A kind of segmental pre-installation method of ship's side door

A broadside door and ship technology, applied in the direction of ships, etc., can solve the problems of large construction volume, constraints of ship construction plan and cycle, limited hoisting resources, etc., to shorten the construction period, achieve integrity, and improve the effect of resource utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

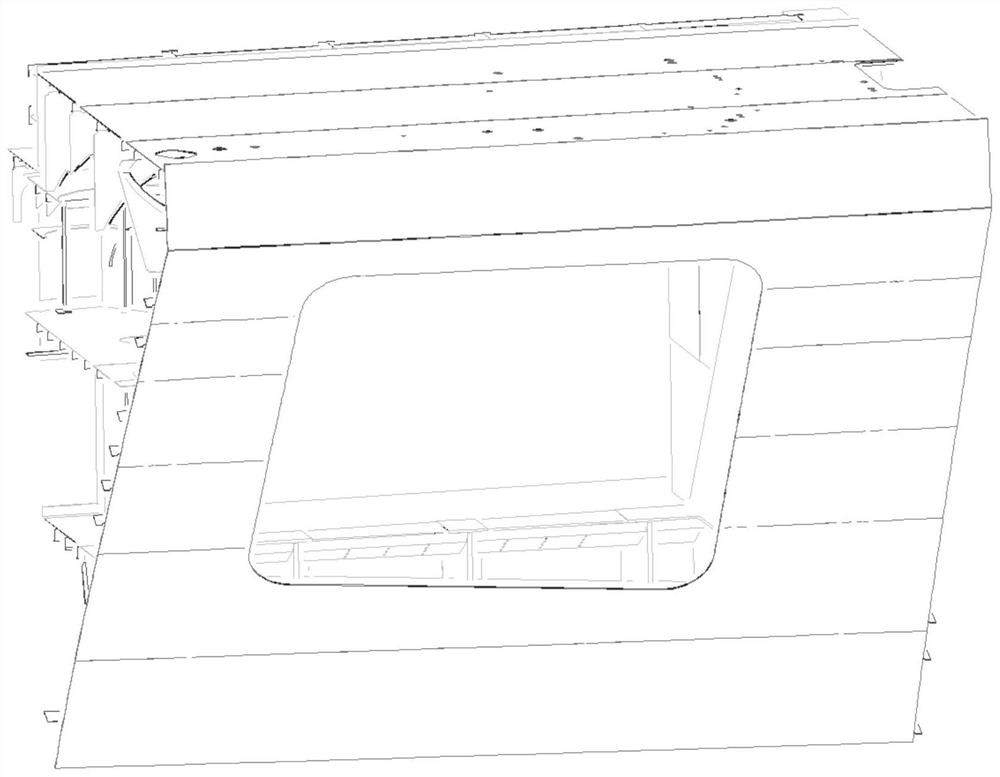

Image

Examples

Embodiment Construction

[0020] The present invention is further described below in conjunction with specific embodiment:

[0021] A segmented pre-installation method for ship side doors, characterized in that the method comprises the following steps:

[0022] Step 1. Segmentation. The installation of the side door needs to be carried out under the condition that the door frame and the surrounding structure are intact. Therefore, it is necessary to plan the structural scope involved in the pre-installation of the side door when dividing the sections. Because the side door It is a large outfitting piece with corresponding structural strength requirements, especially the structural reinforcement at the side door hinge eye plate. The segmented ports should be as far away from the side door hinge eye plate as possible to ensure the installation of the side door hinge eye plate precision.

[0023] Step 2. After the segmented structure is completed, the segmental structure of the side door is as follows: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com