention aims at providing the anti-sinking system for the ship; and by using the anti-sinking system for the ship, the ship navigating safety is enhanced.

Owner:湖州港口船业有限公司

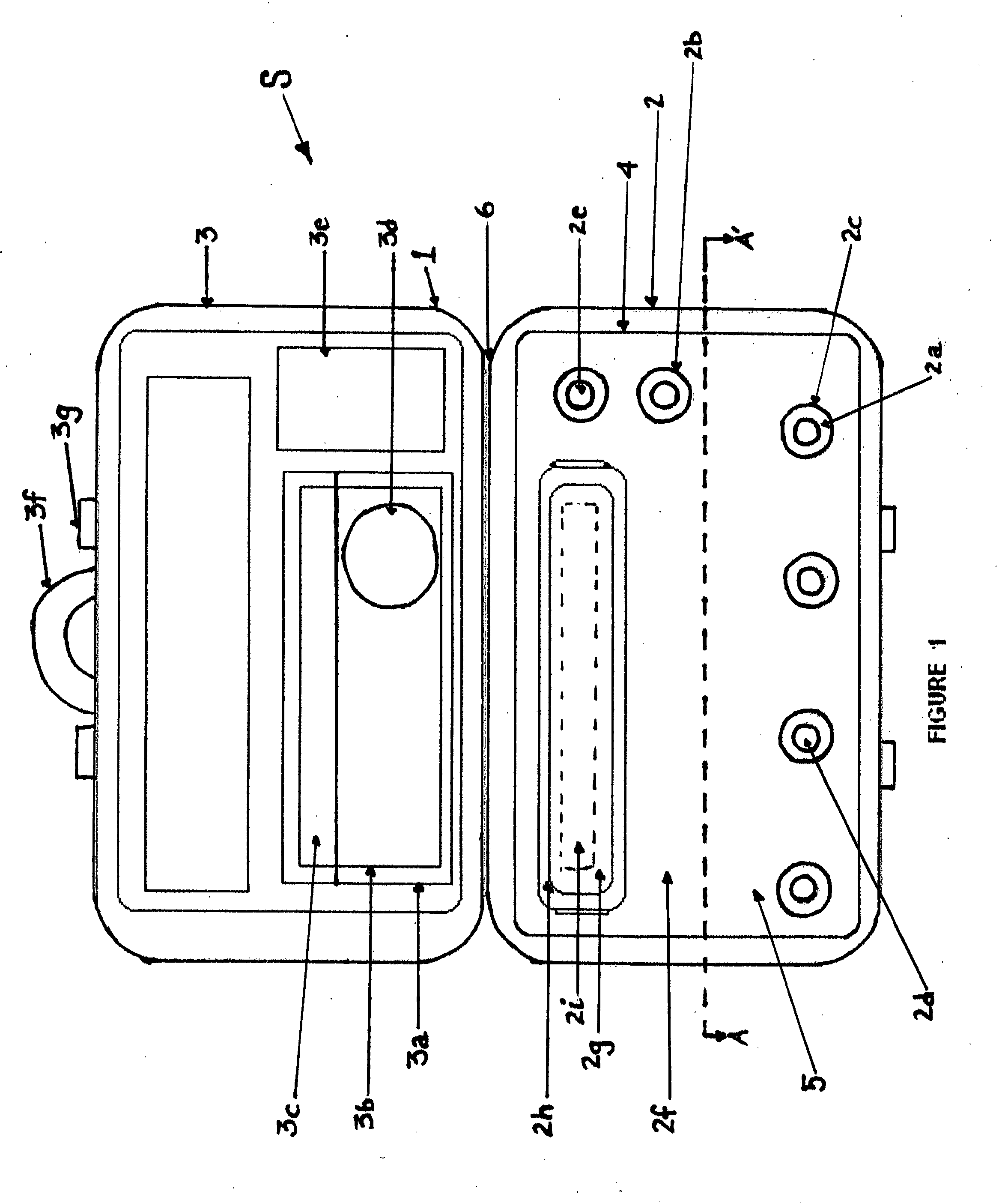

System and method for determining contaminants in wastewater including shipboard bilge water

A wastewater diagnostic system provides a housing that holds equipment to perform contaminant diagnostics in bilge water including shipboard bilge water. The wastewater diagnostic system utilizes a plurality of receptacles to house glass containers and reagents. The wastewater diagnostic system of the preferred embodiment includes shock-absorbing materials in the compartments to prevent movement and securely house glass containers and reagents. The wastewater diagnostic system further utilizes a flat work surface portion providing a test bed to conduct tests in non-laboratory environments. The system also provides methods to conduct tests to determine contaminants while utilizing the system.

