Patents

Literature

167 results about "Ship load" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ship load is a United Kingdom unit of weight for coal equal to 949,760 pounds, 430803.889 kg, or 20 keels.

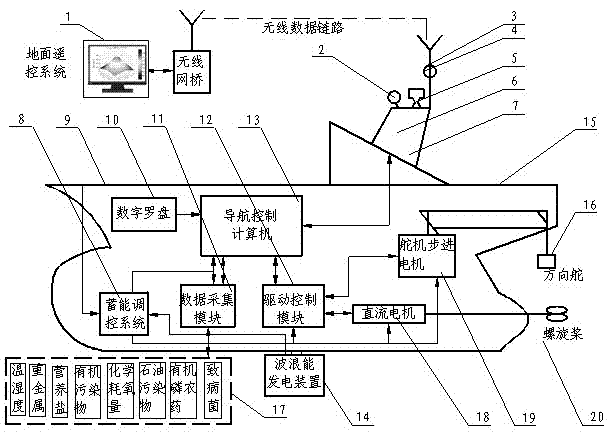

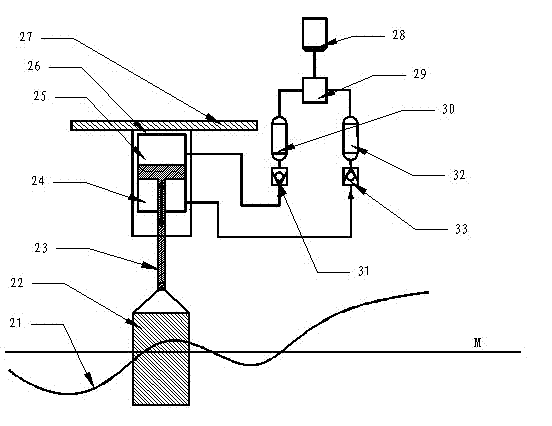

Wave energy and solar energy driven unmanned monitoring ship for marine environment

ActiveCN102381464AImprove power qualityImprove electromagnetic compatibilityPropulsion based emission reductionPropulsion power plantsPower qualityData acquisition

The invention discloses a wave energy and solar energy driven unmanned monitoring ship for a marine environment, which comprises a ship body and an unmanned control system, wherein the ship body has a shape of rigid inflatable boat; the unmanned control system comprises a ground remote control system and a ship-loaded system which are coupled with each other through a wireless data link; the ground remote control system comprises a remote control computer, a wireless network bridge and corresponding top-layer application software; the ground remote control system is used for receiving, analyzing and displaying a ground remote control command and data; a serial port of the remote control computer is connected to the wireless network bridge; and the ship-loaded system comprises a navigationcontrol subsystem, a communication subsystem, a navigation information sensing and collecting subsystem, a wave energy and solar energy power generating and supplying subsystem and a data collecting subsystem. No diesel motor is required in the wave energy and solar energy driven unmanned monitoring ship, a wave energy generating system and a solar energy generating device of the ship are directly used for supplying power, the quality of output electric energy is stable and the electromagnetic compatibility is excellent, thereby ensuring the normal work of ship-loaded equipment under a complex marine environment.

Owner:OCEAN RES CENT OF ZHOUSHAN ZHEJIANG UNIV

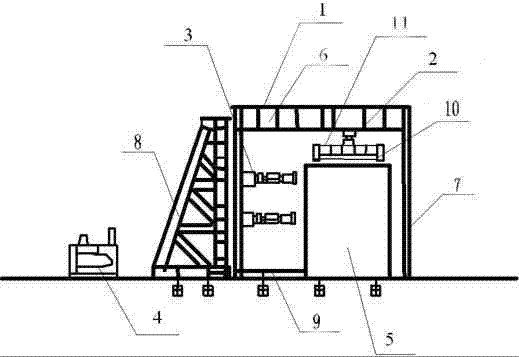

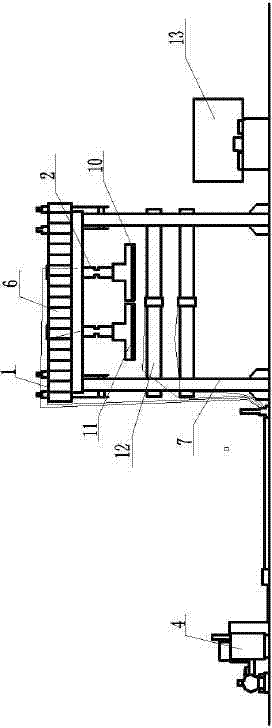

Dynamic and static testing system and method for multifunctional wharf structure

InactiveCN102928293AEasy to assembleStable structureMachine part testingMaterial strength using tensile/compressive forcesActuatorShip load

The invention discloses a dynamic and static testing system for a multifunctional wharf structure. The dynamic and static testing system comprises a detachable large-rigidity bearing frame, a vertical loading actuator, a horizontal loading actuator, a multi-channel controller, an electro-hydraulic servo oil source system, a data collecting system as well as a displacement and force sensor. The maximum clearance size of the loading frame is 4.5m* 4.5m*4.5m (L*W*H); a testing space can be randomly adjusted according to test sample requirements; a loading mode is that vertical and horizontal combined loading can be finished through two 10-100 t static vertical actuators and 3-20t dynamic horizontal actuators; integral or member stress performance tests of the high pile frame wharf structure with large water level difference under a combined effect of various complicated working conditions such as gantry crane load, piling load and ship load are simulated. The invention further provides a dynamic and static testing method for the wharf structure, which can be used for really simulating the stressed deformation performances of the wharf structure under various complicated stressed conditions and can be also used in stress experiments of similar structures.

Owner:CHONGQING JIAOTONG UNIVERSITY

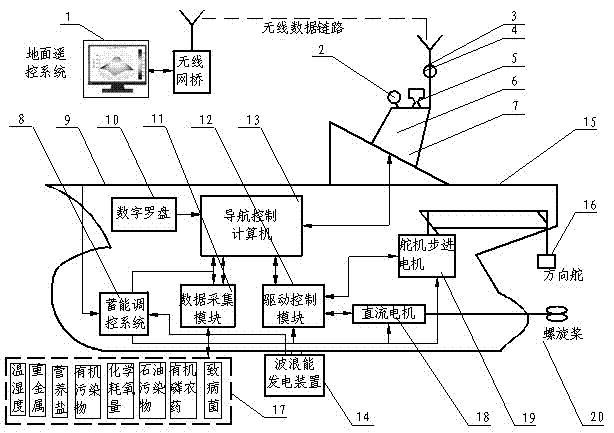

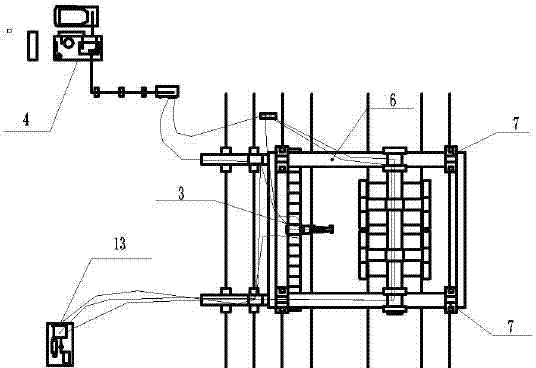

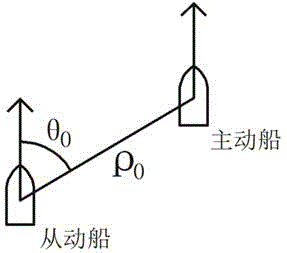

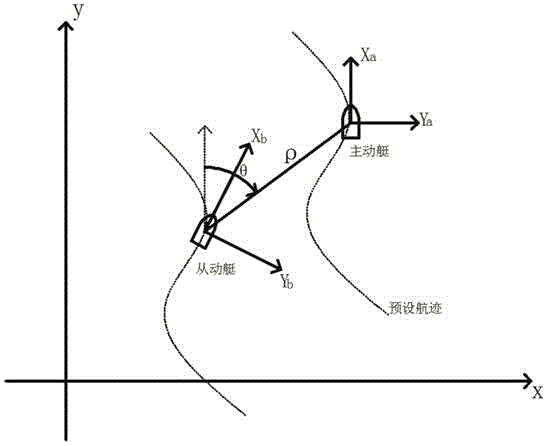

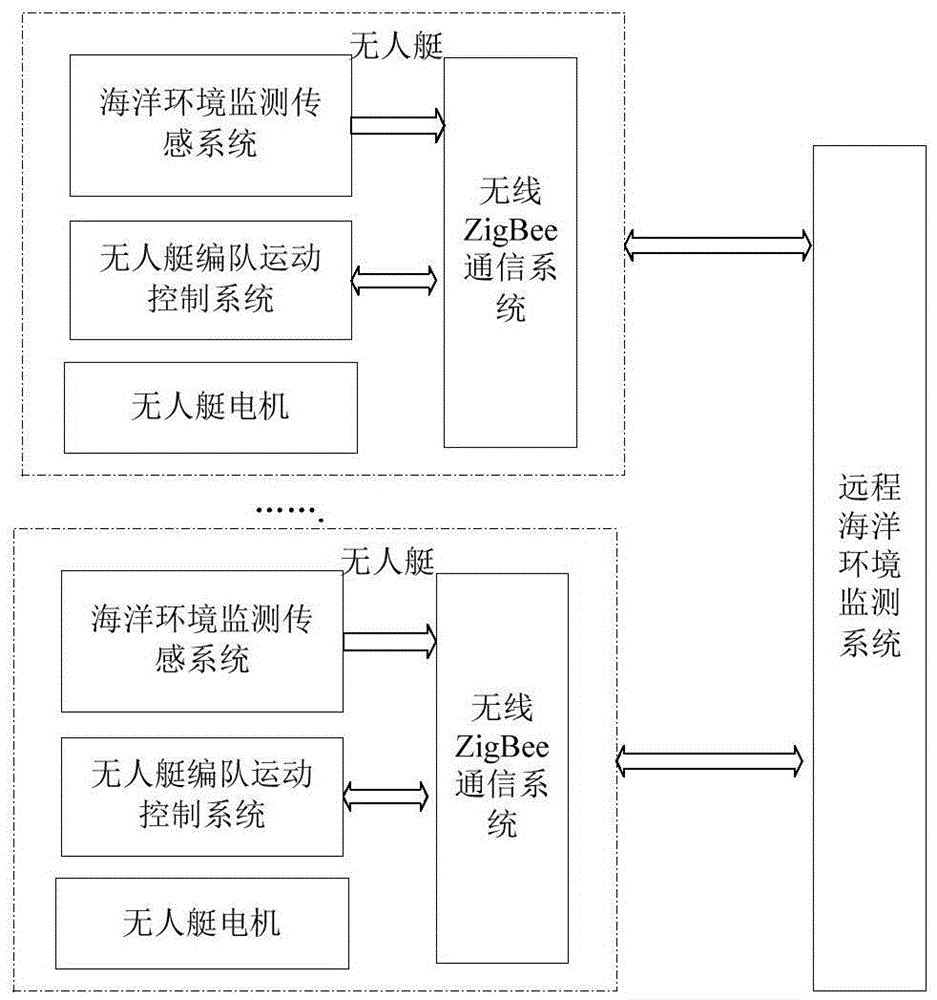

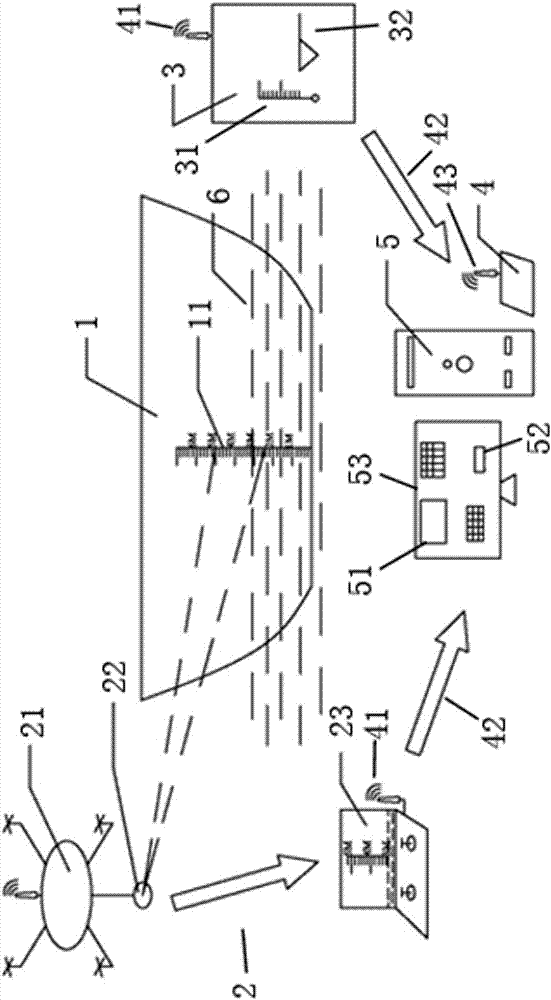

Marine environmental monitoring system based on unmanned ship formation motion

ActiveCN105584599AIncrease initiativeEnable mobilityWaterborne vesselsUnmanned surface vesselsCommunications systemControl system

The invention discloses a marine environmental monitoring system based on unmanned ship formation motion. The system comprises multiple unmanned ships loaded with unmanned ship formation motion control systems, marine environmental monitoring sensing systems and wireless ZigBee communication systems and a remote marine environmental monitoring system. Each unmanned ship formation motion control system drives a corresponding unmanned ship motor in a set unmanned ship formation motion mode to form a shipping formation column and each unmanned ship moves according to the corresponding shipping track. Each marine environmental monitoring sensing system sends acquired marine environmental monitoring data to the remote marine environmental monitoring system in real time. Each wireless ZigBee communication system is connected with the corresponding unmanned ship and the remote marine environmental monitoring system. The remote marine environmental monitoring system forms a visual interface in real time and can remotely control each unmanned ship. By the adoption of the system, movable environmental monitoring, positioning and display comprehensive monitoring can be conducted according to the characteristics of abruptness, uncertainty and the like of the marine environment.

Owner:DALIAN MARITIME UNIVERSITY

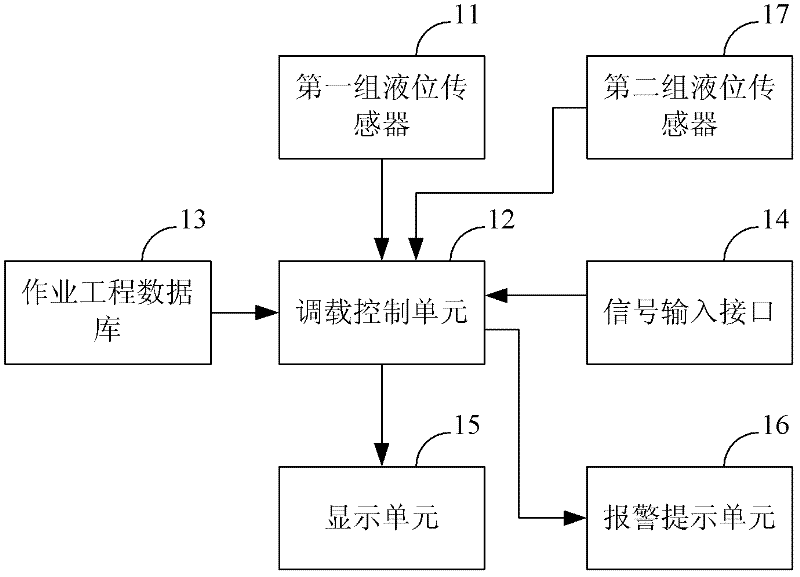

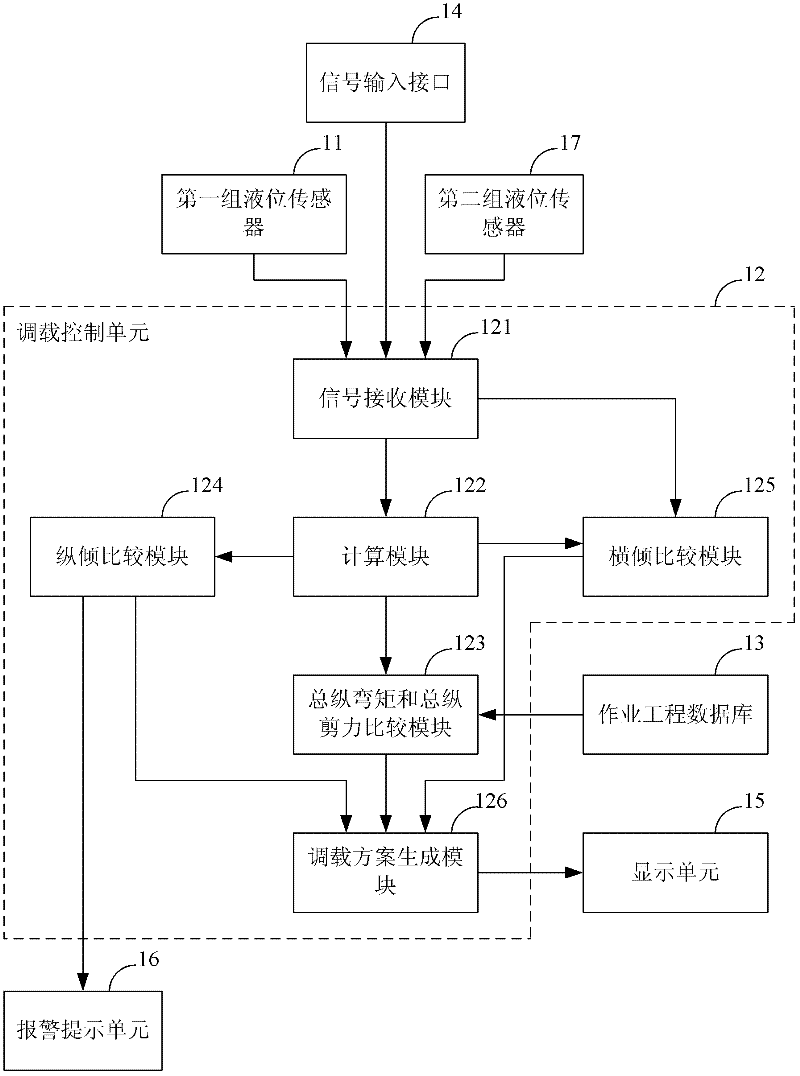

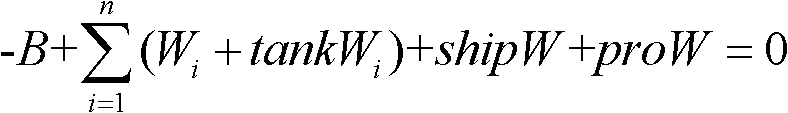

Ship load adjustment control system

InactiveCN102351039AEnsure safetyEasy to implementVessel stability improvementMovement controllersWater dischargeControl system

The invention discloses a ship load adjustment control system. A floating crane ship is provided. The system comprises a display unit, a first group of liquid level sensors, an operation engineering database and a load adjustment control unit, wherein the first group of liquid level sensors are used for acquiring draft at larboard and starboard draft marks of a stem part and a stern part; the operation engineering database is used for prestoring a longitudinal trim threshold value and the liquid level height of each ballast water tank; and the load adjustment control unit is used for calculating a longitudinal trim value of a ship body, judging whether the absolute value of the longitudinal trim value of the ship body exceeds the longitudinal trim threshold value or not, calculating the total water discharge / water injection rate of each ballast water tank if the absolute value exceeds the longitudinal trim threshold value, calculating the respective water discharge / water injection rate of each ballast water tank, and displaying the respective water discharge / water injection rate on the corresponding ballast water tank in a floating crane ship ballast tank arrangement schematic drawing displayed by the display unit. The implementation mode is simple; and compared with a mode of load adjustment through artificial experience, the system has the advantages that: more accurate and reliable load adjustment data can be provided for field operating personnel, and the safety of marine operation is ensured.

