Elastic cabin-penetrating double-layer vibration isolation device for pipeline

An elastic and cabin-penetrating technology, applied in the direction of pipes, pipe elements, pipes/pipe joints/pipe fittings, etc., can solve the problem that the vibration reduction effect is difficult to meet the application requirements of low-noise submarines, and achieve the effect of optimizing the structure of the rubber layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

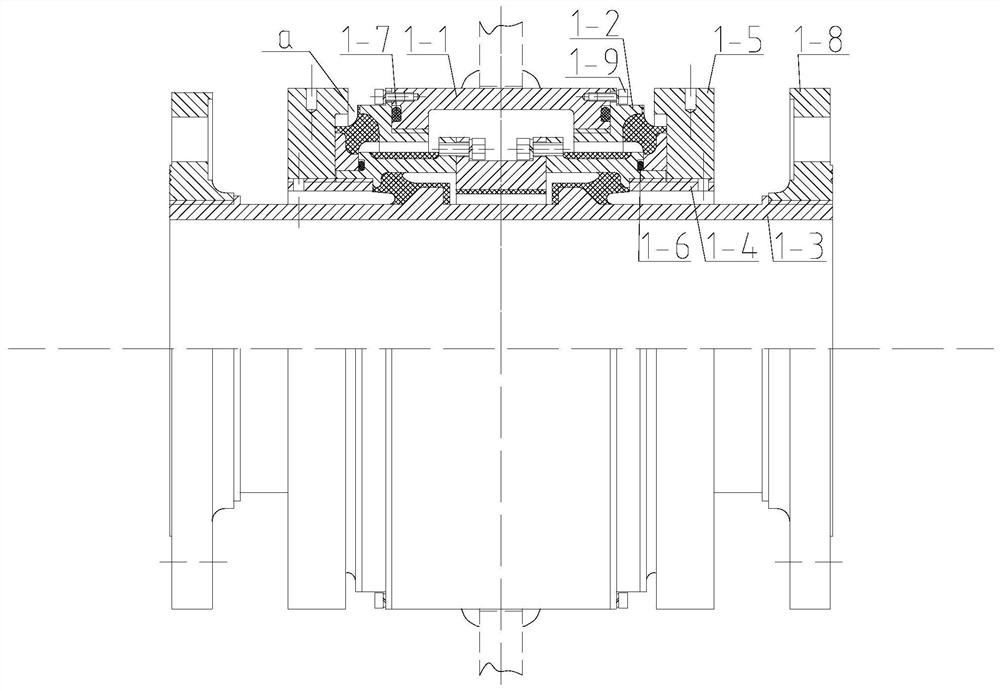

[0029] The following combination Figure 1-5 , to further illustrate the present invention.

[0030] A kind of pipeline elastic cabin penetrating double-layer vibration isolation device, see figure 1 , including a welded gasket 1-1 coaxially assembled, a pair of lower shock absorbers 1-2, an upper shock absorber 1-3, a pair of threaded pipes 1-4, and a pair of compression screws 1-5 and a pair of flanges 1-8; the lower damping body 1-2 is installed on the two ports of the welding gasket 1-1;

[0031] The upper shock absorber 1-3 and the lower shock absorber 1-2 are installed together through a threaded pipe 1-4 and a compression screw disk 1-5.

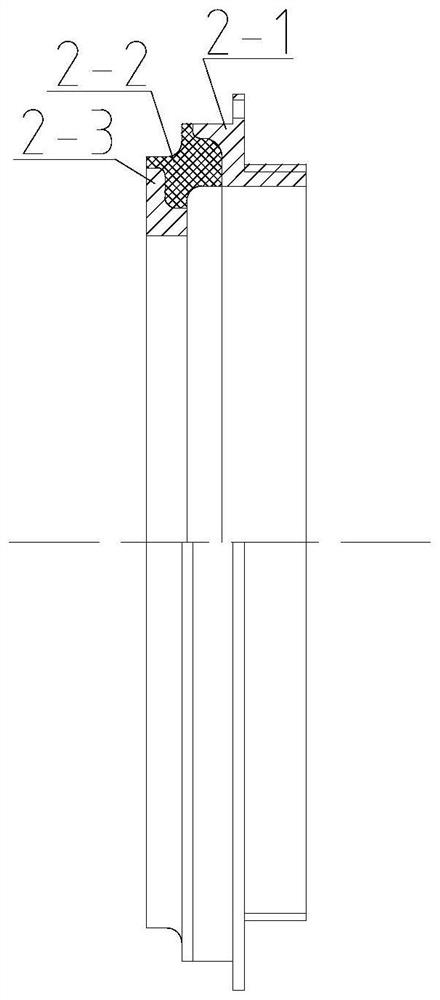

[0032] The lower damping body 1-2 includes an inner steel structure 2-1, a rubber layer 2-2 and an outer steel structure 2-3, and the outer steel structure 2-3 and the inner steel structure 2-1 pass through the rubber layer 1. 2-2 vulcanization connection;

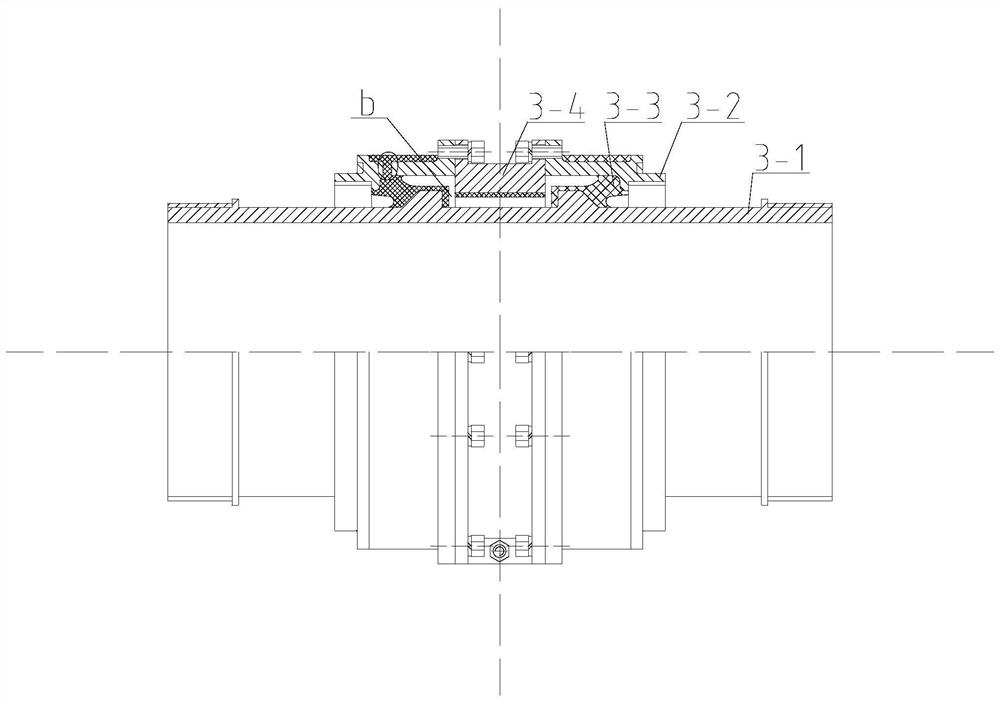

[0033] The upper damping body 1-3 includes a core tube 3-1, a pair of rub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com