Cargo compartment section division design method and cargo compartment sections of 80,000-cubic-level film type LNG (Liquefied Natural Gas) ship

A technology of LNG ship and design method, applied in ship design, ship parts, ship construction, etc., can solve the problems of increasing the pre-outfitting rate of the total section, so as to improve the technological content, increase the pre-outfitting rate, and reduce the difficulty of control Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with specific embodiments in order to understand its structural composition and working method more clearly, but this should not limit the protection scope of the present invention.

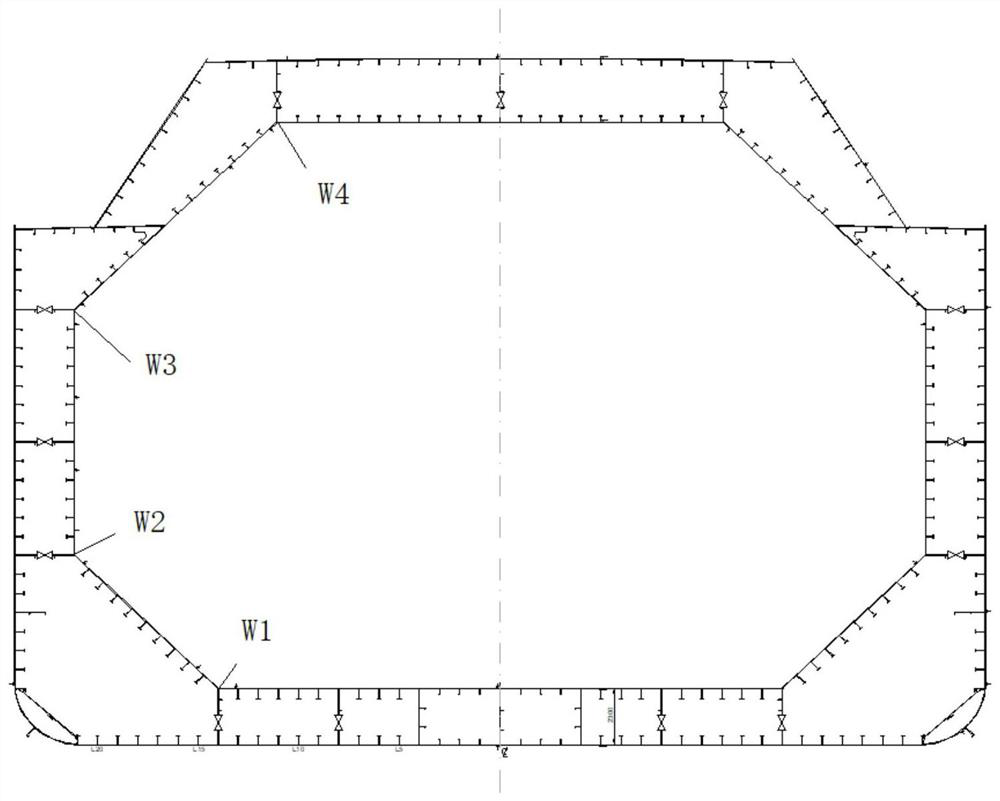

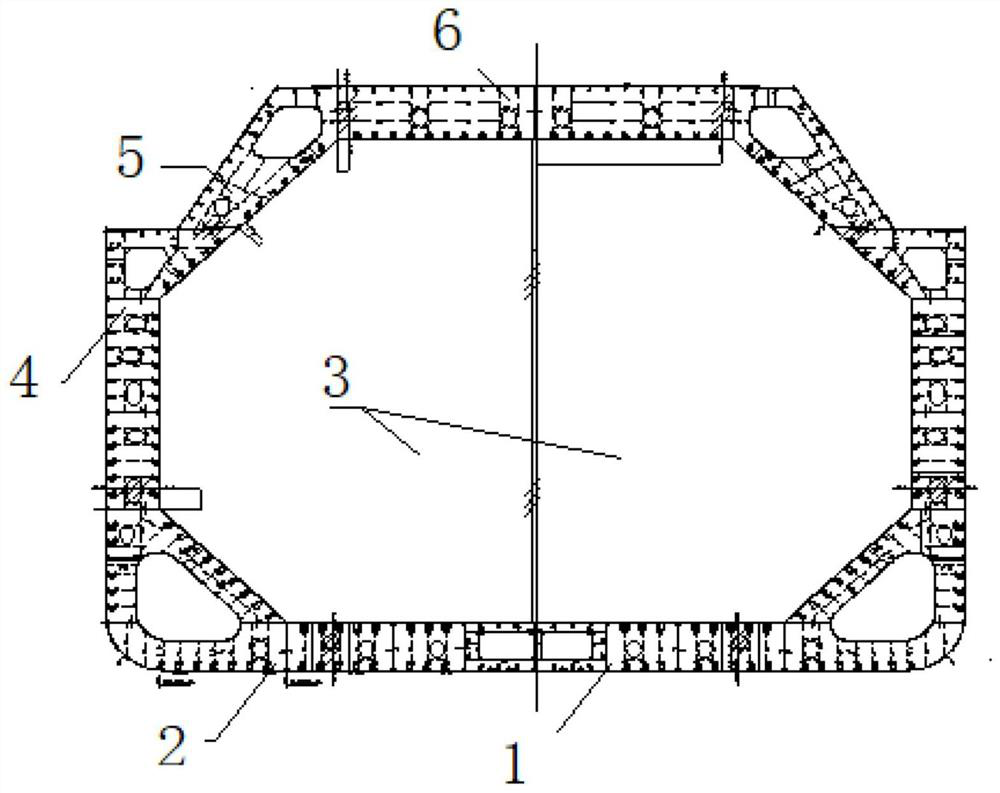

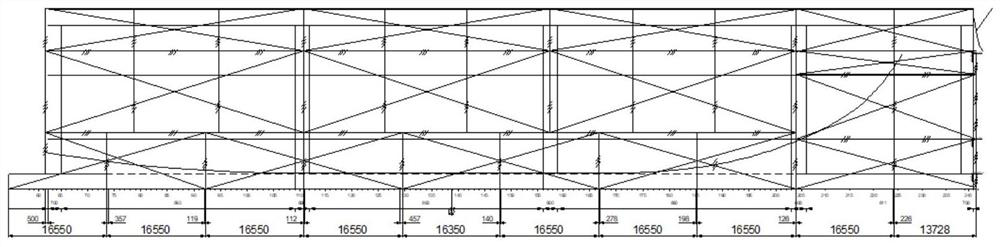

[0037] The dividing principles and requirements of the method of the present invention: 1) to adapt to the upper limit of production factors, the segmental lifting capacity is less than 240 tons, and the total segmental hoisting capacity is less than 960 tons; 2) to meet the challenges brought by the PSPC standard implementation and save dock coating The amount of paint repair tooling should be divided into sections to avoid damage to the paint on the dock as much as possible; 3) The section division of the straight area of the cargo hold should meet the requirements of the assembly line, general tire frame, and segment manufacturing as far as possible; 4) The division line of the cargo hold area should be as far as possi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com