Owner:DALIAN JINMAI OCEANOGRAPHIC ENG TECH

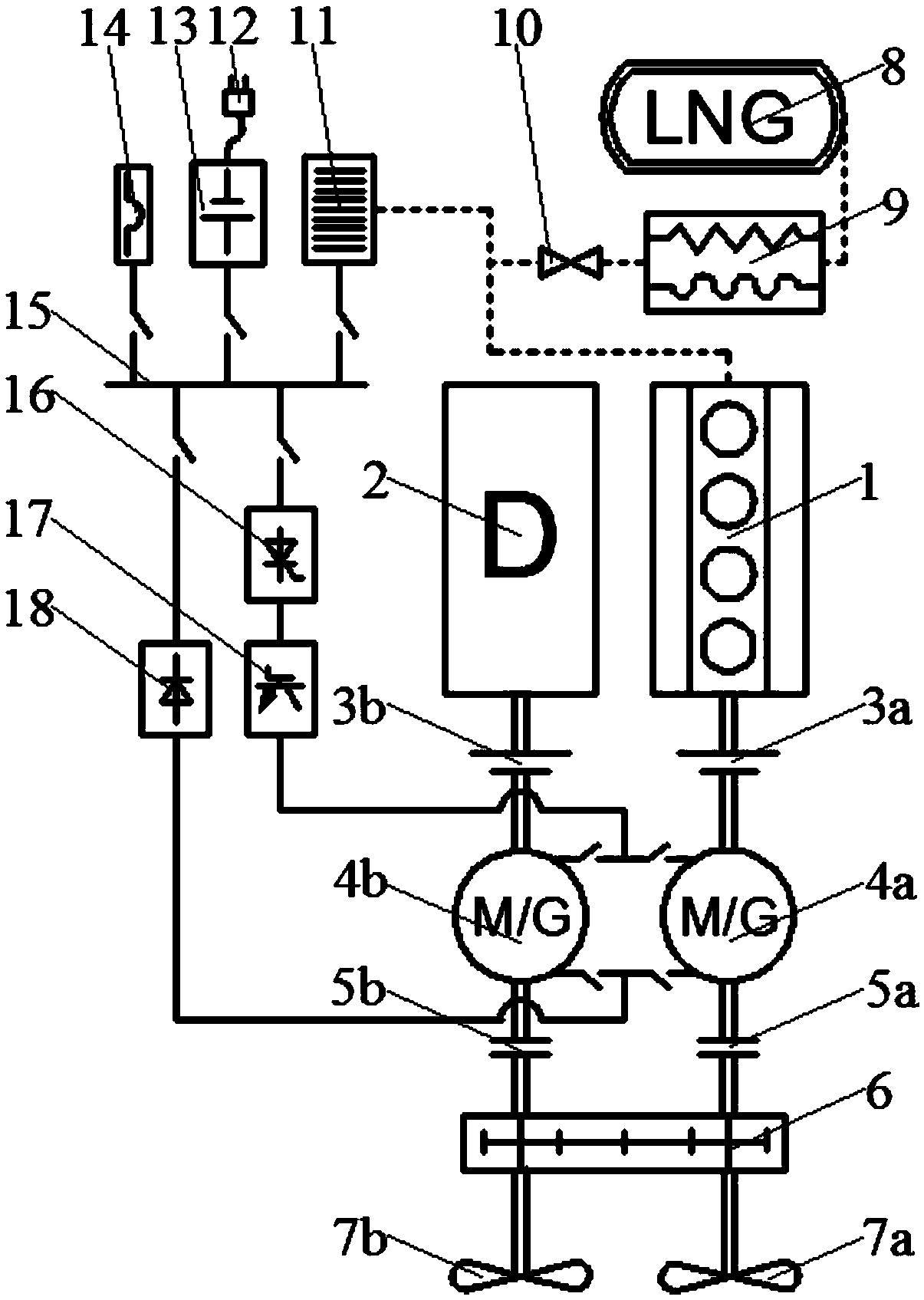

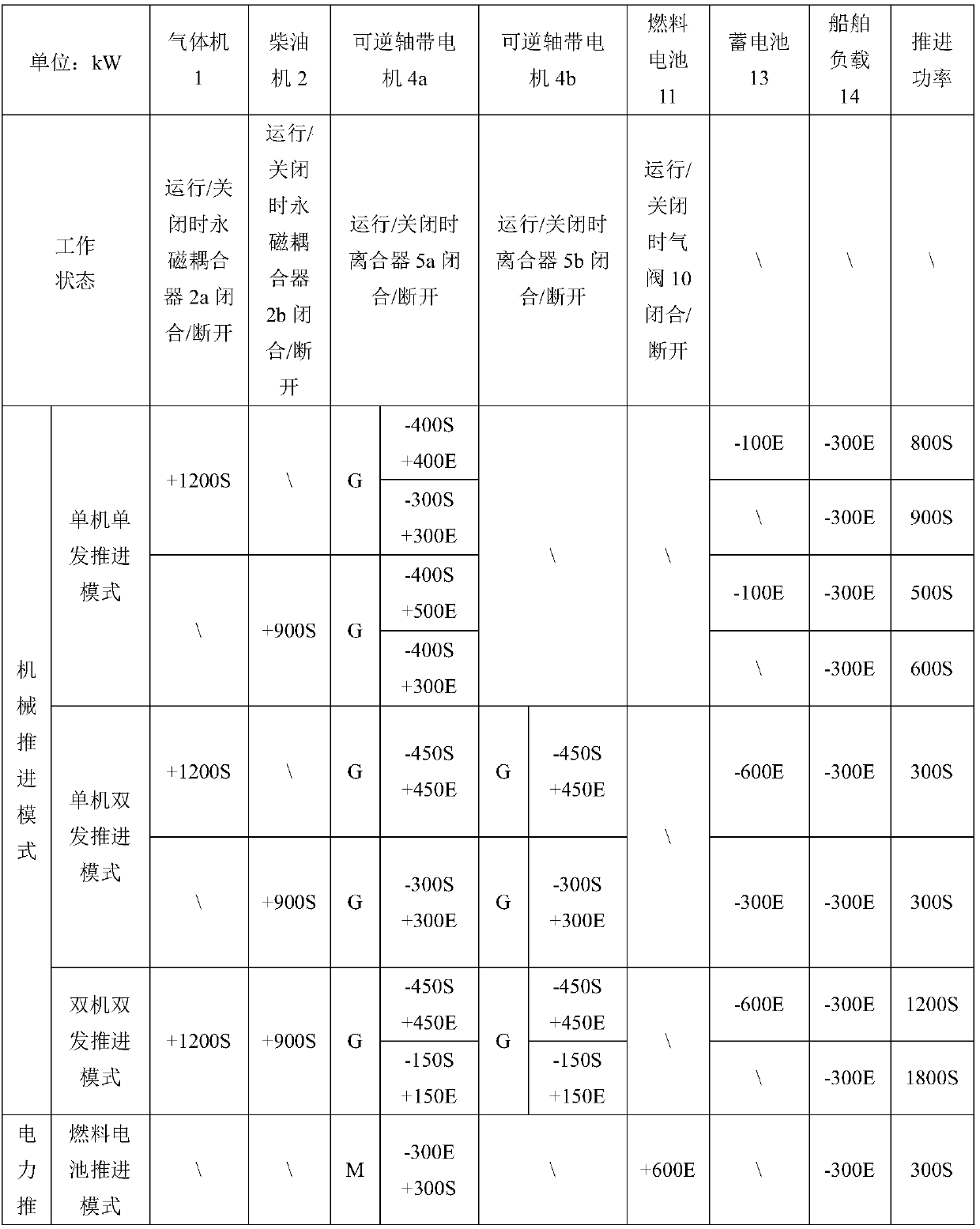

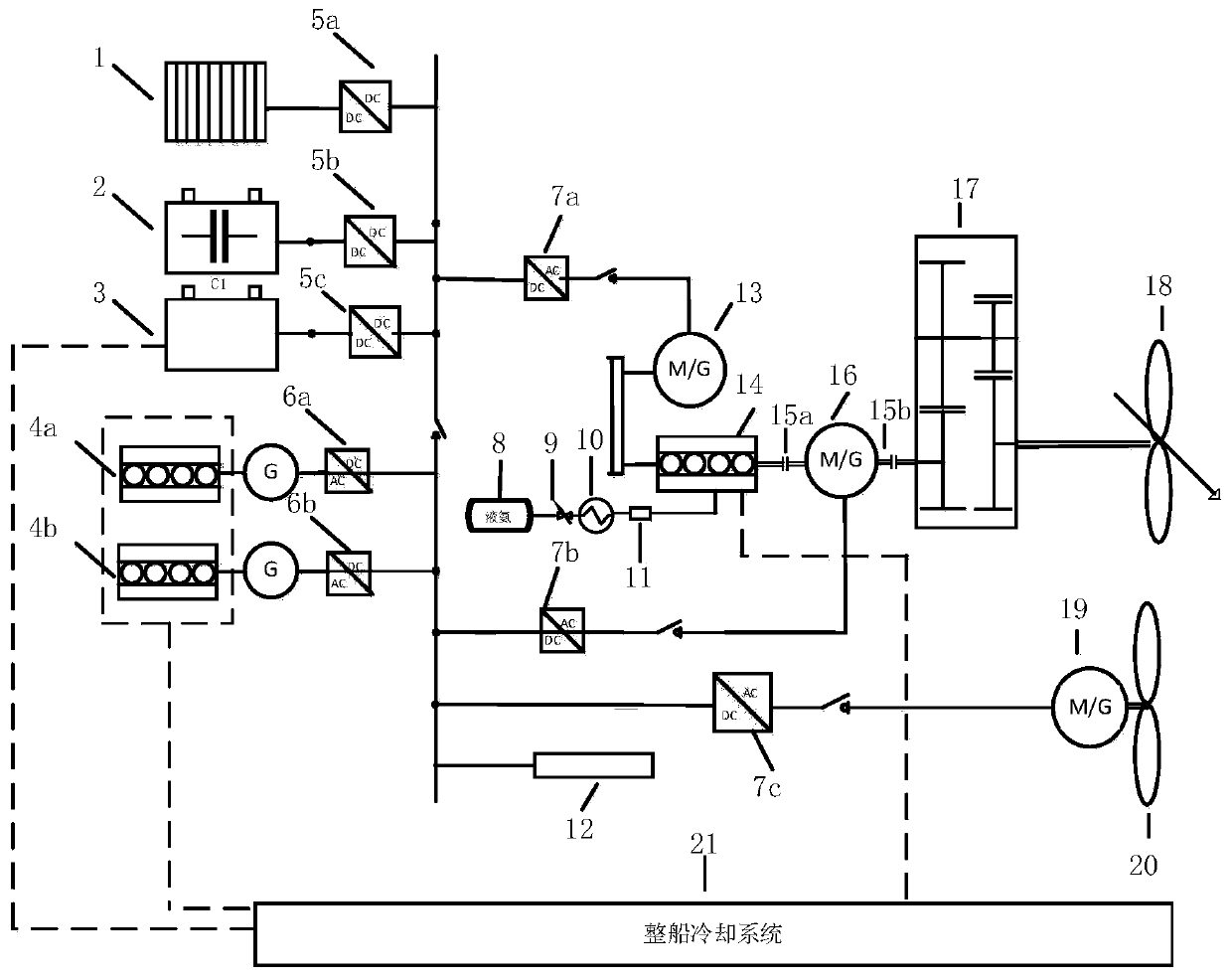

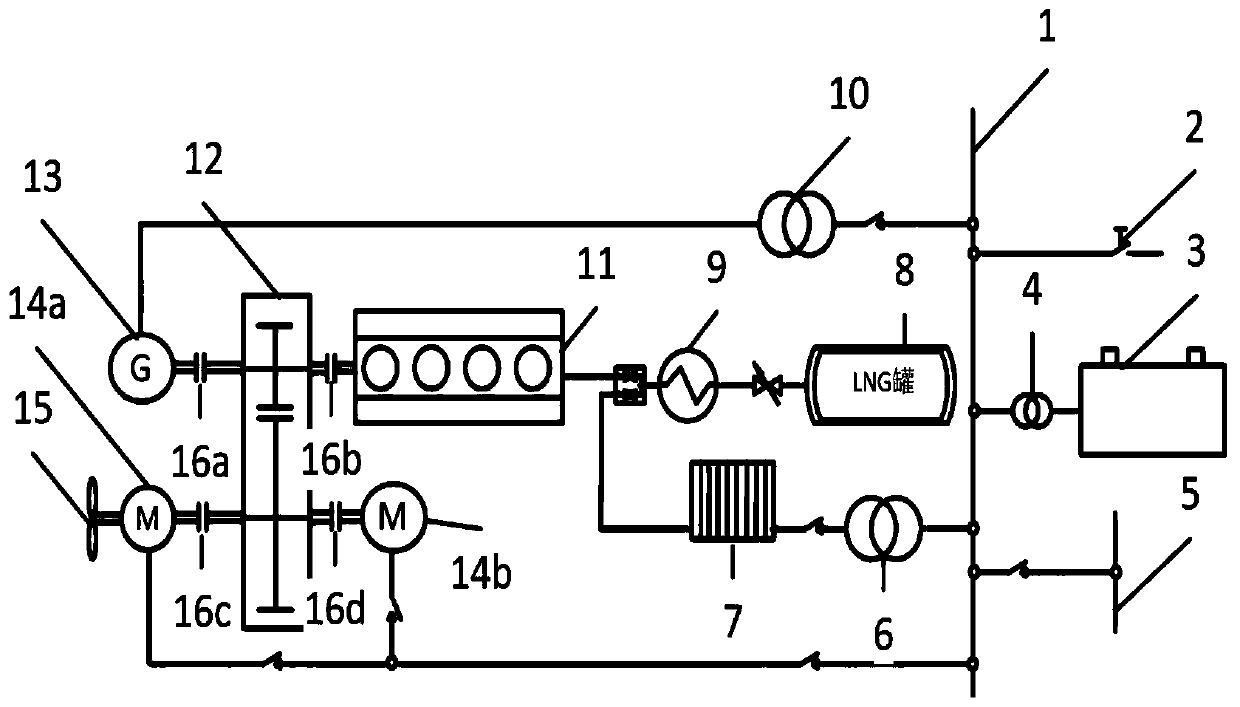

Dual-shaft ship hybrid power system with fuel cell

ActiveCN108674627AReduce fuel consumptionMeet power needsPropulsion based emission reductionPower plants using propulsion unit combinationsFrequency changerEngineering

The purpose of the invention is to provide a dual-shaft ship hybrid power system with a fuel cell. The system comprises a diesel engine, a gas machine, a fuel cell and a storage battery; the gas machine is connected to a first reversible shaft motor; the first reversible shaft motor is connected with a gear case; the diesel engine is connected with a second reversible shaft motor; the second reversible shaft motor is connected with the gear case; the gear case is connected with two propellers; a liquefied natural gas tank is connected with a gas supply device; the gas supply device is connected with the gas machine and the fuel cell; the fuel cell, the storage battery, a ship load, an inverter and a rectifier are all electrically connected with a distributing board; the inverter is connected to the first reversible shaft motor and the second reversible shaft motor through a frequency converter, and the first reversible shaft motor and the second reversible shaft motor are electricallyconnected to the rectifier. The invention can meet the requirements of the ship under various environments and working conditions, further improve the operating efficiency of the gas machine, the diesel engine and the reversible shaft motor, and effectively reduce the fuel consumption and emission of the engine.

Owner:HARBIN ENG UNIV

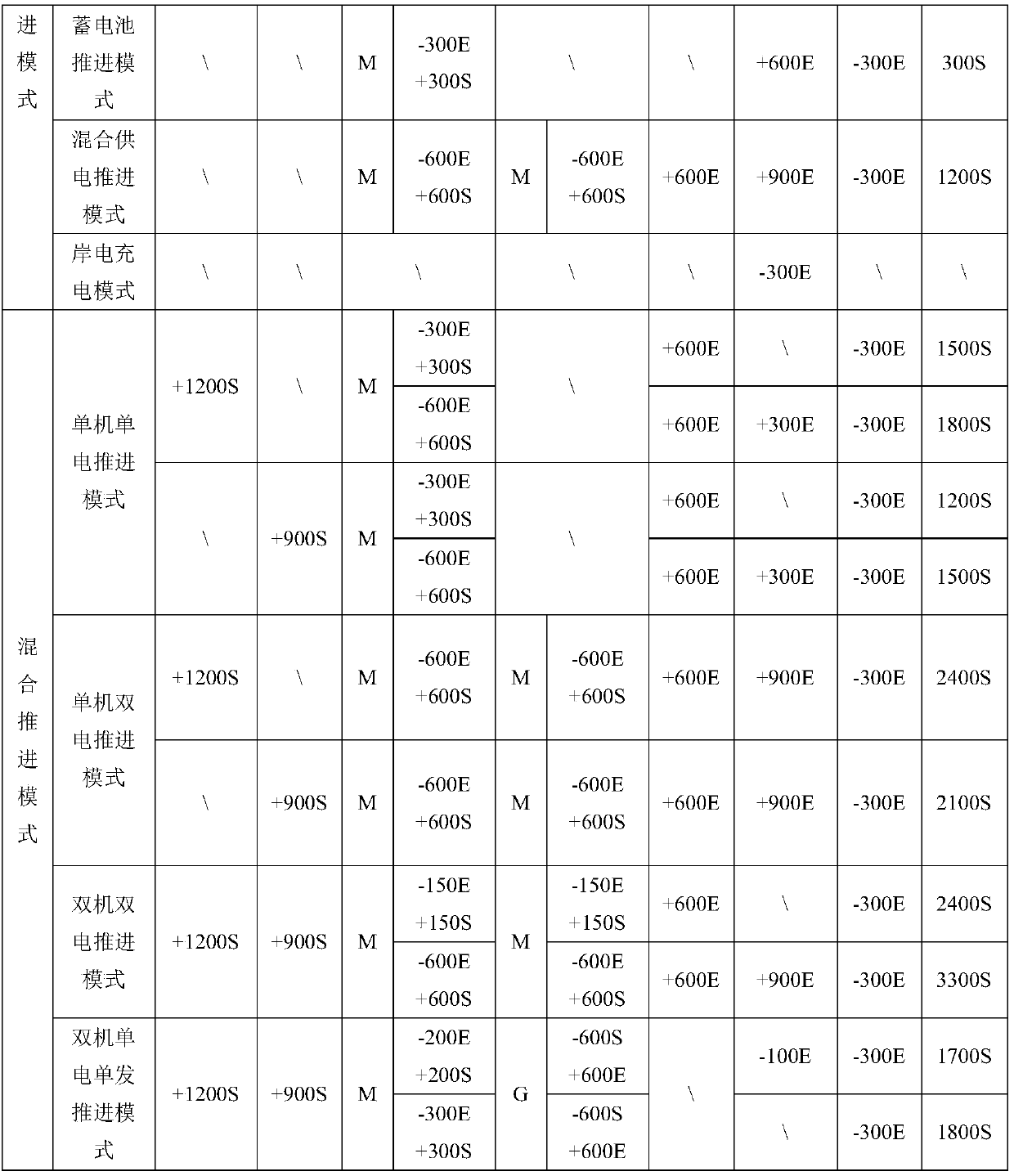

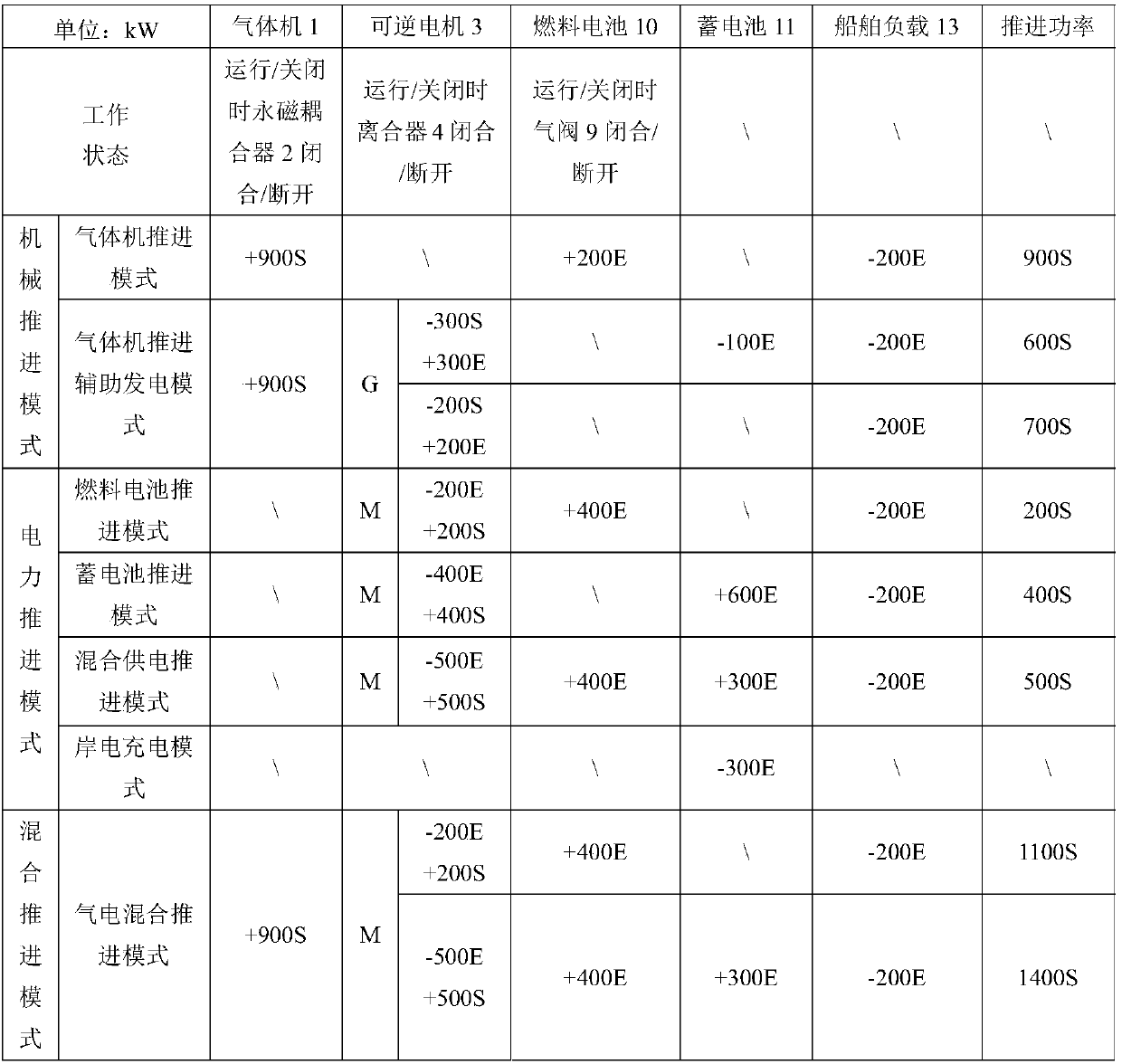

Gas-electric parallel ship hybrid power system with fuel cells

InactiveCN108674625AMeet power needsImprove economyPropulsion based emission reductionPower plants using propulsion unit combinationsFrequency changerShip load

The purpose of the invention is to provide a gas-electric parallel ship hybrid power system with fuel cells. The system comprises a gas machine, a fuel cell, a reversible motor and a gear case; the gear case comprises an input end, an output end and an input / output end; the output of the gas machine is connected to the input of the gear case via a permanent magnet coupler; the output / input end ofthe reversible motor is connected to the input / output end of the gear case via a clutch, the output end of the gear case is connected to a propeller, and a LNG tank is connected to a gas supply device; the gas supply device is connected to the gas machine and the fuel cell, and the fuel cell, the battery, the ship load, the inverter, and the rectifier are electrically connected to a power distribution board, and the inverter is electrically connected to the reversible motor through a frequency changer, and the reversible motor is connected to the rectifier. The various energy forms arranged bythe invention can meet the requirements of the ship under various environments and working conditions, effectively reduce the fuel consumption and emissions of the gas machine, and improve the dynamic response of the ship.

Owner:HARBIN ENG UNIV

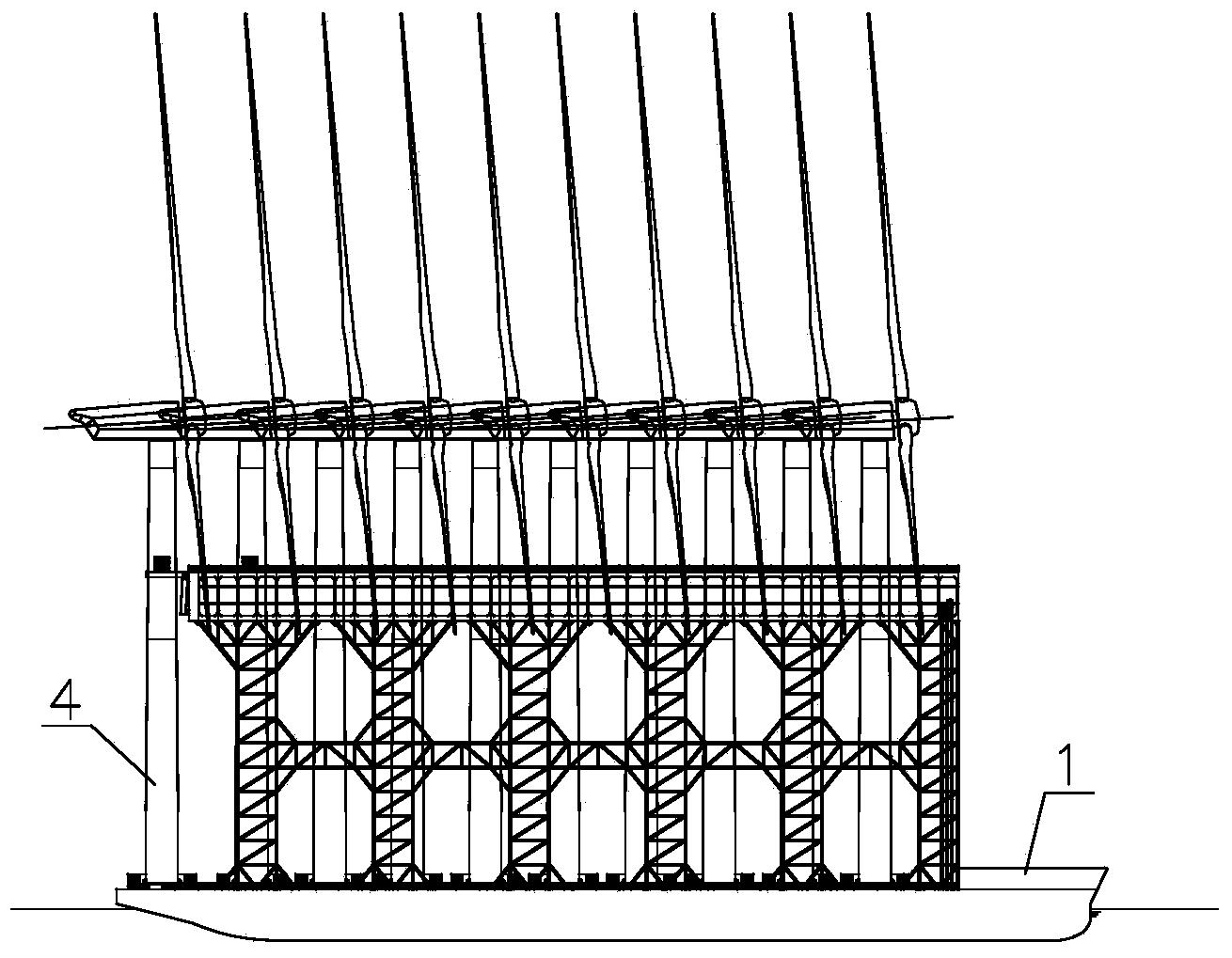

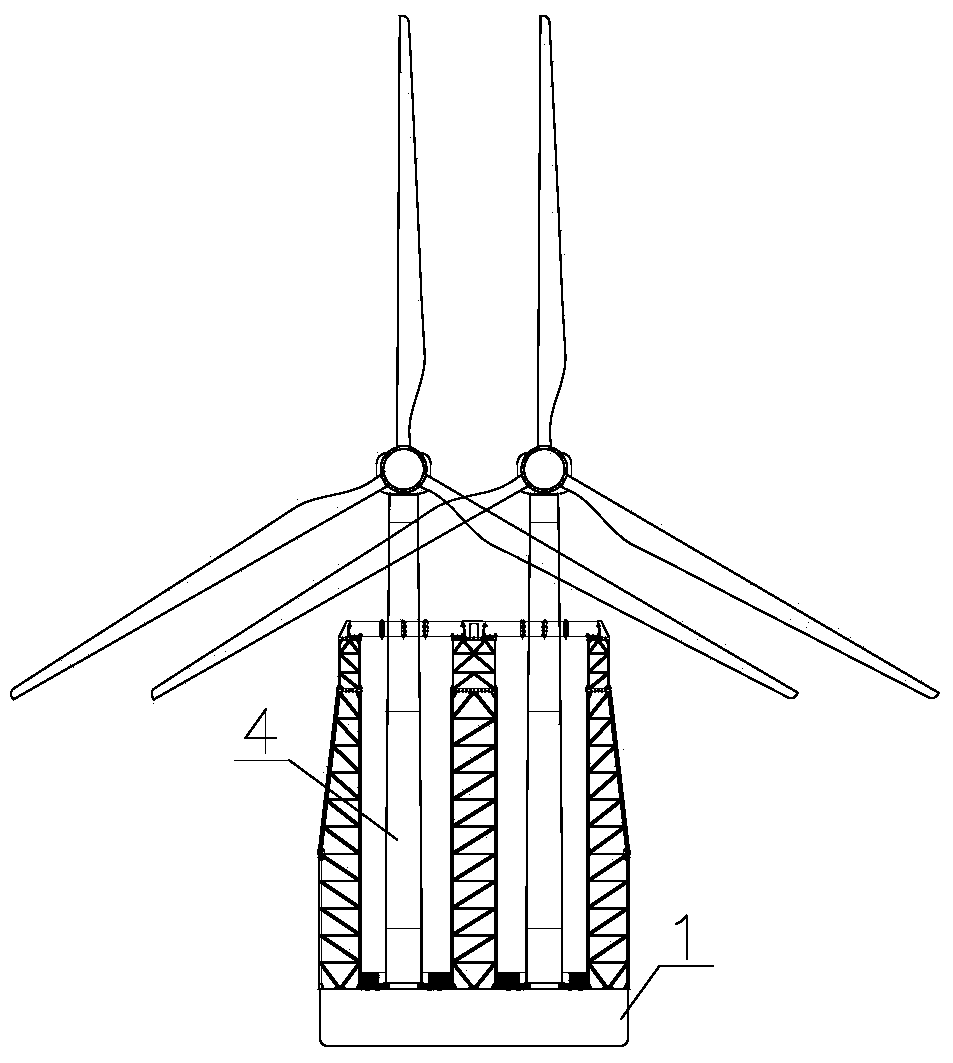

Offshore wind power complete machine installation method

InactiveCN103939300AEasy to operateInstallation accuracy is easy to controlWind energy generationWind motor componentsElectricityOffshore wind power

The invention discloses an offshore wind power complete machine installation method. A roll-on-roll-off ship loaded with a fan complete machine, a crane transport ship provided with a ballast empty compartment and a fan installing ship provided with the ballast empty compartment take position; the crane transport ship is loaded so that the plug-in board of the crane transport ship is inserted in an inserting hole of the fan installing ship; deloading is conducted on the crane transport ship while the fan installing ship is loaded, the plug-in board and the inserting hole are clamped through a vertical bolt, and the crane transport ship and the fan installing ship are closely connected together; the fan complete machine is lifted through a lifting device of the crane transport ship and is installed at the upper portion of a bucket foundation fixed by the fan installing ship; integrated construction installation is conducted on the bucket foundation and the fan complete machine through a negative-pressure sinking installation construction method. By means of the method, the crane transport ship and the fan installing ship form an installing platform capable of associated operation, so that the lifting device lifts the fan complete machine to be installed to the bucket foundation and the operation is simple, installation accuracy is completely controllable, the construction window period needed is short, and construction installation effect and economic effect are obvious.

Owner:TIANJIN UNIV

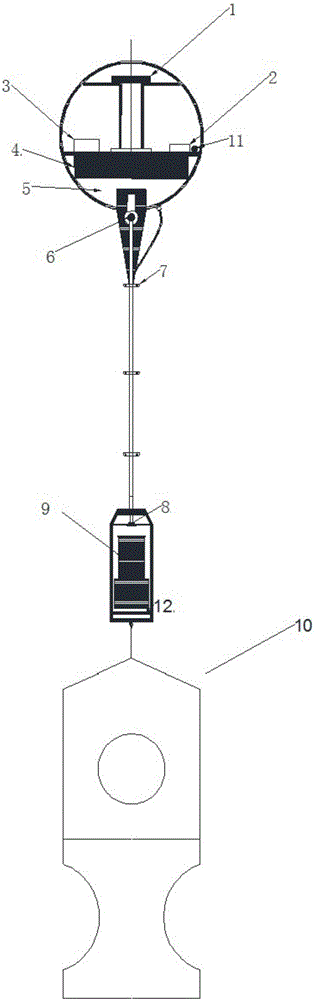

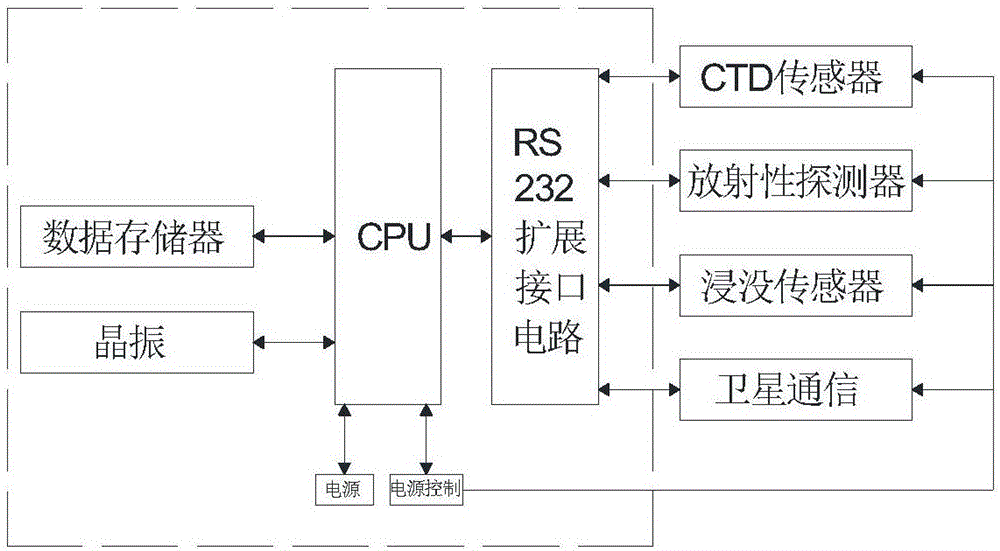

Ship-loaded thrown type radioactivity monitoring drifting buoy

ActiveCN106428434ARealize tracking and monitoringReal-time emergency monitoringWaterborne vesselsBuoysOcean seaBuoy

