Dynamic balance ship compartment gravity ship lifting system

A technology of power balance and ship compartment, which is applied in the field of ship lift system, can solve the problems of increasing the scale of the mechanical transmission device of the winch, the difficulty of realizing the axial arrangement of the main hoist, and the inability to meet the arrangement of the main hoist, etc., and achieve the requirement of reducing the support strength , Reduce the construction strength requirements, reduce the effect of construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

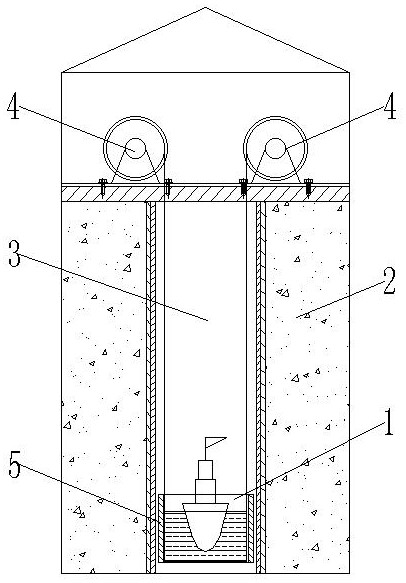

[0044] Another embodiment is that the linear power device 5 is a linear motor, the motor rotor of the linear motor is fixed on the ship compartment 1, and the motor stator matched with the motor rotor is fixed on the concrete wall 2, and the motor stator of the same linear motor is connected with the A motor air gap is left between the motor rotors, and the motor air gap is placed between the motor rotor and the motor stator. Under the action of the traction force, the ship compartment 1 is in a force-balanced state. When the linear motors on both sides of the ship compartment 1 are started, the ship compartment 1 enters into a smooth and uniform upward and downward linear operation. When the linear motors on both sides of the ship compartment 1 feedback brake, the ship Carriage 1 enters into the process of going up and down in a straight line at a steady and constant speed until the process of deceleration and braking.

[0045] Such as Figure 5 As shown, when the ship lift ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com