Owner:RUSSELL BRUCE A +1

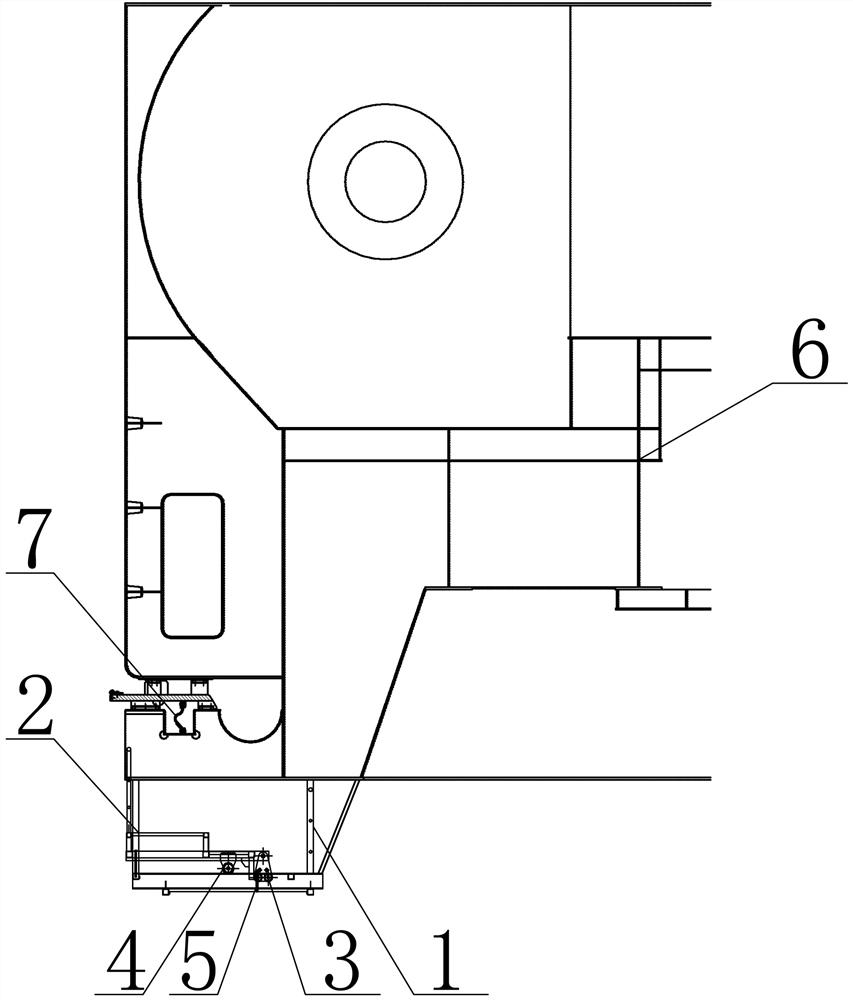

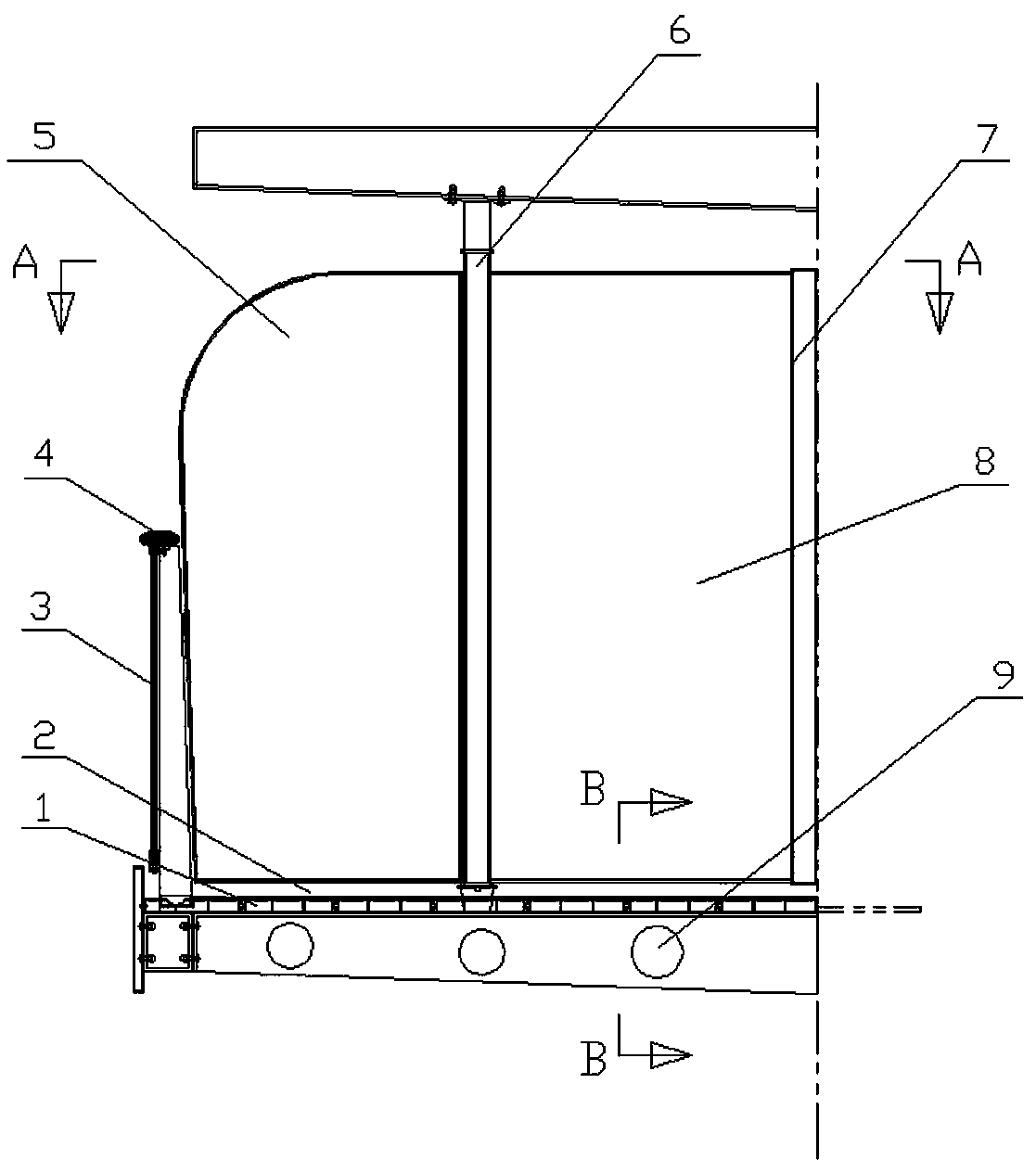

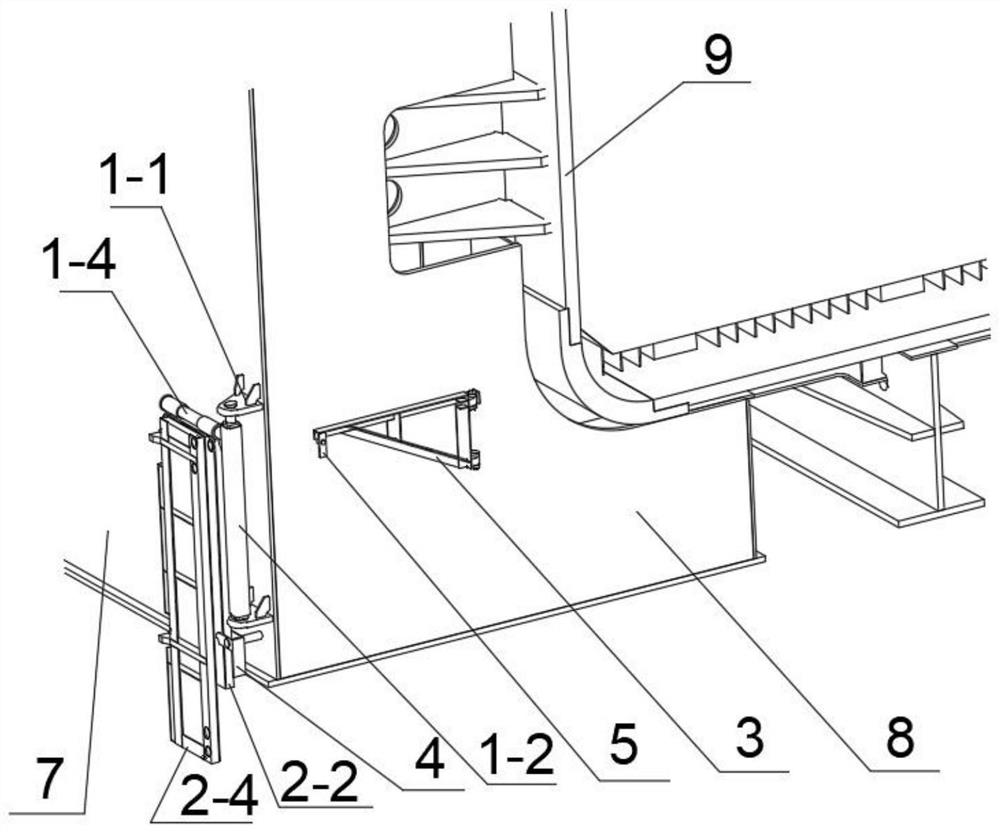

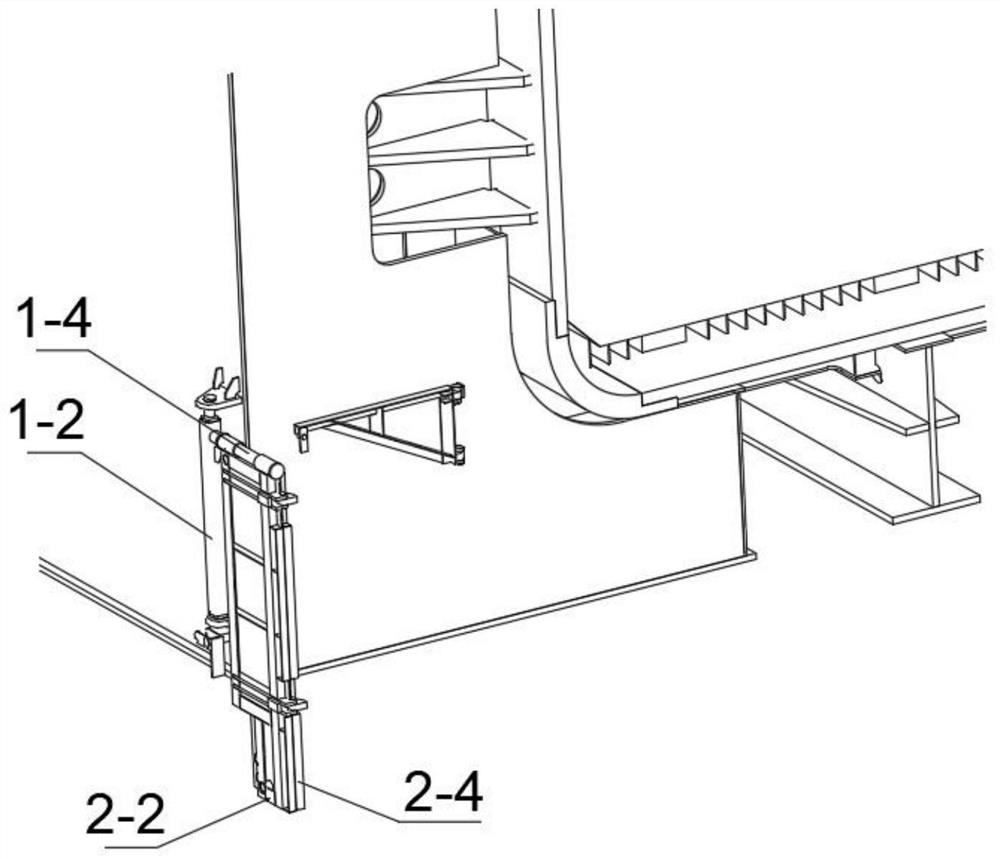

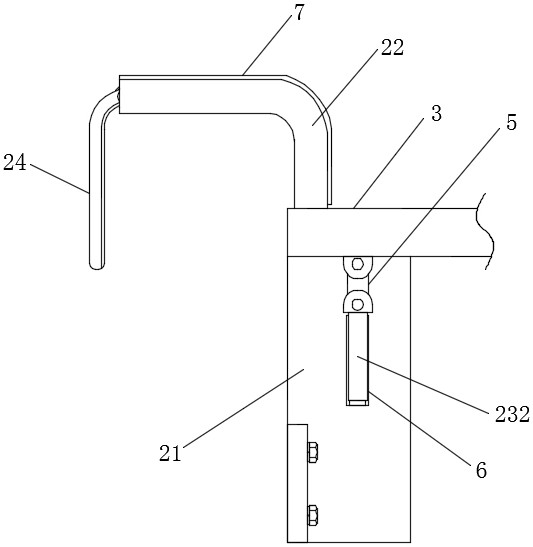

Rapid maintenance method and maintenance platform for ship compartment door of ship lift

ActiveCN114232579AReduce downtime for maintenanceImprove maintenance efficiencyWater cleaningVertical ship-liftingVertical planeMarine engineering

The invention relates to a rapid maintenance method and a maintenance platform for a ship compartment door of a ship lift, and provides a rapid maintenance method for the ship compartment door under the state that a ship compartment is not drained in order to overcome the defects that the maintenance of the ship compartment door of the ship lift is long in time consumption, consumes a large amount of manpower and material resources and the like. The platform used for achieving the rapid maintenance method of the ship compartment door comprises a maintenance platform body, a maintenance platform opening and closing device, a maintenance platform locking device and a guiding and buffering device, the maintenance platform body can rotate around a supporting hinge in a vertical plane through the opening and closing device, and the maintenance platform body is erected and locked through the locking device in the non-maintenance state. According to the rapid maintenance method and maintenance platform for the ship compartment door of the ship lift, the construction workload can be reduced to a great extent, and the ship compartment and the ship compartment door structure are protected against damage.

Owner:THREE GORNAVIGATION AUTHORITY

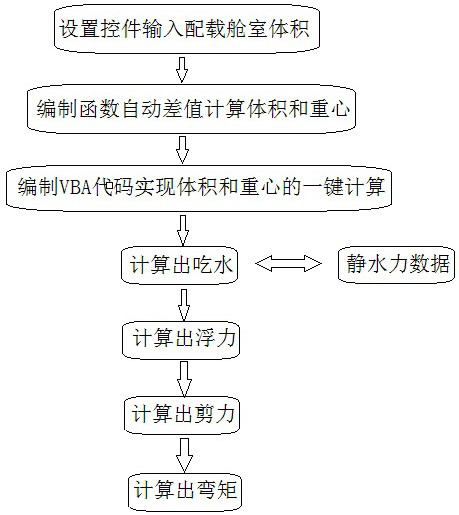

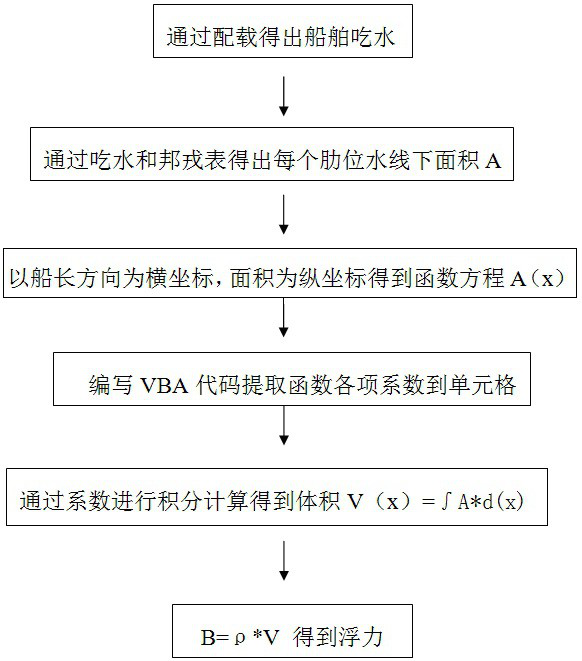

Ship loading calculation method based on Excel

ActiveCN111639396AGuarantee that the strength does not exceed the allowable valueEnsure safe navigationGeometric CADSpecial data processing applicationsLiquid densityClassical mechanics

The invention relates to a ship loading calculation method based on Excel, the basic formula is F = W-B, M = summing F * d (x), the ship loading calculation method comprises the following steps: a, calculating the shearing force, and the formula is that the shearing force F = W-B; a1, calculating the weight W of the ship; a2, calculating the buoyancy B of the ship; a2.1, calculating draught; a2, referring to a formula: D < head > = D < horizontal floating > + delta < head >, and D < tail > = D < horizontal floating > + delta < tail >; a2.2, calculating the volume, namely buoyancy, according tothe final draft calculated in the step a2.1; a3, the shearing force of each rib station number is obtained through F = W-B; b, calculating bending moment, wherein the formula is M = summing F * d (x); c, which comprises water area density, cabin liquid density, allowable shearing force values under different working conditions and allowable bending moment values under different working conditions; d, stowage and automatic calculation, wherein stowage comprises stowage of a ballast compartment and stowage of other compartments; compiling a function to generate hydrostatic data; last-key automatic computation. The method guarantees that the ship strength does not exceed the allowable value, guarantees the safe navigation of the ship, saves the software and time cost, and greatly improves the efficiency.

Owner:江苏新扬子造船有限公司

Detachable ship balcony

PendingCN110712713AEasy to installEasy to disassembleVessel superstructuresVessel mastsMarine engineeringCompartment (ship)

The invention relates to a detachable ship balcony which comprises side plates. The spacing between the adjacent side plates corresponds to the width of a corresponding compartment; front stand columns and back stand columns are connected to the front sides and the back sides of the side plates; movable clapboards are hinged to the front sides of the front stand columns; a glass wall is arranged between the outer sides of the movable clapboards; and a handrail is connected to the upper edge of the glass wall. The detachable ship balcony is characterized by further comprising a bottom plate, wherein the area and the shape of the bottom plate are adaptive to the area and the shape of the space enclosed by the adjacent side plates, the movable clapboards and the glass wall; the lower edges ofthe side plates and the lower ends of the front and back stand columns are connected onto the bottom plate; the upper ends of the front stand columns are connected onto the above balcony bottom plate; the lower edge of the glass wall is connected onto the bottom plate between the outer sides of the movable clapboards; and gaps are formed between the two sides of the glass wall and the corresponding movable clapboards. The balcony is convenient to install and disassemble, and is suitable to be matched with a cabin on a large-scale ship.