Owner:STATE OCEAN TECH CENT

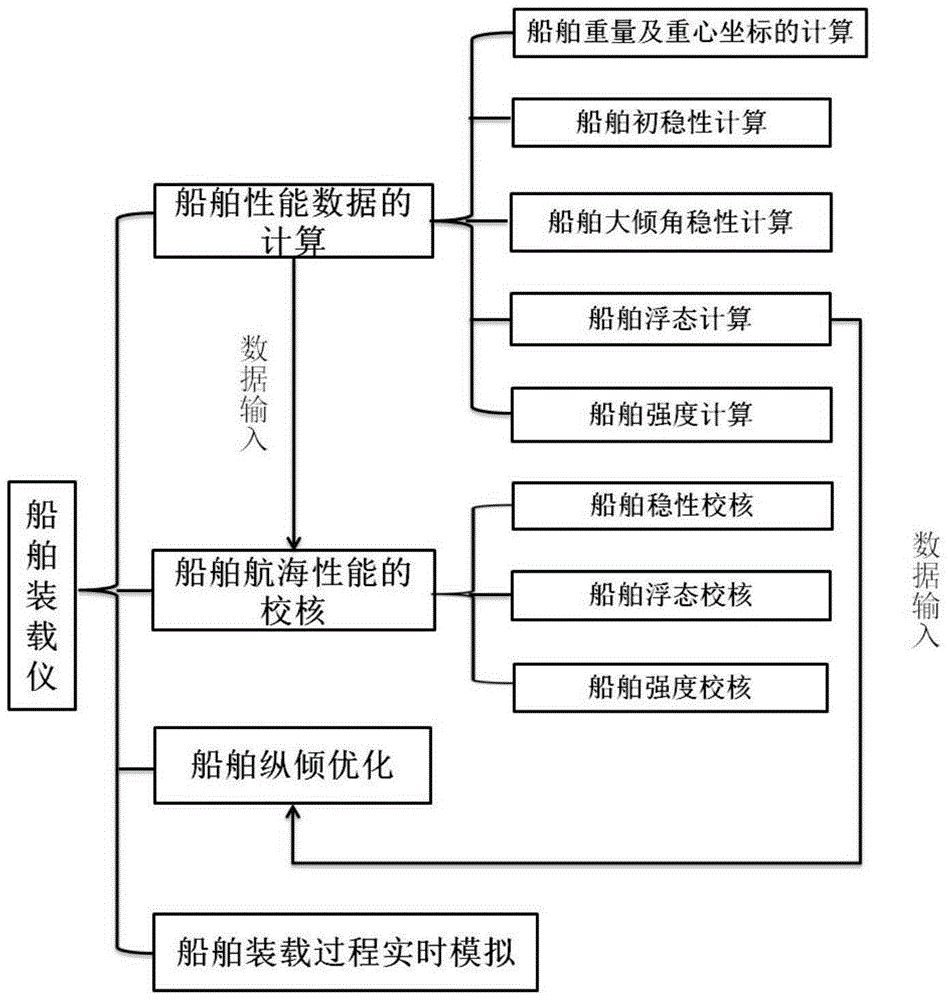

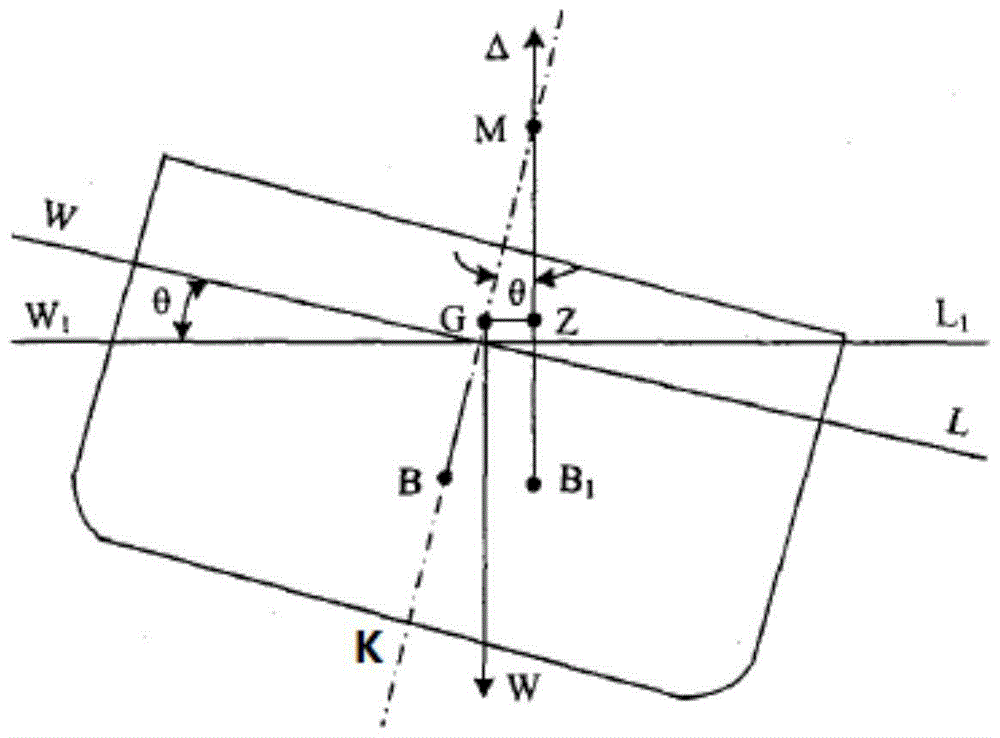

Ship loading performance optimization system

ActiveCN105224745AEasy loadingProper stabilitySpecial data processing applicationsReal-time simulationDriver/operator

The invention discloses a ship professional loading calculating system which helps a navigator to account ship floatation condition, stability and strength, and optimizes running longitudinal trim of a ship, and simulates a ship loading process. The system is a ship loading instrument The system comprises four sub-calculation systems of ship performance calculation, ship performance check, ship longitudinal trim optimization, and ship loading process real-time simulation. Through selecting different sub-calculation systems and cooperation among the sub-calculation systems, and inputting corresponding ship parameters, a basic data condition of safe and economical navigation of the ship can be obtained. The invention also provides a method for ship floating state adjustment, stability and strength accounting, longitudinal trim optimization, and ship loading process real-time simulation by using the above software. The system can ensure ship loading and navigation safety, and simplifies ship loading operation and saves energy, so as to improve security and economical efficiency of shipping, and reduce burden of navigators to a large extent.

Owner:武汉长江船舶设计院有限公司

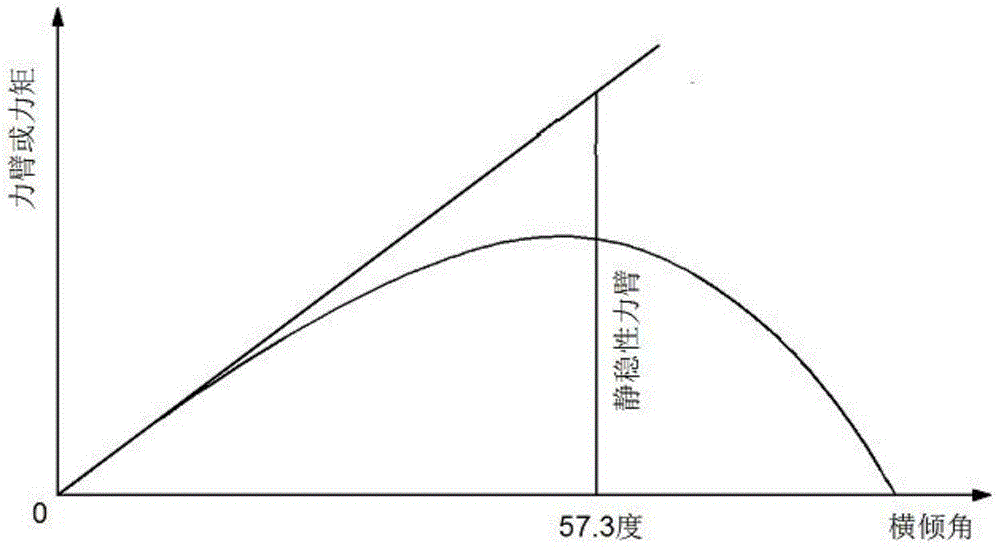

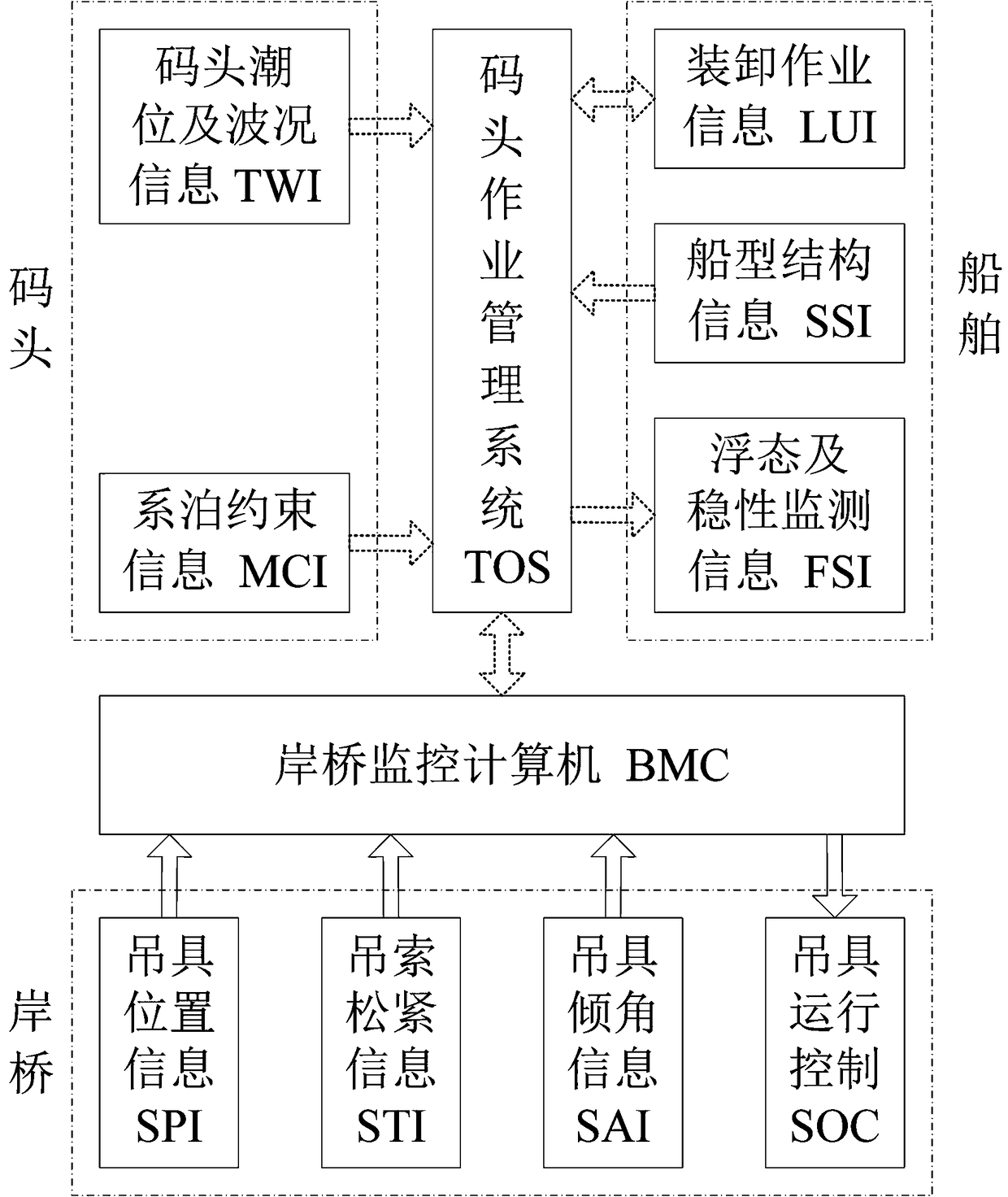

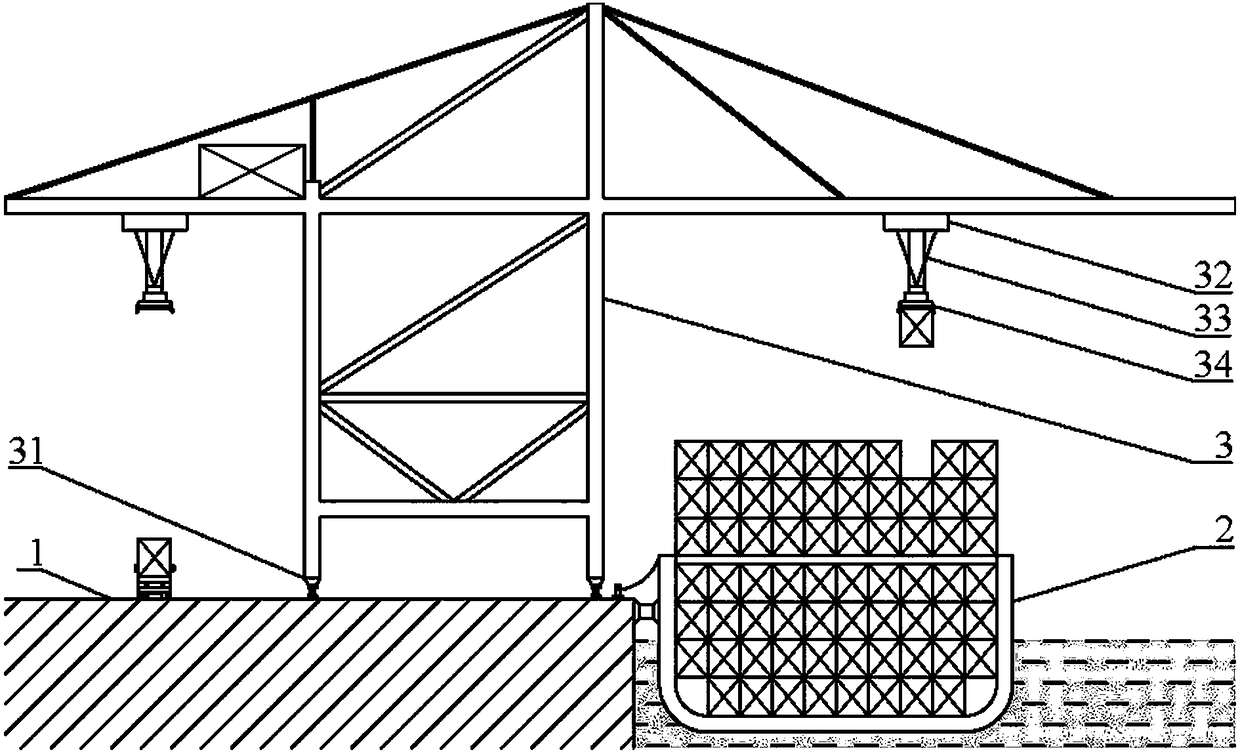

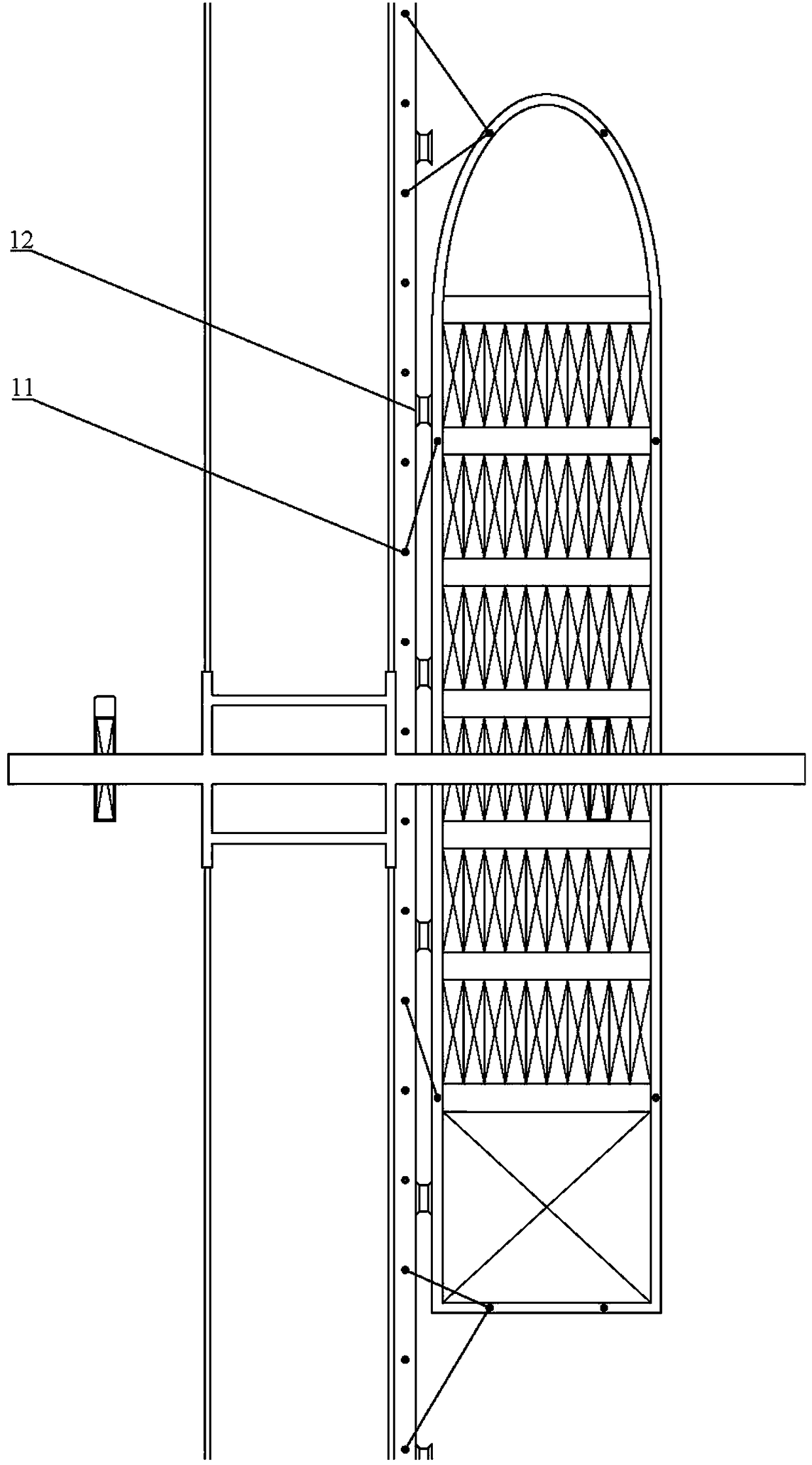

Ship floating state and stability monitoring device and method for container quay crane

ActiveCN109437020AMeet efficiency requirementsReduced measurement timeLoad-engaging elementsVessel typeMonitoring methods

The invention relates to a ship floating state and stability monitoring device and method for a container quay crane. According to information, such as quay tide level and wave conditions, mooring constraints, loading and unloading operation, a ship-type structure, a hanger position, sling tightness, and a hanger inclination angle, obtained through a quay operation management system and a quay crane monitoring computer, a natural period and a steady-state inclination angle are predicted through a ship rolling non-mooring constraint extreme point measurement method, a ship static inclination angle and initial stability safety are calculated and verified, and floating state and stability alarming in the ship loading and unloading processes is conducted; the problems of a small container shipwhich is not equipped with a loader, cannot provide carrying information, and is difficult to accurately verify the initial stability are solved, thus the crew testing work intensity is reduced, andthe ship loading stability safety is ensured; the disadvantage that a rolling period test method needs to remove ship mooring and measures the complete period is overcame, free rolling generated by loading and unloading operation in a quay is effectively used, the measurement time of a hanger loaded on the ship is greatly shortened, and the efficiency requirements of quay crane loading and unloading operation are basically met; and immediate data reference is provided for timely stowage or ballast adjustment of the quay and the ship, and the ship floating state and stability monitoring deviceand method for the container quay crane can be widely applied to various container quay cranes of manual or automated quays.

Owner:UNIV OF SHANGHAI FOR SCI & TECH +1

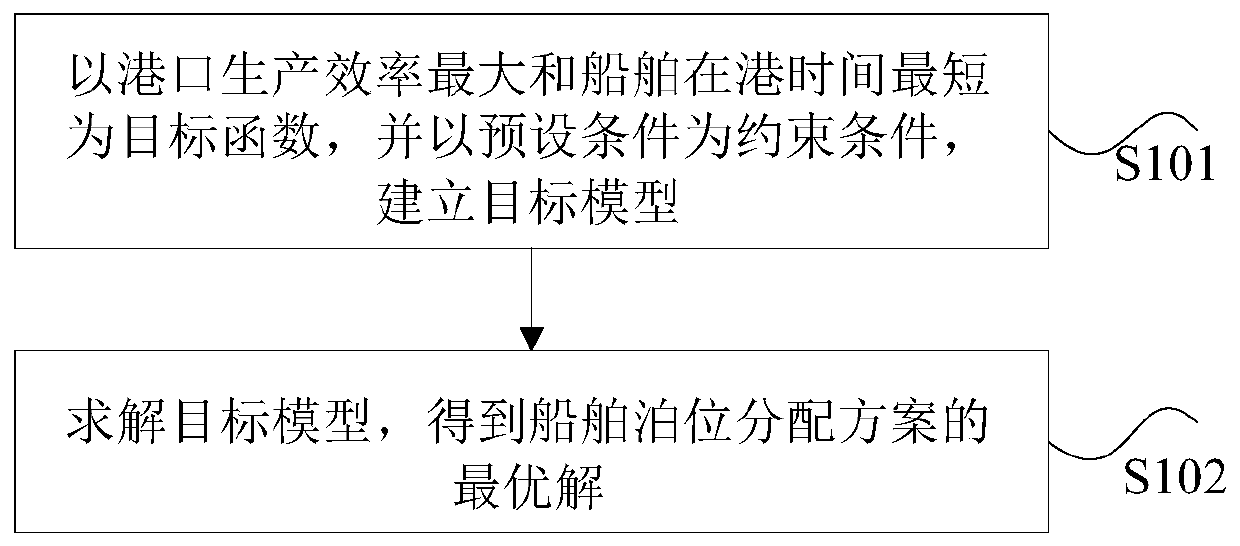

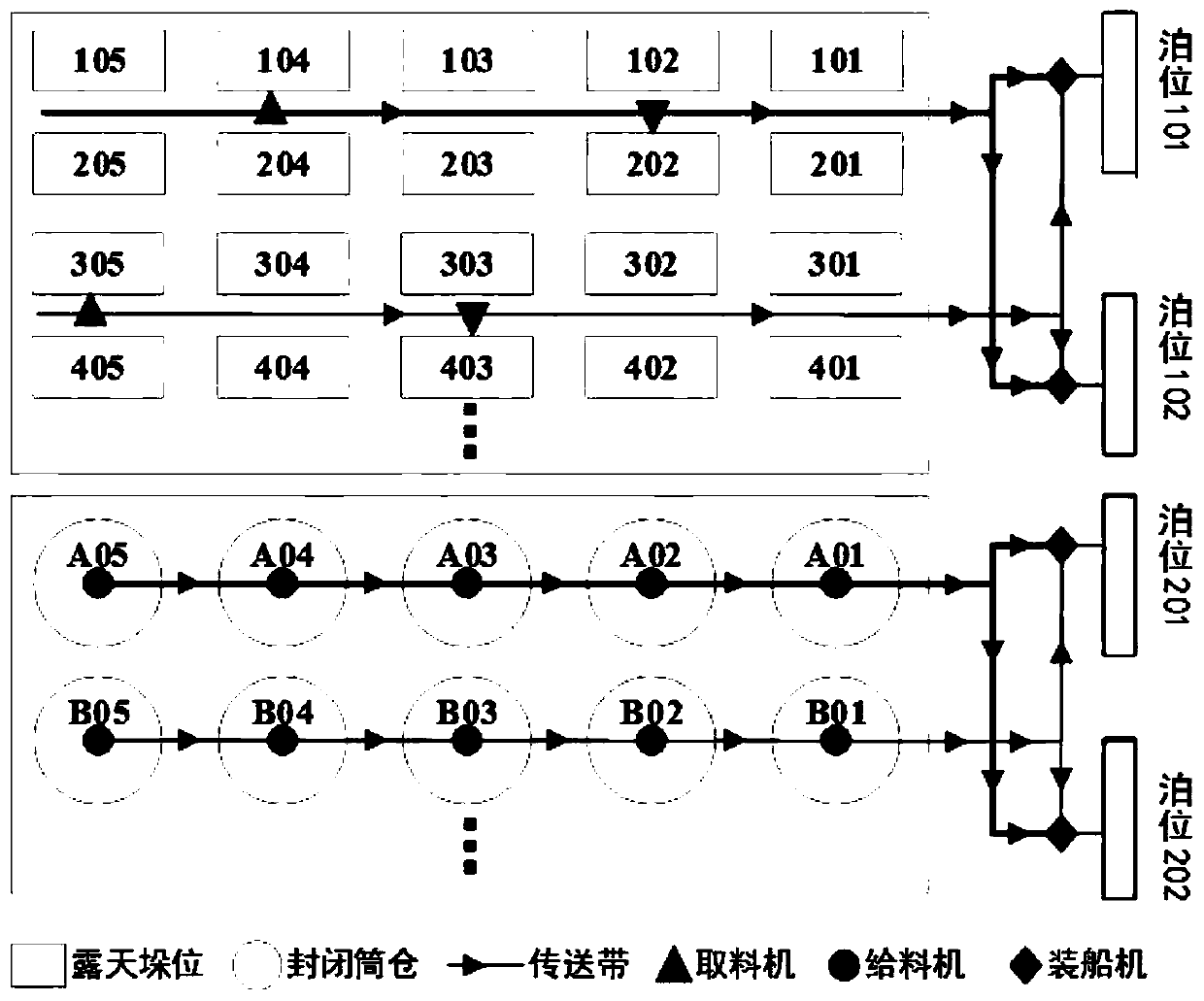

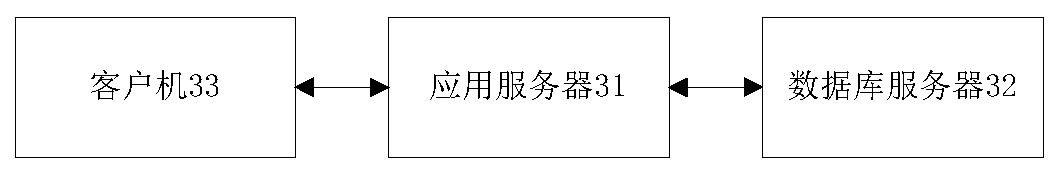

Ship berth distribution method, system and device

The invention discloses a ship berth allocation method, system and device. The method comprises the following steps: a target model is established with the maximum port production efficiency and the shortest ship in-port time as target functions and a preset condition as a constraint condition, the maximum port production efficiency is represented by the minimum sum of departure time of the last ship on each berth, and the shortest ship in-port time is represented by the minimum sum of the in-port time of all the ships; and the target model is solved to obtain an optimal solution of a ship berth allocation scheme, the ship berth allocation scheme is composed of at least one of the following elements: a berth where a ship is berthed, an operation sequence of a plurality of ships on the berth, a ship loading scheme, a ship loading stack position, a ship loading amount, ship operation time and ship arrival and departure time. Through the application, the problem that reasonable distribution is difficult to perform according to actual influence factors when output type coal wharf berth distribution is performed in related technologies is solved.

