A single-flow supercritical water-cooled reactor based on square fuel assemblies

A fuel assembly and square technology, applied in the field of nuclear reactors, can solve the problems of reduced engineering feasibility, complex fuel assembly and core structure, etc., and achieve the effect of improving economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

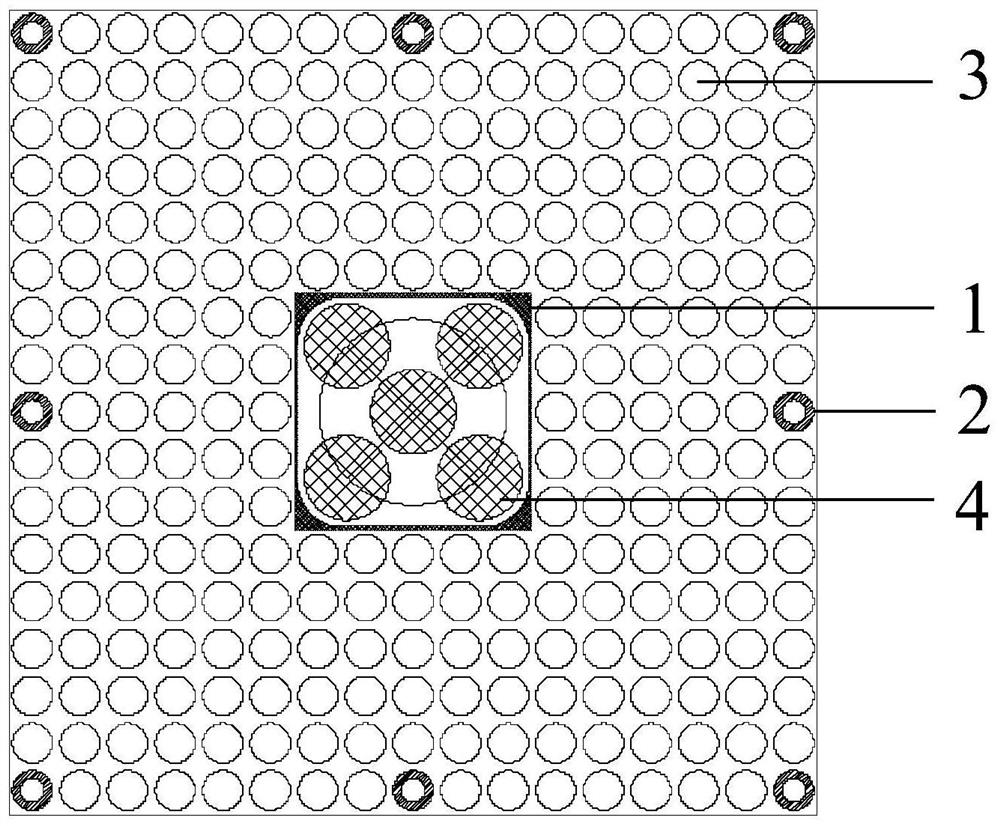

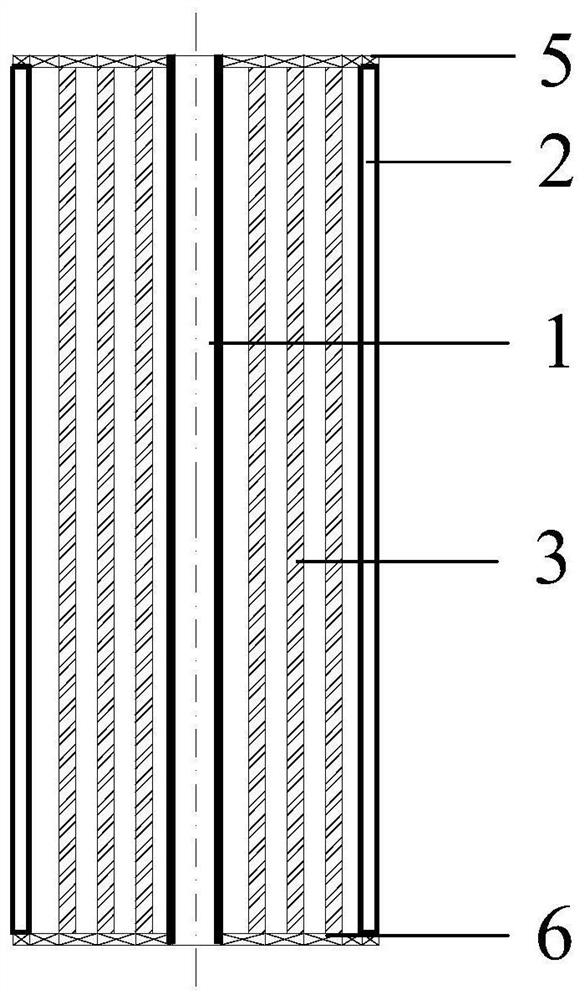

[0029] This embodiment provides a square fuel assembly, in which a guide tube 1 is coaxially arranged at the center of the square fuel assembly, and a control rod bundle 4 is coaxially arranged in the guide tube 1; at the four corners and the periphery of the square fuel assembly One support tube 2 is coaxially arranged at the center points of the four sides in the circumferential direction, a total of 8 support tubes 2; 256 fuel rods 3 are coaxially arranged between the dead plate and the center of the square fuel assembly.

