Intelligent cabin moving method and system for ship loader

A ship loader and cabin moving technology, which is applied in the fields of motor vehicles, loading/unloading, transportation and packaging, etc., can solve the problems of reduced operation efficiency and high operation intensity, and achieves easy operation, accurate calculation of required materials, and low cost of transformation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

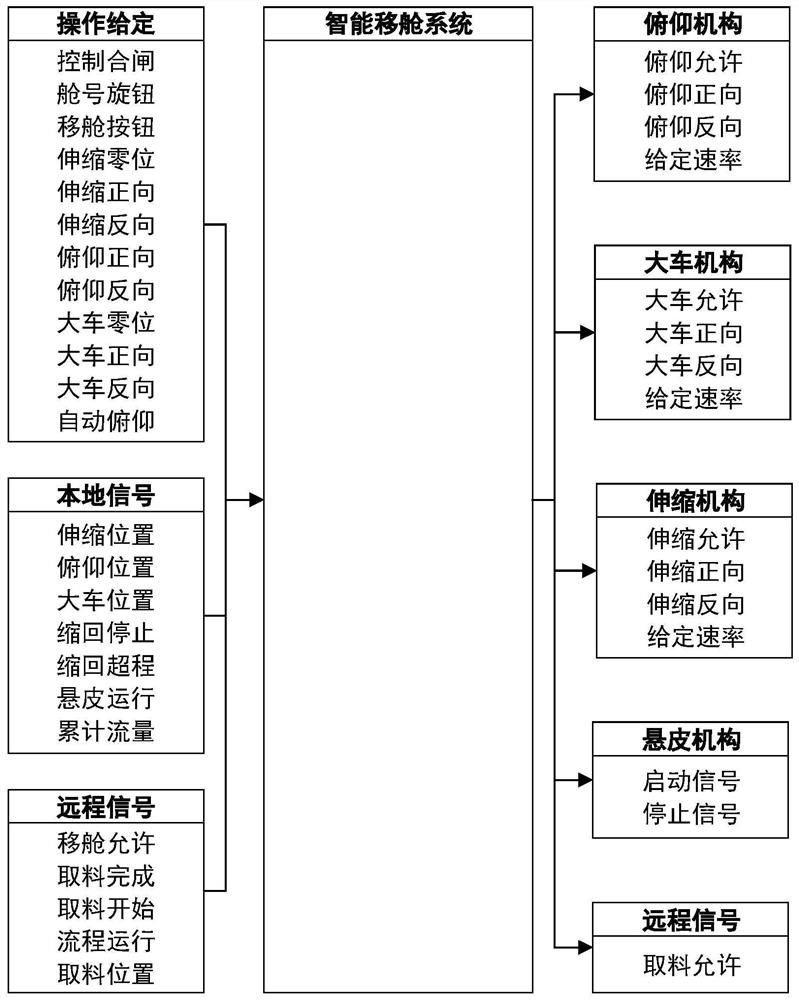

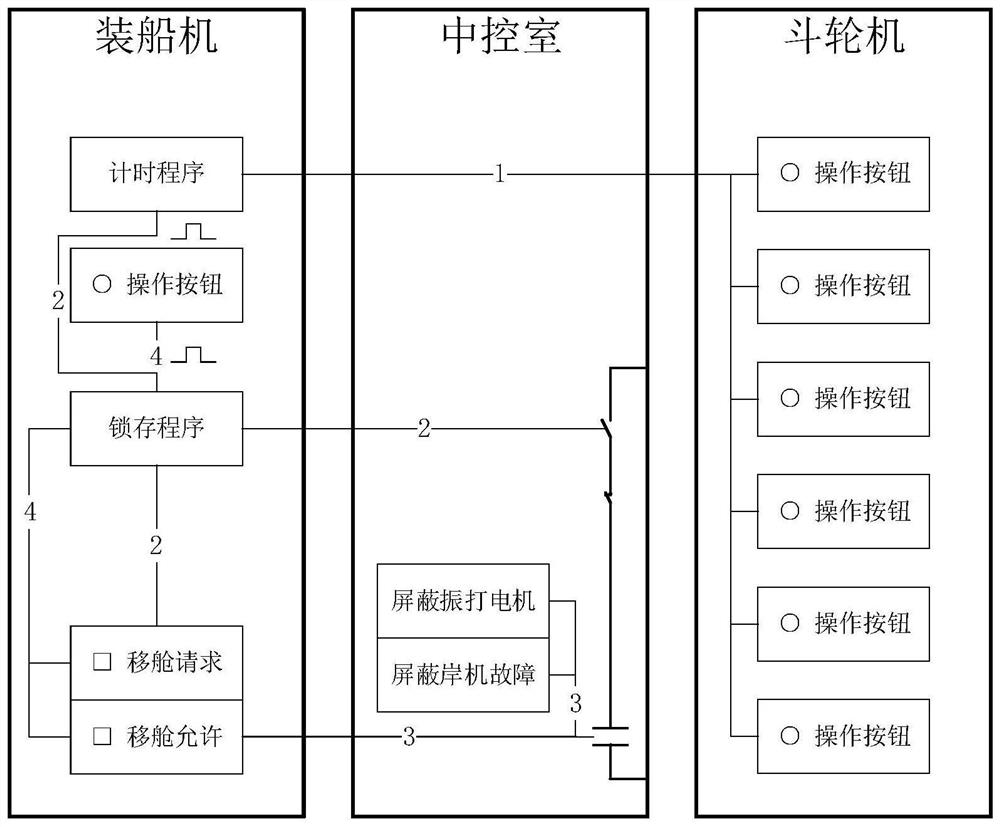

[0025] Realizing an embodiment of the present invention requires the following necessary hardware settings:

[0026] An intelligent cabin shifting system for a ship loader. A button switch is set on the operating console of the driver's cab to realize the setting and operation functions. In the non-tank shifting stage, pitching is close to the position of the safety hook. Clicking is defined as system reset. Clicking near the position of the hatch cover is defined as opening calibration, long press for a few seconds during the non-tank removal stage is defined as winch offset setting, and single-click definition during the tank removal stage is defined as the operation of the tank removal system;

[0027] Set an 8-position switch for selecting the cabin number, and the 8 gears correspond to 1-8# hatches;

[0028] Set a 2-position switch for hatch type calibration, and the 2 gears correspond to vertical and flat covers;

[0029] Set a 2-position switch for obstacle type calibr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com