Owner:WATER TRANSPORT PLANNING & DESIGN INST

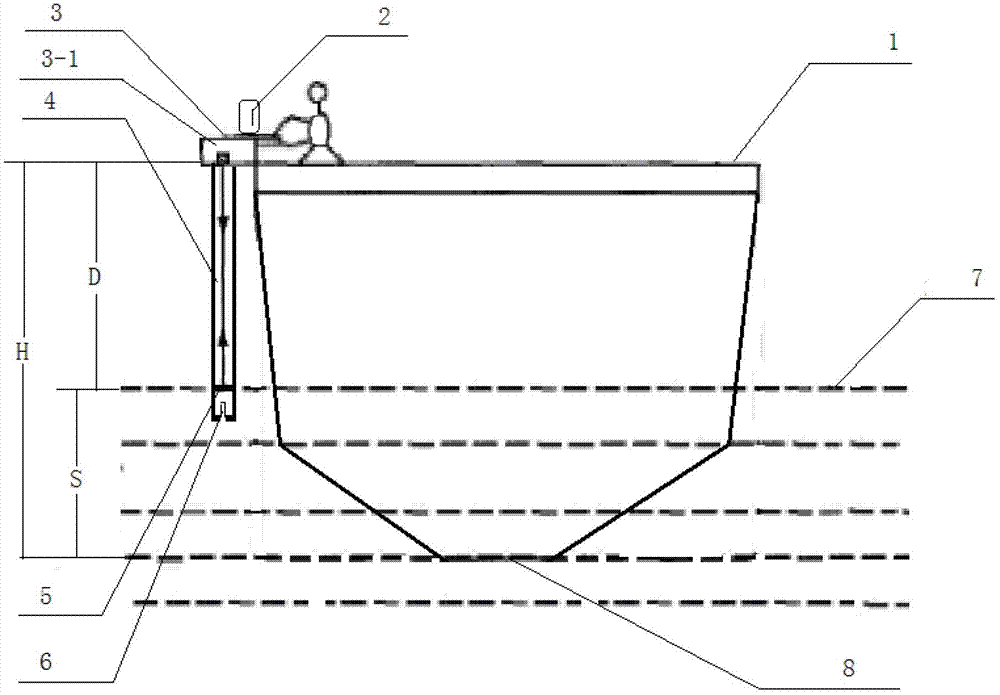

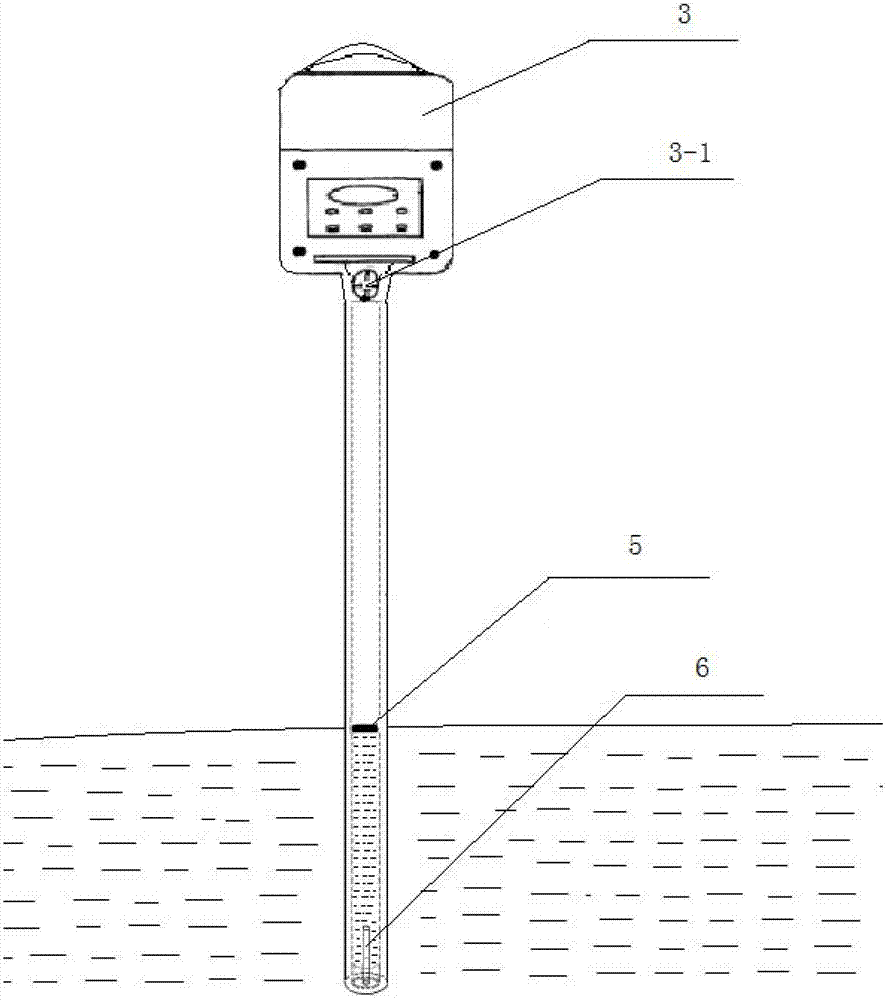

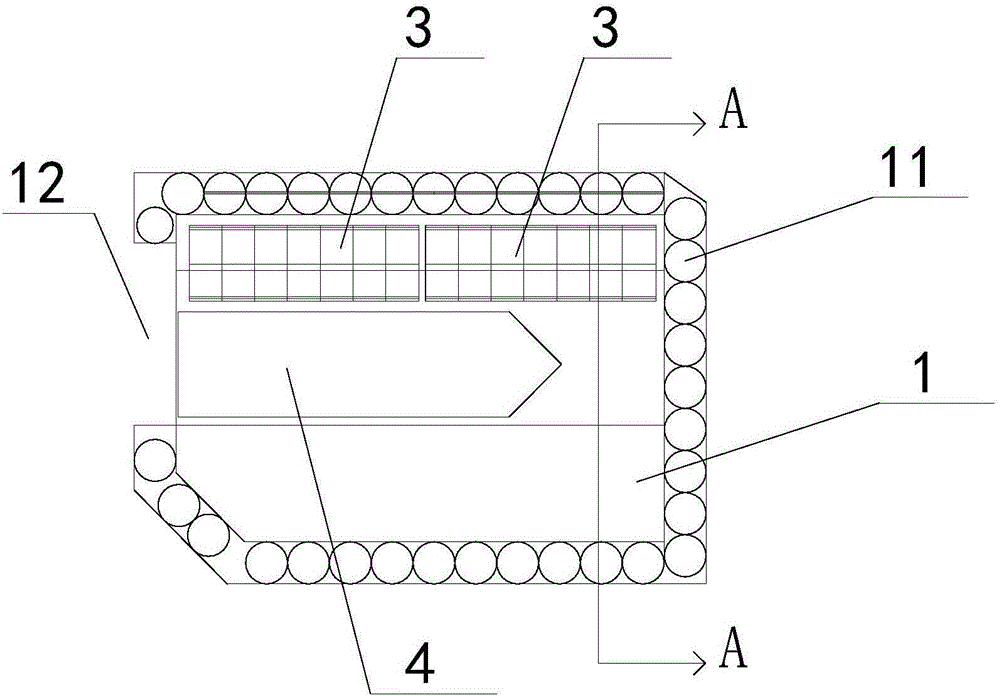

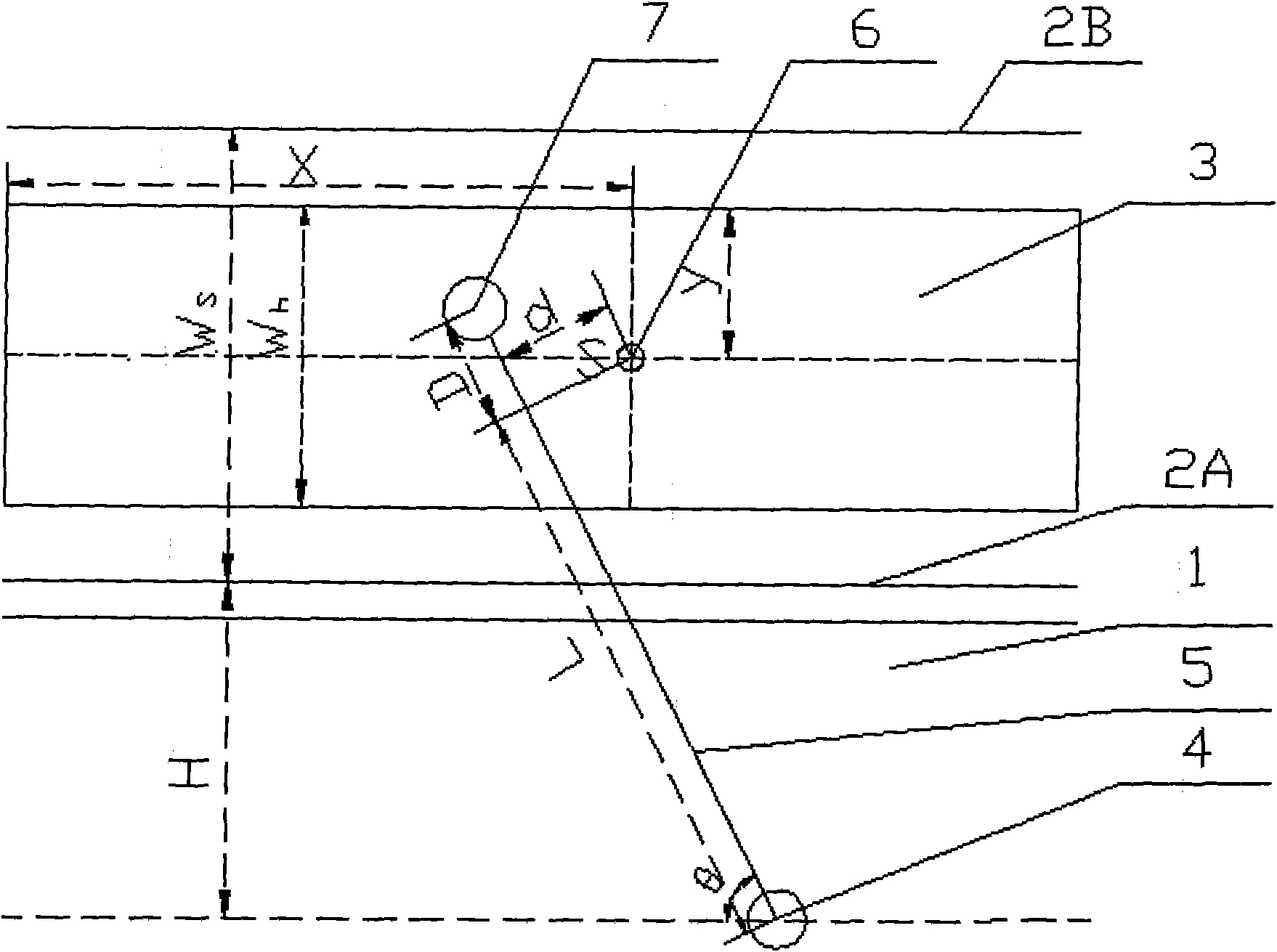

Inland ship load measuring method based on ultrasonic liquid level measuring technology

InactiveCN103192959ARealize automatic measurementHigh loading accuracyVessel stability improvementMovement controllersMeasurement precisionUltrasound probe

The invention discloses an inland ship load measuring method based on the ultrasonic liquid level measuring technology. The method includes that an ultrasonic probe of an ultrasonic liquid level detection device fixed on the edge of a ship deck is adopted to measure a distance D between the ship deck and the water, a computer connected with the ultrasonic liquid level detection device is adopted to calculate draught depth S of a ship, S=H-D, and H is the height of the ship. The computer conducts conversion according to the draught depth S of the ship and 'ship load and water gauge comparison table' to obtain the ship load and display the load through a display screen of the computer. By means of the measuring method, automatic measurement of the inland ship load can be achieved, and ship load accuracy is greatly improved compared with that measured by a traditional visual measuring method. Specifically, the method has the advantages of being capable of automatically obtaining ship load, convenient to use due to the fact that the measured data can be used for remote transmission, capable of preventing effect of water wave on measuring accuracy, high in measuring accuracy, capable of conducting measurement when the ship moves and high in application value.

Owner:TIANJIN RES INST FOR WATER TRANSPORT ENG M O T +2

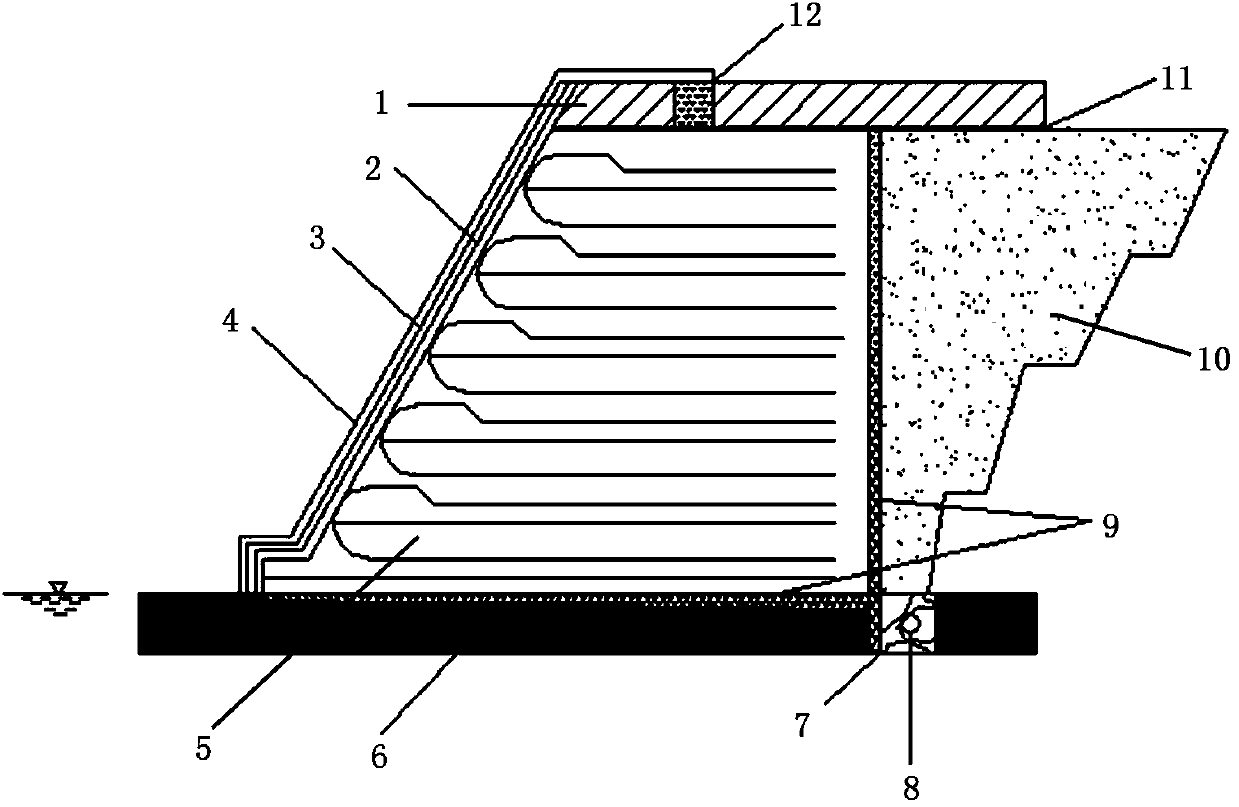

Construction method for ecological flexible geogrid reinforcement pier

PendingCN107354911AEnhanced to withstand ship loadsIncrease pressureBreakwatersQuaysPlant rootsBreakdown phenomenon

The invention belongs to the field of pier protection and earthquake resisting and provides a construction method for an ecological flexible geogrid reinforcement pier to solve the problems that most pier soil retaining facilities are of a rigid structure, and under the combined effect of seismic waves, ship loads and water pressure, breakdown phenomena that tie bars are pulled out, slip surfaces are caused inside and outside or slope faces are deformed and uplifted seriously occur easily. According to the pier, a soil body is reinforced by geogrid devices which are manufactured through the reverse wrapping technology and plant root systems, the geogrids and the plant root systems are jointly used for being occluded with soil particle padding, the stability of slopes can be greatly enhanced, and the capacity of bearing the ship loads and the water pressure of the slope faces is enhanced. The geogrid devices are distributed in an upper-lower layer graded step shape, stress is more reasonable, the structure is more stable, and deformation fatigue life is long.

Owner:ZHENGZHOU UNIV

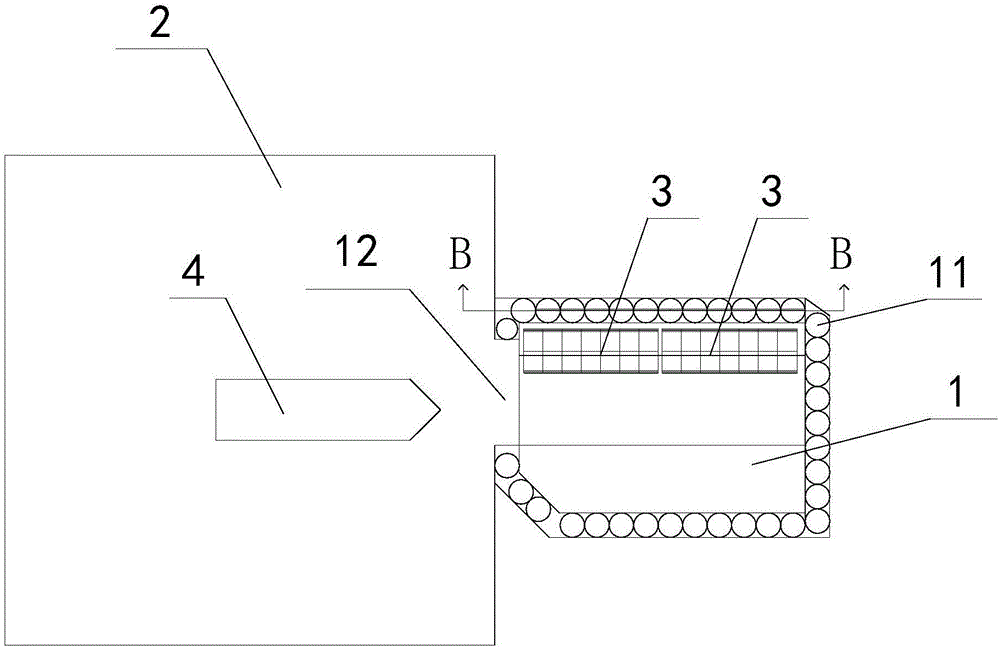

System and method for ship water gauge measurement based on UAV

PendingCN107340031AImprove acceptance efficiencyQuality assuranceMachines/enginesLevel indicatorsData acquisitionComputation process

The invention relates to a system and method for ship water gauge measurement based on a UAV. The system and method comprise a ship with water gauge scales. The system is characterized by comprising an UAV water gauge video collection device, a terminal collection device, a data receiving device and a data processing server, wherein the UAV water gauge video collection device is configured to track changes of the position of a waterline area; the terminal collection device is configured to collect seawater density and the liquid level height of a water-oil cabin; the data receiving device is configured to receive data sent by the two devices; and the data processing server is configured to process the data sent by the data receiving device and compute the load capacity of the ship according to the data. The system and method mainly aim at data collection, transmission and processing during computation of the ship load capacity; and just and efficient computation of the ship load capacity can be ensured.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

Construction process for shipping large sinking pipes by self-propelled semi-submerged ship

ActiveCN106522275AReduce distanceImprove work efficiencyArtificial islandsUnderwater structuresWork productivityPrefabrication

The invention provides a construction process for shipping large sinking pipes by a self-propelled semi-submerged ship for transporting the sinking pipes from a sinking pipe prefabrication factory to a foundation trench region for sinking pipe mounting construction. A mooring and outfitting region is arranged next to the foundation trench region, the semi-submerged ship loads the sinking pipes in a deep dock of the sinking pipe prefabrication factory and transports the same to the mooring and outfitting region, and after an outfitting step of the sinking pipes in the mooring and outfitting region is finished, the sinking pipes are transported to the foundation trench region in a floating manner through a sinking pipe mounting ship and a tug. According to the construction process for shipping large sinking pipes by the self-propelled semi-submerged ship provided by the invention, the floating transportation distance of the sinking pipe is greatly reduced, and the work efficiency of transporting the sinking pipe to 3-4 times; secondly, as draft of the semi-submerged ship which transports the sinking pipes is smaller compared with that of sinking pipe floating transportation in the prior art, the requirement on channel depth is greatly reduced. The channel needs not to be excavated, so that the time and economical costs are further saved; furthermore, the requirements on natural conditions such as a water wave flow by transporting the sinking pipes by the semi-submerged ship are relatively low, the limiting condition of transporting the sinking pipes is reduced, and the work efficiency of transporting the sinking pipes is further improved.

