Linear motor hydraulic ship lift

A technology of linear motors and ship lifts, applied in the field of ship lifts, can solve the problems of increasing the scale of the mechanical transmission device of the winch, the difficulty of realizing the axial layout of the main hoist, and the inability to meet the layout of the main hoist, etc. The effects of directional layout, reducing support strength requirements, and reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to make the technical problems, technical solutions and beneficial effects to be solved by the present invention clearer, the following further describes the present invention in detail with reference to the accompanying drawings and embodiments. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention.

[0044] 1. Description of ship lift structure:

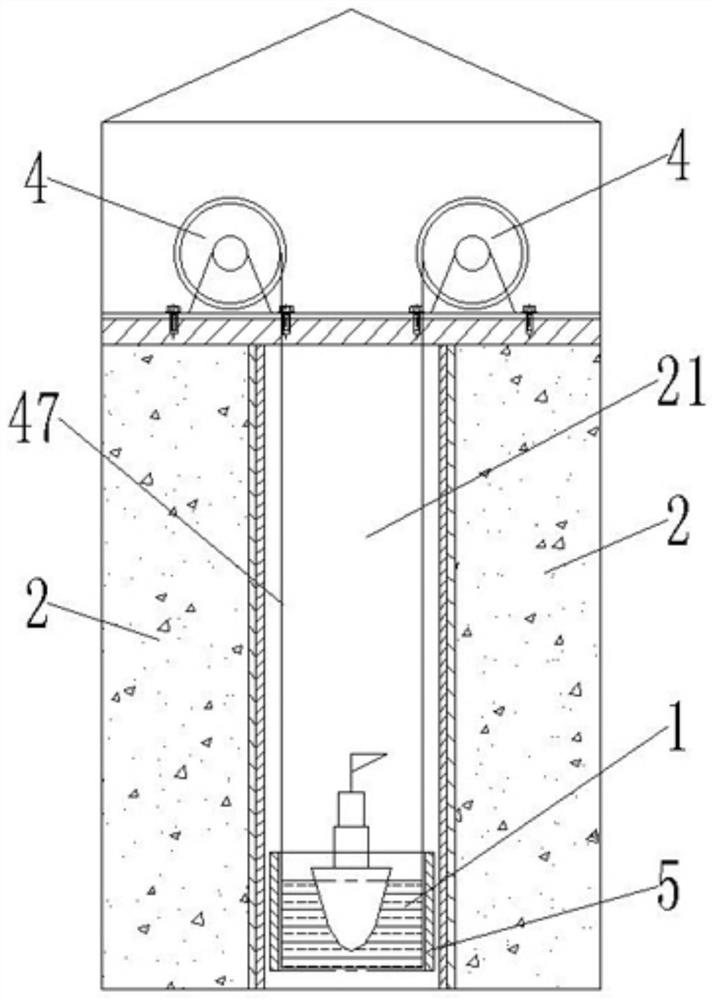

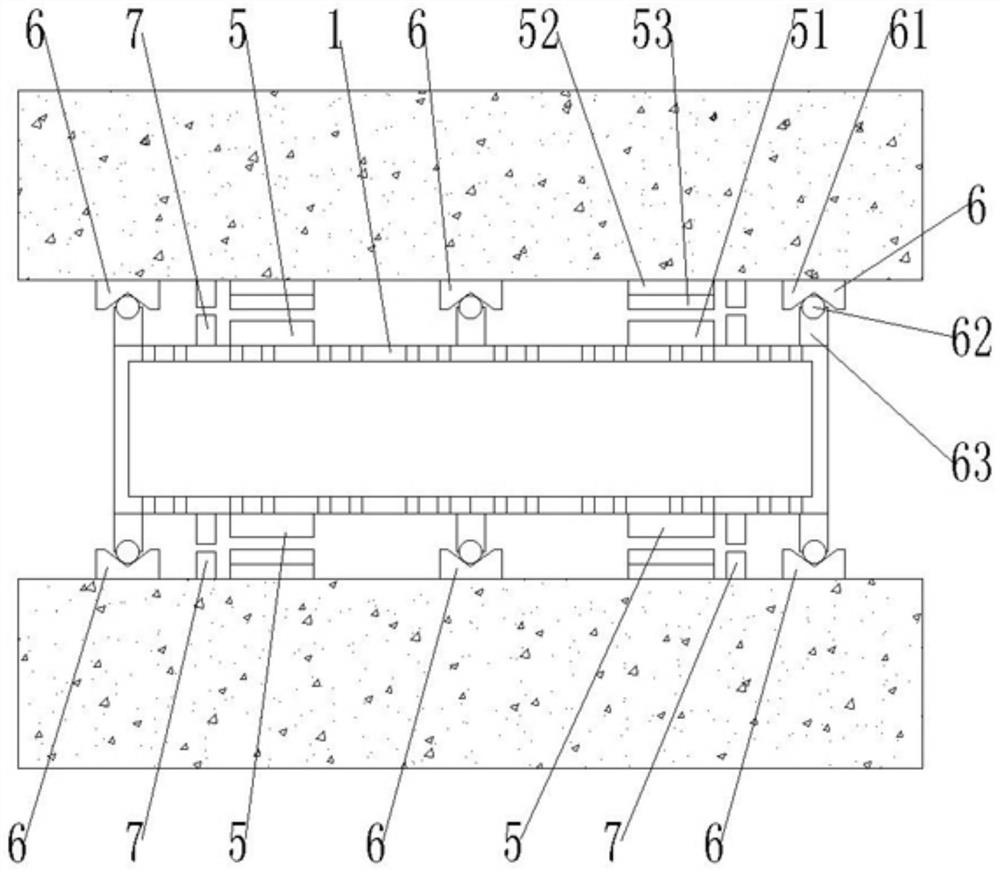

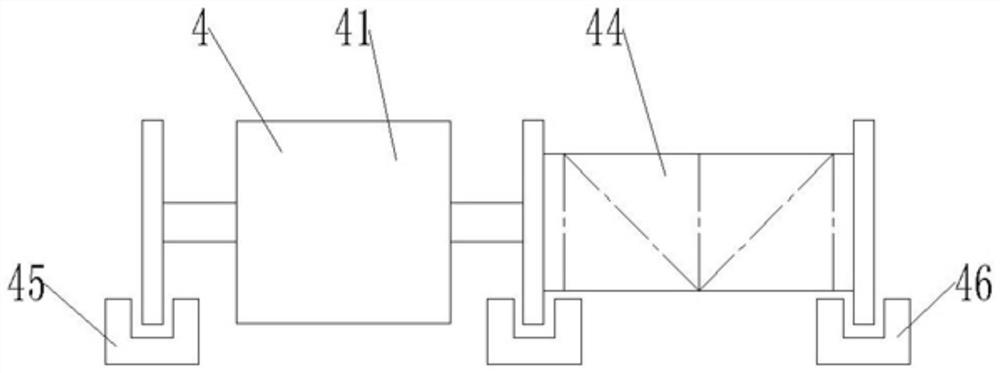

[0045] Such as figure 1 , image 3 , Figure 5 As shown, the linear motor 5 hydraulic ship lift includes a ship cabin 1, a concrete wall 2 arranged in parallel and oppositely, a ship lifting channel 21 is formed between the concrete walls 2 on both sides, and the ship cabin 1 is placed in the ship lifting channel 21 Inside.

[0046] The cabin 1 is a dry water tank. When the ship enters or leaves the cabin 1, the cabin 1 will not be completely immersed in the water, and water will not enter the cabin 1 from both sides.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com