[0030] The outer diameter of each fuel rod 3 is 9.5mm, the wall thickness is 0.65mm, and the cladding material is SiC; the core body is UO 2 ceramics, the outer diameter of the core is 8.0 mm; the center-to-center distance between adjacent fuel rods 3 is 10.5 mm, which is used as a coolant flow channel. The cladding material of the fuel rod 3 is silicon carbide.

[0031]The guide tube 1 occupies 25 grid positions at the center of the square fuel assembl...

Embodiment 2

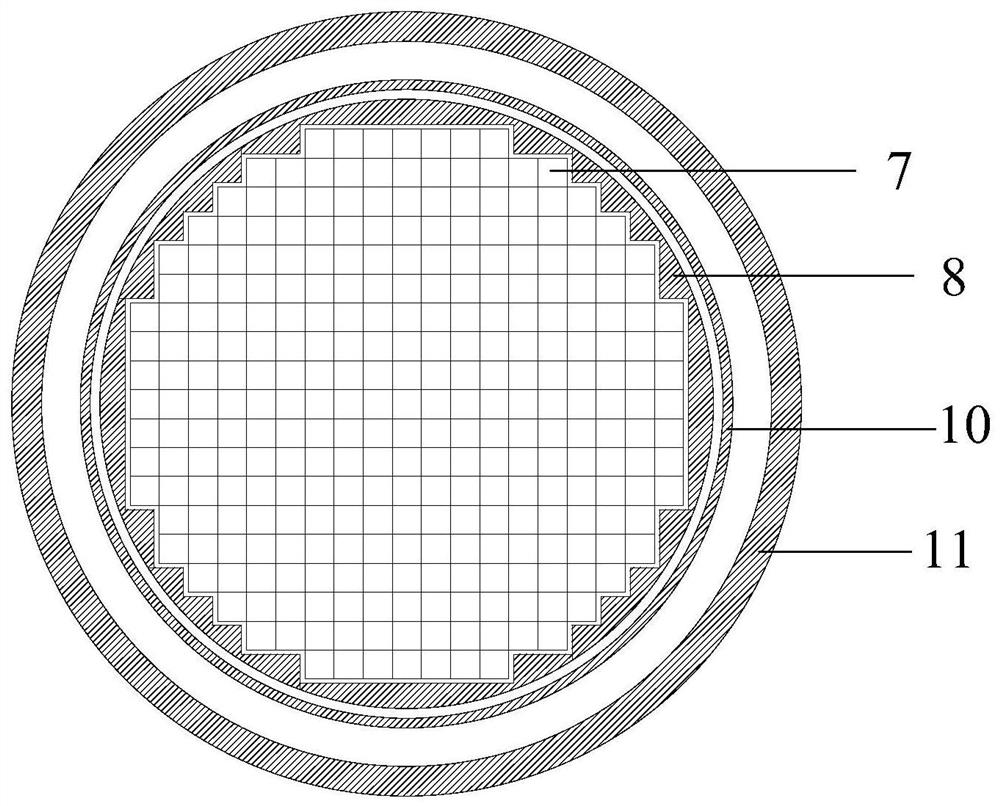

[0036] This embodiment provides a single-flow supercritical water-cooled reactor, which includes 293 square channels 7, and the 293 square channels 7 are adjacent to each other to form a honeycomb integral structure, and a metal reflective layer 8 is arranged outside the honeycomb integral structure; the square channel 7 For accommodating the square fuel assembly provided in Embodiment 2, the inner side of the metal reflective layer 8 is an irregular polygonal structure that is in contact with the outer side of the honeycomb monolithic structure.

[0037] The wall thickness of the square channel 7 is 2.0mm, the center-to-center distance between adjacent square channels 7 is 182.0mm, the structural material is stainless steel, and the circumscribed circle diameter of the honeycomb integral structure core is 3686mm; the outer diameter of the metal reflective layer 8 is 3790mm The outer diameter of the hanging basket 10 is 3850mm, and the wall thickness of the hanging basket 10 is...

Embodiment 3

[0040] Based on the single-flow supercritical water-cooled reactor fuel management method provided in Embodiment 2:

[0041] In this embodiment, a coolant flow distributor 9 is provided at the bottom of each square channel 7 in the core. According to the location of the square channel 7 in the core, the layout of the core control rods and the three-dimensional power distribution shape of the core, each square The coolant flow in channel 7 is regulated.

[0042] According to the core power, height and other parameters, the fuel management method of multi-batch refueling is adopted, that is, multiple boxes of square fuel assemblies are arranged in each square channel 7 of the core, the coolant adopts a single-flow flow scheme, and the coolant in each square channel 7 The flow rate is fixed, which greatly improves the feasibility of the project. The coolant density at the bottom of the core is high and the coolant density at the top is low. New fuel assemblies enter from the top...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com