Anti-sinking system for ship

A ship and anti-sinking technology, applied in the direction of hull, hull bulkhead, ship construction, etc., can solve problems such as damage, and achieve the effect of reducing damage and avoiding sinking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

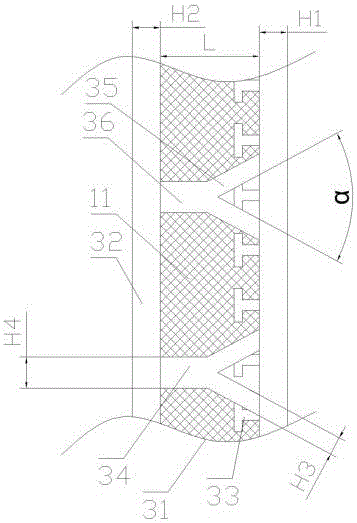

[0055]The size of the composite splint 31 is 250mm×100mm, and the thickness of the steel plate 32 is H1=H2=3mm, and the distance L=6mm between the two steel plates 32, wherein the thickness of the V-shaped head 35 in the Y-shaped skeleton 34 is H3=2mm, The thickness H4 of the tail portion 36 is 4mm, and the included angle is 60°. And the composite splint 31 is provided with flame-retardant polyurethane foam 11 .

[0056] Among them, the formula of flame-retardant polyurethane foam 11 is combination polyether polyol, 100 / phr; PAPI, 110 / phr; surfactant, 0.1-0.3 / phr; catalyst, 1.4-1.6 / phr; stabilizer, 3.9-4.2 / phr; water, 5 / phr; combined flame retardant, 50 / phr. in,

[0057] The combined polyethers include polyether 4110 with a hydroxyl value of 410 mgKOH / g and a viscosity of 110 mPa.s / 25°C, polyether 403 with a hydroxyl value of 780 mgKOH / g and a viscosity of 4800 mPa.s / 25°C, and polyether 210 , the hydroxyl value is 110mgKOH / g, the viscosity is 120mPa.s / 25℃, and the mass rat...

Embodiment 2

[0064] The size of the composite splint 31 is 250mm×100mm, and the thickness H1=H2=3mm of the steel plate 32, and the distance L=7mm between the two steel plates 32, wherein the thickness H3=2mm of the V-shaped head 35 in the Y-shaped skeleton 34, The thickness H4 of the tail portion 36 is 5 mm, and the included angle is 90°. And the composite splint 31 is provided with flame-retardant polyurethane foam 11 .

[0065] Among them, the formula of flame-retardant polyurethane foam 11 is combination polyether polyol, 100 / phr; PAPI, 110 / phr; surfactant, 0.1-0.3 / phr; catalyst, 1.4-1.6 / phr; stabilizer, 3.9-4.2 / phr; water, 5 / phr; combined flame retardant, 50 / phr. in,

[0066] The combined polyethers include polyether 4110 with a hydroxyl value of 410 mgKOH / g and a viscosity of 110 mPa.s / 25°C, polyether 403 with a hydroxyl value of 780 mgKOH / g and a viscosity of 4800 mPa.s / 25°C, and polyether 210 , the hydroxyl value is 110mgKOH / g, the viscosity is 120mPa.s / 25℃, and the mass ratio b...

Embodiment 3

[0073] The size of the composite splint 31 is 250mm×100mm, and the thickness H1=H2=3mm of the steel plate 32, and the distance L=8mm between the two steel plates 32, wherein the thickness H3=2mm of the V-shaped head 35 in the Y-shaped skeleton 34, The thickness H4 of the tail part 36 is 5mm, and the included angle is 120°. And the composite splint 31 is provided with flame-retardant polyurethane foam 11 .

[0074] Among them, the formula of flame-retardant polyurethane foam 11 is combination polyether polyol, 100 / phr; PAPI, 110 / phr; surfactant, 0.1-0.3 / phr; catalyst, 1.4-1.6 / phr; stabilizer, 3.9-4.2 / phr; water, 5 / phr; combined flame retardant, 50 / phr. in,

[0075] The combined polyethers include polyether 4110 with a hydroxyl value of 410 mgKOH / g and a viscosity of 110 mPa.s / 25°C, polyether 403 with a hydroxyl value of 780 mgKOH / g and a viscosity of 4800 mPa.s / 25°C, and polyether 210 , the hydroxyl value is 110mgKOH / g, the viscosity is 120mPa.s / 25℃, and the mass ratio betw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com