Owner:NO 2 ENG CO LTD OF CCCC FIRST HARBOR ENG +1

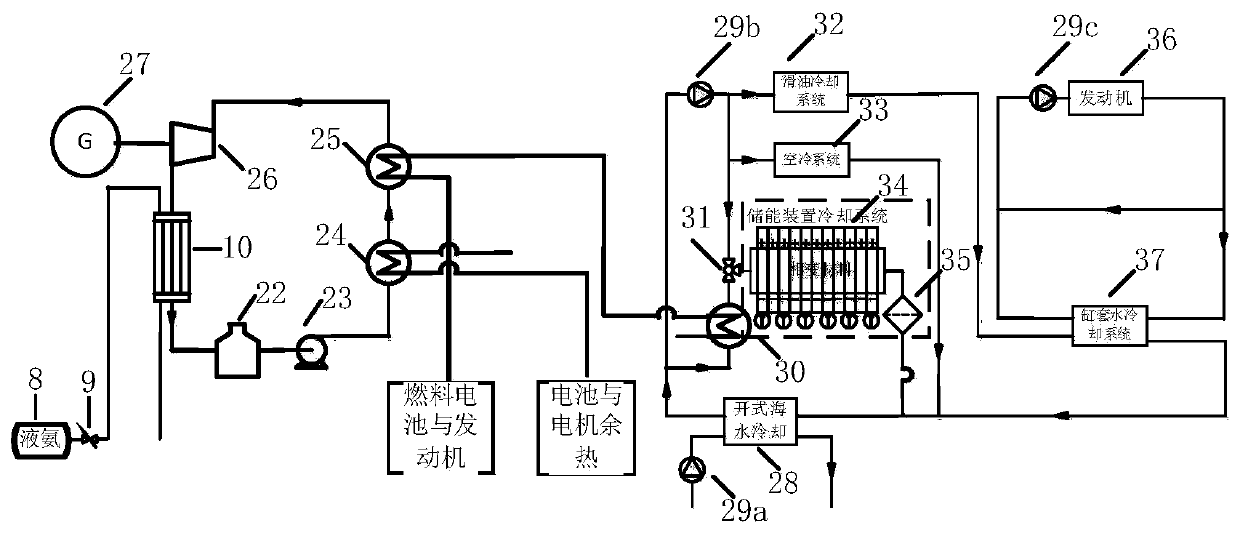

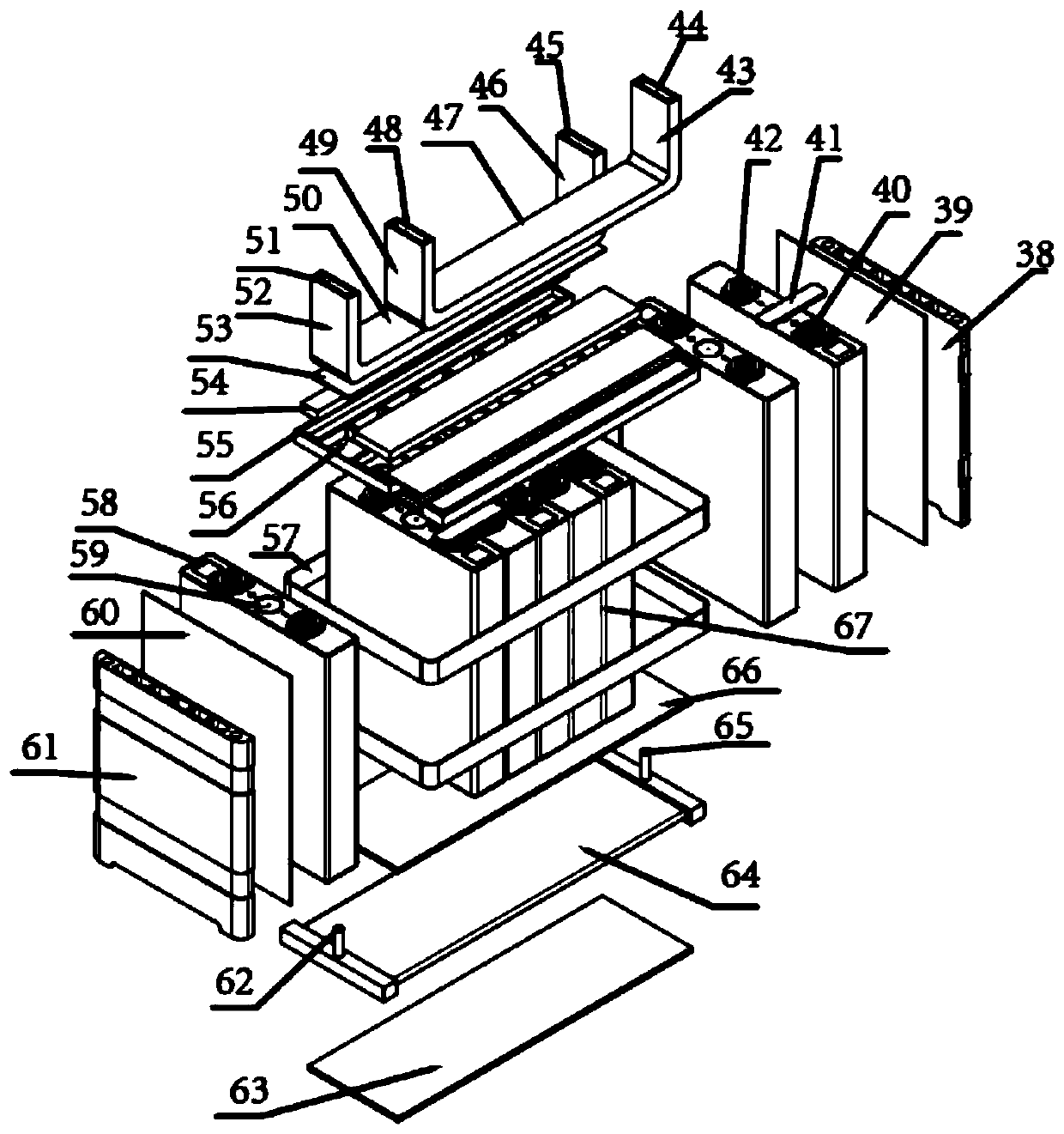

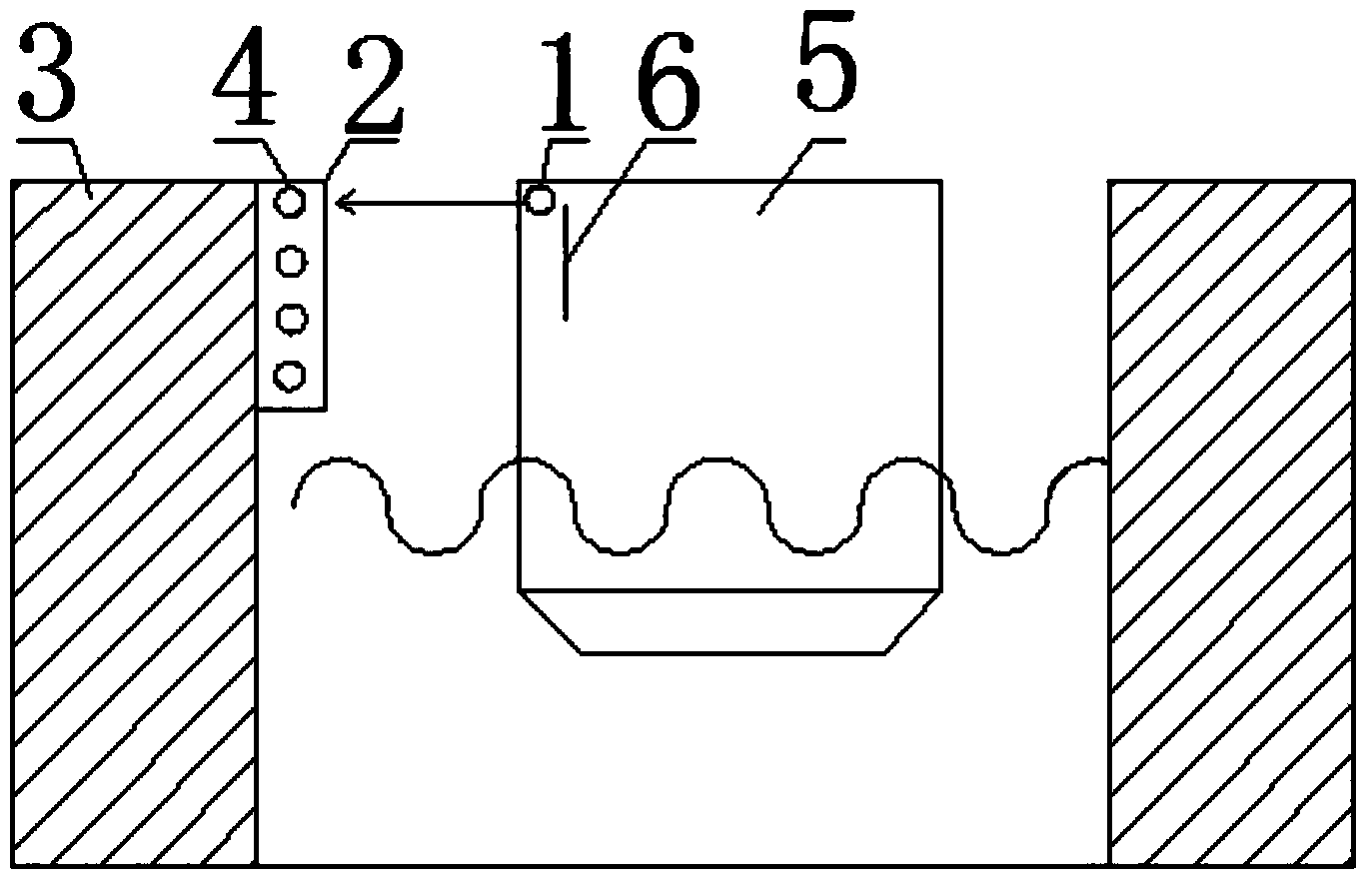

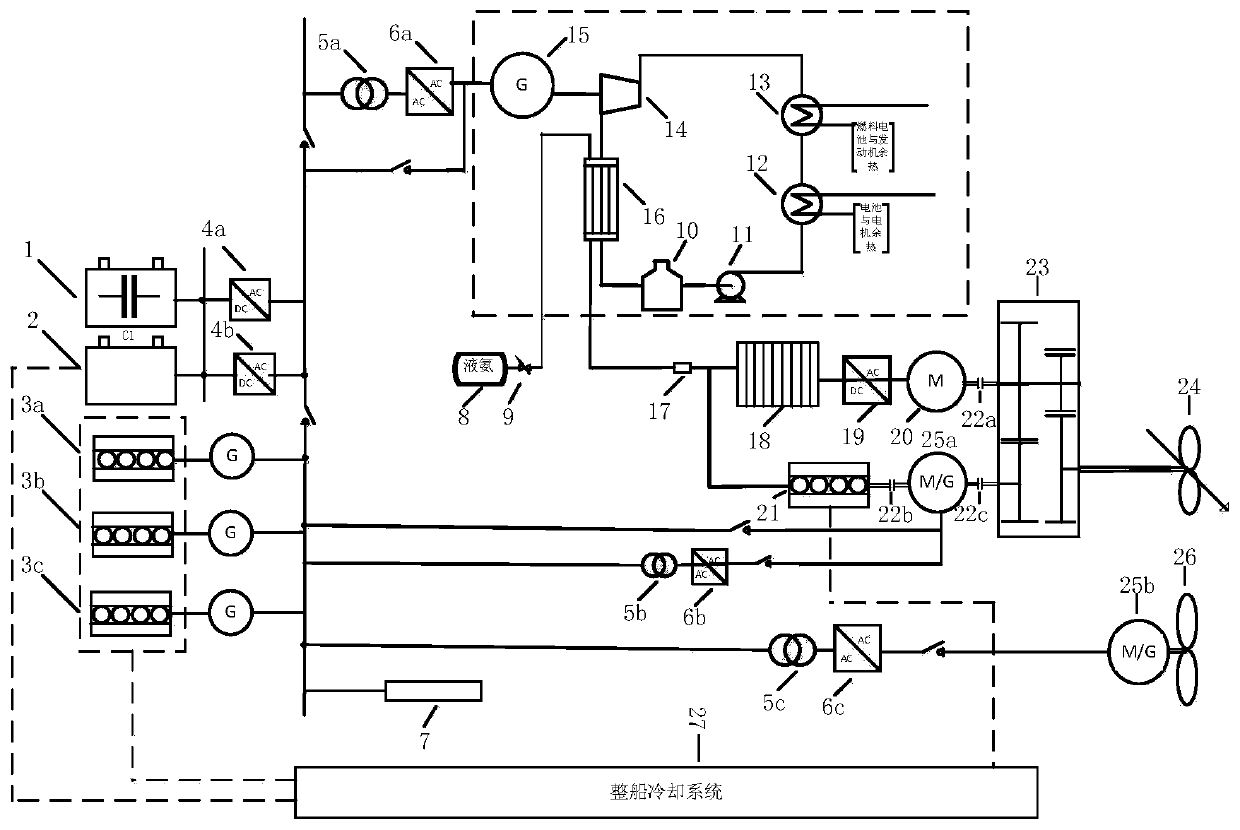

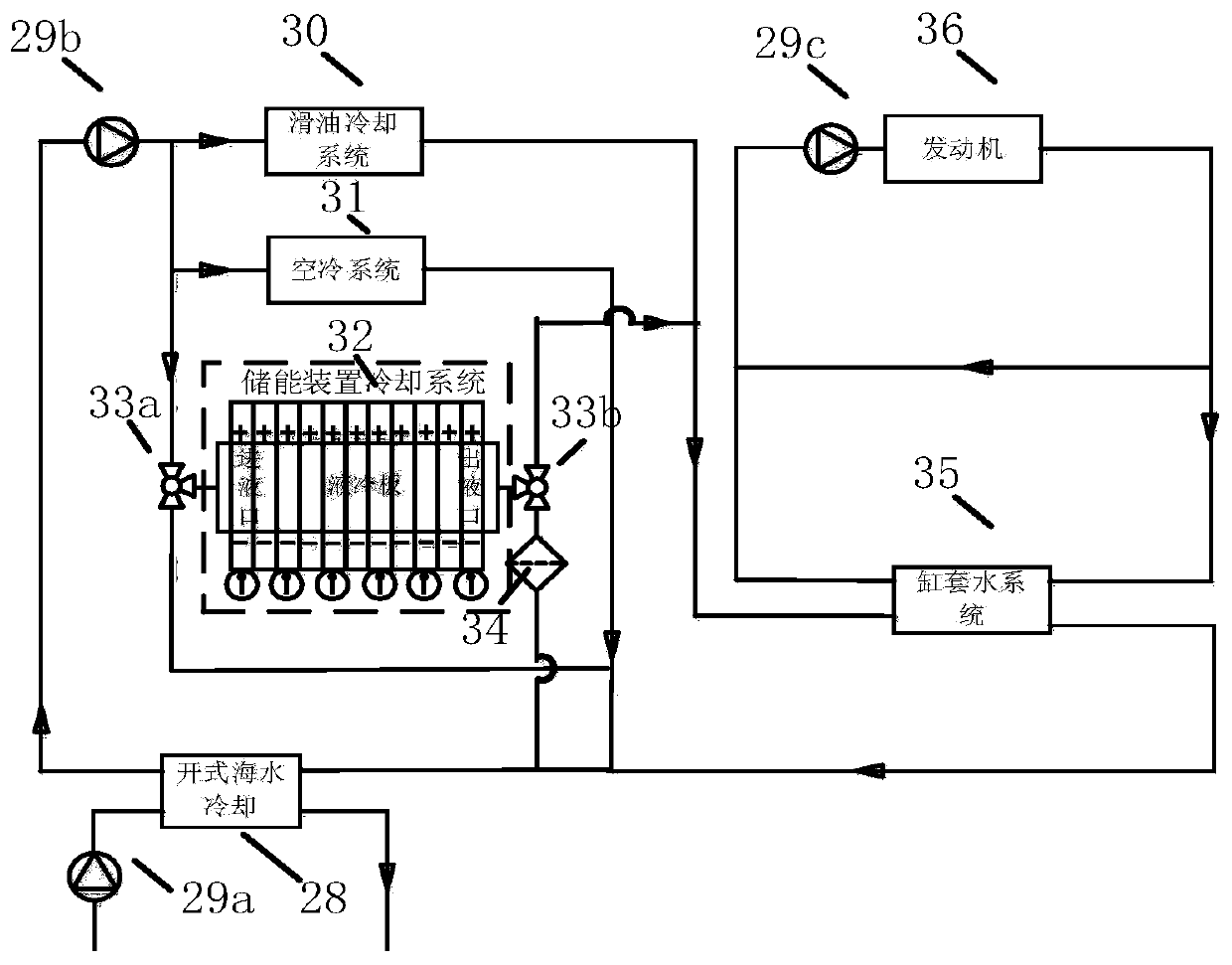

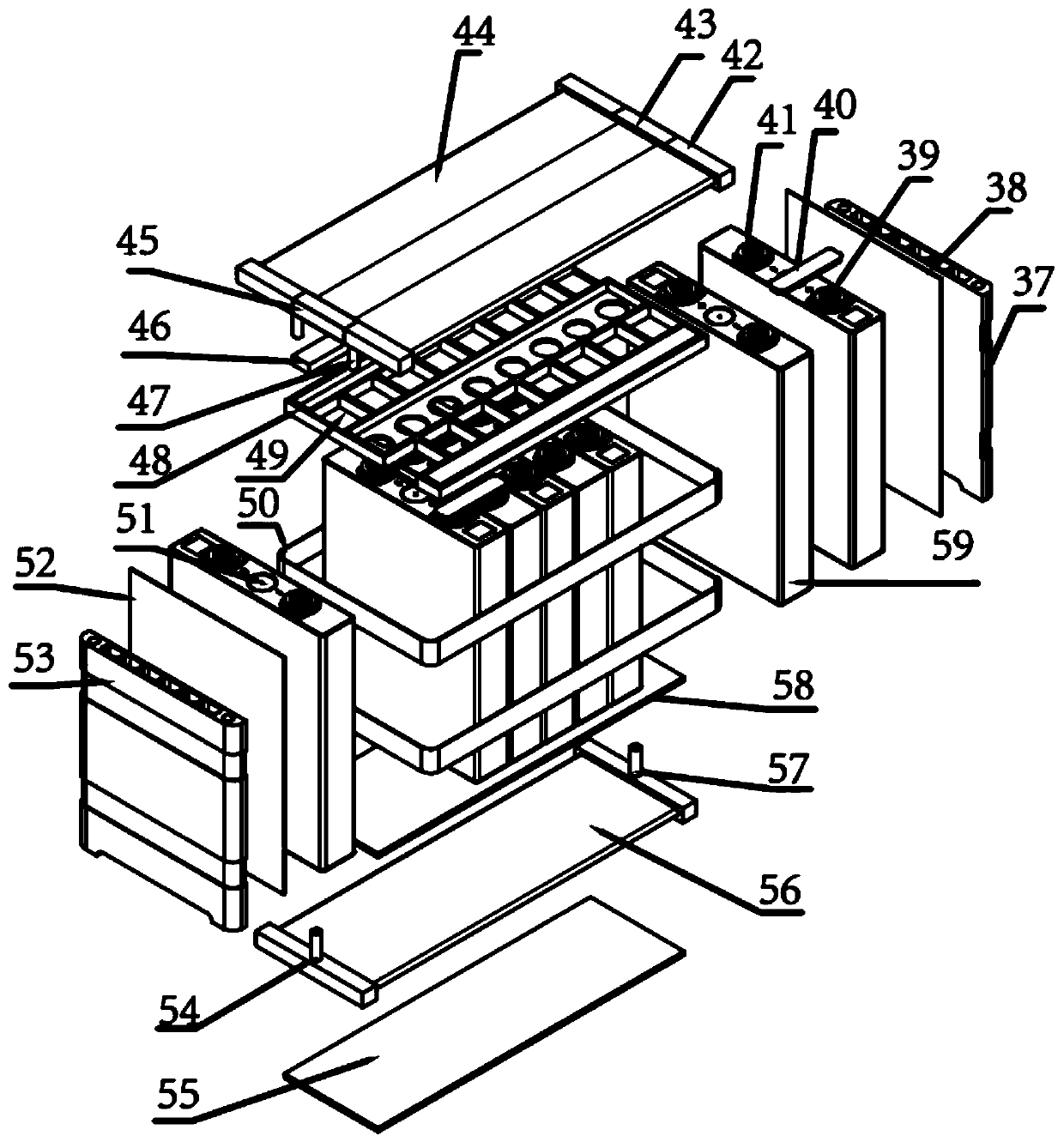

Ship ammonia-electricity hybrid power system with heat storage-cooling battery heat management system

ActiveCN111332441AMeet power needsEmission reductionPower plants using propulsion unit combinationsCell temperature controlElectrical batteryElectric capacity

The invention aims to provide a ship ammonia-electricity hybrid power system with a heat storage-cooling battery heat management system. The ship ammonia-electricity hybrid power system comprises an ammonia fuel engine, a reversible motor, a diesel generator set, a storage battery, a capacitor, a fuel battery, a propeller, a liquid ammonia storage and supply device, a power transformation device,a ship mainstream power grid, a ship load, a whole ship cooling system and a waste heat system. Hybrid propulsion of the ammonia fuel engine and the motor and coordinated power supply of the diesel generator set and the energy storage unit can be achieved, multi-stage utilization of cold energy of the energy storage unit and the engine is achieved, and the waste heat system can achieve multi-stageheat energy utilization and is integrated with the cooling system.

Owner:成都美安科技有限公司

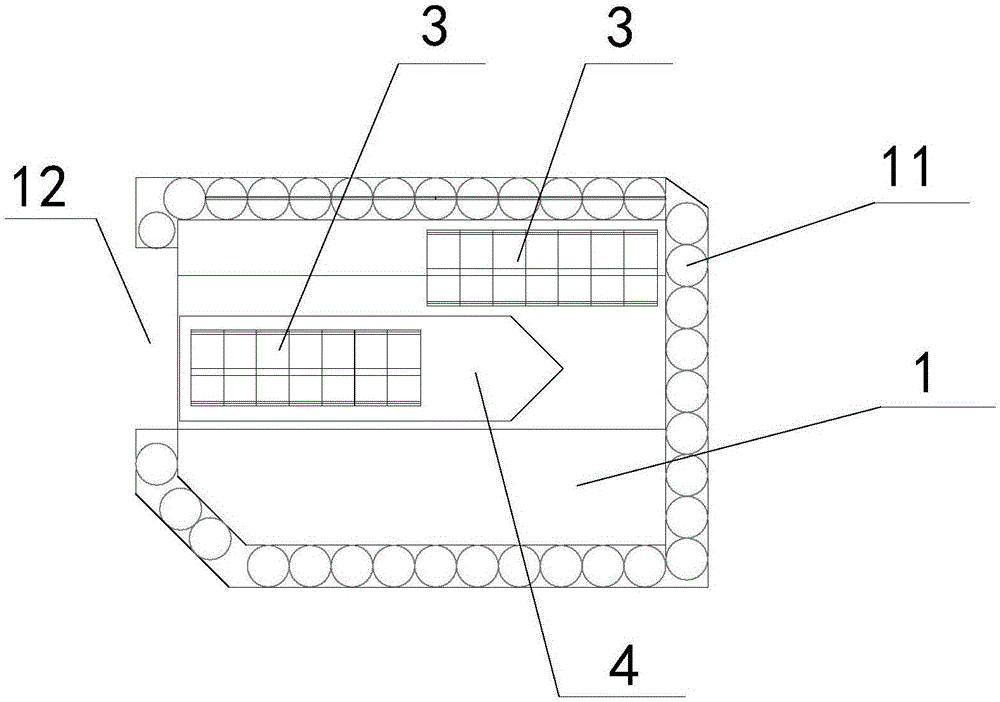

Inland port ship load measuring system and method

InactiveCN103963939AAvoid feesAvoid missing gate feesVessel stability improvementMovement controllersEngineeringInland port

The invention relates to an inland port ship load measuring system and a method for applying the measuring system. The inland port ship load measuring system comprises a signal sending device, a signal receiving device, a signal processing unit and a signal transmitting device. The signal sending device comprises a sending probe. The signal receiving device comprises a receiving panel and a plurality of receiving probes, wherein the receiving probes are vertically arranged on the receiving panel at equal intervals along a straight line. The signal receiving device is used for receiving signals sent by the signal sending device so as to produce signal hopping. The signal processing unit is used for inputting empty-ship waterlines and corresponding ship models, it is determined the sent signals are received by the corresponding receiving probes on the receiving panel according to the signal hopping, and changes of drafts are determined by the receiving probes producing the signal hopping. The signal transmitting device is used for sending data of the signal processing unit to law-enforcing departments and supervisory institutions of the port office and related workers of all ship locks. Through the inland port ship load measuring system and the method, workers related to port administrative affairs can obtain the weight of the cargo of a cargo ship in real time.

Owner:SHANDONG UNIV

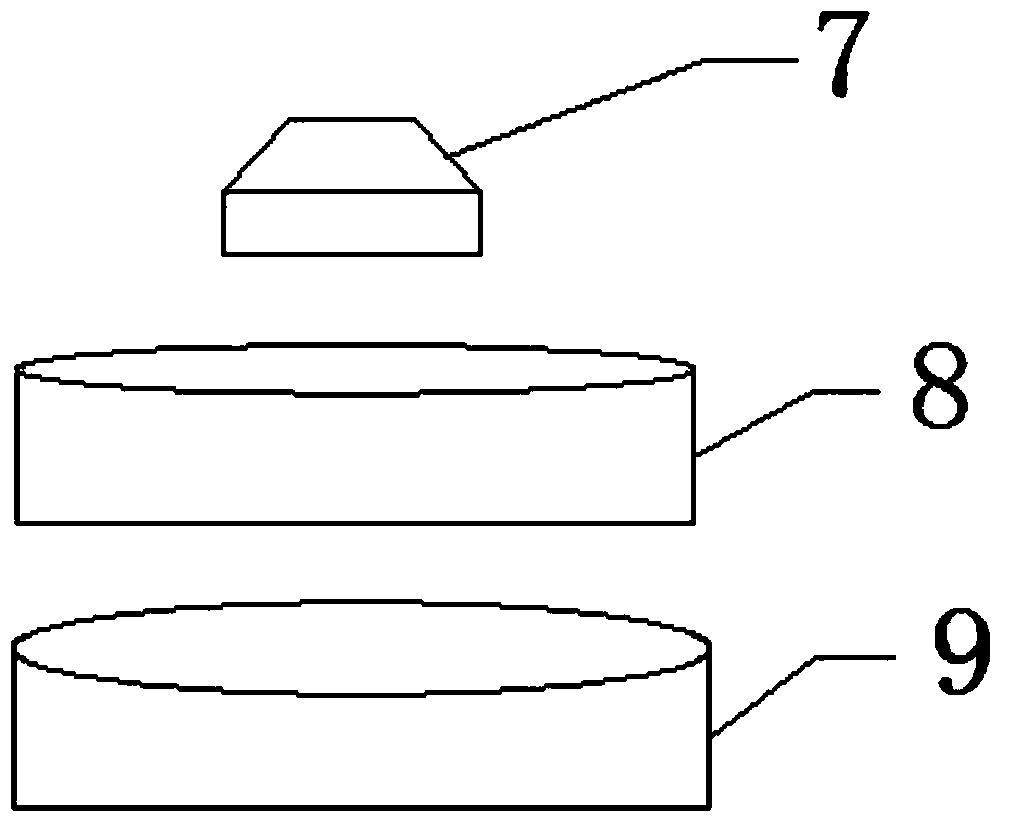

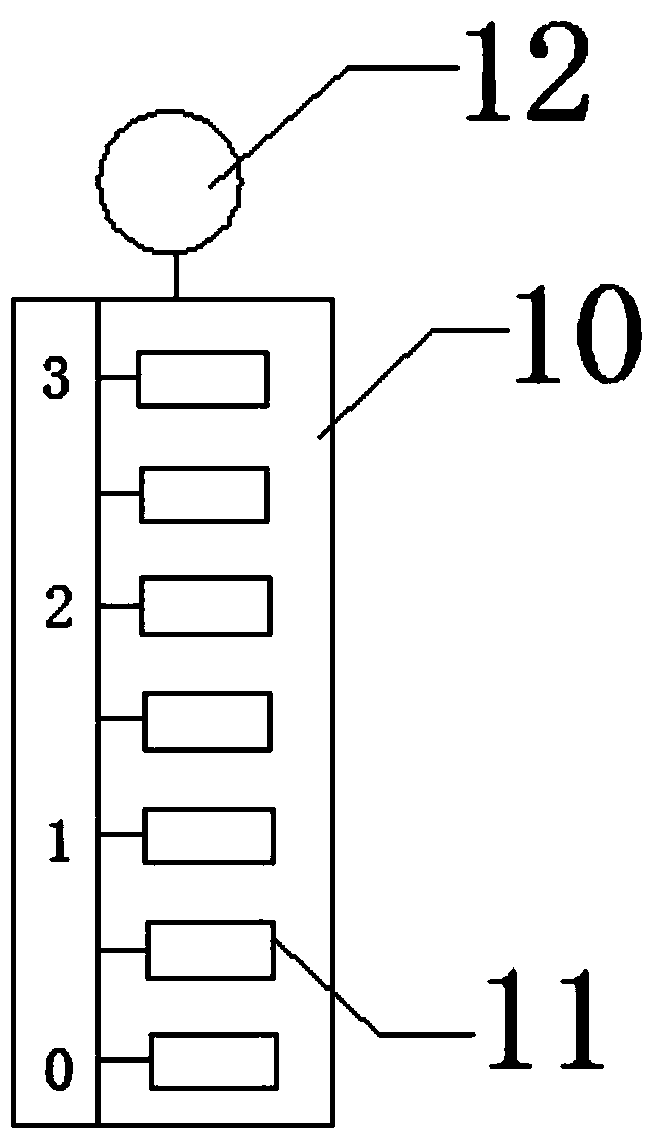

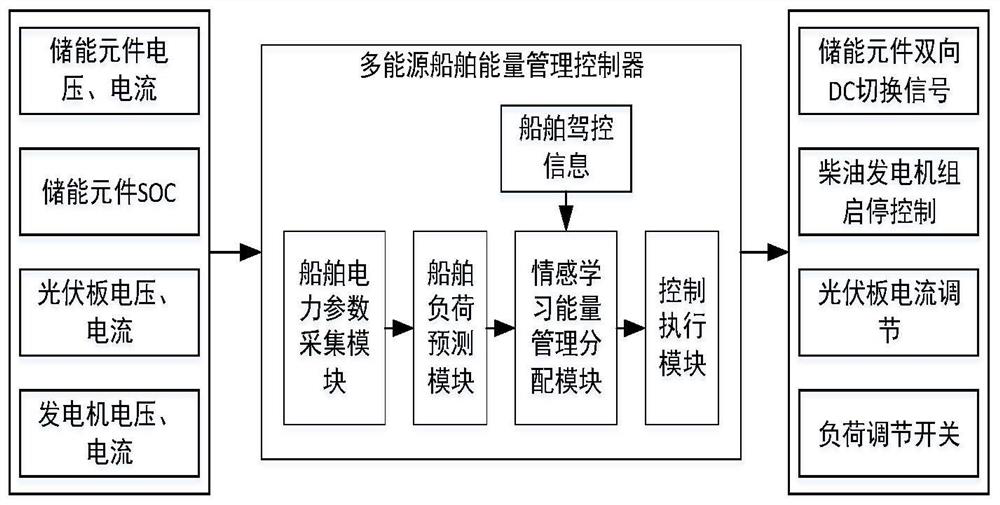

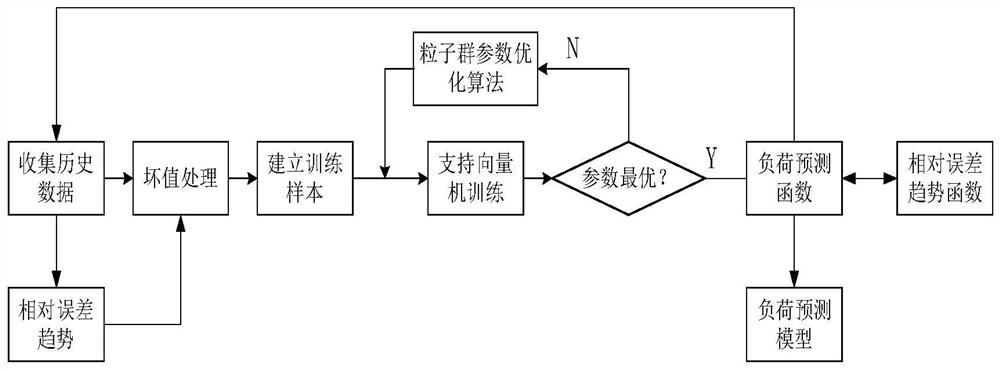

Energy management and control device and method for multi-energy ship

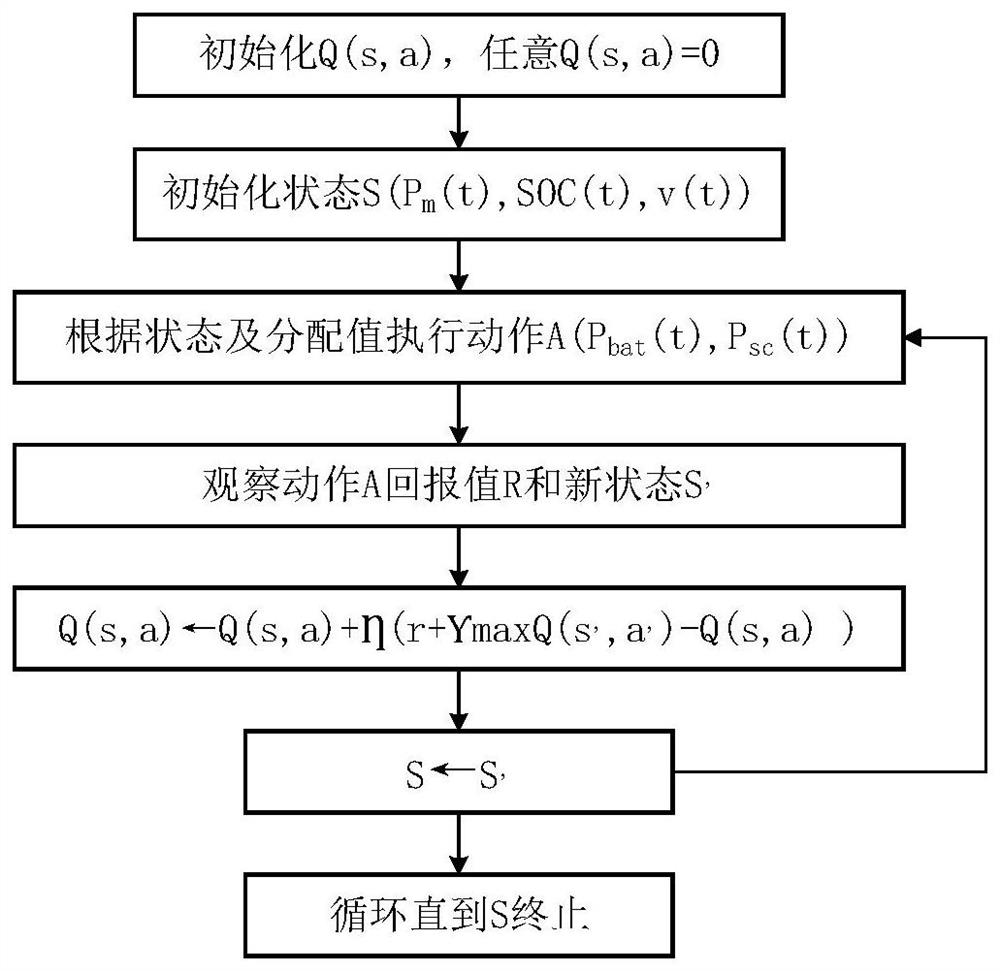

PendingCN112510701ASolve the shortcomings of insufficient energy densityStrong randomnessLoad forecast in ac networkKernel methodsPower qualityEngineering

The invention discloses an energy management and control device for a multi-energy ship. The device comprises an acquisition module for electric power parameters of the ship, a ship load prediction module, an energy management and distribution module and a control execution module, wherein the acquisition module for the electric power parameters of the ship acquires the electric power parameters of the multi-energy ship, and the electric power parameters are preprocessed by the ship load prediction module; a load prediction model is trained, and a load prediction data value at a current momentis calculated; the energy management and distribution module acquires ship driving control information; and a Q-learning algorithm is utilized to solve a multi-energy power distribution target in combination with the load prediction data value at the current moment; the control execution module acquires a solution; and therefore, distribution of various energies of the multi-energy ship are controlled. The invention further provides a corresponding control method. According to the characteristics and real-time operation conditions of a multi-energy power system, various energy sources are reasonably distributed and coordinately controlled, so the voltage and frequency fluctuation of the ship power grid is reduced, and the electric energy quality of a ship power grid and the economic performance of ship operation are optimal.

Owner:JIANGSU UNIV OF SCI & TECH

Double-shaft double-motor ship ammonia-electricity hybrid power system with waste heat utilization function

ActiveCN111332446AMeet power needsEmission reductionCell seperators/membranes/diaphragms/spacersPower plants using propulsion unit combinationsElectric capacityControl theory

The invention aims to provide a double-shaft double-motor ship ammonia-electricity hybrid power system with a waste heat utilization function. The double-shaft double-motor ship ammonia-electricity hybrid power system comprises an ammonia fuel engine, a reversible motor, motors, a diesel generator set, a storage battery, a capacitor, a fuel cell, a propeller, a liquid ammonia storage and supply device, a power transformation device, a ship power grid, a ship load, a whole ship cooling system and a waste heat system. Hybrid propulsion of the ammonia fuel engine and the motor and coordinated power supply of the diesel generator set and the energy storage unit can be achieved. Meanwhile, multi-stage utilization of cold energy of the energy storage unit and the engine is achieved, a waste heatsystem can achieve multi-gradient utilization of heat energy, ship energy consumption is reduced, the whole ship efficiency is improved, and the application range of the system is widened.

