Construction technology of infrastructure truss for deep sea cage culture equipment

A cage culture and infrastructure technology, applied in the field of truss construction technology for deep sea cage culture equipment infrastructure, can solve the problems of long construction period, time-consuming and material-consuming, unfavorable construction, etc., to reduce the number of construction, shorten the construction period, The effect of reducing the construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0024] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. The following examples can enable those skilled in the art to understand the present invention more comprehensively, but the present invention is not limited to the scope of the described examples.

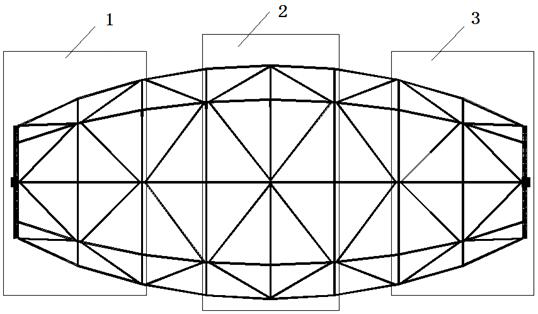

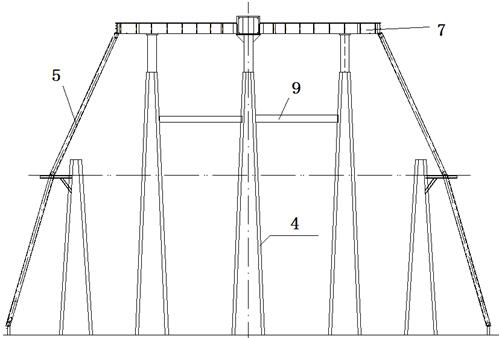

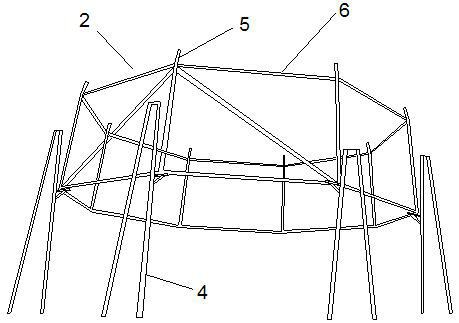

[0025] Such as Figure 1-Figure 6 As shown, the specific implementation method adopts the following technical scheme: the truss is divided into three parts, and the island-type construction method is used to divide the truss into three parts for separate construction, and then the three parts are integrated as a whole; the truss is an ellipse connected by pipes. Type hollow structure, including truss front section 1, truss mid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com