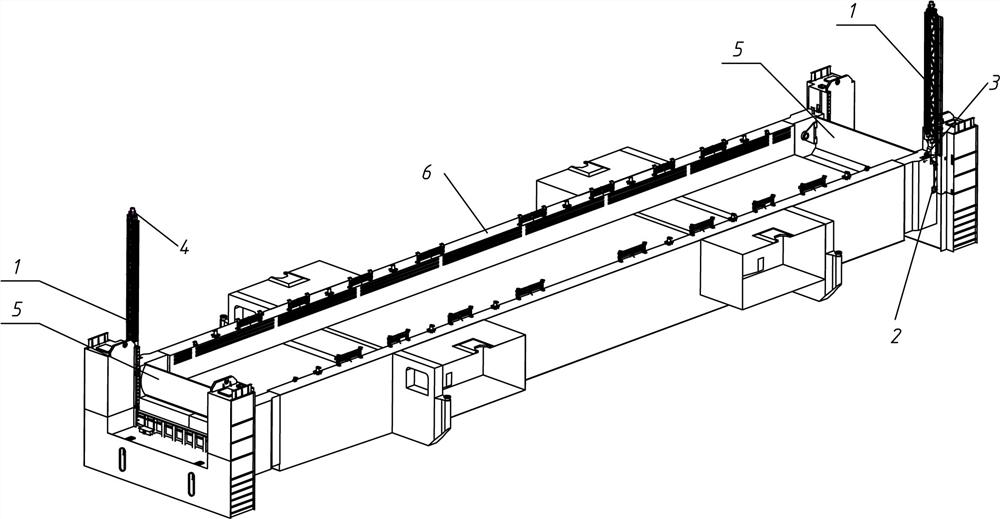

Rapid maintenance method and maintenance platform for ship compartment door of ship lift

A technology for repairing platforms and ship lifts, which is applied to vertically lift ship machinery, ship lifting devices, buildings, etc., and can solve problems such as increased construction costs, large differences in layout locations and environments, and long repair time, so as to save maintenance and construction The effect of reducing costs, shortening the time of outage for maintenance, and improving construction safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