Owner:WUXI DELIN DEFENSE EQUIP CO LTD

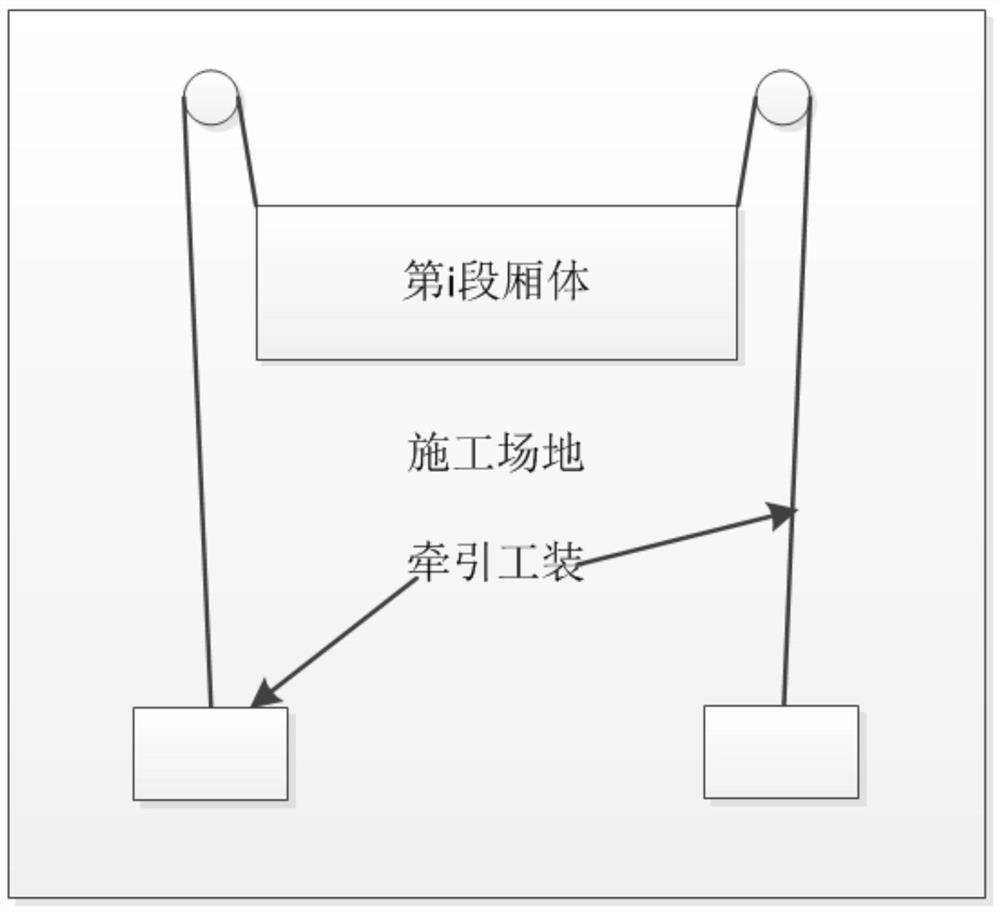

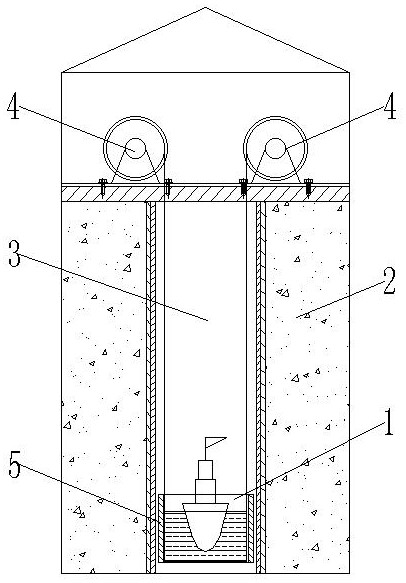

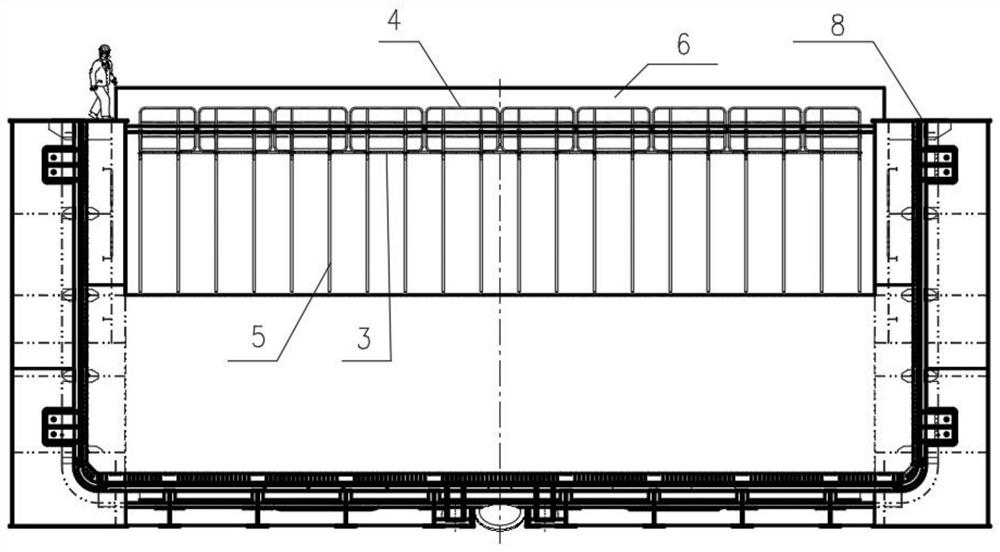

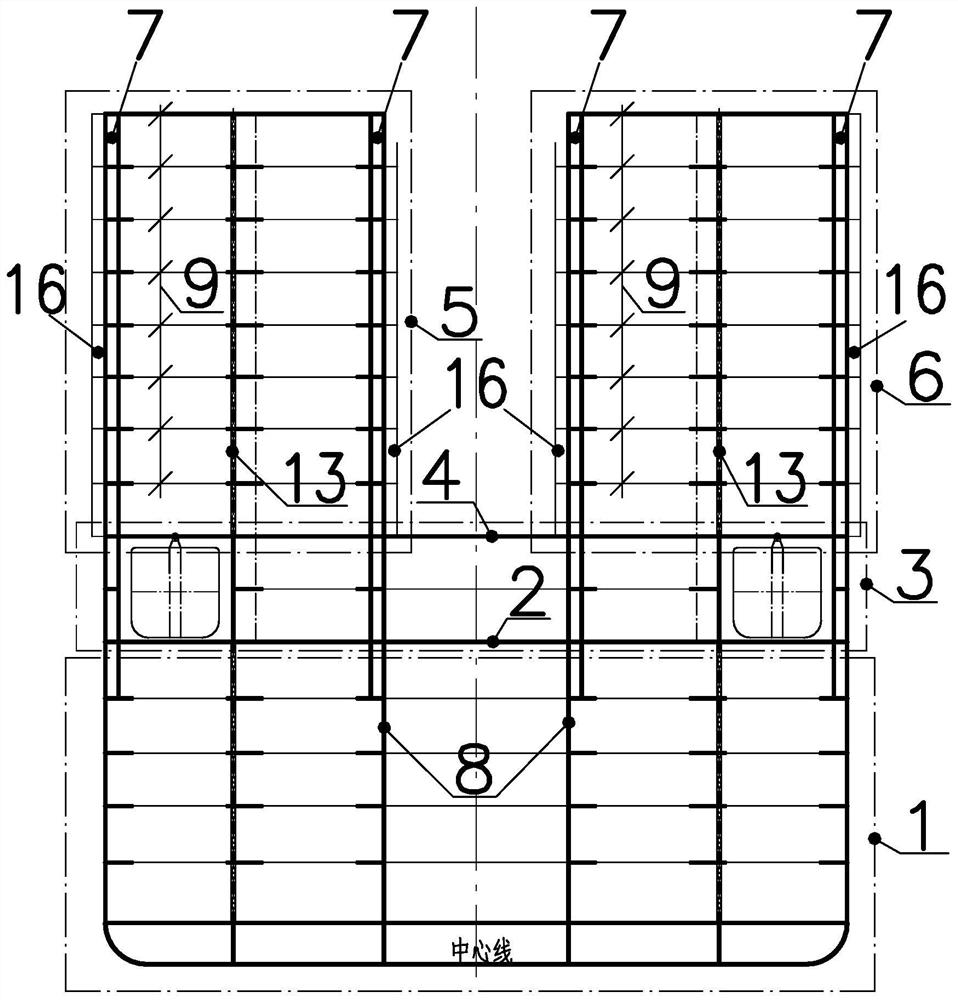

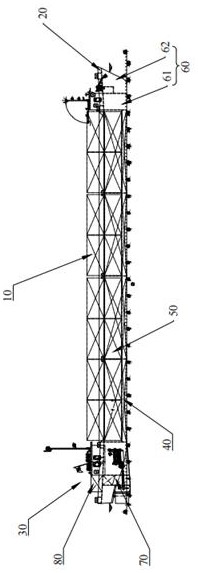

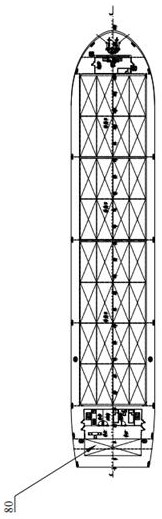

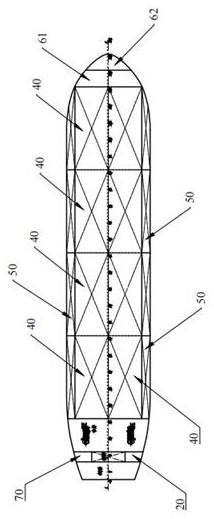

Dynamic balance ship compartment gravity ship lifting system

InactiveCN111648335AReduce construction strength requirementsSubtract the balance weightVertical ship-liftingMarine engineeringDynamic balance

The invention belongs to the technical field of water conservancy and hydropower engineering. According to the specific technical scheme, a dynamic balance ship compartment gravity ship lifting systemcomprises a ship chamber and concrete walls which are arranged in parallel and oppositely, a power balance mechanism is fixed at the top of the concrete wall body; under the traction of the dynamic balance mechanisms on the concrete wall bodies on the two sides, the ship chamber is in a gravity and traction balance state, beam prestress is preset in a top beam of the concrete wall, the action direction of the cross beam prestress is opposite to the gravity direction of the ship chamber, the prestress of the beam is the same as the gravity of the ship chamber, the beam prestress is counteracted with the ship chamber gravity, the outer side of the ship chamber and the concrete wall body on the same side are driven by a linear power device. According to the ship lift, the self weight is balanced through the power balance mechanism, the balance weight is reduced, the requirement for the construction strength of concrete walls on the two sides of the ship chamber is lowered, and safe operation of the ship lift is guaranteed through a dual-drive system.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Rapid overhaul platform for maintenance of ship lift ship compartment door water stop rubber

ActiveCN112392022AQuick assemblyEasy to assembleArtificial islandsFencingMarine engineeringStructural engineering

The invention relates to the technical field of maintenance and overhaul platforms, and particularly discloses a rapid overhaul platform for maintenance of ship lift ship compartment door water stop rubber. The rapid overhaul platform comprises fixed piles, an outrigger, a platform plate and a guardrail; the fixed piles are arranged at intervals at the bottom empty space of a ship compartment doorin the arrangement direction of the ship compartment door water stop rubber; the outrigger is detachably connected with the fixed piles; a limiting structure is arranged on the outrigger; the limiting structure abuts against the back face of a ship compartment door structure when the outrigger is in a self-weight state; the extending end of the outrigger extends in the direction away from the ship compartment door water stop rubber; a guardrail mounting position is arranged at the end of the extending end; the platform plate is detachably arranged at the extending end of the outrigger; the horizontal plane of the platform plate is higher than a water containing surface of a ship compartment; and the guardrail is detachably arranged on the guardrail mounting position. A set of working platform capable of being quickly erected is provided as a ship lift ship compartment door water stop rubber maintenance construction platform, so that the maintenance period is shortened, and quick erection, quick disassembly and reutilization can be realized.

Owner:HEAVY EQUIP ENG CO LTD OF WUCHANG SHIPBUILDING IND

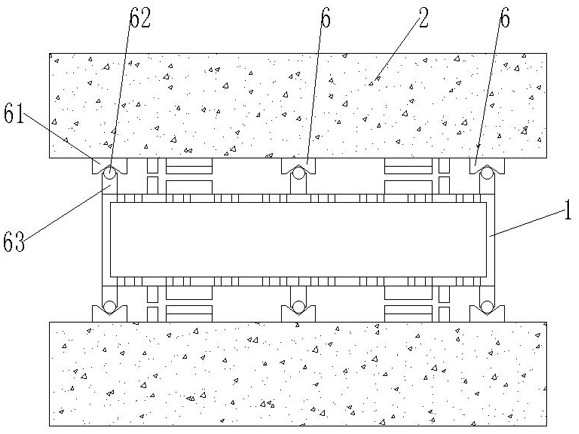

Passenger cabin deck structure and ship

PendingCN113715958ALow costReduce weightHull decksHull panellingsMarine engineeringMechanical engineering

The invention relates to the technical field of ships, and discloses a passenger cabin deck structure and a ship. The passenger cabin deck structure comprises a steel deck, a ceiling and a rock wool board, and no fireproof layer is arranged on the steel deck; the ceiling is arranged below the steel deck; and the rock wool board is arranged on the side, close to the steel deck, of the ceiling, a preset distance is formed between the rock wool board and the steel deck, and an air layer is arranged within the preset distance. The fireproof layer arranged on a steel deck in the prior art is omitted, the fireproof layer cost and the labor cost are reduced, and the weight and the work amount of the steel deck are reduced; and the ceiling is arranged below the steel deck, the rock wool board is arranged above the ceiling, and the rock wool board and the steel deck are arranged at the preset interval, so that it is guaranteed that the rock wool board and the air layer have the good fireproof effect, meanwhile, the ceiling is easy to lay, the rock wool board only needs to be placed on the ceiling, construction operation is easy, and construction cost is low. The labor cost is saved, and meanwhile the shipbuilding period can be guaranteed.