Owner:HARBIN ENG UNIV

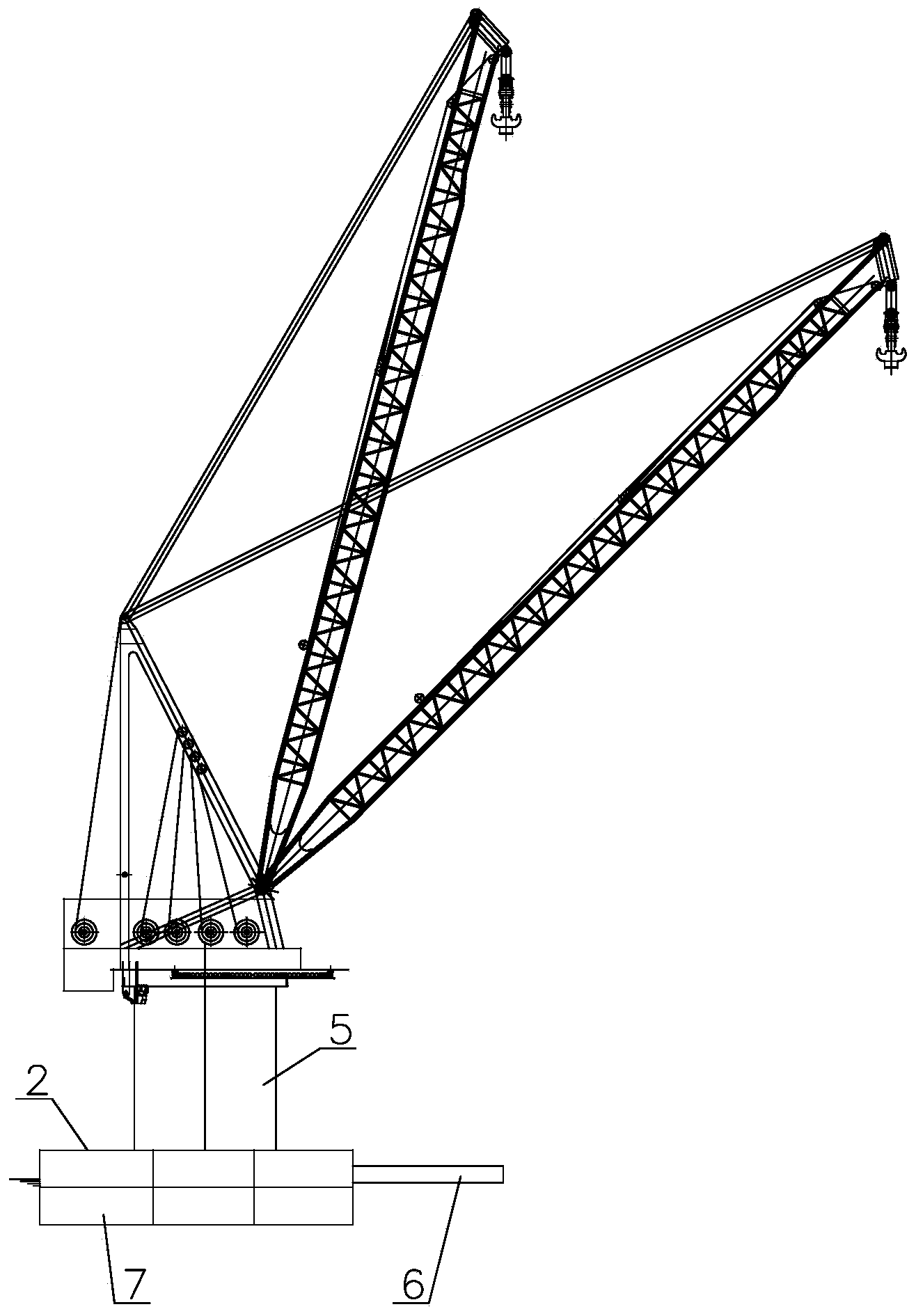

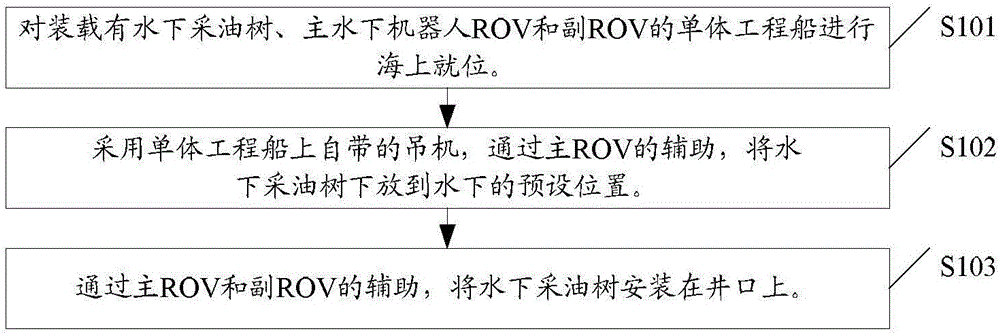

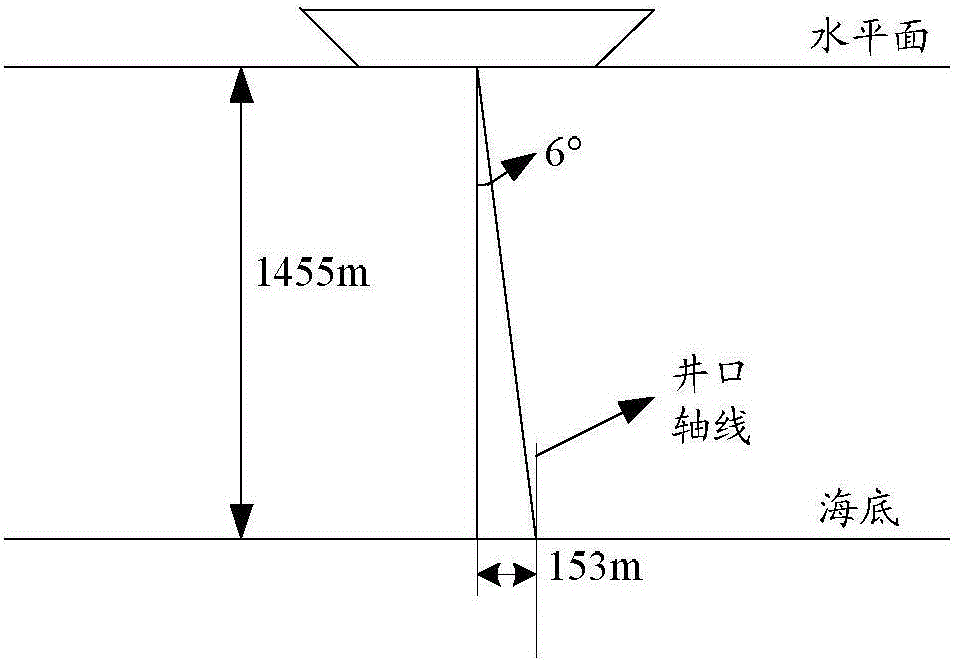

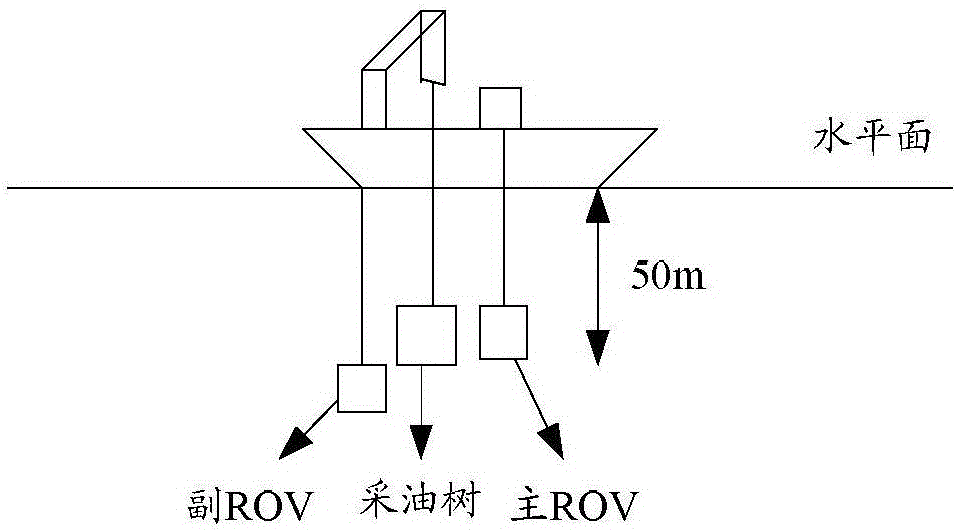

Underwater Christmas tree installing method and system

InactiveCN106321028ASolve insufficient resourcesSmall diameterFluid removalPaymentMarine engineering

The invention discloses an underwater Christmas tree installing method and system. The underwater Christmas tree installing method comprises the steps that marine arrangement is conducted on a single engineering ship loaded with an underwater Christmas tree, a main underwater robot ROV and an auxiliary ROV; then, a build-in crane of the single engineering ship is adopted and is aided by the main ROV to put the underwater Christmas tree at an underwater preset position, and the underwater Christmas tree is aided by the main ROV and the auxiliary ROV to be installed on a well mouth. By the adoption of the scheme, the single engineering ship having self-propulsion capability can be adopted to perform operation, daily payment is reduced, and ship resources are sufficient. In addition, the build-in crane of the single engineering ship carries the underwater Christmas tree to reach the well mouth and can be continuously and rapidly put down, the putdown efficiency is very high, and the diameter of a steel wire rope is small and facilitates reduction of the interference of environment load to the installing process.

Owner:CHINA NAT OFFSHORE OIL CORP +1

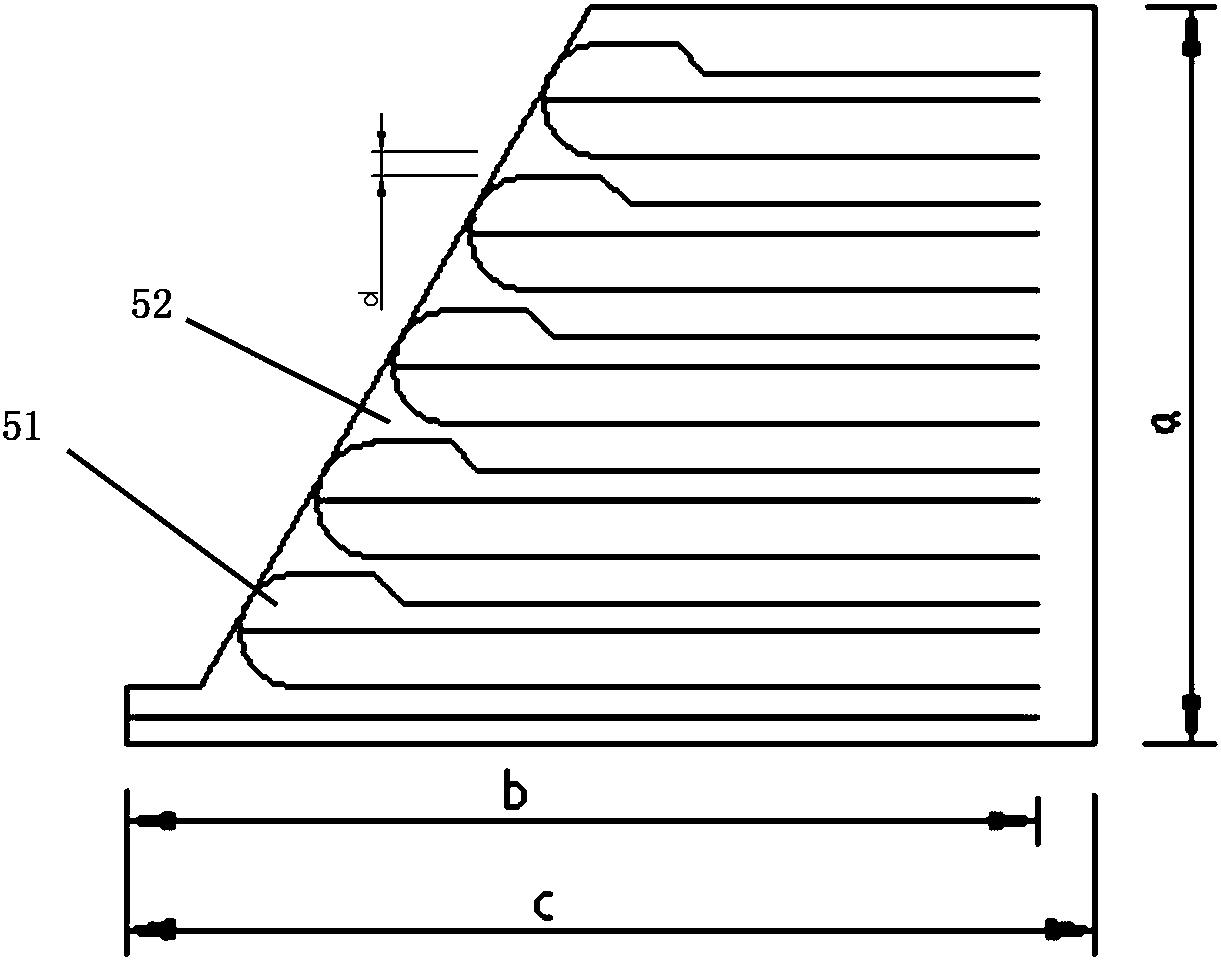

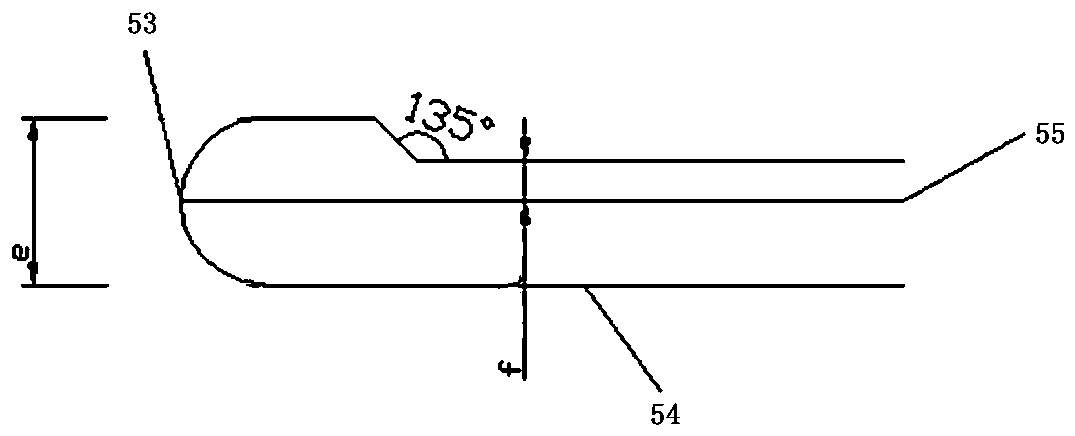

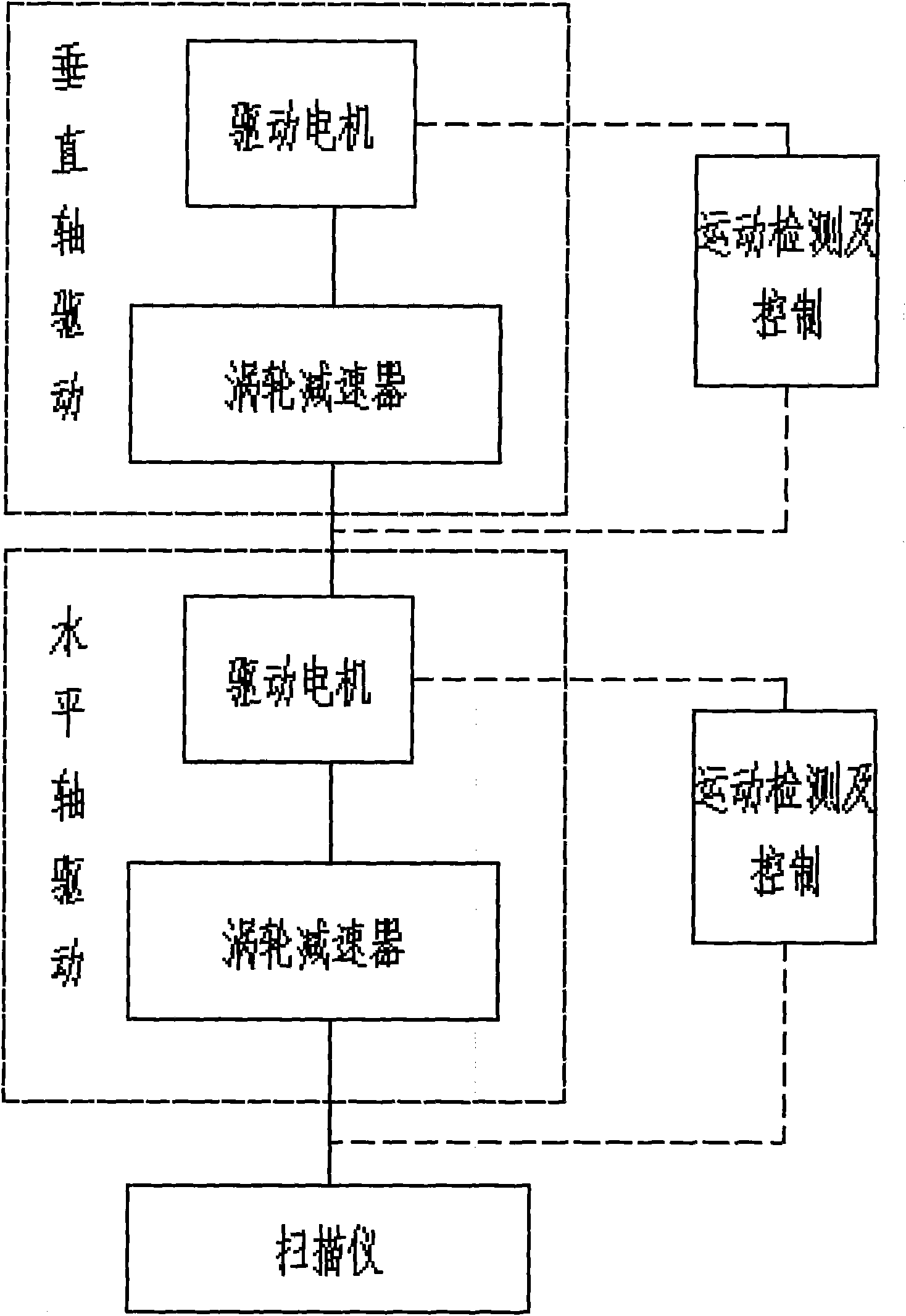

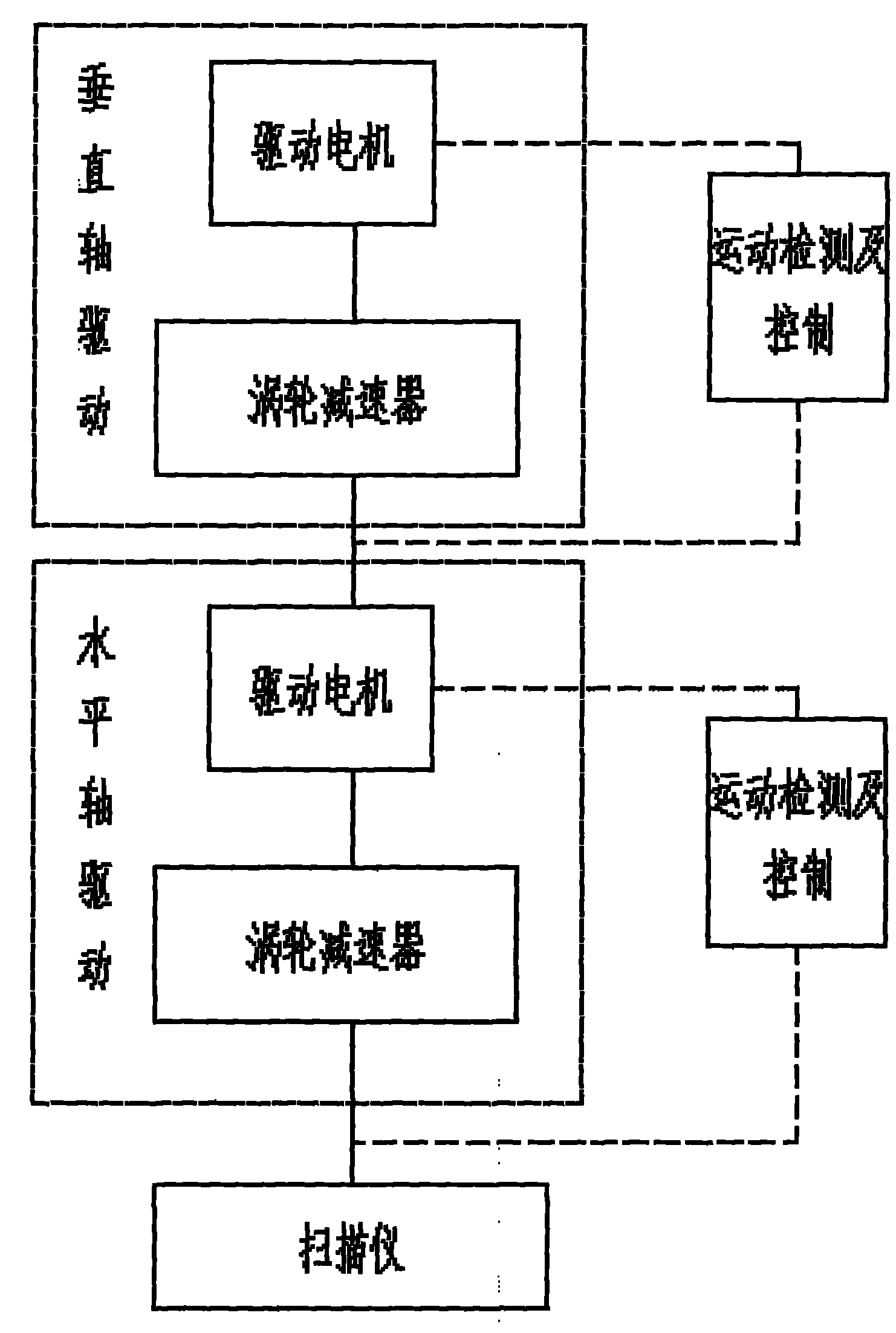

Method for detecting height of materials by bulk cargo automatic ship loading detector

InactiveCN101788317AEffective detection of positional relationshipsEffective detection of additionsMachines/enginesLevel indicatorsBulk cargoControl system

The invention belongs to the divisional application of a bulk cargo automatic ship loading detector and a method, and mainly relates to a method for detecting the height of materials by the bulk cargo automatic ship loading detector. The method comprises the following steps: measuring the position of the materials through a straight line extraction algorithm according to the position relationship between a chute tube and a scanner; scanning the ship cabin wall through rotating the scanner for measuring the position of the upper edge of the ship cabin through the upper end point of a straight line formed by extracted scanning points on the vertical surfaces of the cabin walls of the ship cabin; and obtaining the height of the materials through subtracting the value of the distance from the materials to the ship cabin from the depth value of the ship cabin. The invention adopts data obtained by a three-dimensional detector formed by a multiple scanner and a movement control system thereof, and effectively detects the position relationship between the materials and the upper edge of the ship cabin, so the height of the materials is calculated. The operation method is simple and effective, and can be easily realized.

Owner:SHANGHAI MARITIME UNIVERSITY

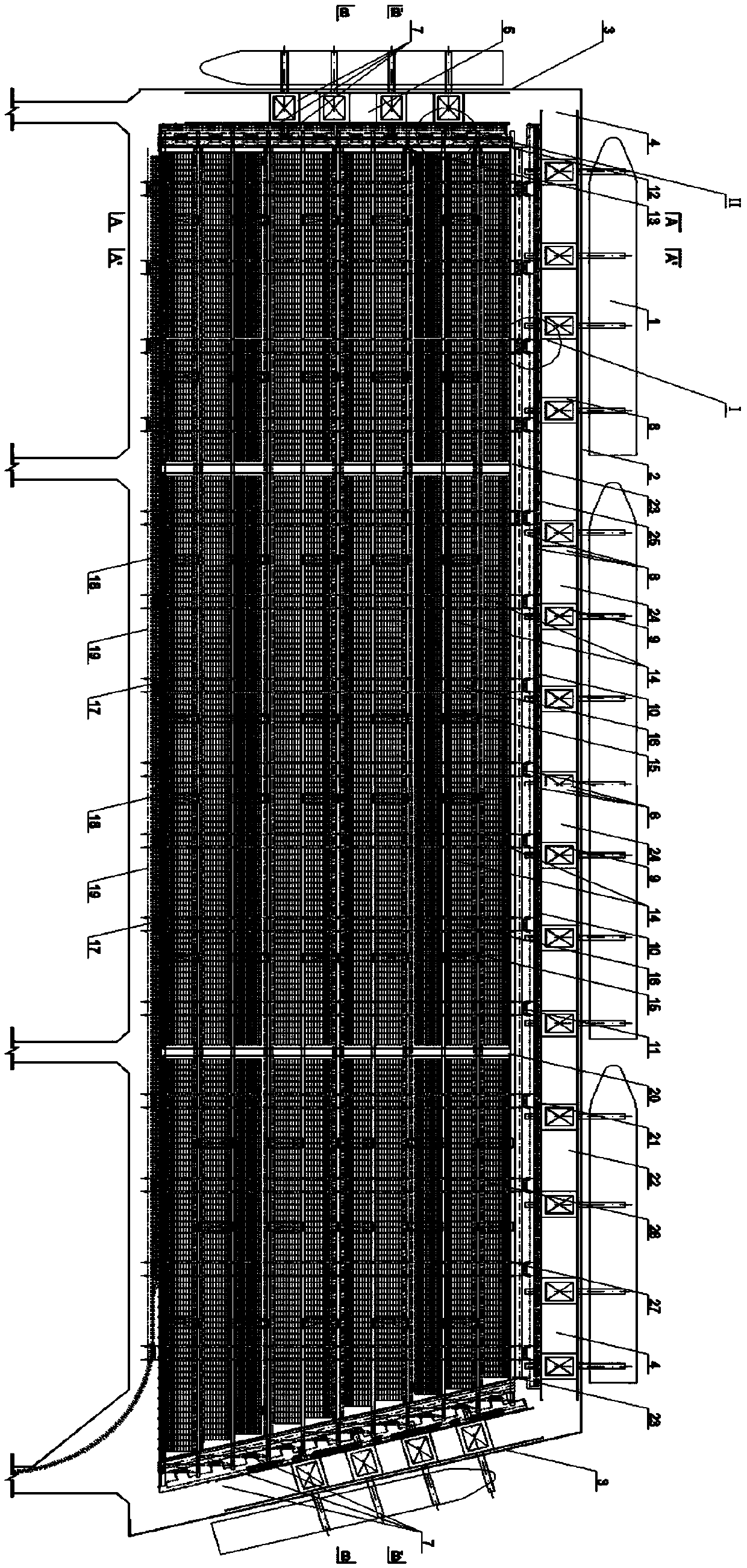

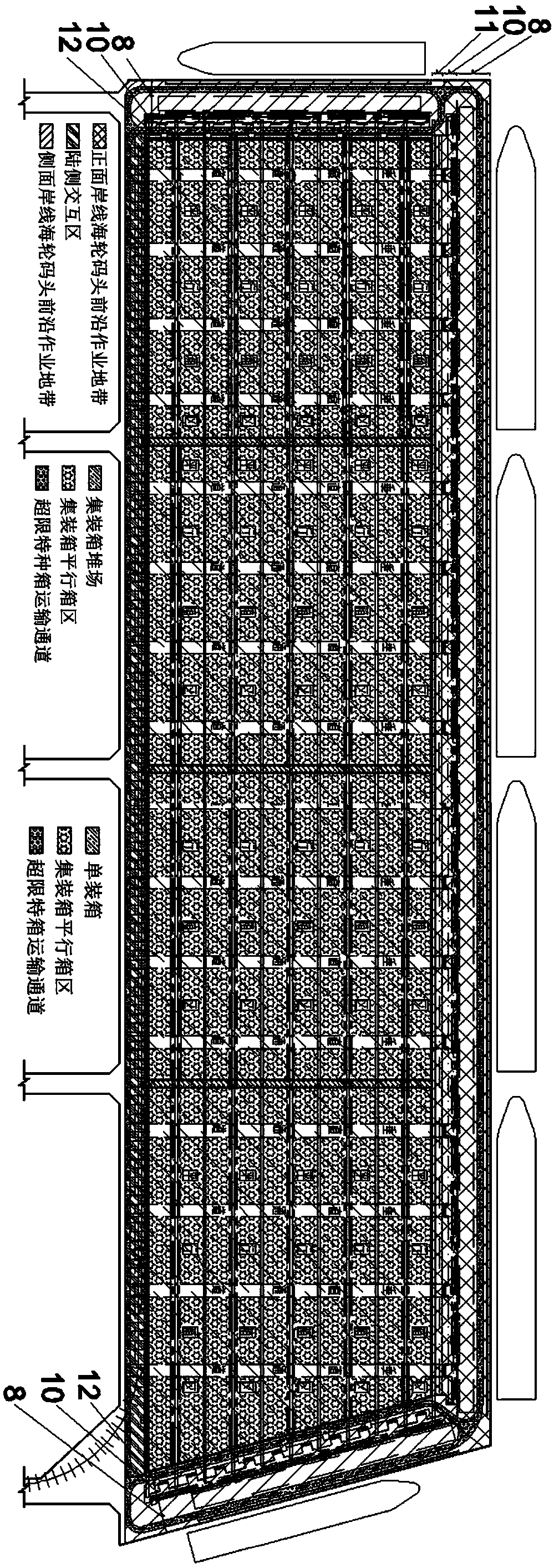

Container wharf of three-side shorelines, loading and unloading system and working method of loading and unloading system

PendingCN109626004AHigh degree of intensificationIncrease profitStorage devicesTransfer systemEngineering

The invention discloses a container wharf of three-side shorelines, a loading and unloading system and a working method of the loading and unloading system. The container wharf comprises a container yard, a front face shoreline seagoing vessel wharf and side face shoreline seagoing vessel wharves are arranged at the front end and on the two sides of the container yard correspondingly, and a landside interaction area is arranged between the container yard and rear land; and the loading and unloading system of the container wharf comprises a ship loading and unloading system constituted by single trolley shore bridges, a seagoing vessel wharf front edge stereo track horizontal transporting system constituted by a double-layer track and a son-mother track vehicle, and a container yard stereoloading and unloading stockpiling system composed of a parallel container area loading and unloading stockpiling system and a vertical channel loading and unloading transfer system; and the working method of the loading and unloading system comprises the steps that firstly, containers are unloaded from a ship through the ship loading and unloading system and transported into the container yard stereo loading and unloading stockpiling system through the son-mother track vehicle, and the containers are placed at the designated positions by the container yard stereo loading and unloading stockpiling system; and the ship loading steps are the reverse process of the ship unloading steps.

