Arctic heavy-tonnage carrier and ice-resistant pylon for connecting the ship underwater and above-water bodies

a technology of arctic heavy-tonnage carriers and pylons, which is applied in the direction of icebreakers, waterborne vessels, special-purpose vessels, etc., can solve the problems of reducing the choice of cargo transportation methods, reducing the speed of ships to them, and ineffective ice-breaking assistance, so as to reduce the resistance of ship navigation, reduce the area of ice belts, and reduce the height of underwater hulls

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

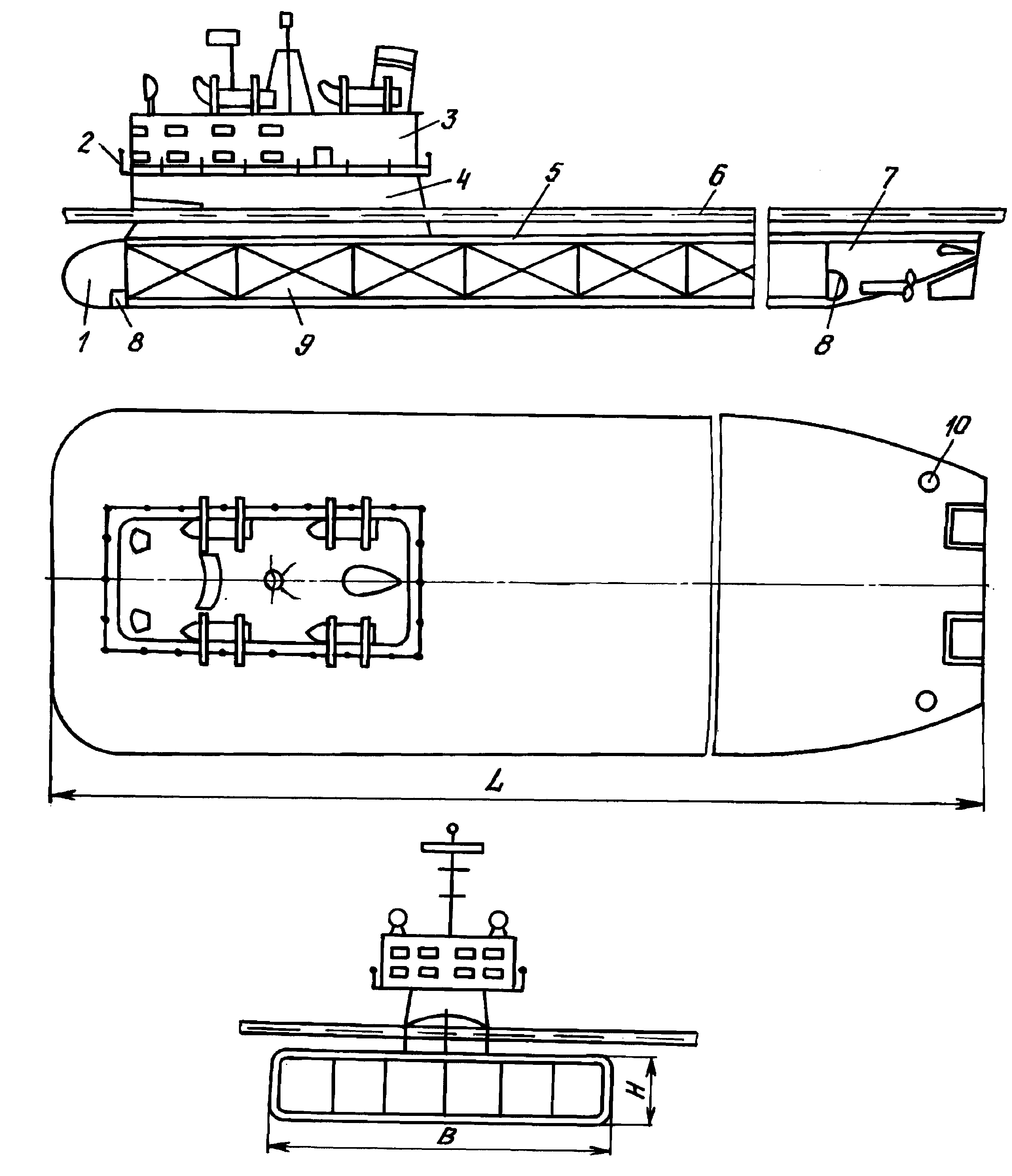

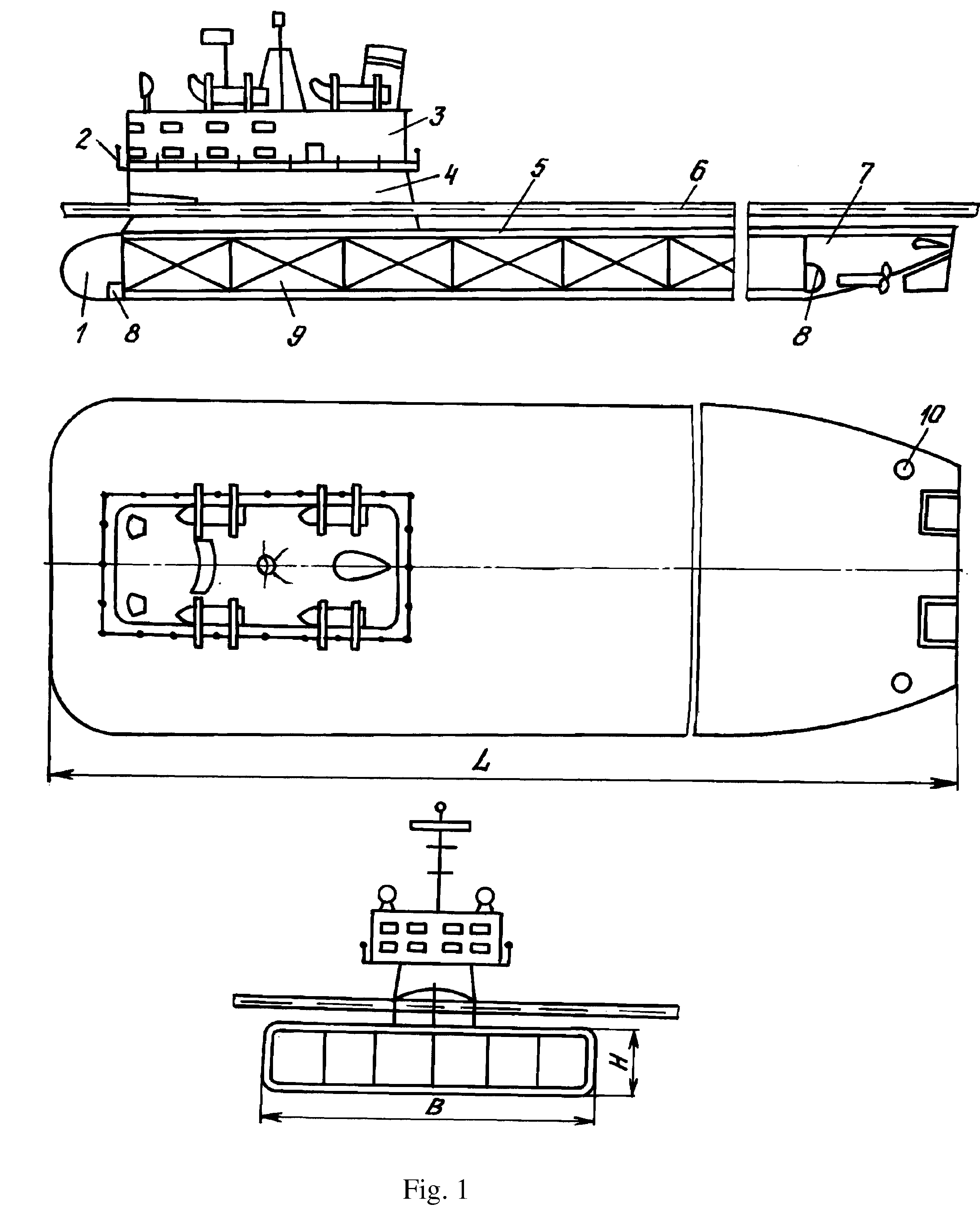

[0025]The Arctic heavy-tonnage carrier is a triple-hulled structure (FIG. 1), the principal particulars of which are forepeak 1, main deck 2, superstructure 3, pylon 4, upper deck of underwater hull 5, ice field (broken ice) 6, machinery compartment 7, steering gear 8, cargo-fuel tanks 9 and retractable bollards 10; L, B, H—length, breadth and height of underwater hull.