Owner:GUANGZHOU SHIPYARD INTERNATIONAL LTD

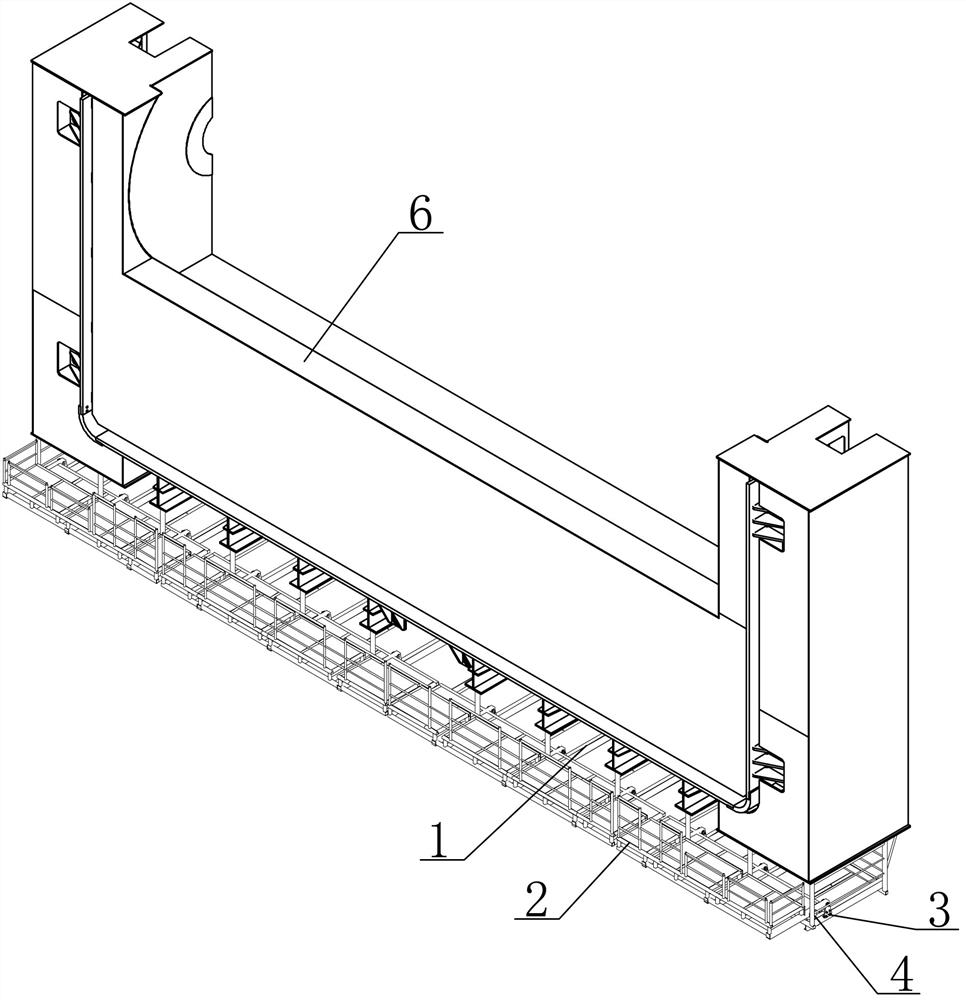

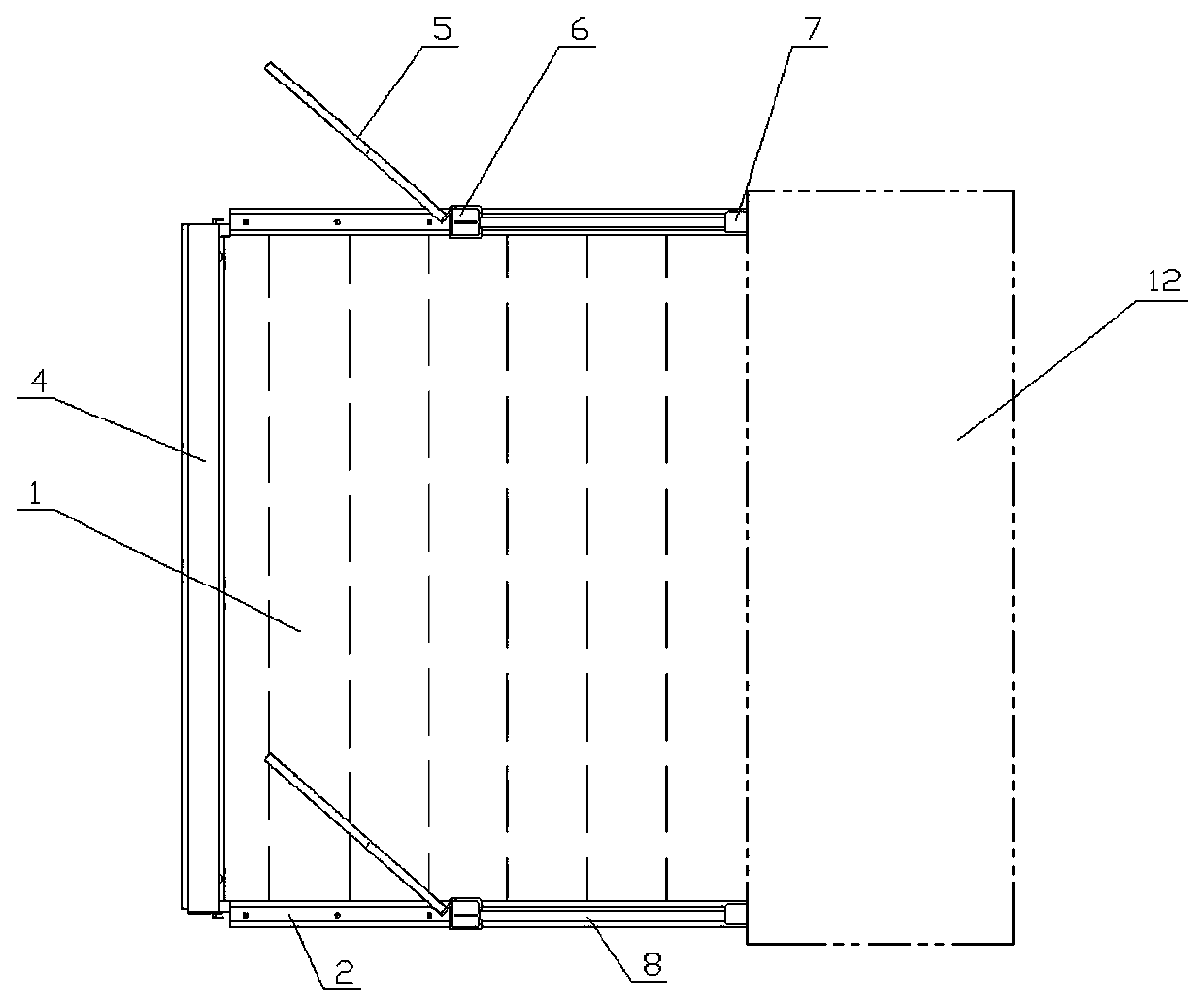

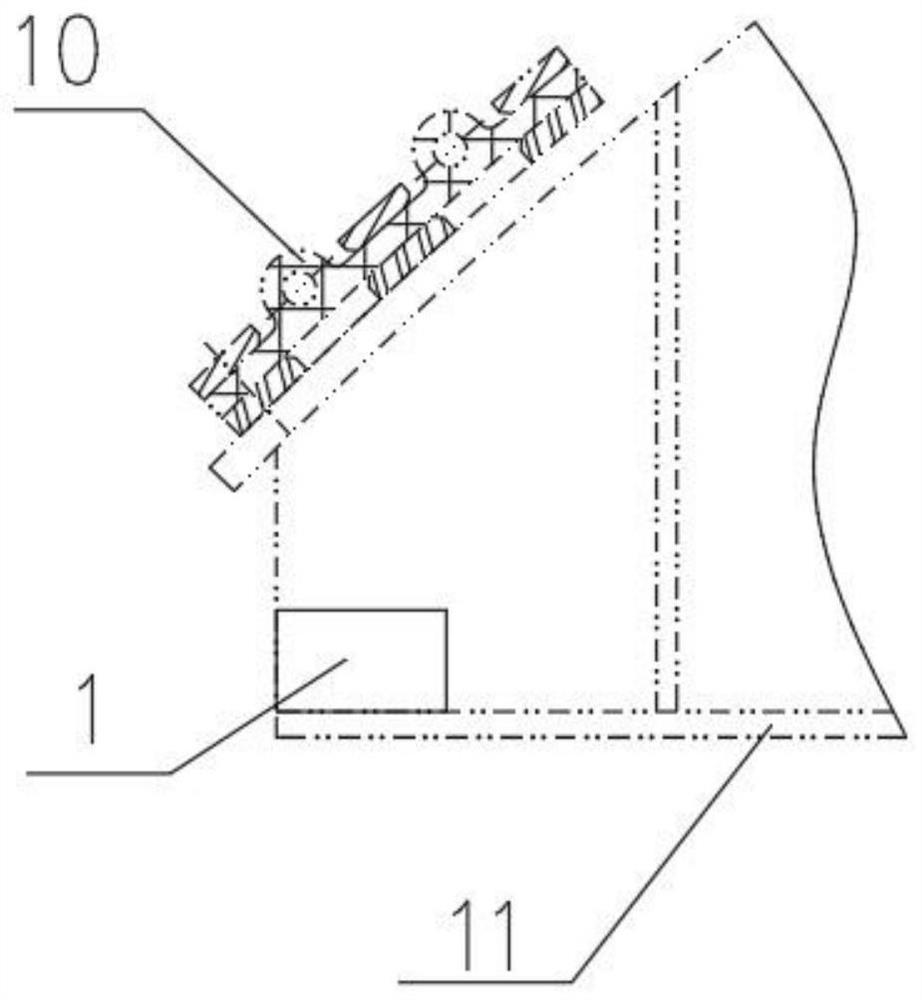

Overturning and folding working platform for maintenance of ship lift clearance sealing water stop rubber

ActiveCN112392246ASolve problems that are difficult and take a long time to set upDoes not affect navigationMarine site engineeringScaffold accessoriesMarine engineeringStructural engineering

The invention relates to the technical field of overhaul and maintenance working platforms, and particularly discloses an overturning and folding working platform for maintenance of ship lift clearance sealing water stop rubber. The working platform comprises a plurality of overturning and folding type platform bodies and first rotary connecting mechanisms; the platform bodies are sequentially arranged along the outer side of a vertical section of a clearance sealing mechanism arranged on the end face of a ship compartment head structure of a ship lift in the vertical direction through the first rotary connecting mechanisms; and the driving path of each platform body under the action of the corresponding first rotary connecting mechanism comprises reciprocating in the direction from the side face of the compartment head structure to the end face of the compartment head structure. In a maintenance state, all the platform bodies can be transferred to the end face of the compartment headstructure from the side face of the compartment head structure through the first rotary connecting mechanisms, the platform bodies are rapidly converted into a working state from a storage state through overturning and folding actions, and the purposes of lowering working intensity, saving the working platform building time, and shortening the maintenance period and the downtime are achieved.