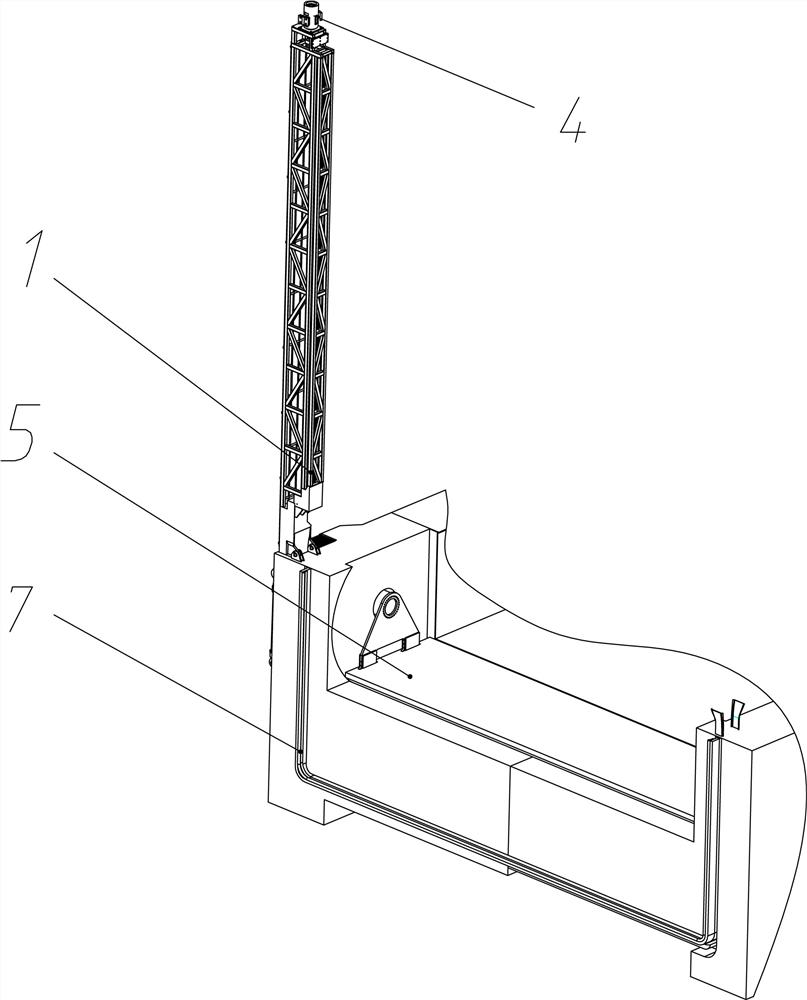

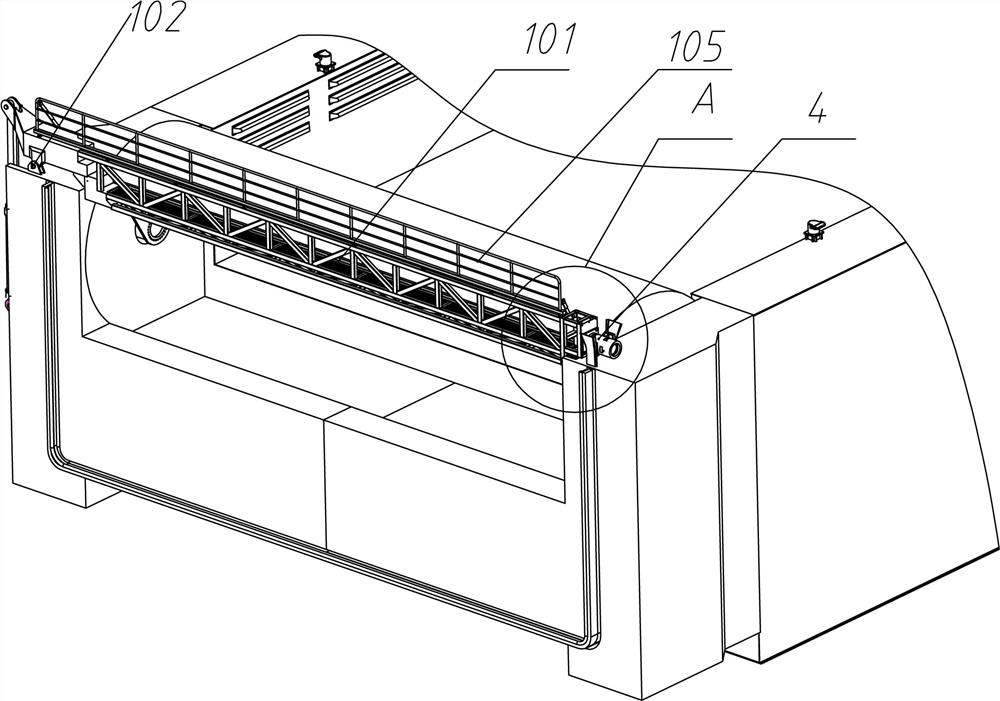

Method used

Image

Examples

Embodiment 1

[0076] When the upstream water level is 175m, take the maintenance of the upstream cabin door as an example to describe the quick maintenance method of the cabin door of the ship lift.

[0077] Step 1): Check that the water seal at the upstream butt joint sealing frame of the ship compartment is reliable and no defects are found. When the upstream water level is 175m, place 8 sections (3.5 meters high each) on the upper lock head to overhaul the stacking beam door and a section (high 12m) inspection door, the elevation of the bottom sill of the upstream channel is 141m, the elevation of the top of the upstream inspection door is 181m, the highest water level may appear in the upstream of 175m, and the top elevation of the upstream inspection door exceeds the maximum water level of the upstream by 6 meters, which can prevent the upstream water from overflowing the inspection block Accidents caused by water gates;

[0078] Step 2): Run the ship lift cabin to the upstream docking...

Embodiment 2

[0091] Take the downstream cabin door maintenance when the downstream water level is 73.8 meters as an example to describe the quick maintenance method of the ship lift cabin door.

[0092] Step 1): Check that the water seal at the downstream docking sealing frame of the ship compartment is reliable and no defects are found. When the downstream water level is 73.8m, drop the first 8 sections of the lock (each section is 3.25m high) to overhaul the stacking beam doors, and the bottom sill of the downstream channel If the elevation is 58 meters, the elevation of the top of the downstream inspection door is 84m, and the highest water level in the downstream may be 73.8m. The elevation of the top of the downstream inspection door exceeds the maximum water level of the downstream by 10.2 meters, which can prevent accidents caused by the downstream flooding over the inspection water retaining door;

[0093] Step 2): Run the ship lift cabin to the downstream docking position, stop the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com