Sand-spraying dust-removing equipment

A dust removal equipment and sand blasting technology, which is applied to metal processing equipment, used abrasive processing devices, abrasives, etc., can solve the problems of complex sand and pellet separation devices, increased maintenance costs, and easy damage, and achieves good results. , reduce losses, low maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

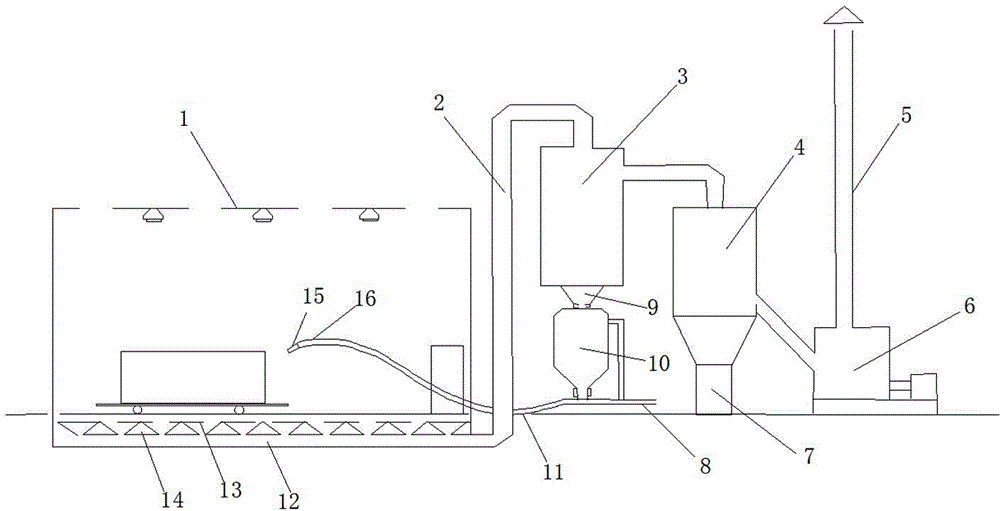

[0009] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0010] The sandblasting and dust removal equipment of the present invention comprises a sandblasting chamber body 1, and the bottom of the sandblasting chamber body 1 is respectively a floor grille 13, a honeycomb recovery floor 14, and a shot transport air duct 12 from the upper layer to the lower layer, The honeycomb recovery floor 14 replaces the common mechanical conveying systems such as deep pit-type hinged dragon scraper, belt, bucket elevator, etc., which saves foundation construction costs and avoids a large number of maintenance workpieces and costs. The pellets, impurities and dust sprayed down from the sandblasting room are recovered by aerodynamic force to the pellet conveying duct 12 under the honeycomb recovery floor 14, and enter the pellet sorting machine 3 through the sand-lifting duct 2 . The pellets are in a suspended state during the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com