Ship loading calculation method based on Excel

A calculation method, excel technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of lower loading efficiency, high price, high cost, etc., to improve efficiency, ensure safe navigation, save software and time cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

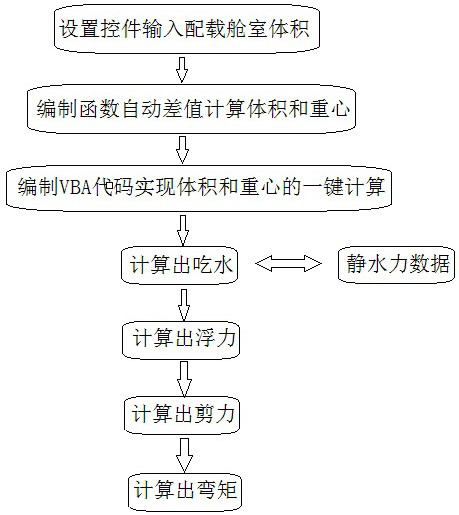

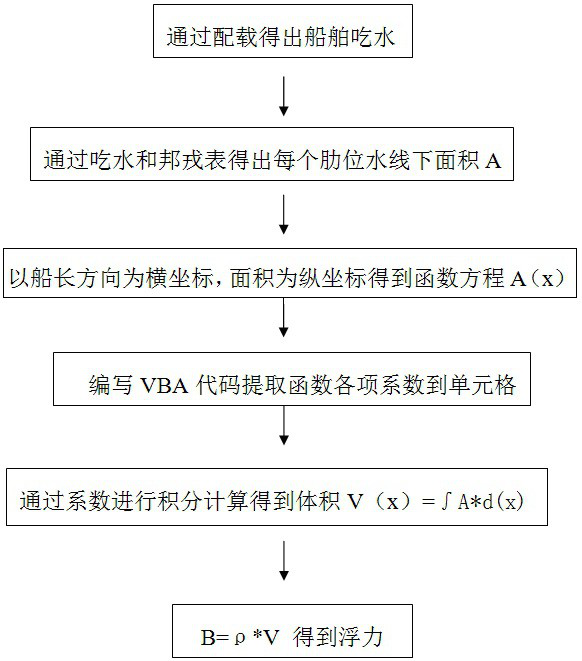

[0034] see figure 1 , an Excel-based ship loading calculation method involved in the present invention, the basic formula is F=W-B, M=∫F*d(x) (wherein: F shear force W ship weight B buoyancy M bending moment) The specific method steps are as follows :

[0035] The first part is to calculate the shear force. According to the shear force F=W-B, it is necessary to know the weight of the W ship and the buoyancy of the B ship;

[0036] 1.1. Calculate the ship's weight W:

[0037] The weight W of the ship can be divided into two parts for calculation, the first part is the weight of the empty ship, and the second part is the weight brought by the loading of the cabin;

[0038] The weight of the light ship and its distribution along the length of the ship are compiled according to the loading manual; the weight brought by loading can be obtained from the sounding table. This step requires the preparation of functions (offset\trend\match\) to generate the corresponding weight and C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com