[0026]For the claimed ship the cargo to be carried is stowed in underwater hull 5 having dimensions providing the requisite carrying capacity and capability for navigating in the restricted depth conditions of Arctic shelf. Owing to shallow operating depth of the ship the underwater hull does not require a strengthened version except the area of upper underwater hull deck to be connected with the pylon.

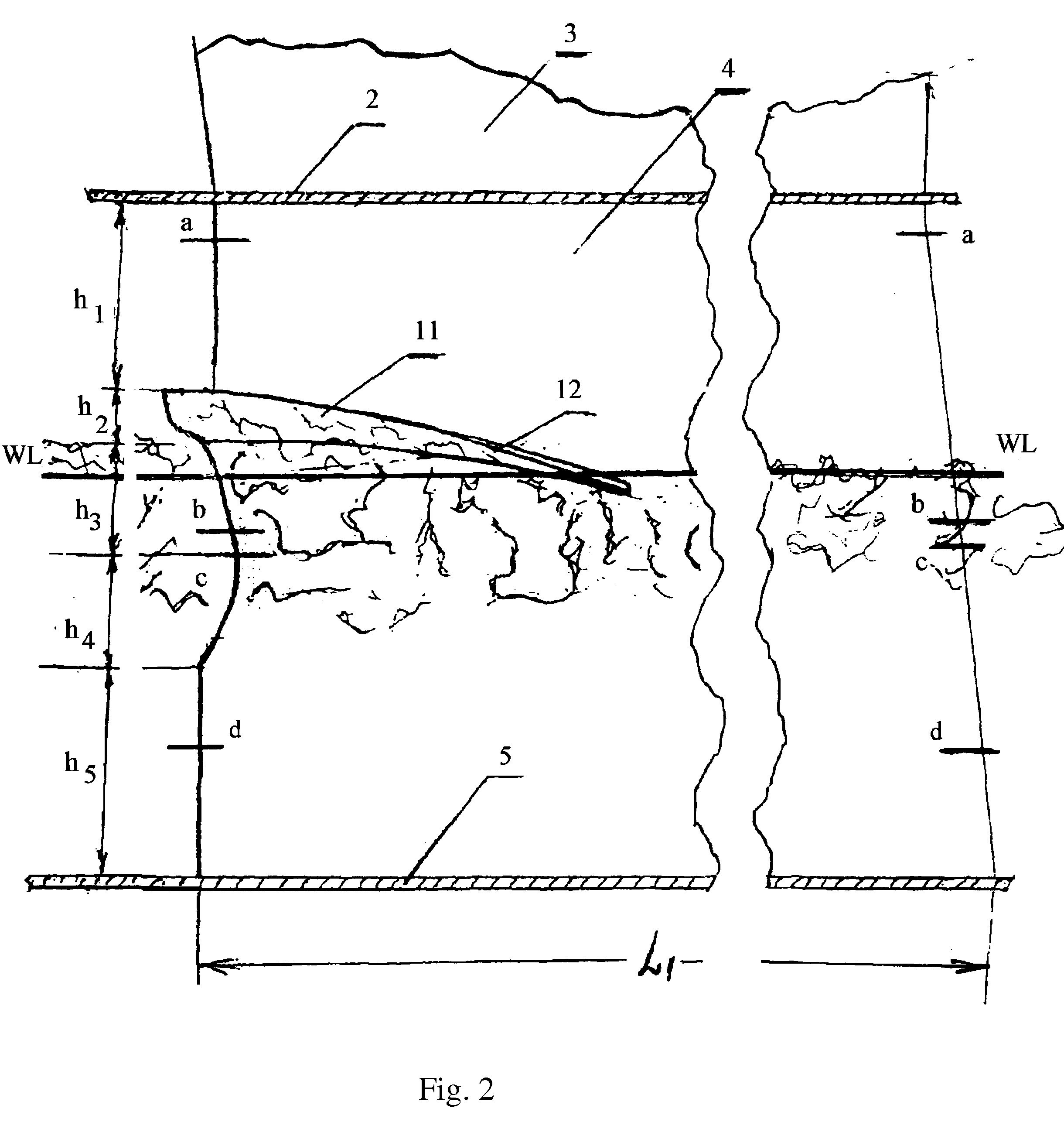

[0027]The pylon height must be sufficient to provide navigation of underwater hull 5 beneath the ice and above-water body 2—above the ice surface. In case of freezing the pylon 4 in the ice field its height and trapezoi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com