Method for detecting height of materials by bulk cargo automatic ship loading detector

A detection device and material technology, applied in the direction of measuring device, engine lubrication, lubrication indicator device, etc., can solve the problem of long measurement time, and achieve the effect of easy implementation and simple and effective operation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

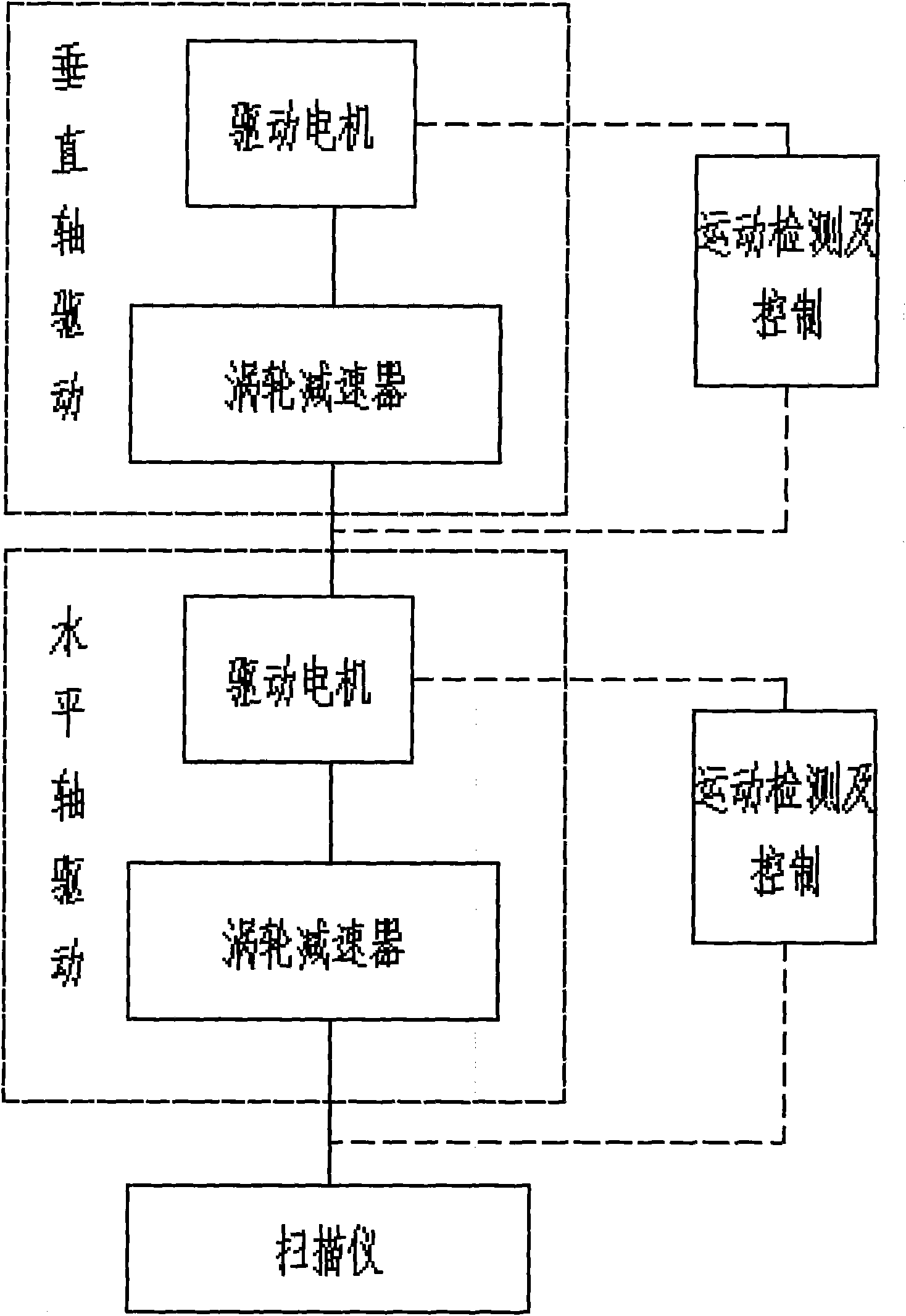

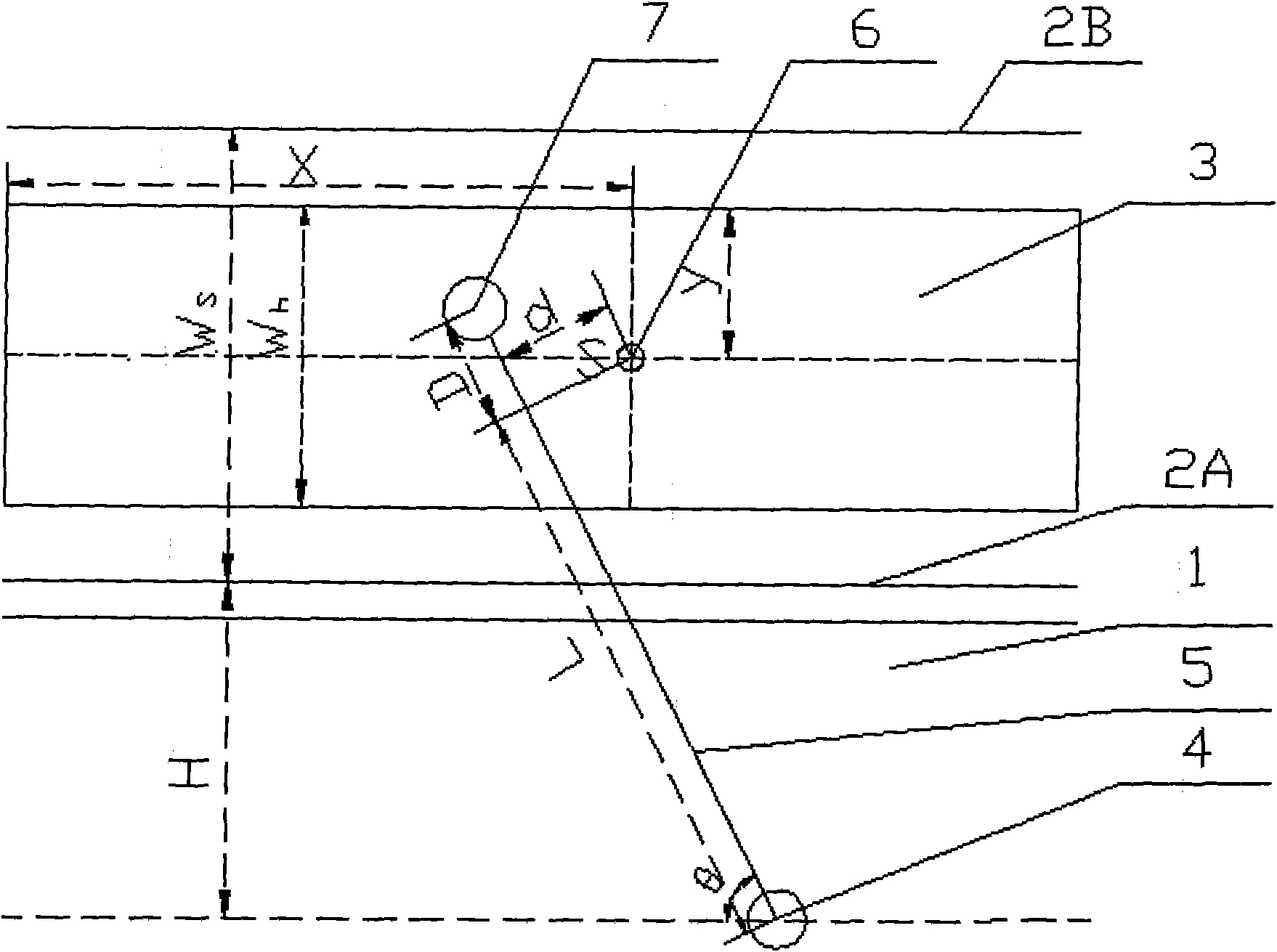

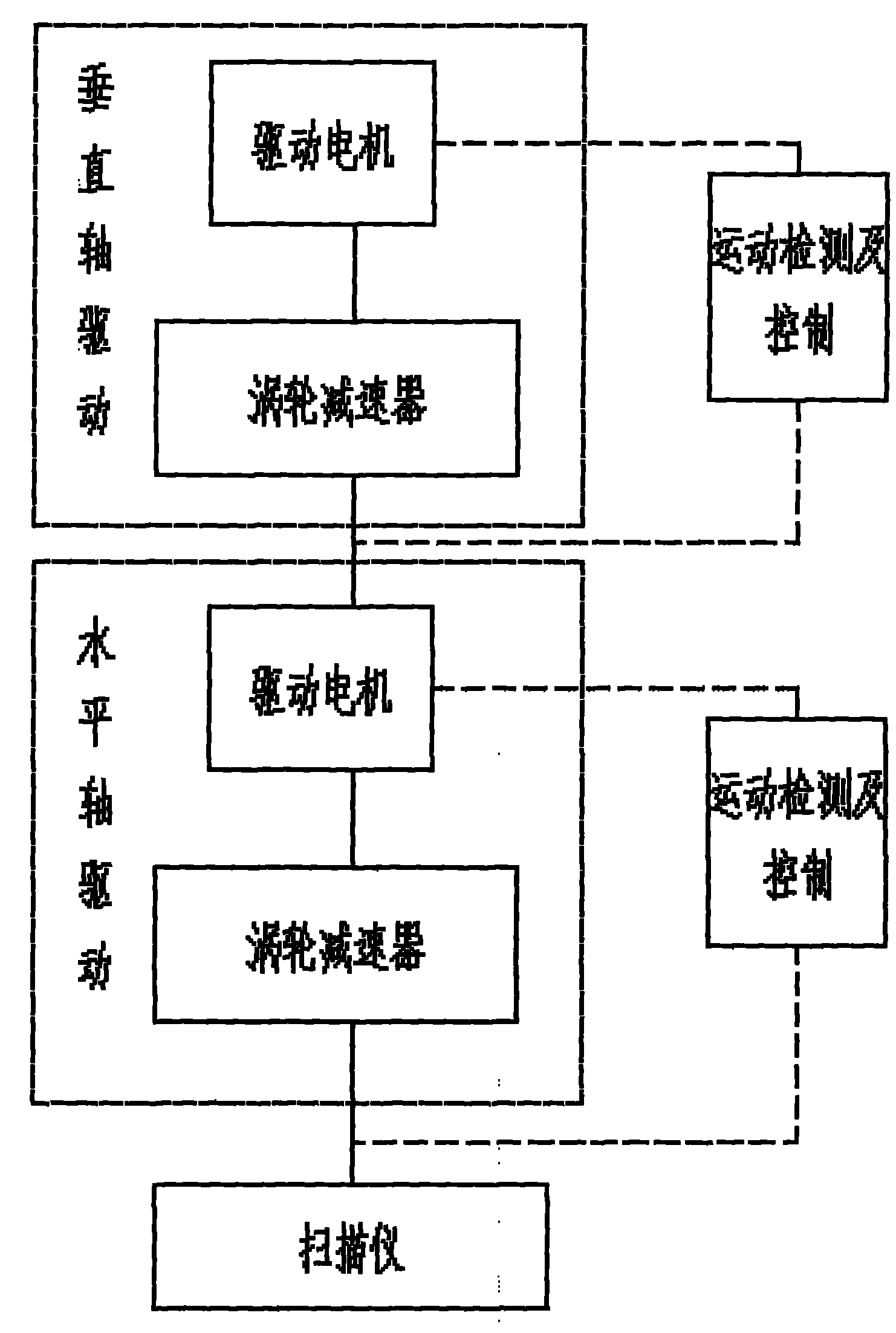

[0038] The bulk cargo automatic loading detection device and method of the present invention are used to measure the positional relationship between the loading mechanism and the ship and the feeding situation, that is, the relative positional relationship between the chute of the shiploading machine and the cabin and the height of the material during feeding. The ship system provides these data to complete the automatic shipment.

[0039] The present invention will be described below in combination with specific embodiments.

[0040] Install the device on the telescopic mechanism of the bulk cargo ship loader so that it can move to the top of the cabin to detect the cabin and materials. It is a more suitable choice to install it on the front end of the fixed arm. figure 2 . Define the 0-degree position of the scanning plane rotation angle of the scanner, and make the vertical axis of rotation coplanar with the scanning plane of the scanner and the axis pass through the optic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com