Owner:HEAVY EQUIP ENG CO LTD OF WUCHANG SHIPBUILDING IND

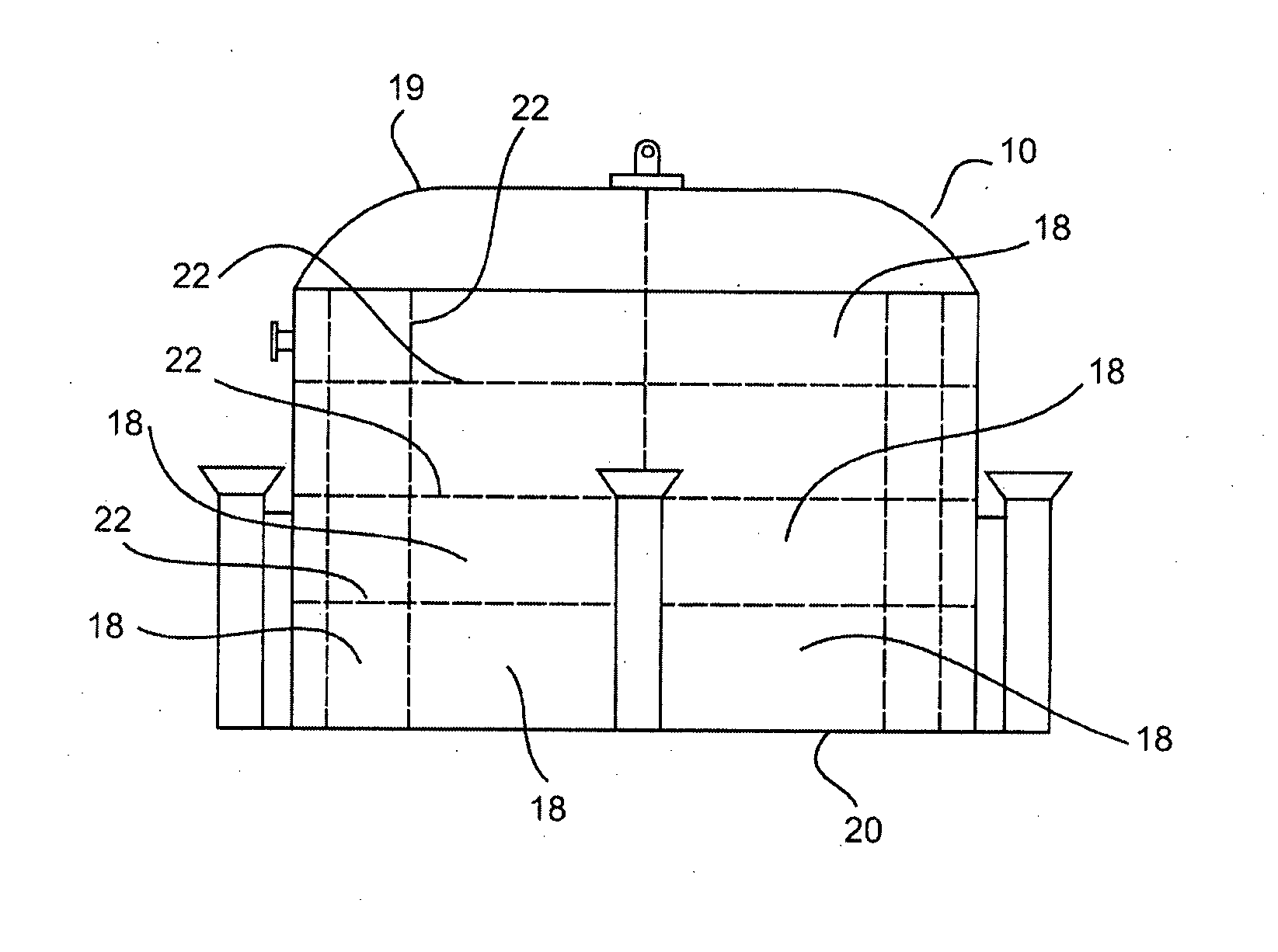

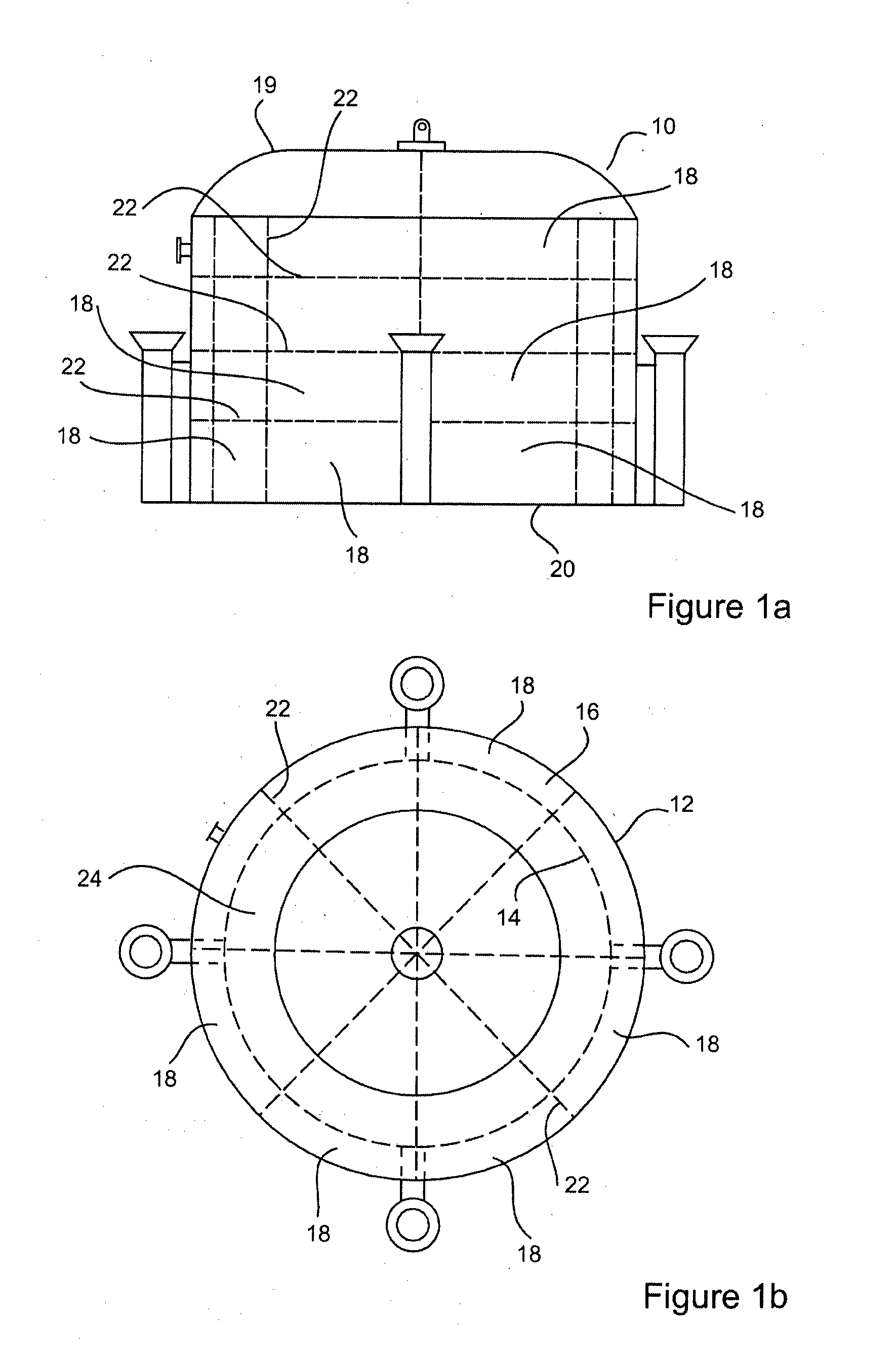

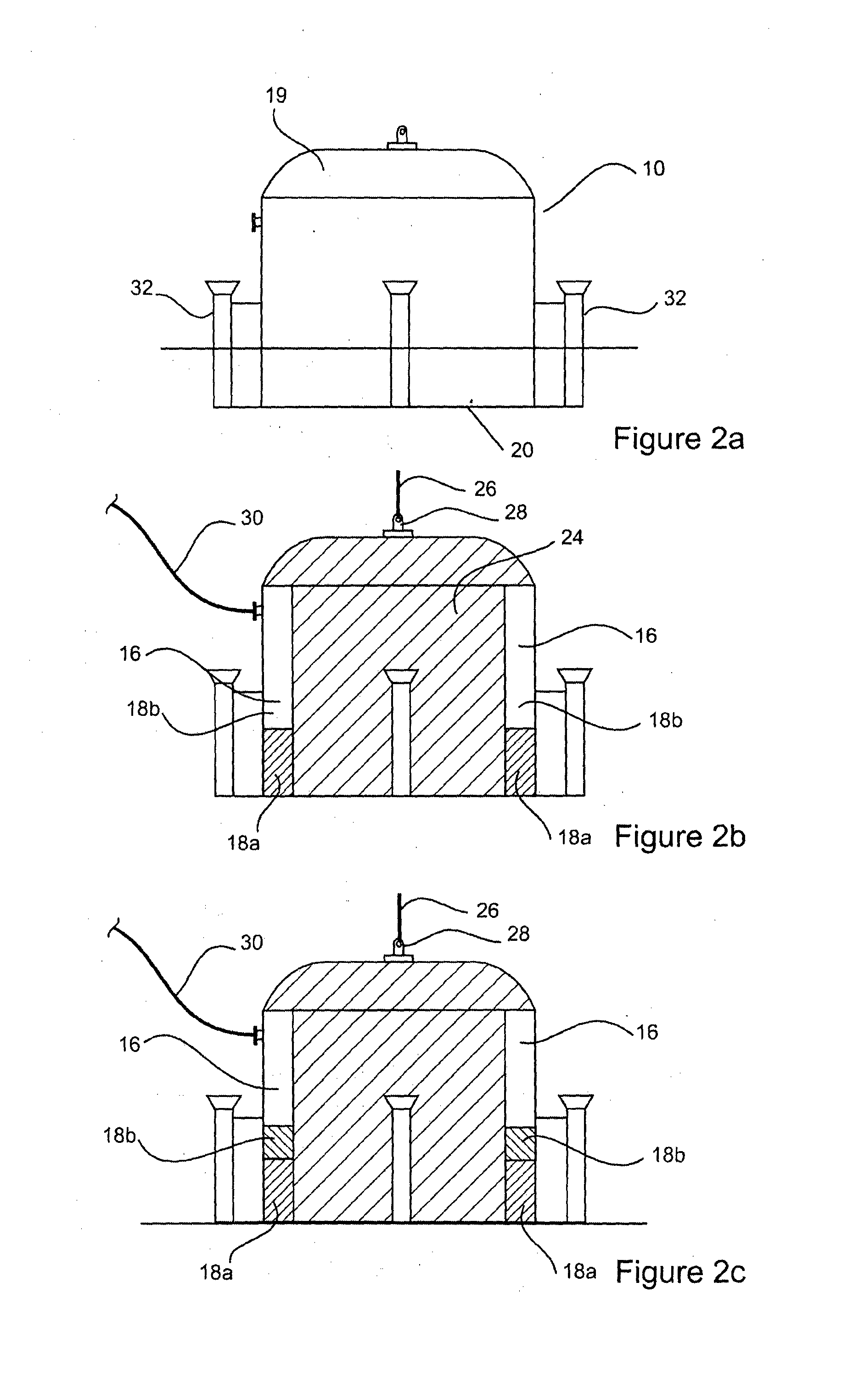

Tank

InactiveUS20150176764A1Reduce floodingReduce hydrostatic pressureLarge containersContainer/bottle contructionCisternNeutral buoyancy

A tank for storage of hydrocarbon liquids on the seabed, being of double hull construction which is compartmented to form a plurality of chambers, such that the tank may be safely towed from its build location or shipyard, to offshore deployment location as marine warranty compliant vessel, having appropriate intact and damaged stability characteristics. There is also provided a method for deploying a tank for storage of hydrocarbon liquids on the seabed, the method comprising the step of towing the tank having un-ballasted storage areas and compartments to the location of deployment; flooding at least partially the storage area to achieve substantial neutral buoyancy of the tank to allow decent of the tank up to a submerged equilibrium; allowing decent of the tank to the seabed and injecting air into at least one compartment for maintaining equilibrium between the pressure applied by the surrounding sea and the pressure inside compartments and storage area.

Owner:SEACAPTAUR IP

Anti-ship mutilating device capable of realizing self-induction and step-by-step and compartment-by-compartment release of energy and use method of device

PendingCN111207627AEfficient damageExpand the scope of damageAmmunition projectilesMarine torpedoesDetonationMarine engineering

The invention discloses an anti-ship mutilating device capable of realizing self-induction and step-by-step and compartment-by-compartment release of energy and a use method of the device. Multiple stages of concatemers perform self-induction blasting reactions in compartments sequentially and produce high blasting heat and flames to cause burning of component facilities in the compartments, induced detonation of stored ammunition and blasting of reserved fuel oil, blasting energy is produced through self-induction and is released to the compartments step by step, the mutilating range is enlarged remarkably, the fire setting effect is enhanced, and the device can be used for mutilating functional components in large ships efficiently to eliminate the operational capability of the functional components and even causing large-area fuel oil blasting or induced detonation of ammunition on the ships to cause sinking of the ships.

