Inland river ship with ballast system

A technology for ballast systems and inland ships, which is applied in the direction of pipelines, hulls, and ship components for emptying/ballasting, and can solve problems affecting ship performance and limited ballast heights

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The implementation of the present invention will be described in detail below with reference to the drawings and examples, so as to fully understand and implement the implementation process of how to use technical means to solve technical problems and achieve technical effects in the present invention.

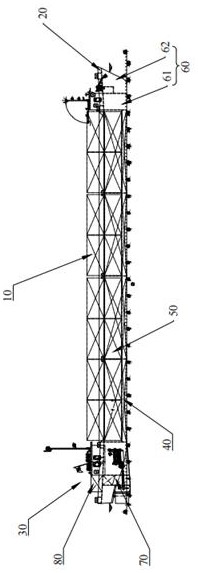

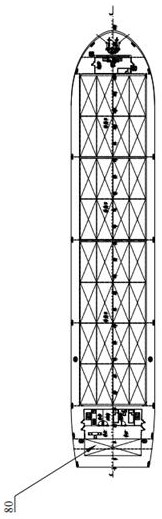

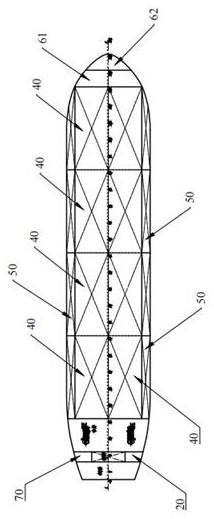

[0029] Please also refer to Figure 1 to Figure 3 , figure 1 It is a side view of an inland ship with a ballast system according to an embodiment of the present invention; figure 2 It is a top view of an inland ship with a ballast system according to an embodiment of the present invention; image 3 It is an internal sectional view of an inland waterway ship with a ballast system according to an embodiment of the present invention.

[0030] As shown in the figure, a kind of inland watercraft with ballast system, it comprises middle cargo hold part 10; Ship bow 20; And stern part 30, ballast system comprises: double bottom ballast tank 40, double bottom ballast The ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com