Owner:CCCC FHDI ENG

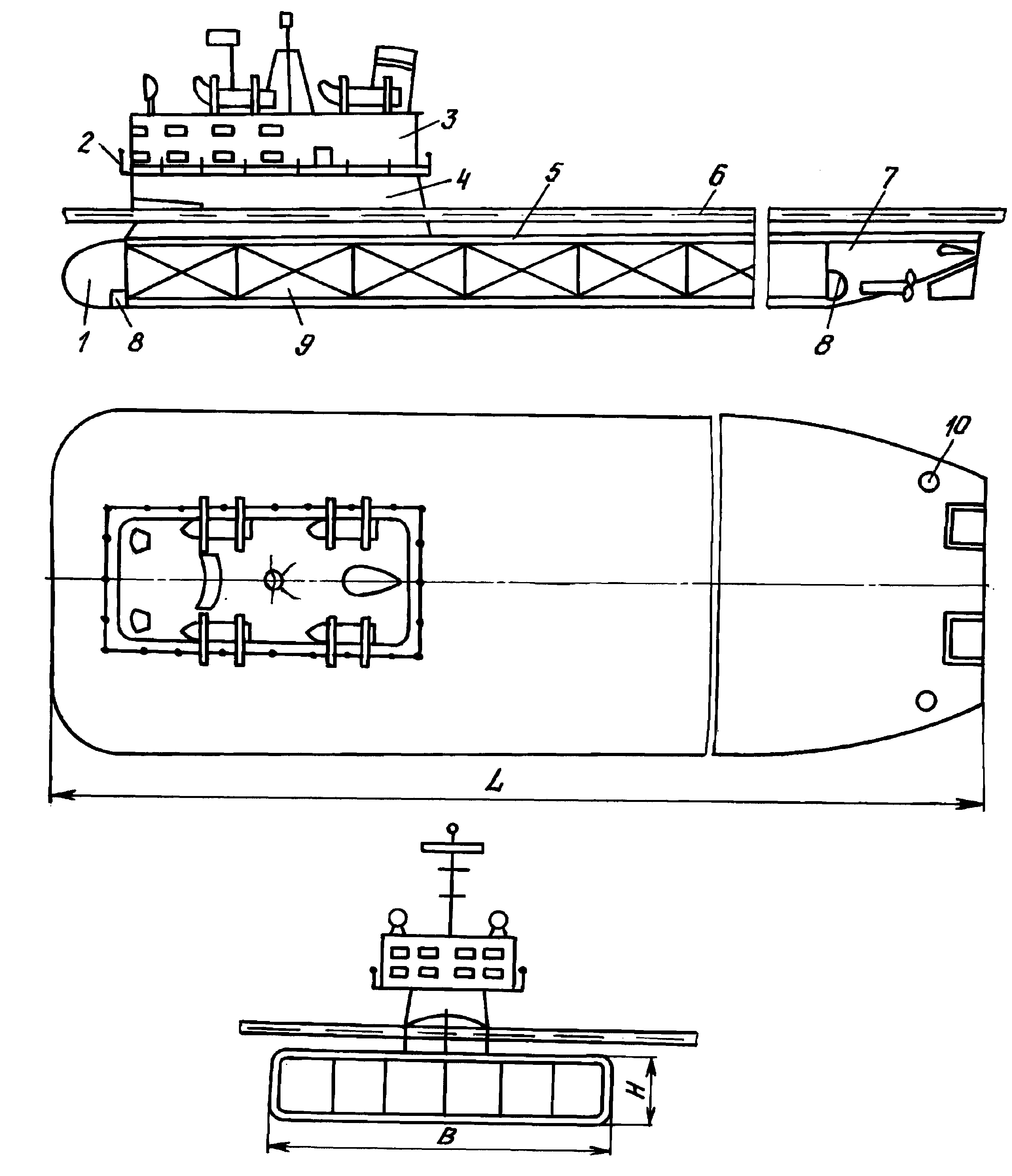

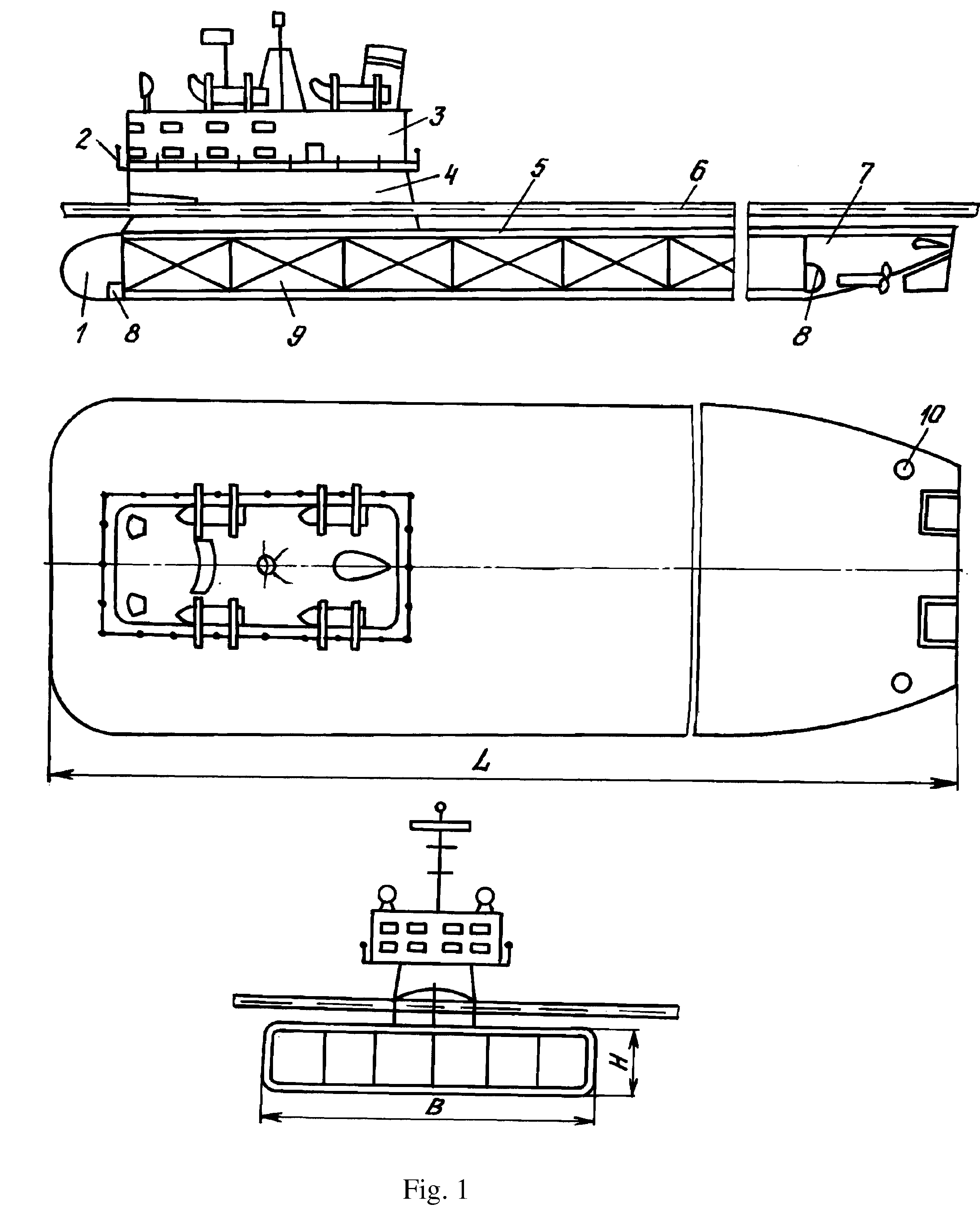

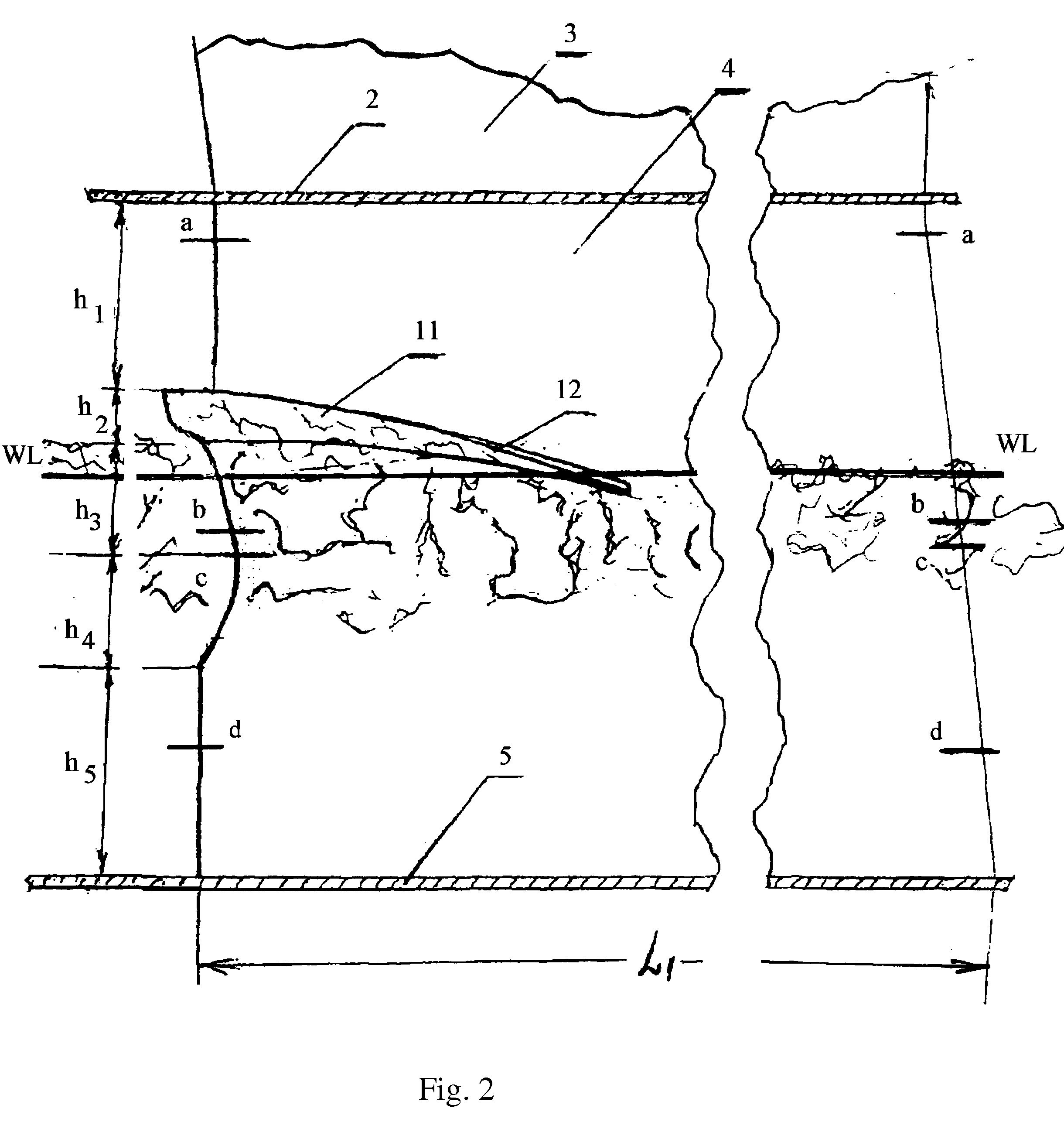

Arctic heavy-tonnage carrier and ice-resistant pylon for connecting the ship underwater and above-water bodies

The invention applies to shipbuilding dealing with the construction of Arctic heavy-tonnage carriers. The Arctic heavy-tonnage carrier comprises an underwater cargo hull and above-water body in the form of the main deck with a superstructure. The underwater hull is connected to the main deck with an ice-resistant pylon along which the ship load waterline passes and which is located in the fore body of the underwater hull directly behind the forepeak symmetrically related to the center plane of the ship hull. The upper deck of the underwater ship hull has in the area of the pylon a strengthened construction. The pylon structure is a bearing one for the main deck. The underwater hull can be made in the cross-sectional view to the shape of a round-angled rectangle the height of which is 10-12 m and a height-breadth ratio does not exceed 1:6. The underwater hull of said ship has along each side the aft arranged retractable mooring bollard. The ice-resistant pylon for connecting the ship underwater hull to above-water body is executed in the form of a strength longitudinally and transversely framed hull having in the plan view a long and symmetrical shape. The pylon breadth or diameter is significantly less than that of the ship load hull as well as the practical width of channel to be laid by the icebreaker. The pylon height provides the movement of the main deck above the ice surface and underwater hull—beneath the lower ice edge. The invention enables to increase the ship heavy ice-breaking capabilities when going after the icebreaker in the Arctic shelf areas with shallow waters as well as to decrease the ship navigation resistance in broken ice and decrease the height of ship underwater hull.

Owner:JSC SHIPBUILDING & SHIPREPAIR TECH CENT

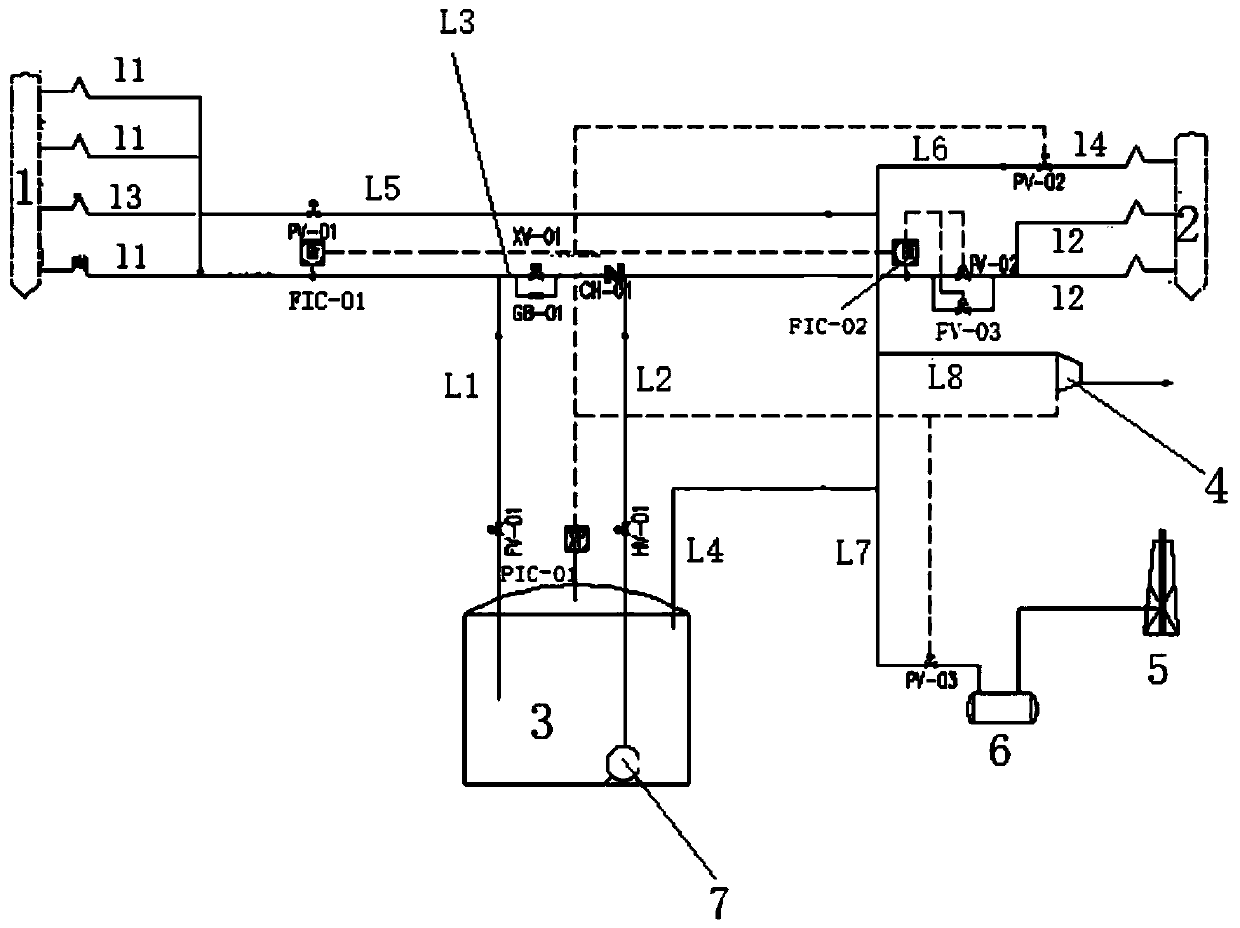

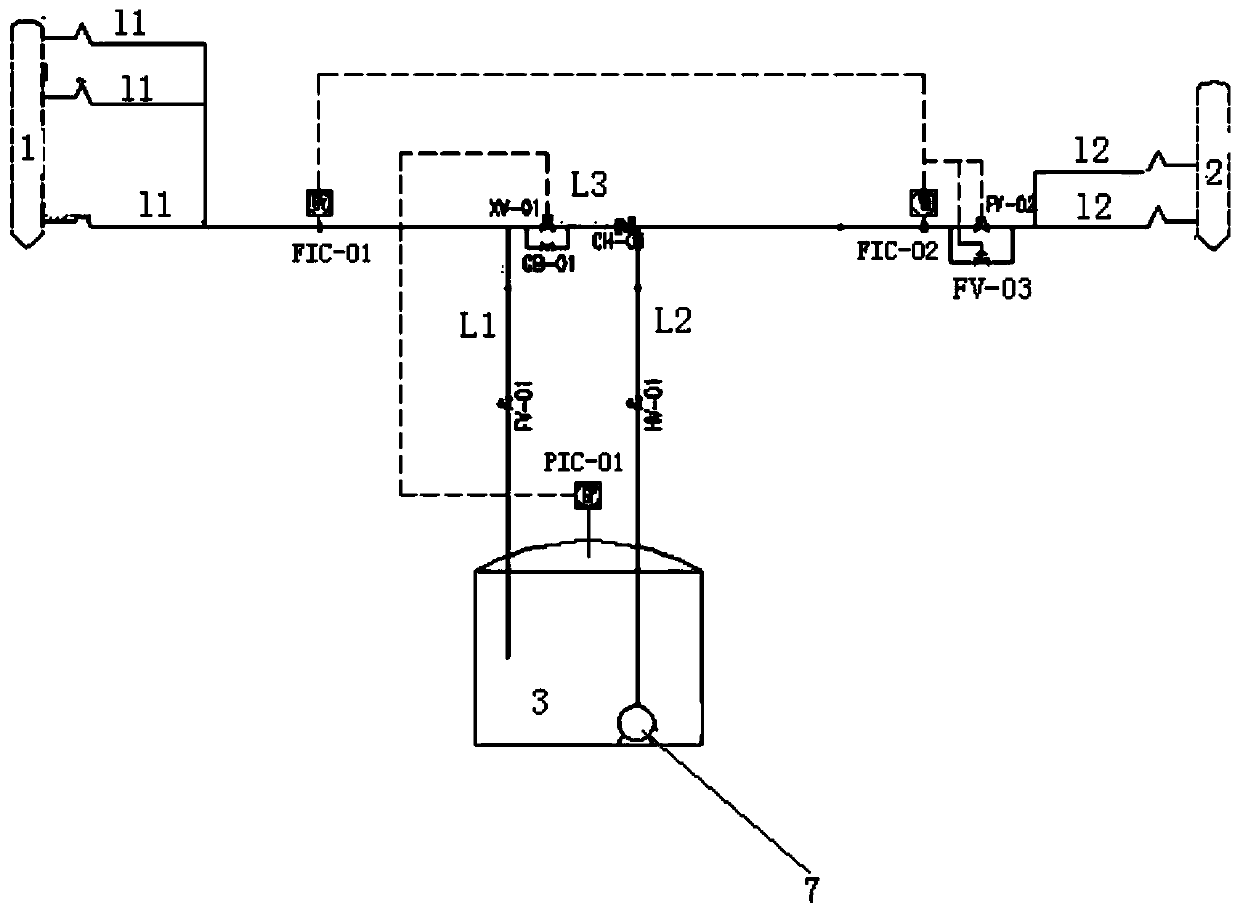

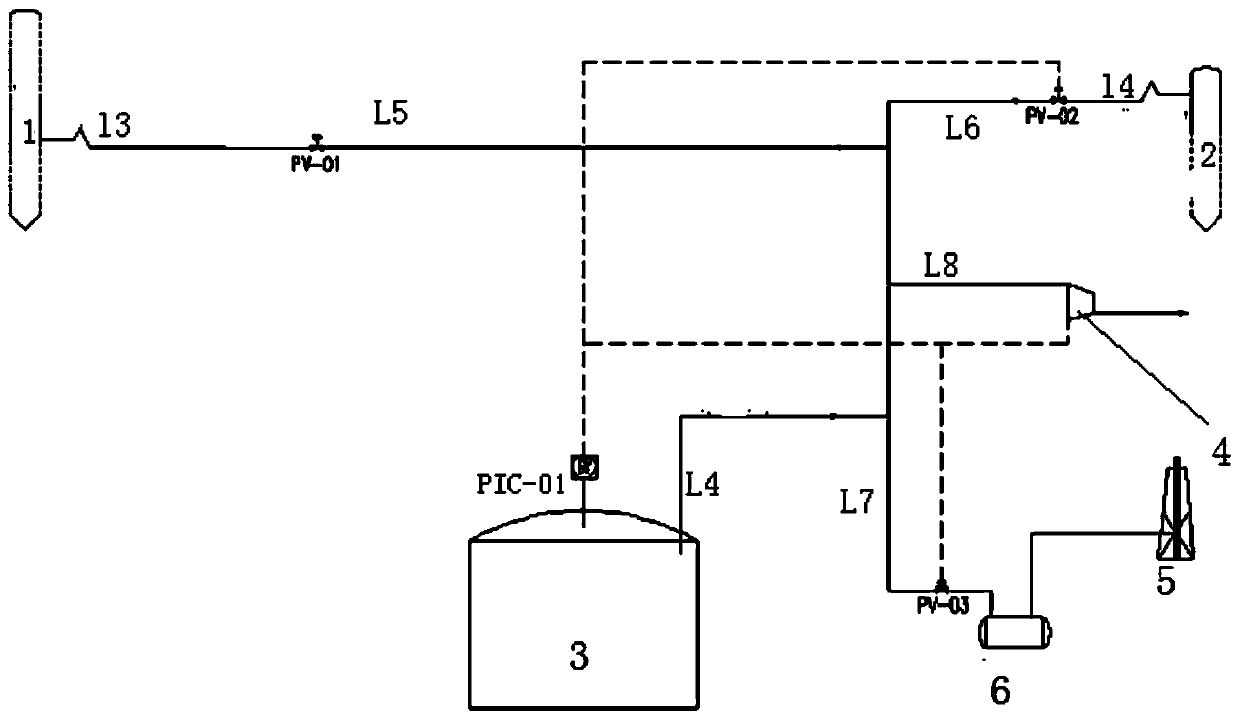

Method and system for realizing simultaneous ship loading and unloading of LNG receiving station

PendingCN111174084AReduce loadRestoration of unloading conditionsWaterborne vesselsGas handling/storage effectsLine tubingControl system

The invention provides a method and system for realizing simultaneous ship loading and unloading of an LNG receiving station. The system comprises a barge pipeline used for being connected with an LNGship loading and unloading pipeline, a pneumatic control switching valve, a BOG compressor, an LNG storage tank, a torch control system and a corresponding LNG pressure control system. One part of LNG unloaded from a first LNG transport ship is unloaded to the LNG storage tank through a normal unloading pipeline, and one part of LNG passes through the barge pipeline and is unloaded to a second LNG transport ship by controlling the flow through an adjusting valve arranged on a ship loading pipeline. Meanwhile, the pressure of a cabin is matched with the pressure of the LNG storage tank at a fixed value. Under an emergency condition, the gas phase pressure of the top of the LNG storage tank realizes interlocking to shut down an XV valve on the barge pipeline to restore the single ship unloading process. In addition, on the one hand, the load of the BOG compressor is adjusted through pressure control, and on the other hand, a certain quantity of BOG is released to a torch through a PV control valve in front of the torch, so that the pressure of a whole BOG system remains stable. Interlocking of the whole control system is realized mainly through a pressure sensor, a transmitter and aPLC hard wire.

Owner:XINDI ENERGY ENG TECH

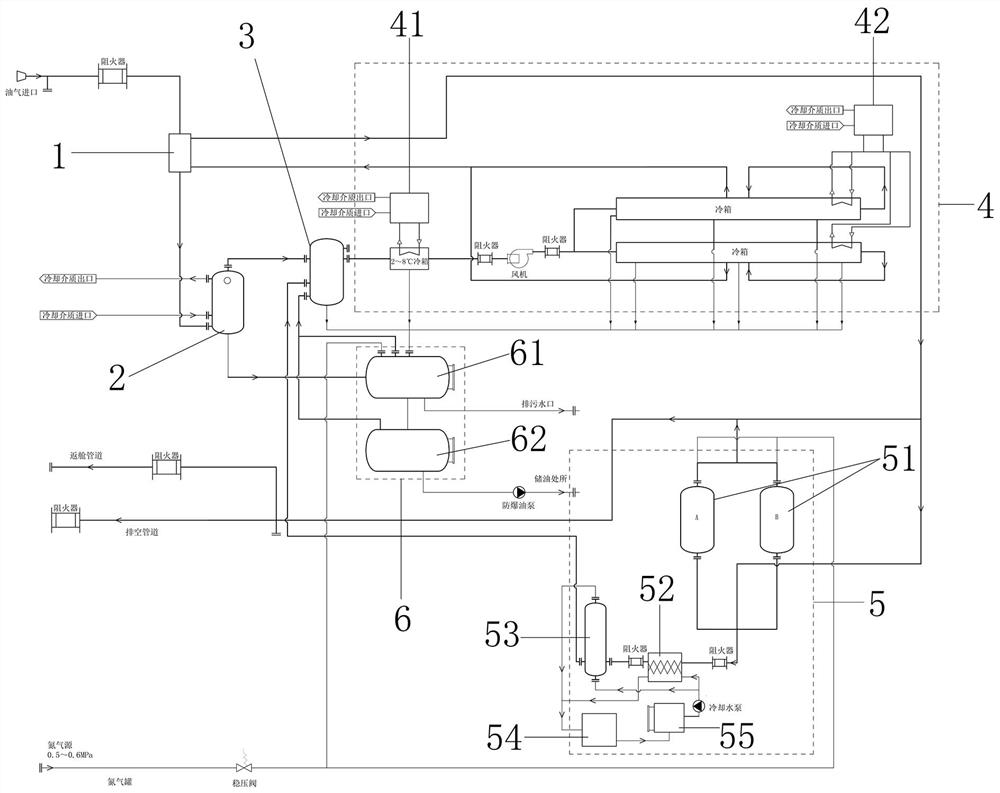

Multi-stage condensation, adsorption and cabin returning treatment capacity adjustable oil gas recovery device

PendingCN112870754AMultiple-effect/fractional condensationDispersed particle separationVacuum pumpPollution

The invention discloses a multi-stage condensation, adsorption and cabin returning treatment capacity adjustable oil gas recovery device which comprises a precooling heat exchanger, a desulfurizing tower, a buffer tank, a multi-stage condensing unit, an adsorption device and an oil-water separation device, the multi-stage condensing unit comprises a first-stage refrigerating unit and a deep cooling unit, and the adsorption device comprises two adsorption tanks connected in parallel and a vacuum pump. The oil-water separation device comprises an oil-water separator and an oil storage tank, solves the problem of emission of high-concentration and large-treatment-capacity oil gas generated in transportation and wharf ship loading operation of crude oil, reduces the problem of huge economic loss caused by oil gas emission, and reduces the problem of environmental pollution of the ocean and areas around the wharf. And potential safety hazards caused by oil gas emission to production and life are reduced.