Owner:GENERAL ENG RES INST CHINA ACAD OF ENG PHYSICS

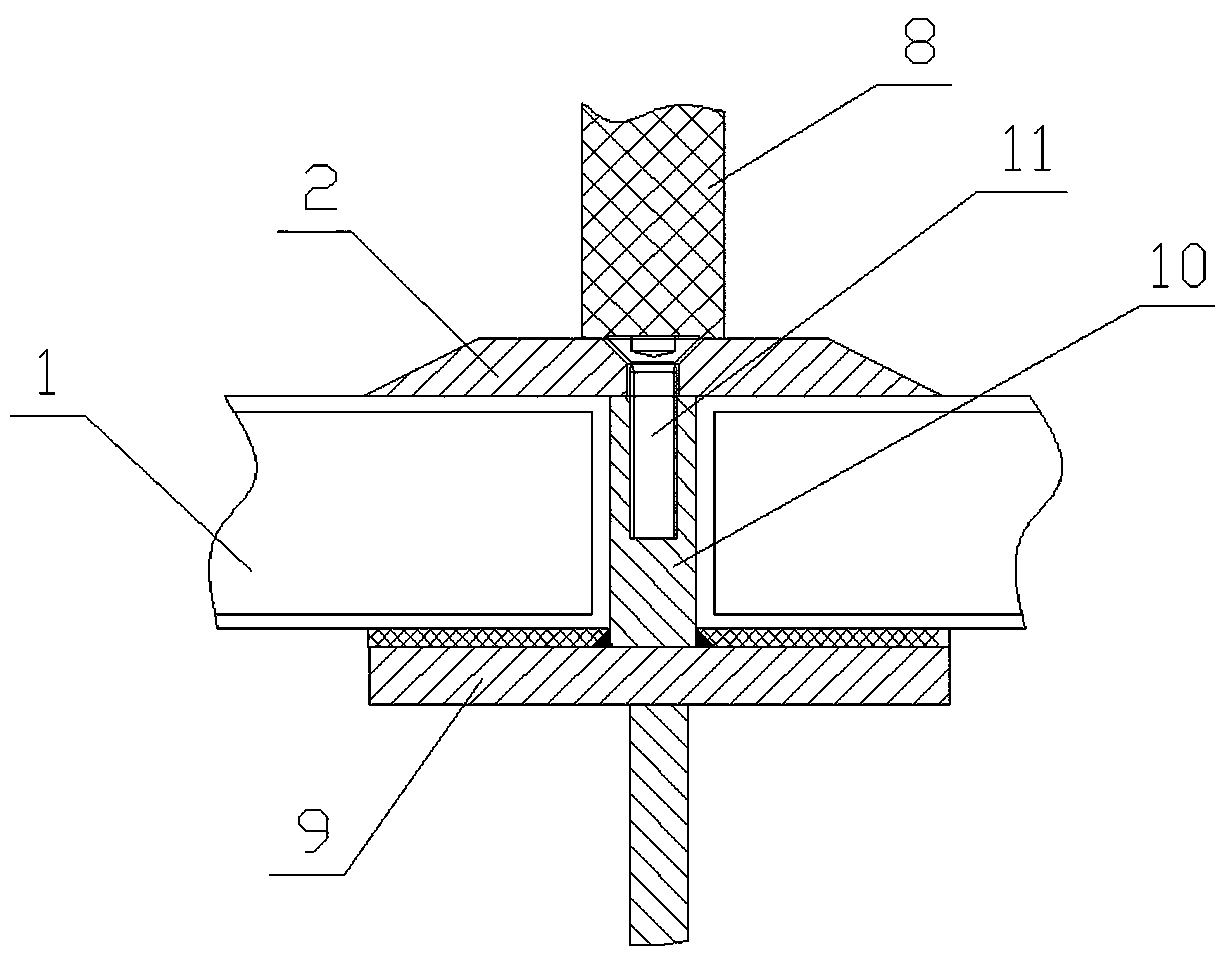

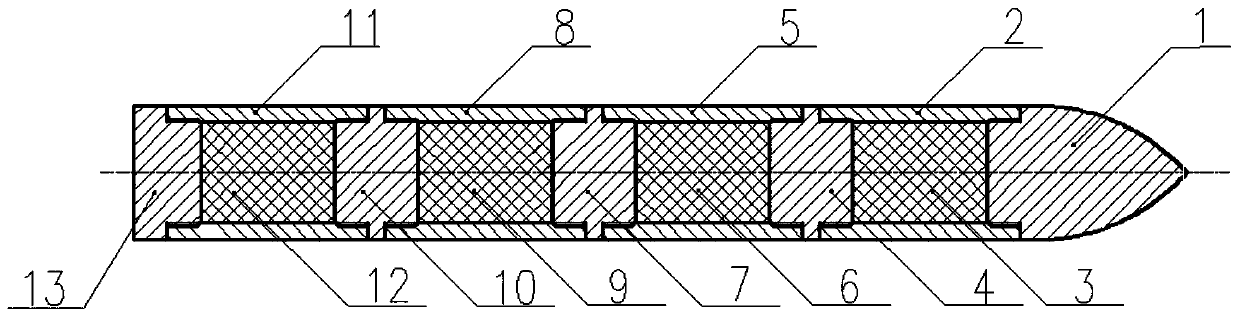

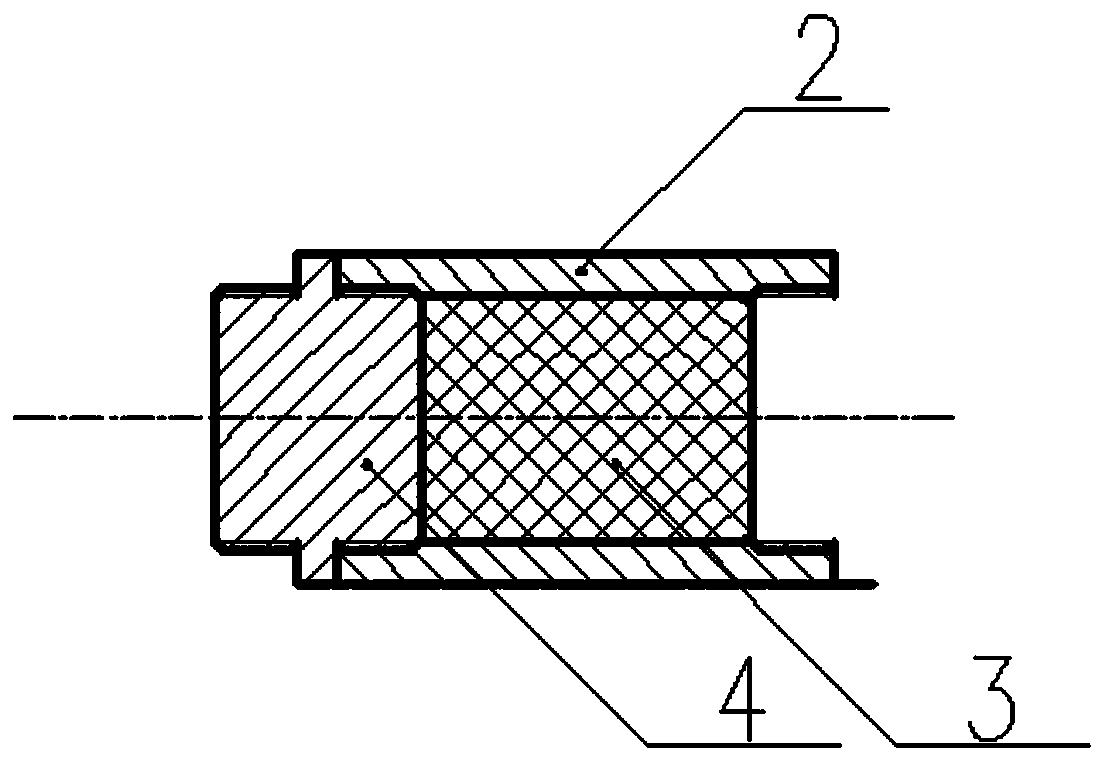

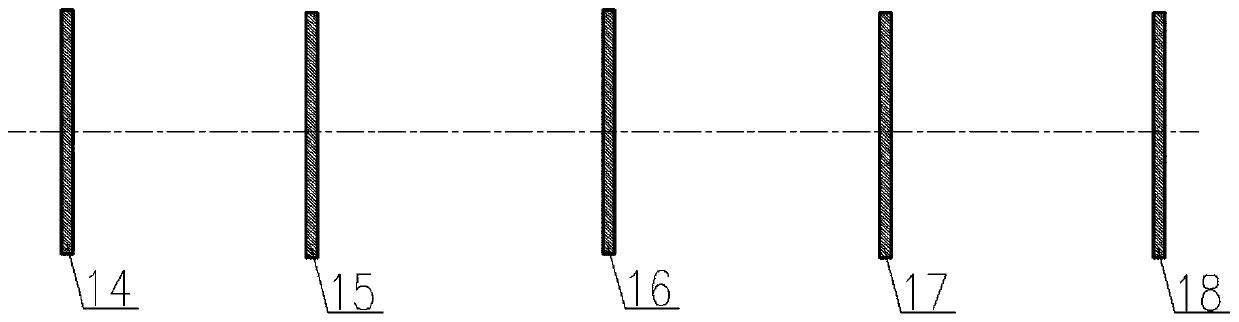

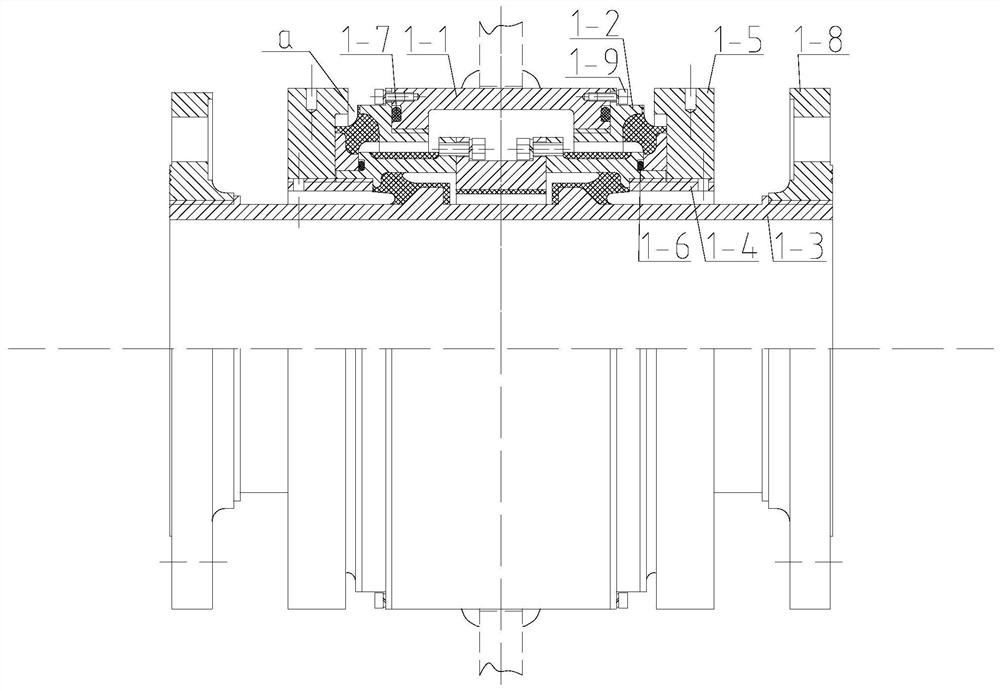

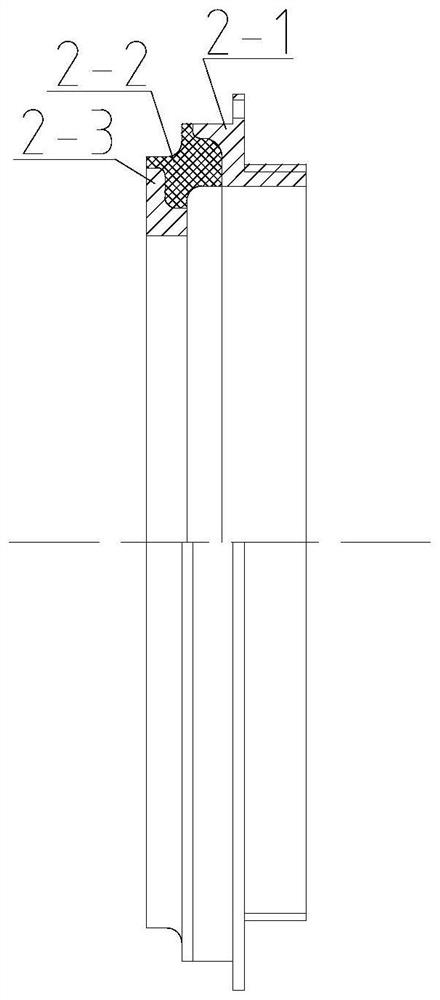

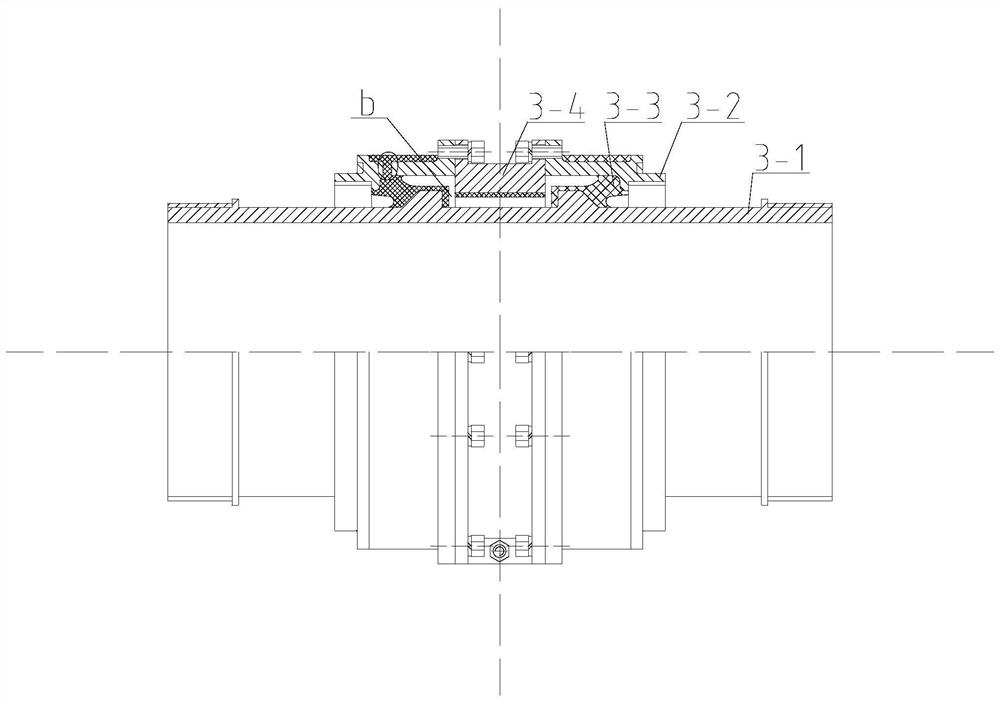

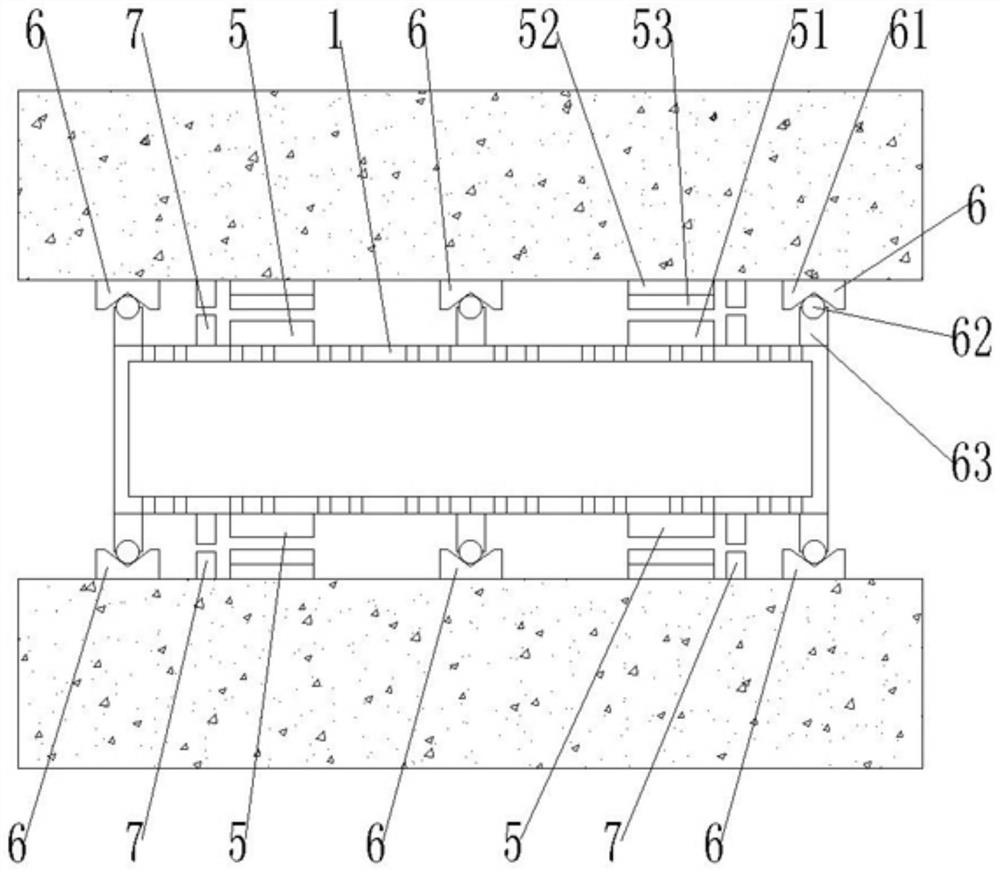

Elastic cabin-penetrating double-layer vibration isolation device for pipeline

InactiveCN112963627AEfficient formationAchieve sealingPipesPipe elementsEngineeringVibration isolation

The invention discloses an elastic cabin-penetrating double-layer vibration isolation device for a pipeline. The invention relates to the technical field of vibration and noise reduction of ships and warships, in particular to an elastic cabin-penetrating double-layer vibration isolation device for a pipeline. Compared with a single-layer vibration isolation system, the elastic cabin-penetrating double-layer vibration isolation device for the pipeline has the advantage that the vibration reduction performance of a cabin-penetrating part of the pipeline can be effectively improved. Through a reasonable assembly design, the double-layer vibration isolation design is achieved between a core tube of an upper-layer vibration reduction body and a welding cushion cylinder, the mass of a middle mass body of the double-layer vibration isolation system can reach 30% or above of the mass of a 1-meter liquid passing tube, the double-layer vibration isolation system can be effectively formed, and according to actual measurement, the design scheme has the advantages that under a simulated actual ship working condition, the vibration isolation effect is not lower than 35dB (10Hz and 10kHz total level). By means of a limiting design and a rubber layer structure optimization design, compartment sealing not smaller than 3 MPa can be achieved under the condition that the vibration isolation effect is guaranteed.

