Remote monitoring, diagnosis and prediction and intelligent maintenance control system for hydraulic turbine

A remote monitoring system and intelligent maintenance technology, applied in the transmission system, mechanical equipment, measuring devices, etc., can solve the problems of inability to accurately identify the failure mode and location of the unit, and the low-efficiency operation of the unit, so as to reduce the probability of downtime maintenance and improve operation. Efficiency, the effect of avoiding under-maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solution of the present invention will be described in further detail below in conjunction with the accompanying drawings. It should be noted that the specific implementation is only a detailed description of the present invention and should not be regarded as a limitation of the present invention.

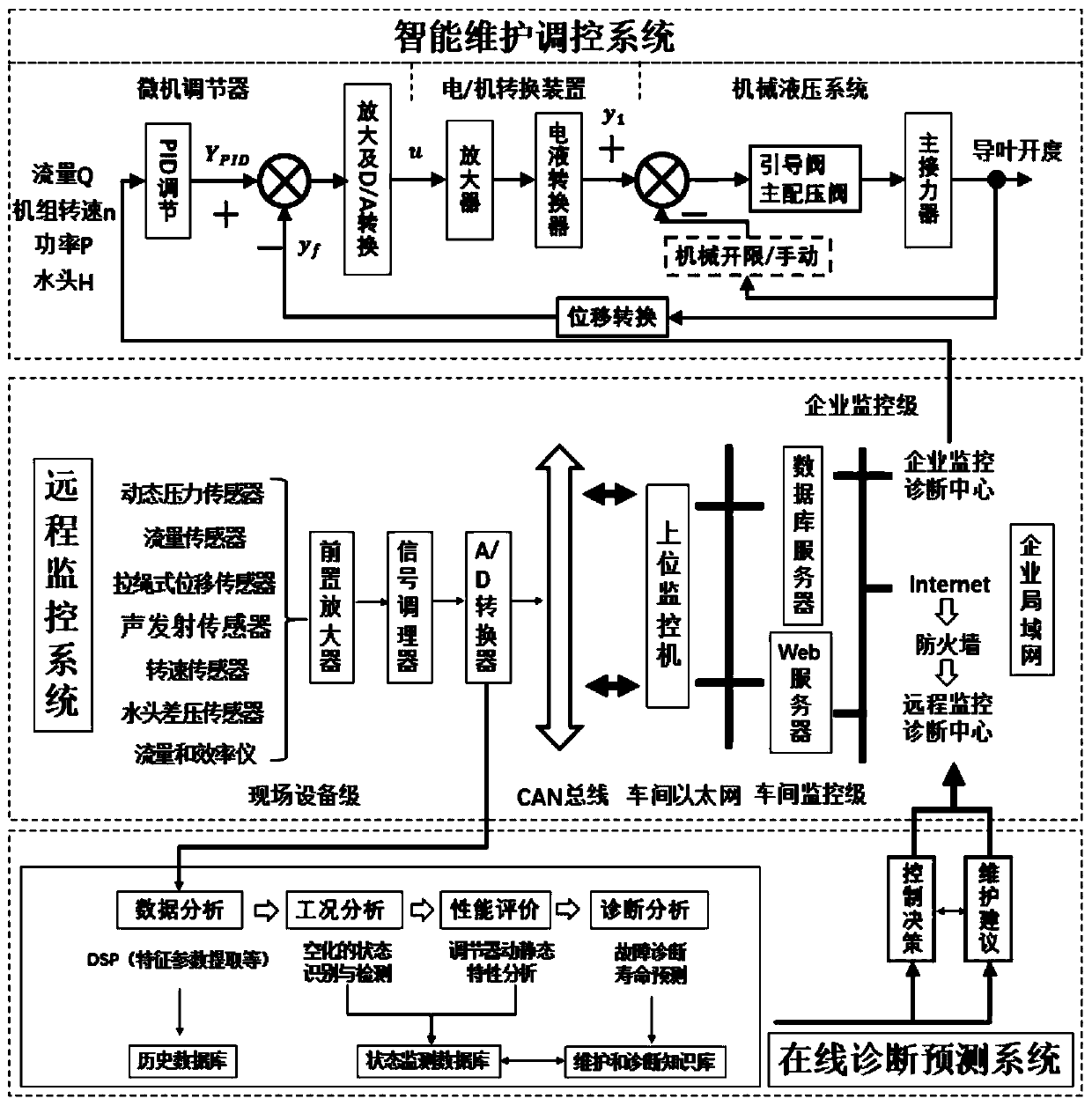

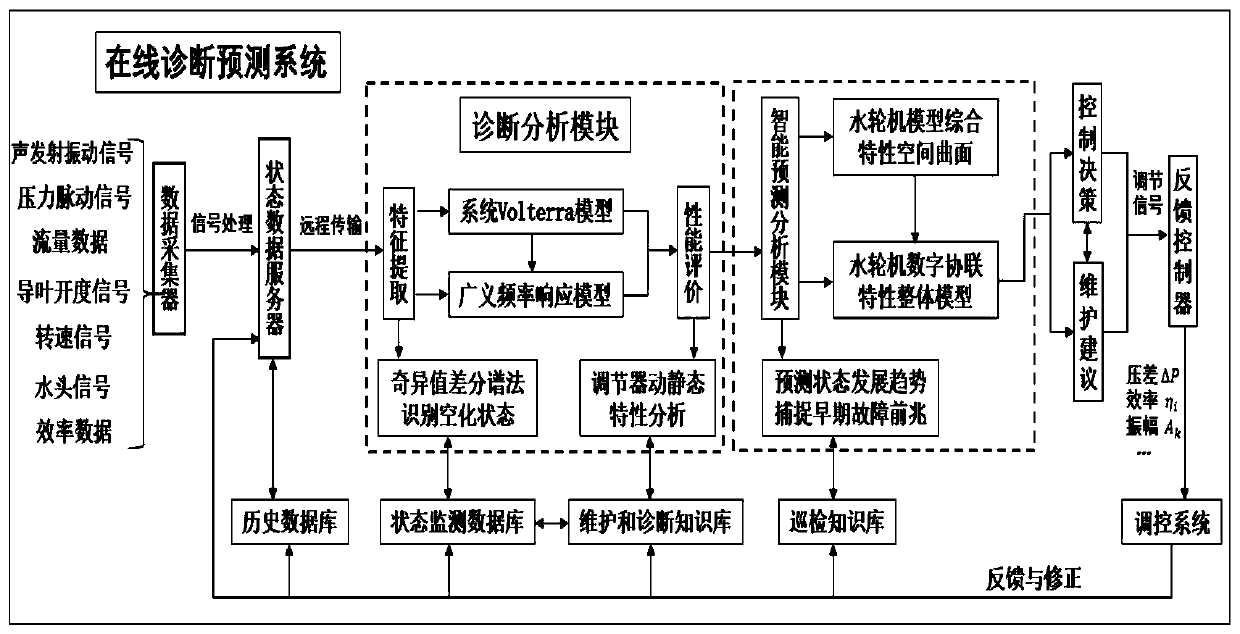

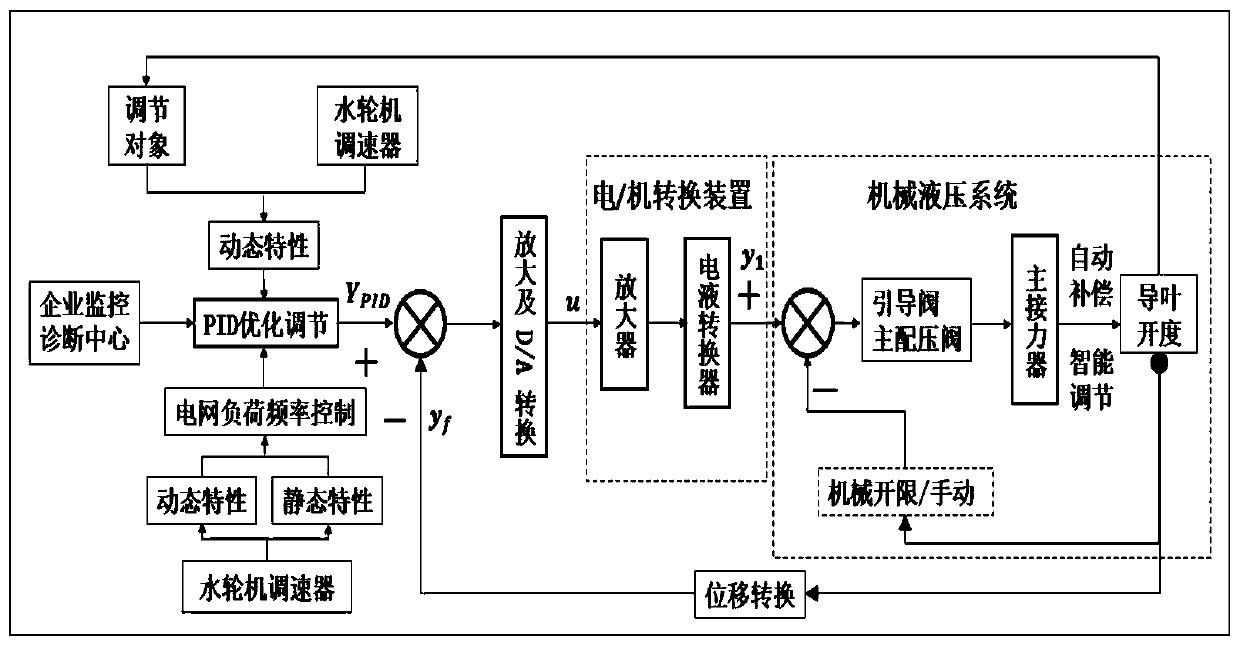

[0026] The hydraulic turbine remote monitoring, diagnosis and prediction and intelligent maintenance control system of the present invention, such as figure 1 As shown, including remote monitoring system, online diagnosis and prediction system and intelligent maintenance control system;

[0027] The remote monitoring system includes dynamic pressure sensor, flow sensor, pull-cord displacement sensor, speed sensor, water head differential pressure sensor, flow and efficiency meter, acoustic emission sensor, preamplifier, signal conditioner, A / D converter, and host monitoring computer, database server, Web server, firewall, enterprise monitoring and diagnosis ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com