Quick push-pull platform for maintenance of clearance seal C-shaped water stop rubber of ship lift and using method

A technology of water-stop rubber and ship lift, which is applied to vertical lifting ship machinery, machinery for lifting ships along the slope, ship lifting device, etc., can solve the problems of difficulty in erecting platforms and long erection time, etc., and achieve the effect of shortening the stoppage time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

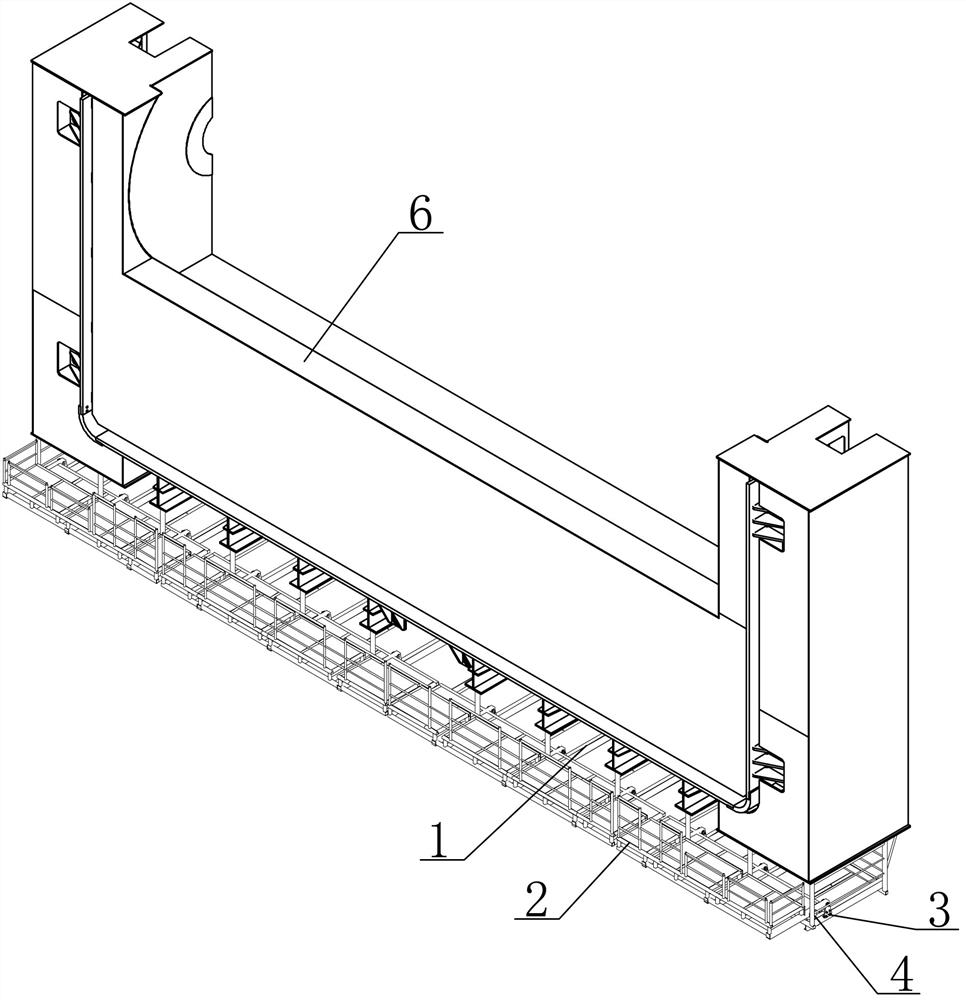

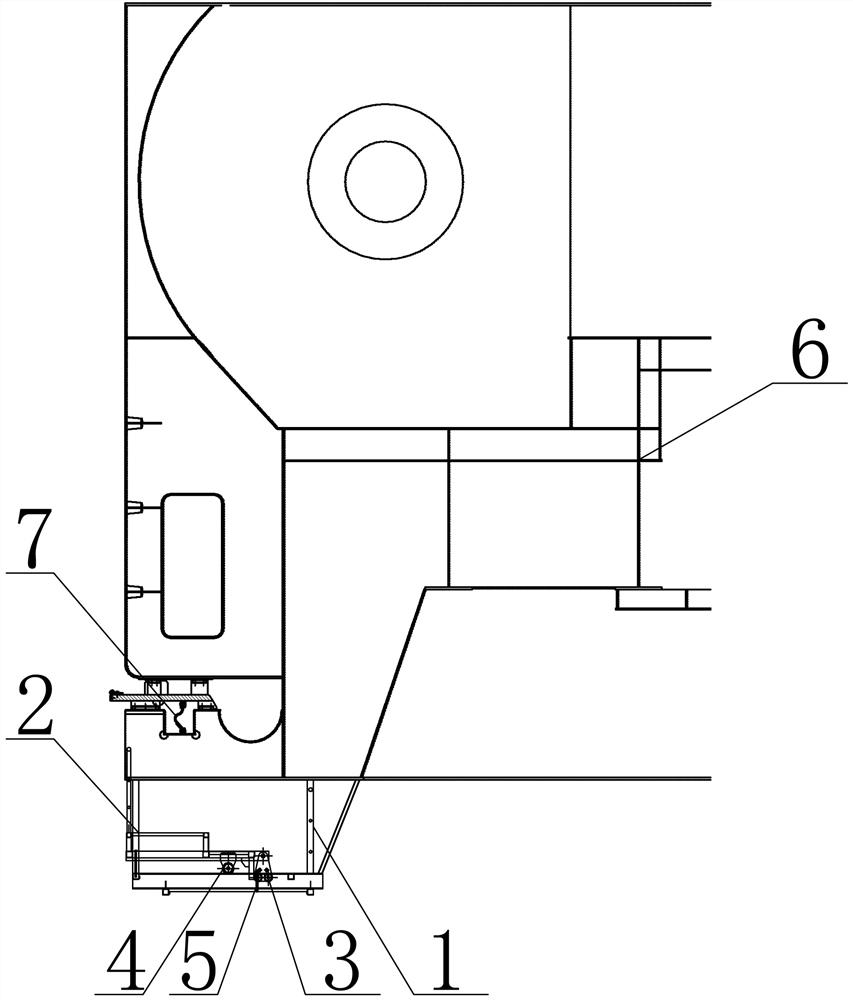

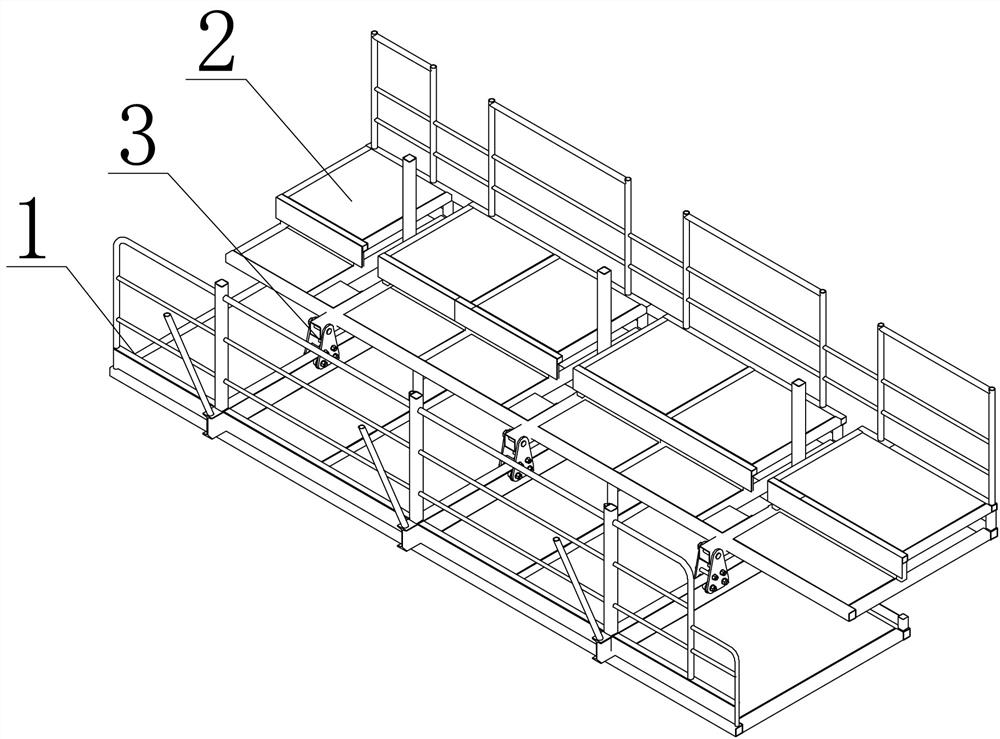

[0053] Such as Figure 1-19, a fast push-pull platform for maintenance of ship lift gap seal C-type water-stop rubber, which includes a fixed platform 1 for supporting the entire platform, and the fixed platform 1 is fixedly installed on the cabin head structure 6 of the ship lift The bottom end is located directly below the C-shaped water-stop rubber 7; the fixed platform 1 is slidably supported by a movable platform 2 through a reverse travel wheel set 3 and a supporting wheel set 4; the reverse travel wheel set 3 is fixed on The position of the end of the movable platform 2, and forms a sliding fit with the fixed platform; the support wheel group 4 is fixed on the bottom of the movable platform 2, and is slidably supported on the top of the fixed platform 1; the fixed platform 1 and the movable platform 2 A latch locking mechanism 5 is arranged between them. This platform solves the problems of difficulty and long erection time in the maintenance of the gap seal C-type wat...

Embodiment 2

[0063] The method for using the fast push-pull platform for the repair of the ship lift gap seal C-type water-stop rubber includes the following steps:

[0064] Step 1, fix and install the fixed platform 1: park the ship lift at a low position close to the ground, and weld and fix the fixed platform 1 under the cabin head structure 6;

[0065] Step 2, install the movable platform 2: support the movable platform 2 on the top of the fixed platform 1, and ensure that the support wheel group 4 is supported on the top of the guide rail 101, then install the reverse travel wheel group 3, and pass the reverse travel The wheel set 3 supports the entire movable platform 2 on the fixed platform 1 in a limited sliding manner;

[0066] Step 3, the movable platform 2 is limited and fixed: after the movable platform 2 is installed, manually pull the movable platform 2 back to the parking position, insert the safety plug 501, relatively fix the movable platform 2 and the fixed platform 1, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com