Owner:JIANGSU YANGZHOU HELI RUBBER PROD

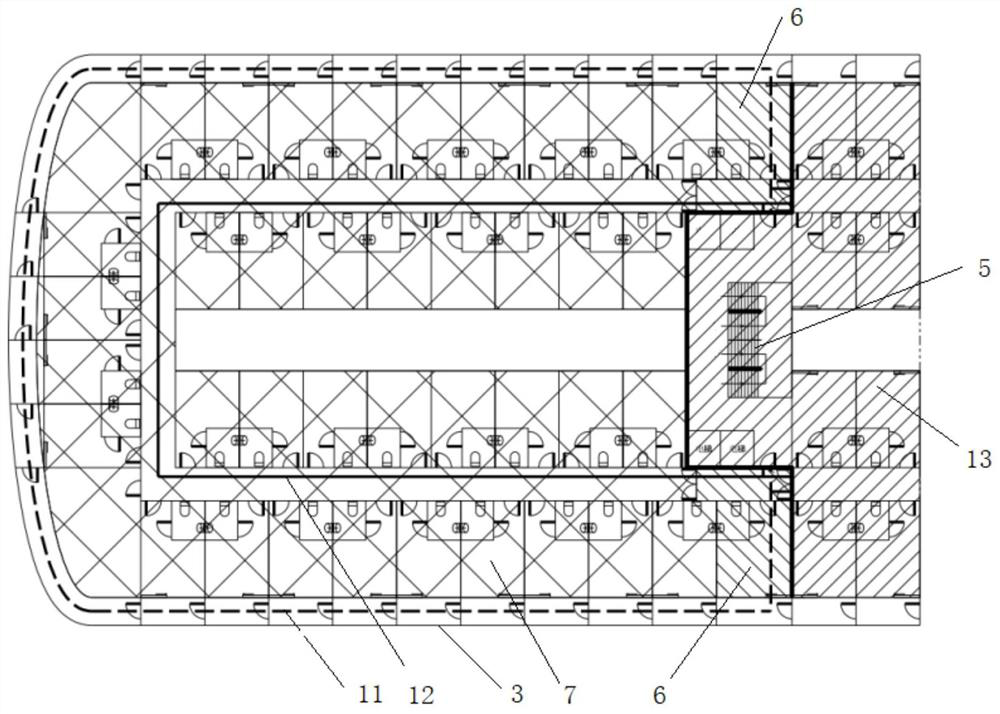

Floating platform for quickly carrying container function unit

ActiveCN111661263ALower center of gravityImprove stabilityVessel superstructuresHull decksFloating platformMechanical engineering

The invention discloses a floating platform for quickly carrying a container function unit. The platform is characterized in that the platform comprises a main ship body divided by taking a strong deck as a boundary, and a superstructure used for carrying the container function unit; and the strong deck is arranged on the main ship body, the superstructure is arranged on the strong deck, the superstructure comprises a lifeboat area and a frame deck layer, the frame deck layer is located on the lifeboat area and comprises a left island and a right island which are relatively independent, and anexposed deck is arranged between the left island and the right island. The platform can meet different task requirements, cabin units can be quickly assembled in a modular mode, and a cabin module can be used as a luxurious cruise ship or a floating hotel when a cabin module is carried; and when a medical cabin module is carried, the medical cabin module can be used as a carrying platform for offshore mobile cabin hospitals. The platform is high in adaptability, flexible in use, good in stability, convenient to construct and replace cabin units, high in sunlight room proportion and capable ofenabling most passenger cabins to meet natural ventilation, and has good economical efficiency and a certain strategic reserve value.

Owner:708TH RES INST OF CSSC

Ship anti-overturning device for anti-wind and waves

ActiveCN112193383BAvoid overall overturningImprove the protective effectVessel safetyOn boardWind wave

The invention discloses a ship anti-overturning device for preventing wind and waves, and specifically relates to the field of ships, including a ship hull. A group of protective mechanisms are respectively fixed on the inner walls of both sides of the hull compartment, and each group of protective mechanisms is evenly distributed along the inner wall of the hull compartment. In a row, each row of protective mechanisms corresponds to multiple seats in the hull compartment; each protective mechanism includes a lower box, an upper box, a seat lifting structure, a flip guard structure and a guard flip drive structure . The invention drives the winding and unwinding of the steel rope through the meshing of the tooth groove and the rack, thereby driving the flip guard structure to rotate to the side of the wind and waves. The whole operation can make the center of gravity of people shift to the side of the direction of the wind and waves, which can prevent the hull from capsizing. On the one hand, the rotating flip guard structure can also prevent the occupants on the seat from tilting and falling into the water. Compared with the existing technology, the whole device has better protection ability for the occupants on board and anti-overturning ability for the hull. Great improvement.

Owner:东营海欣港务有限公司

Inland river ship with ballast system

PendingCN114212203AQuickly adjust headroomAchieve the purpose of crossing the bridgeSelf-bailing equipments/scuppersVessel partsMarine engineeringBallast tank

The invention discloses an inland ship with a ballast system. The inland ship comprises a middle cargo hold part; a bow; the ballast system comprises a double-layer bottom ballast tank, a ballast tank, a ballast tank, a ballast tank, a ballast tank, a ballast tank, a ballast tank body and a ballast tank body, the gunwale ballast tanks are located below the decks on the two sides of the middle cargo compartment part; the head ballast tank is located at the bottom of the ship head; the tail ballast tank is located at the bottom of the ship tail; and the water ballast tank is arranged on a deck at the tail part of the ship and is used for leveling the whole ship. The ship is suitable for inland river transportation, the ballast tanks are arranged in the ship body to form a ballast system, the ballast pump of the engine room is used for pumping and draining water, then the clearance height of the ship is rapidly adjusted, and the bridge crossing purpose is achieved.

Owner:苏州恒裕达航运有限公司

Method for butting and assembling of bottom sections of chemical tanker

InactiveCN110789678AGuaranteed Build QualityAccurately provide the actual installation locationWaterborne vesselsStringerIndustrial engineering

The invention discloses a method for butting and assembling of bottom sections of a chemical tanker. The method comprises the following steps of scribing a theoretical line used for mounting a stringer on a framework surface of the bottom sections; scribing a first inspection line at a preset distance from the theoretical line on the framework surface; mounting the stringer on the framework surface, and measuring an offset distance between the stringer and the first inspection line; re-punching the first inspection line in the cargo hold surface to form a second inspection line; translating the second inspection line in the direction of the stringer for the offset distance on a cargo hold surface to form a mounting line; and butting and assembling a side section or a middle longitudinal compartment section on the cargo hold surface of the bottom section with reference to the mounting line. According to the method, under the condition that segmented plates are not damaged, the actual mounting precision of a bottom section butting structure is verified. Meanwhile, a large amount of nondestructive flaw detection operation is avoided while the ship construction precision is met, the butting operation production cycle is shortened, and the production cost is reduced.

Owner:HUDONG ZHONGHUA SHIPBUILDINGGROUP

Linear motor hydraulic ship lift

PendingCN111648336AReduce construction strength requirementsReduced support strength requirementsVertical ship-liftingLinear motionDynamic balance

The invention belongs to the technical field of water conservancy and hydropower engineering, and particularly relates to a linear motor driven hydraulic transmission ship lift capable of balancing dead weight. According to the specific technical scheme, the linear motor hydraulic ship lift comprises a ship chamber and concrete walls which are arranged in parallel and oppositely. A plurality of groups of constant-torque hydraulic transmission mechanisms are arranged at the top of the concrete wall body, a drum in the hydraulic transmission mechanism is connected with the ship chamber through asteel wire rope, and gravity information of the ship compartment is dynamically measured through the electronic scale sensors on the two sides of the ship compartment. The hydraulic motor drives thewinding drum to rotate to dynamically balance the gravity of the ship chamber; the stress balance of the ship chamber is realized; the linear motors on the two sides of the ship chamber drive the shipchamber to do reciprocating linear motion along the guide rails. Stable movement of the ship chamber in the guide rail is achieved through double fault tolerance of the hydraulic transmission mechanism and the linear motor, the requirement for the construction strength of a concrete wall of the whole ship lift is low, the ship lift can meet the ship lifting requirement for large tonnage and largelifting height, the overall construction cost is low, and practicability is higher.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