Owner:NANTONG YATAI ENG TECH

Dual-motor coaxial gas-electric hybrid ship power system

InactiveCN109878675AMeet power needsImprove economyPower plants using propulsion unit combinationsTransmission with mechanical gearingShoreElectric power

The purpose of the invention is to provide a dual-motor coaxial gas-electric hybrid ship power system. The system includes a gas engine, a generator, motors, a storage battery, a fuel cell, clutches,a gear case, a propeller, a natural gas storage and supply device, substation devices, a shore power device, a ship power grid, and a ship load. The gas engine is connected to the gear case through the clutch. The first motor and the second motor are connected to the gear case through the clutches. The generator is connected to an output end of the gear case. The two motors are connected to each other through a shaft. An electric power source is the storage battery, the generator and the fuel cell. The dual-motor coaxial gas-electric hybrid ship power system adopts a plurality of energy form arrangements, has a plurality of working modes, can meet requirements of ships in various environment and working conditions, can maintain the gas engine and the motors in a high efficiency zone all the time, reduces the fuel consumption and discharge of the gas engine, improves the power response of ships, and enlarges seaworthiness of the ships.

Owner:HARBIN ENG UNIV

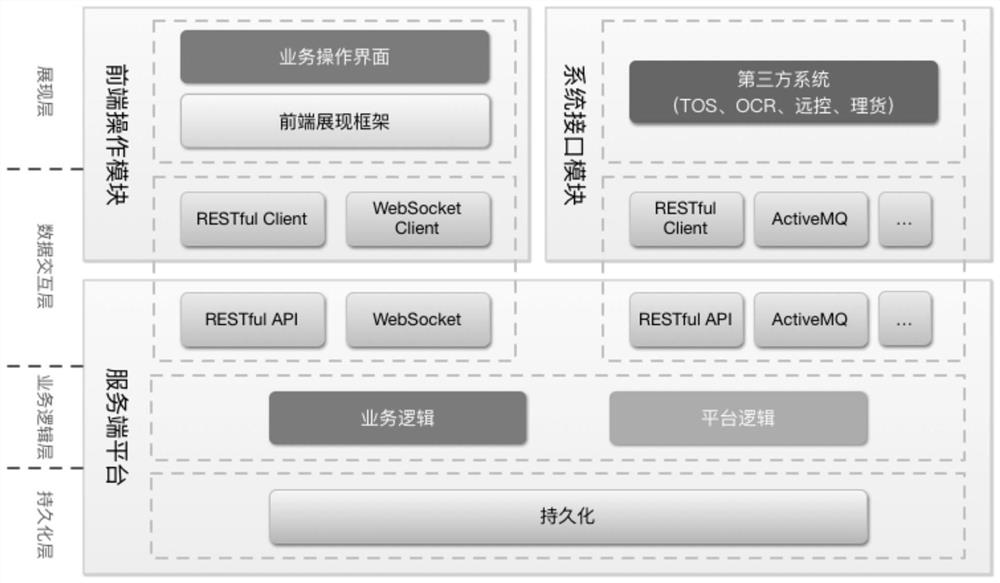

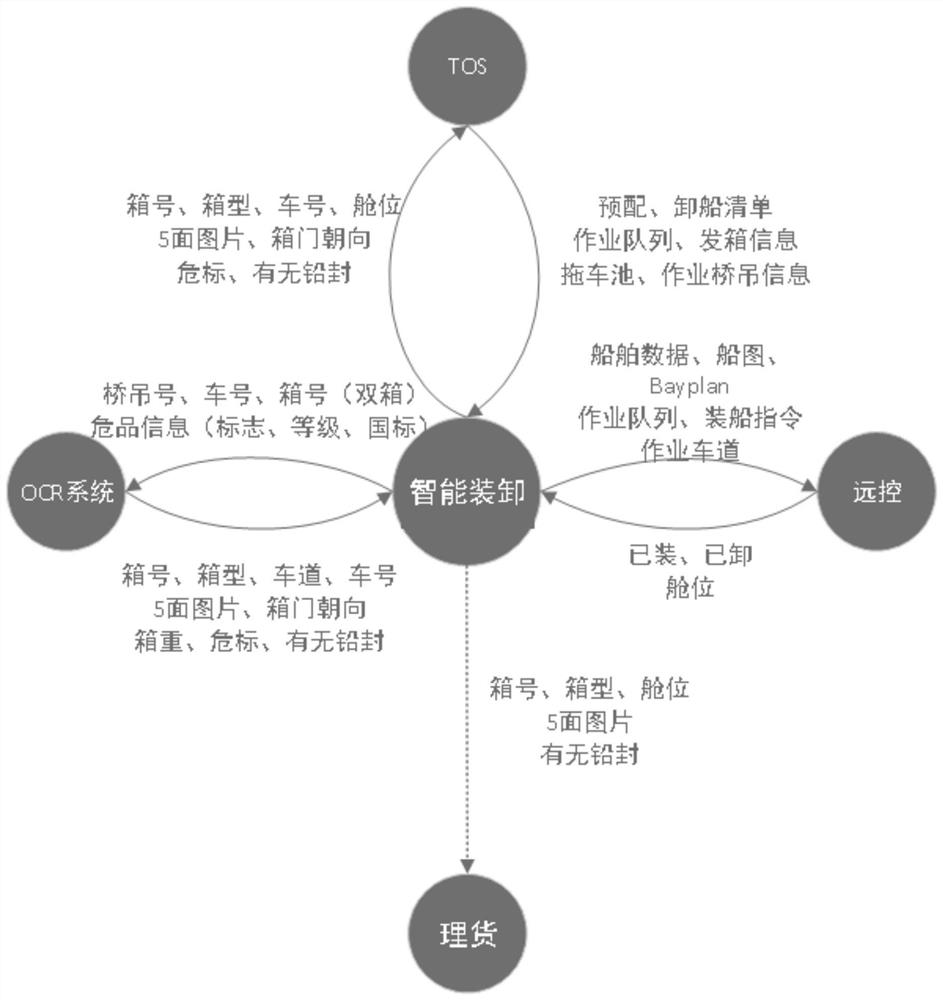

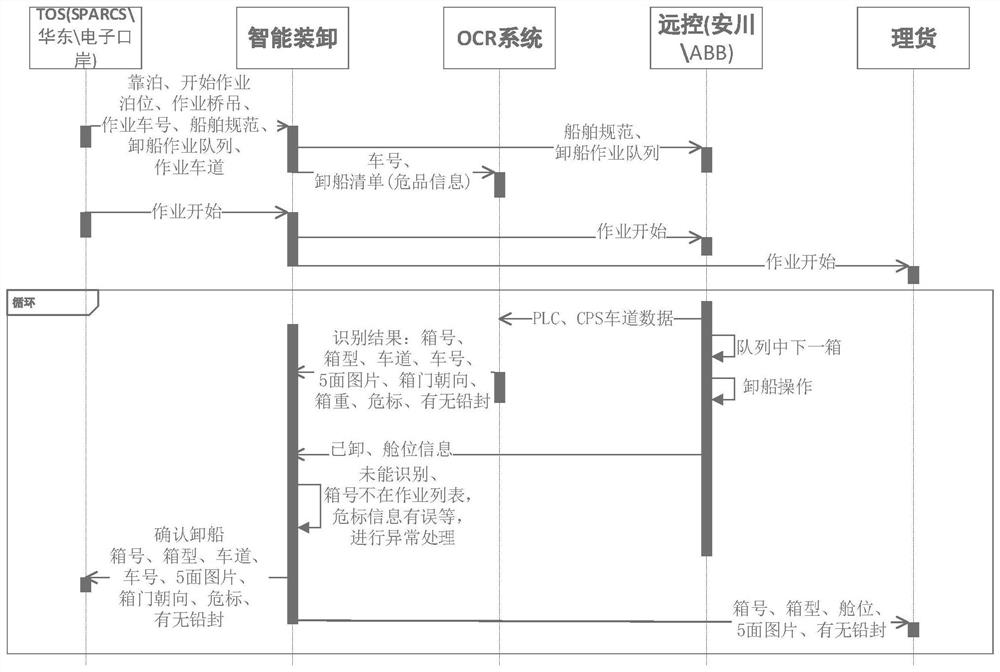

Intelligent loading/unloading platform and loading/unloading method

ActiveCN112707178ARealize unified schedulingFacilitate unified schedulingStorage devicesRemote controlControl engineering

The invention discloses an intelligent loading / unloading platform and a loading / unloading method. The intelligent loading / unloading platform comprises a TOS system interface module, a remote control system interface module, an OCR system interface module, an intelligent cargo tallying system interface module, a backstage server and a remote-control data handling-over operation module, wherein the TOS system interface module is used for acquiring ship loading / unloading operation data from a TOS system; the remote control system interface module is used for acquiring operation state information from the remote control system; the OCR system interface module is used for receiving an identification result of the OCR system; the intelligent cargo tallying system interface module is used for pushing operation state information to an intelligent cargo tallying system after ship loading or unloading; the backstage server is used for realizing data storage, data interaction among the all interface modules and submitting the data to the all systems according to loading / unloading operation service processes; and the remote control data handling-over operation module is used for matching the result obtained through identification of the OCR system with the ship loading / unloading operation data of the TOS system, acquiring the operation state information after ship loading / unloading and conveying the operation state information to the TOS system. According to the intelligent loading / unloading platform and the loading / unloading method disclosed by the invention, unified deployment access of a plurality of docks is supported, the situation that handling-over operation of shipsides of the all docks can be carried out in a centralized way in one operation center can be realized, and unified dispatching of operators at the each dock is conveniently realized.

Owner:XIAMEN CONTAINER TERMINAL GRP CO LTD

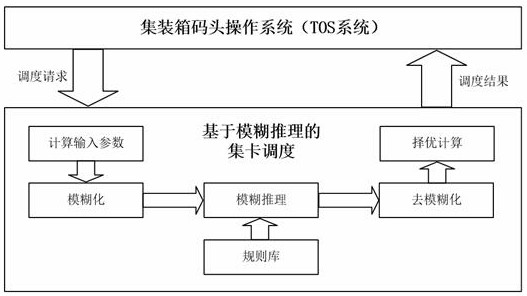

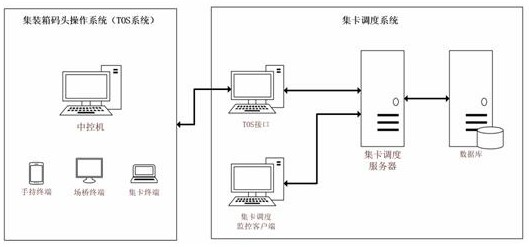

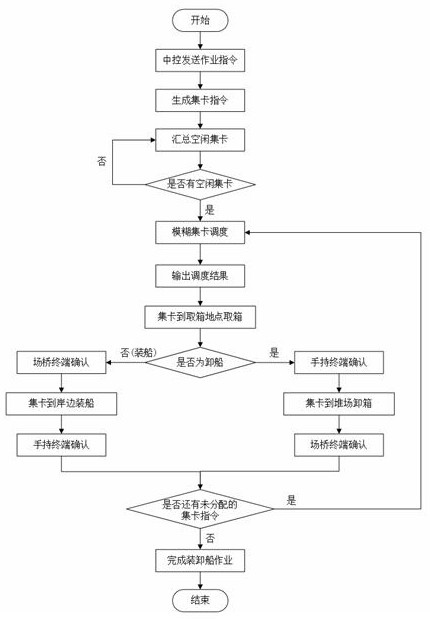

Container truck dispatching method based on fuzzy reasoning

ActiveCN112070296AReduce travel timeShorten driving distanceForecastingResourcesFuzzy ruleFuzzy reasoning

The invention discloses a container truck dispatching method based on fuzzy reasoning, and the method is characterized in that the method comprises the following steps: deploying an operation system,setting an optimal path of an operation region, defining an input parameter, setting a fuzzy rule, requesting container truck dispatching by a container wharf operation system, carrying out the container truck dispatching calculation, and executing a container truck dispatching result by the container wharf operation system. According to the method, a fuzzy mathematics method is adopted to realizethe operation dispatching of the container trucks, the ship loading and unloading efficiency is improved, the ship period is shortened, the operation efficiency of the container trucks is greatly improved, the number of the container trucks is controlled, the production cost is reduced, the wharf traffic flow is reduced, and the safety coefficient is improved.

Owner:广州南沙联合集装箱码头有限公司

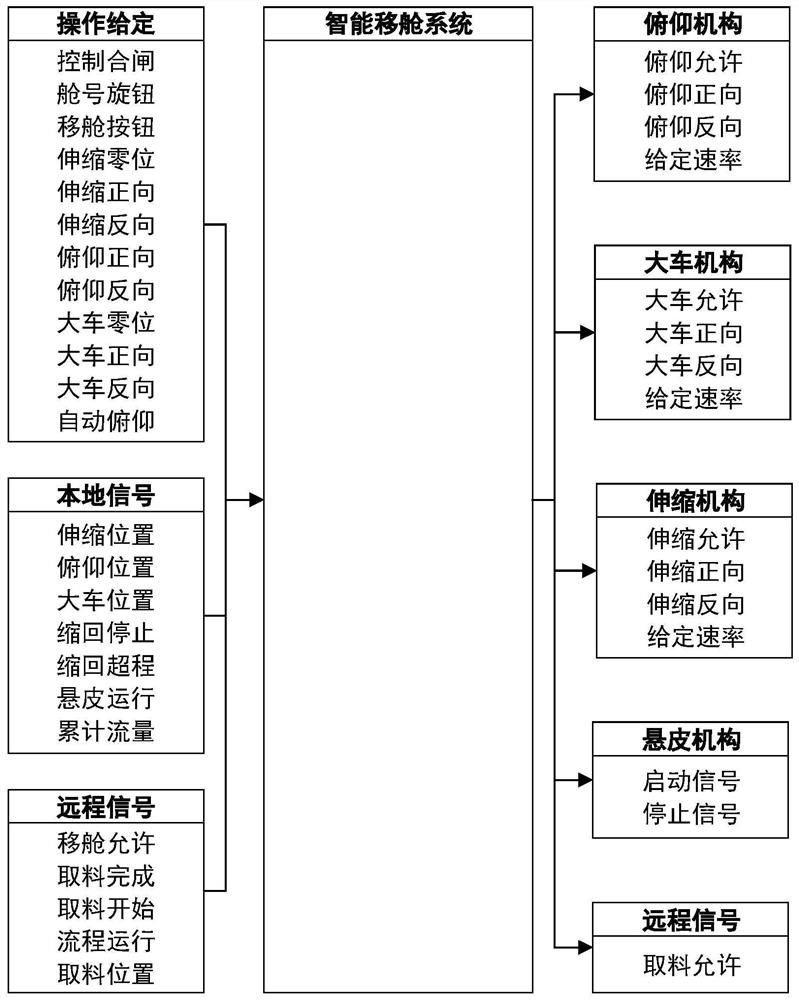

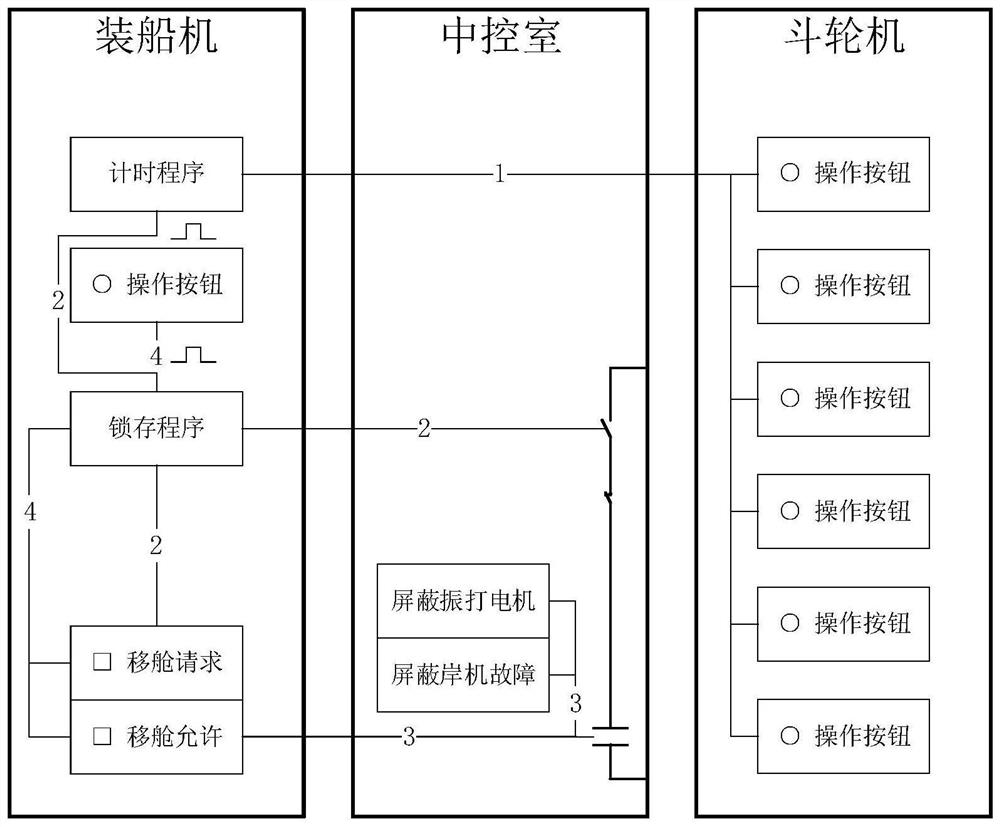

Intelligent cabin moving method and system for ship loader

ActiveCN111873884AAccurate calculationLow retrofit costDashboard fitting arrangementsItem transportation vehiclesTransfer switchMachine

The invention discloses an intelligent cabin moving method and system for a ship loader. The method comprises the steps that cabin opening calibration is completed, cabin moving confirmation is conducted, cabin moving operation is completed, automatic advanced feeding of a bucket wheel machine is achieved, and the cabin moving operation is completed through a five-section cabin moving algorithm. The system is installed on a cab operation table and comprises a plurality of change-over switches, a button switch used for defining setting and running and a PLC program used for processing the method. The ship loading device is used for saving the cabin moving time, so that the problems of high-altitude material scattering caused by too early material requirement and operation efficiency reduction caused by too late material requirement are solved, and the ship loading efficiency is effectively improved.

Owner:TANGSHAN PORT GRP

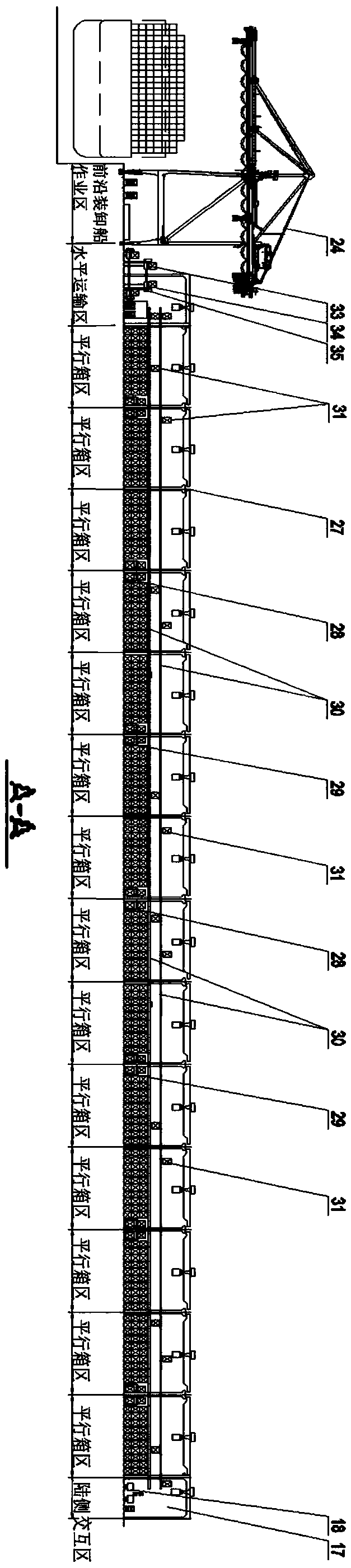

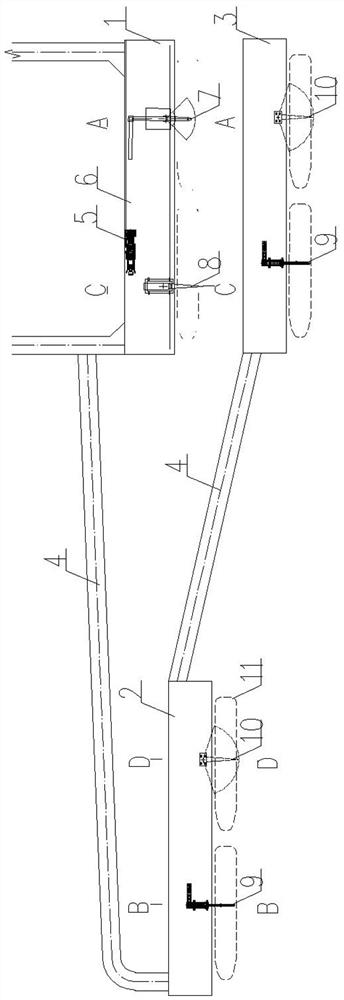

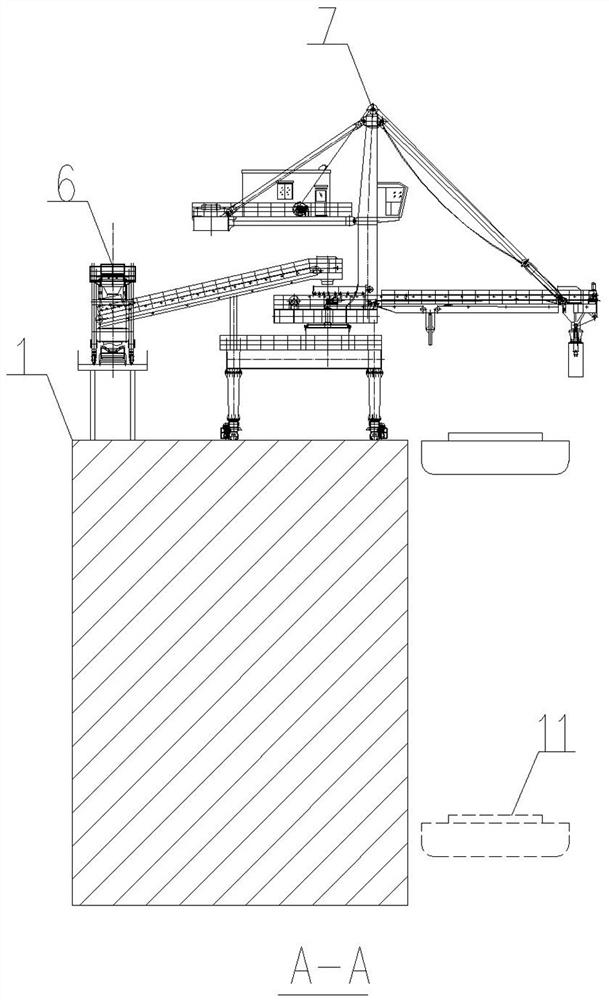

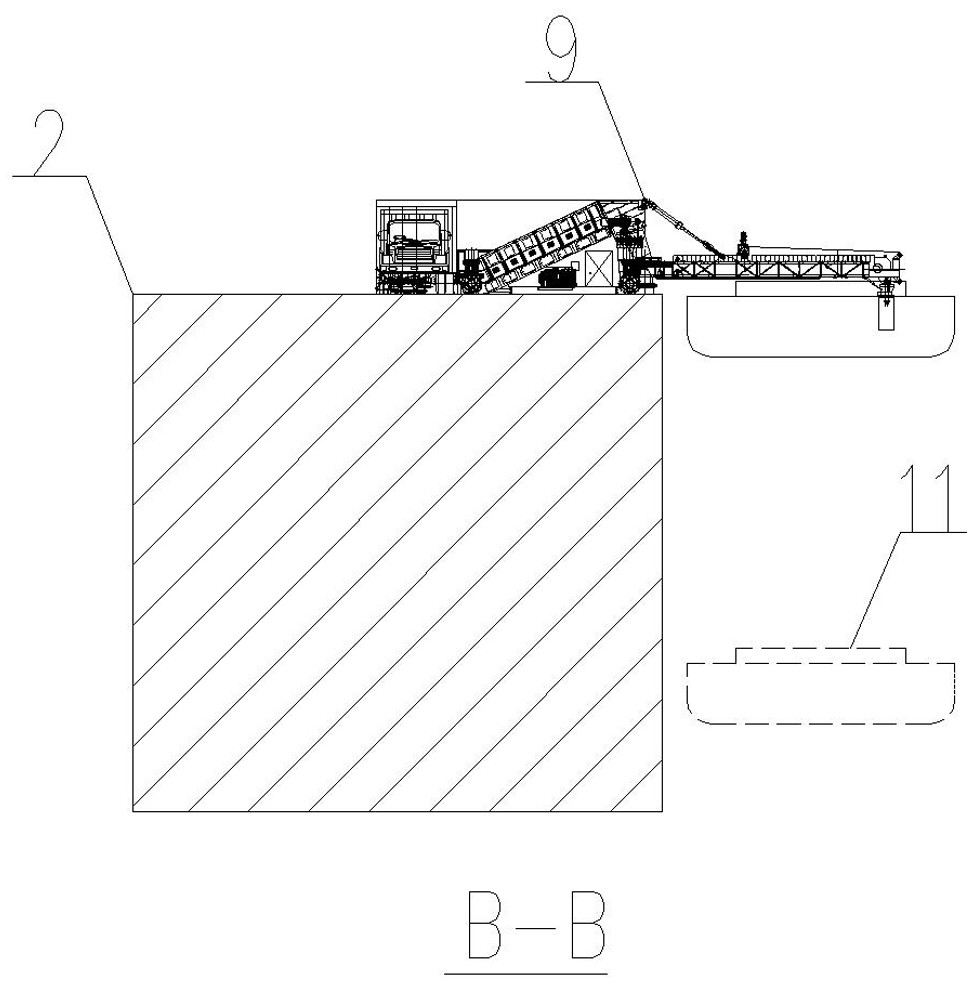

Dry bulk cargo wharf loading and unloading process system and method suitable for ultra-large water level difference

PendingCN113371473ASolving Bulk Cargo Handling and Unloading Ship ProblemsEconomical and reasonable loading and unloading processStorage devicesBulk cargoEarth surface

The invention relates to a dry bulk cargo wharf loading and unloading process system and method suitable for an ultra-large water level difference. The invention is suitable for the technical field of dry bulk cargo wharf engineering, in particular to a dry bulk cargo loading and unloading ship wharf with 60-meter water level difference for a large hydropower station reservoir area. According to the technical scheme, the dry bulk cargo wharf loading and unloading process system suitable for the ultra-large water level difference is characterized by being provided with a high-water-level loading and unloading platform, a middle-water-level loading and unloading platform and a low-water-level loading and unloading platform which are located at different elevations, and the loading and unloading platforms communicate with one another through connecting roads; a ship loading berth of the high-water-level loading and unloading platform is provided with an earth surface feeder, a belt conveyor and a rail ship loader, and a ship unloading berth of the high-water-level loading and unloading platform is provided with a portal crane with a grab bucket; the ship loading berths of the medium-water-level loading and unloading platform and the low-water-level loading and unloading platform are both provided with truck unloading ship loaders, and the ship unloading berths of the medium-water-level loading and unloading platform and the low-water-level loading and unloading platform are both provided with rubber-tyred cranes with grab buckets.

Owner:POWERCHINA HUADONG ENG COPORATION LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com