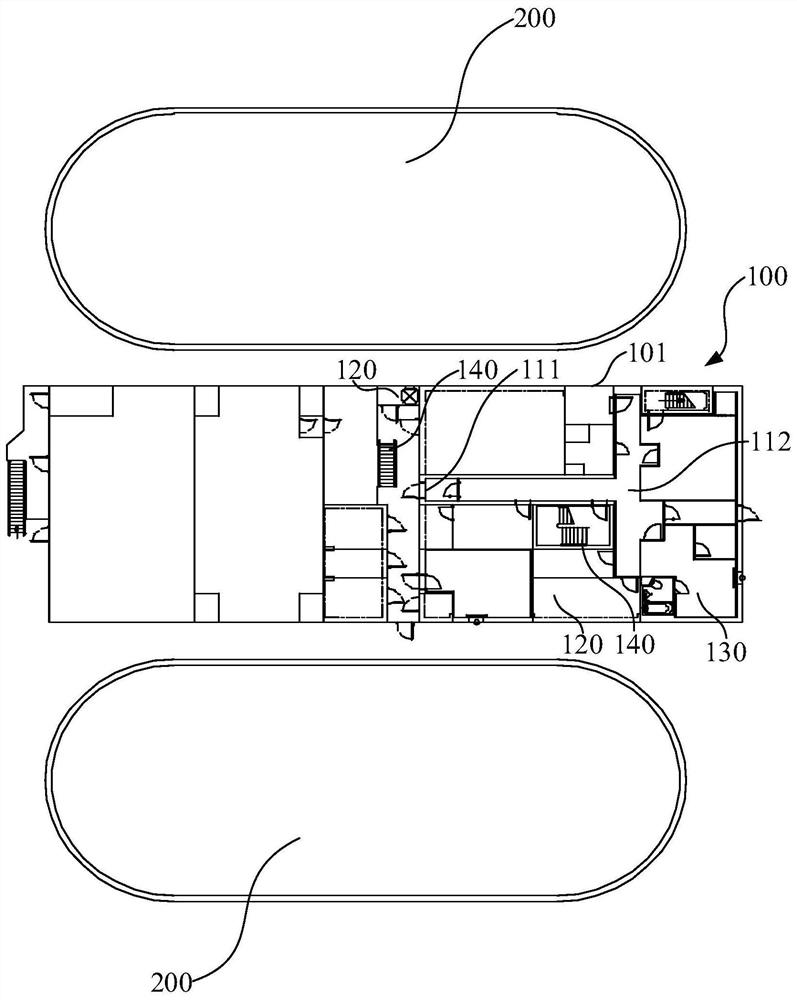

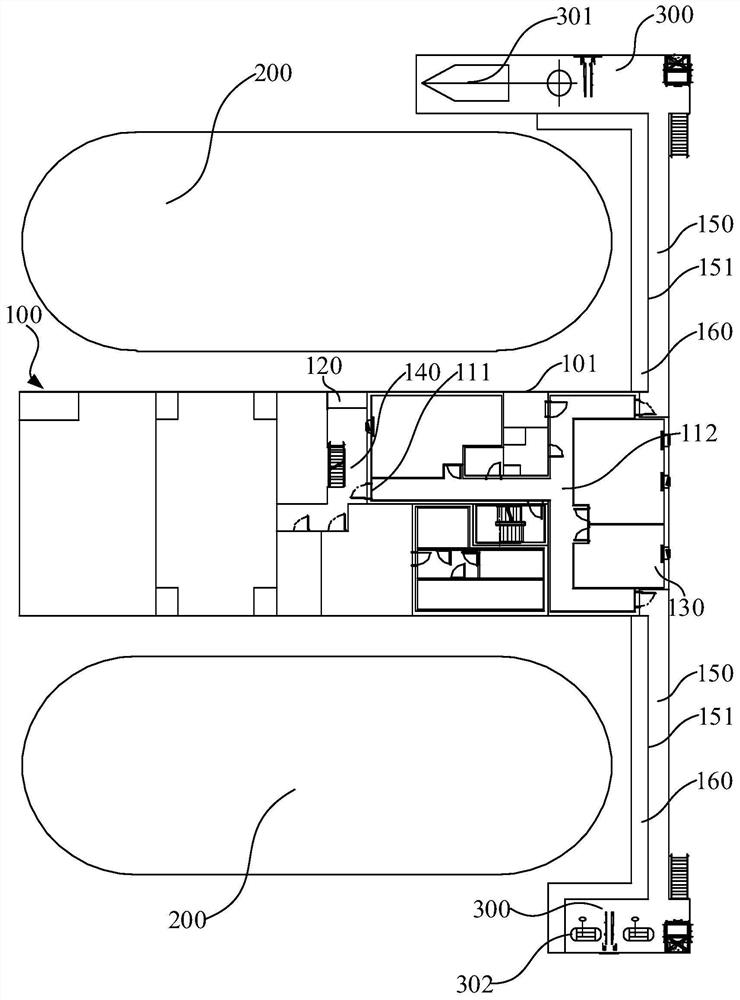

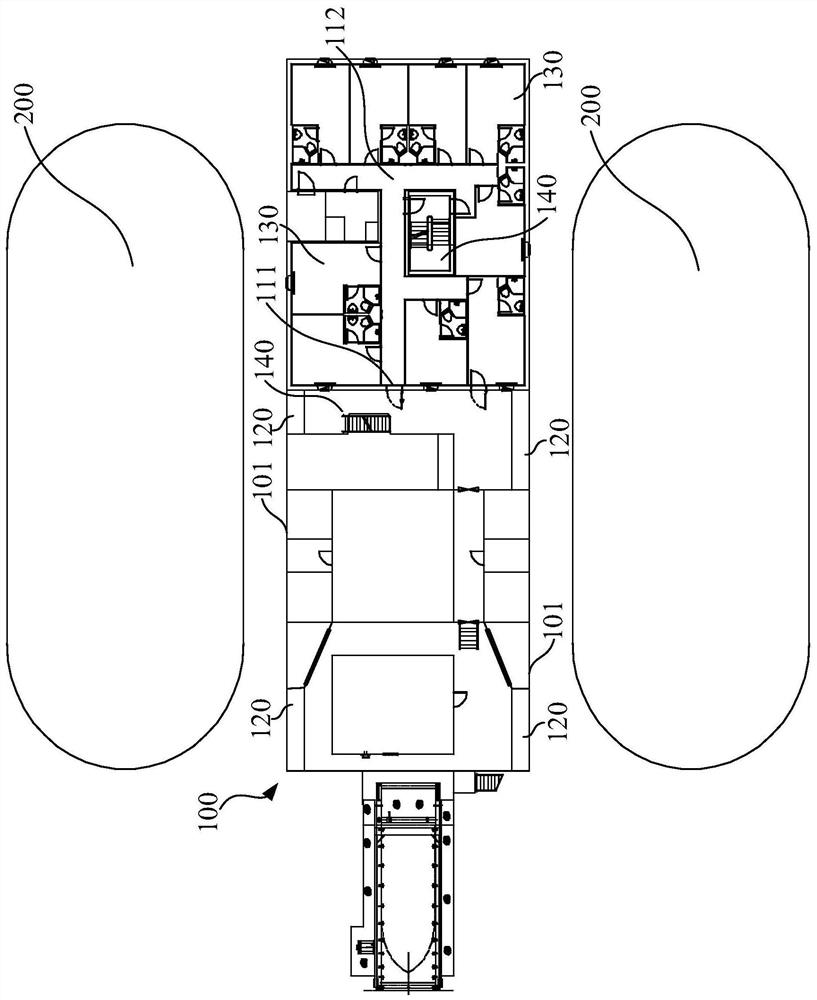

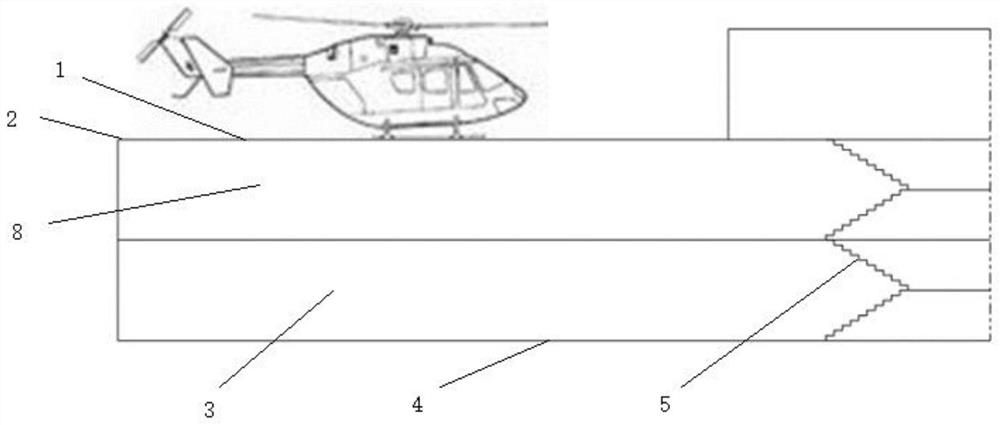

Ship body structure capable of achieving rapid quarantine and ship

ActiveCN113511300AFast quarantineRealize disseminationHull decksRemovable cabin wallsHull structureQuarantine

The embodiment of the invention discloses a ship body structure capable of achieving rapid quarantine and a ship, and the ship body structure comprises a parking apron which is arranged on a top-layer exposed deck of a stern; a concentrated isolation area is arranged on the top-layer passenger cabin deck in the multiple passenger cabin decks under the top-layer exposed deck, a first main vertical area is located on the stern, a channel is arranged between the concentrated isolation area and the parking apron, and the concentrated isolation area comprises a transition area and a pollution area; the transition area is one or a plurality of adjacent passenger cabin rooms close to the first main vertical area and separated from other main vertical areas in the concentrated isolation area, and a first isolation door is arranged between the transition area and the pollution area. The distance between the concentrated isolation area and the parking apron is reduced, so that epidemic prevention personnel can rapidly boarding through the parking apron and directly reach the concentrated isolation area through the channel to rapidly collect specimens and rapidly transfer materials, meanwhile, gas in the concentrated isolation area can be diffused to the outside of the ship, spreading of epidemic situations on the ship is reduced, and cross infection is avoided.

Owner:中船邮轮科技发展有限公司

Sound-absorbing and vibration-reducing sheet for passenger cabin of ship

ActiveCN114044083AChange the sound absorption loss coefficientReduce sound pollutionHull panellingsFiberNoise

The invention provides a sound-absorbing and vibration-reducing sheet for a passenger cabin of a ship, which comprises an arc-shaped composite sheet, and a plurality of sound-absorbing grooves tangent to the arc surface of the arc-shaped composite sheet are formed in the arc-shaped composite sheet; the sound-absorbing groove comprises a first cavity and a second cavity which are sequentially formed from the outer side to the inner side of the arc-shaped composite sheet and are communicated with each other, an elastic film layer for isolating the first cavity from the second cavity is arranged at the inner end of the first cavity, and a mass block is embedded in the center of the elastic film layer; a composite fiber layer is adhered to one side, deviating from the second cavity, of the elastic film layer; the second cavity comprises an outer cavity connected with the first cavity and an inner cavity, a telescopic adjusting rod is fixedly arranged in the center of the bottom end of the inner cavity, and an end block is arranged at the free end of the telescopic adjusting rod; and a closed cavity is formed between the end block and the elastic film layer. According to the invention, the noise of different frequencies can be effectively absorbed, and the best vibration and noise reduction effect is achieved.

Owner:江苏航运职业技术学院

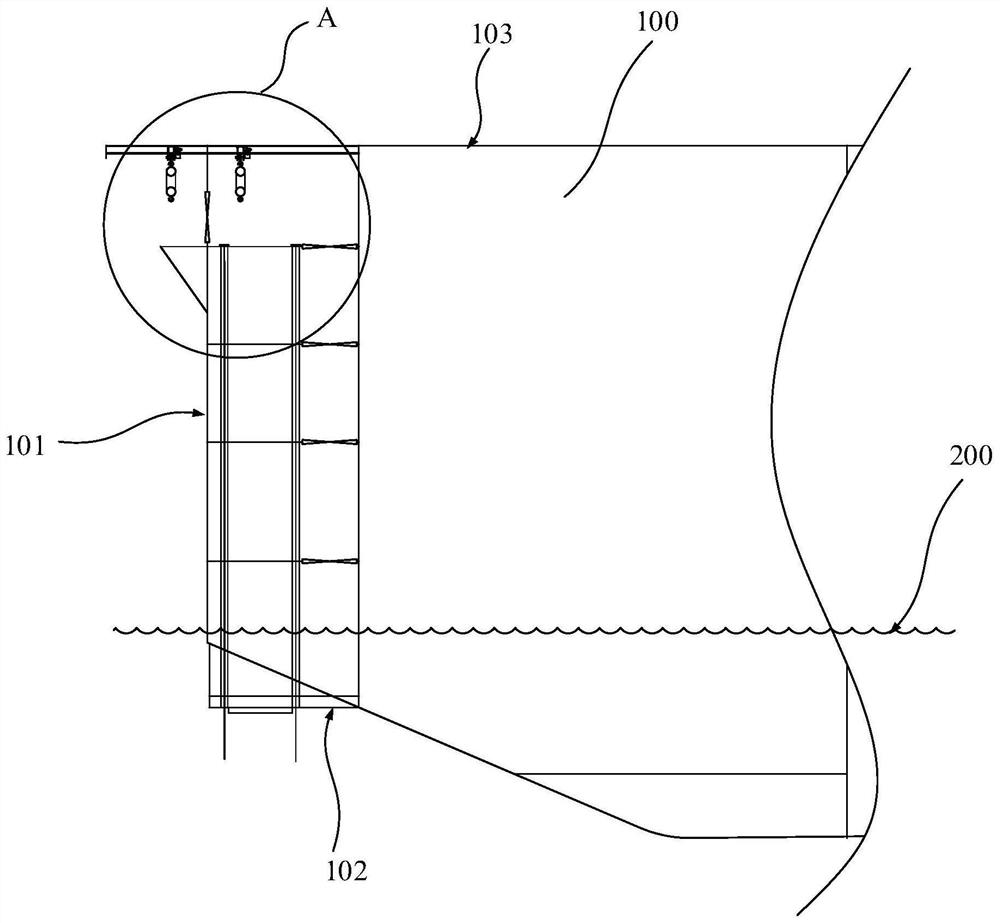

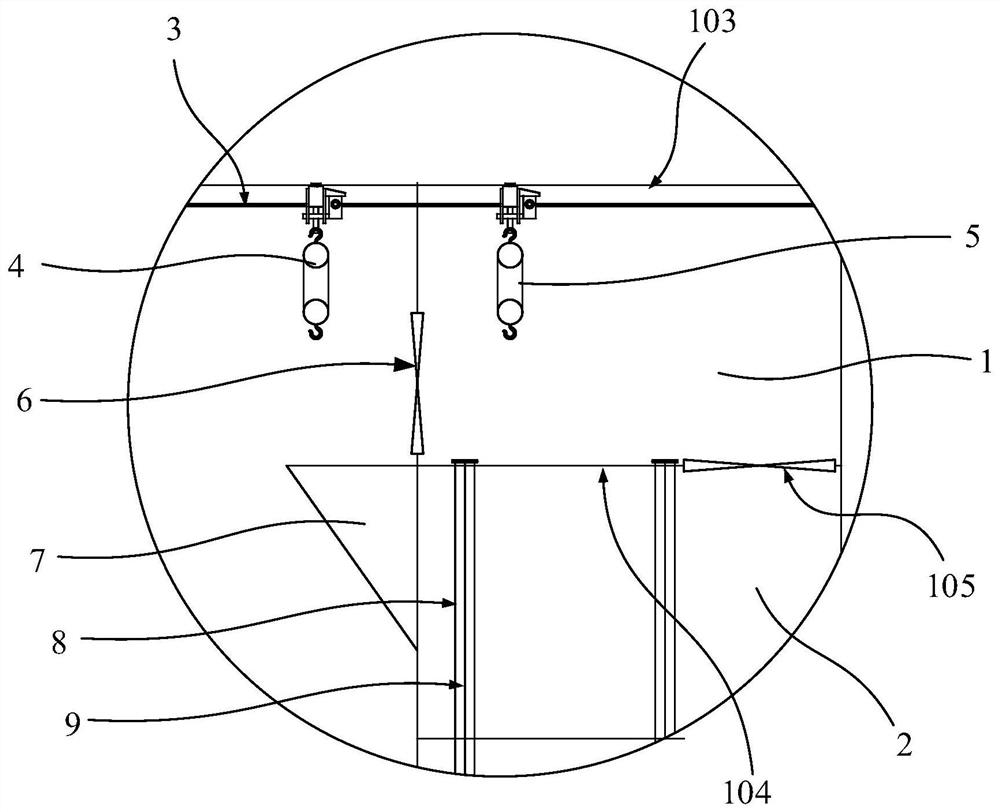

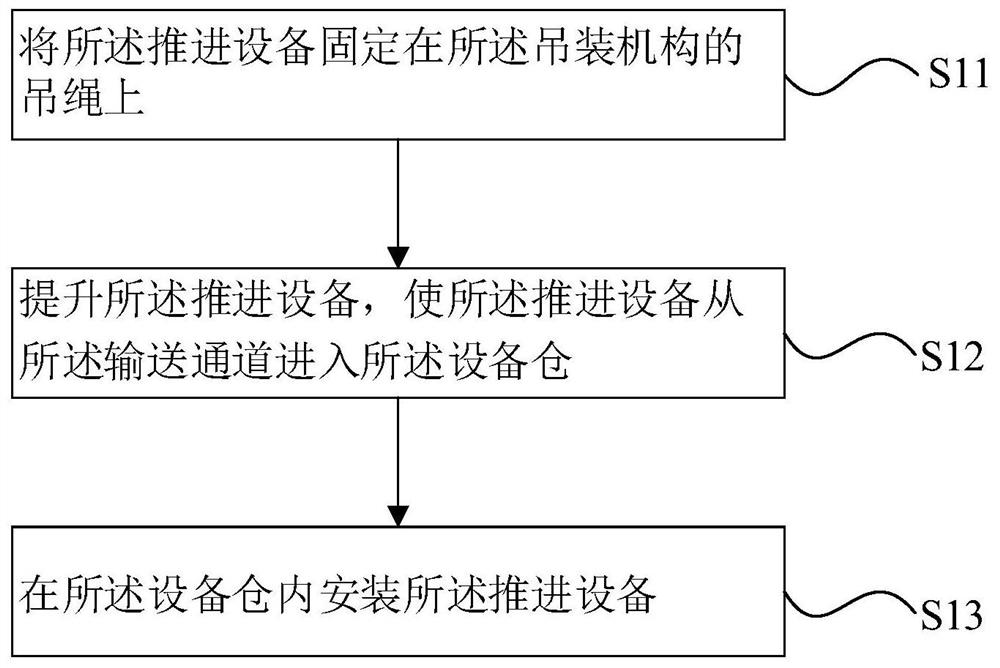

A kind of installation method of propulsion equipment and propeller of ship, propeller

The invention discloses a ship, a propulsion device of a propeller and an installation method of a propeller. The ship includes a ship body and an equipment compartment arranged inside the ship body. The upper end of the stern seal plate of the ship body is provided with an opening. There is a conveying channel between the equipment compartment, and a guide rail is provided on the inner top of the transport channel, and the guide rail extends from above the equipment compartment toward the direction of the opening and protrudes out of the opening, and the guide rail There is a hoisting mechanism on it. In the present invention, an opening for entering the equipment compartment is set on the stern seal plate of the hull, and the propulsion equipment of the thruster is transported to the equipment compartment under the main deck through the hoisting mechanism, which changes the traditional hoisting mode that needs to be reserved on the main deck. The method of lifting objects will not take up valuable deck space and squeeze the main deck equipment layout, and there is no need to set up heavy cranes on the deck or rent external engineering ships, which effectively reduces costs.

Owner:SHANGHAI WAIGAOQIAO SHIP BUILDING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com