Method for assembling ship reception chamber of ship lift

A ship-carrying box and ship-lifting technology, which is applied in vertical lifting of ship machinery, ship-lifting device, construction, etc., can solve the problems of long construction period, large economic cost, large size, etc., and achieve the effect of shortening the time of hoisting and assembling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

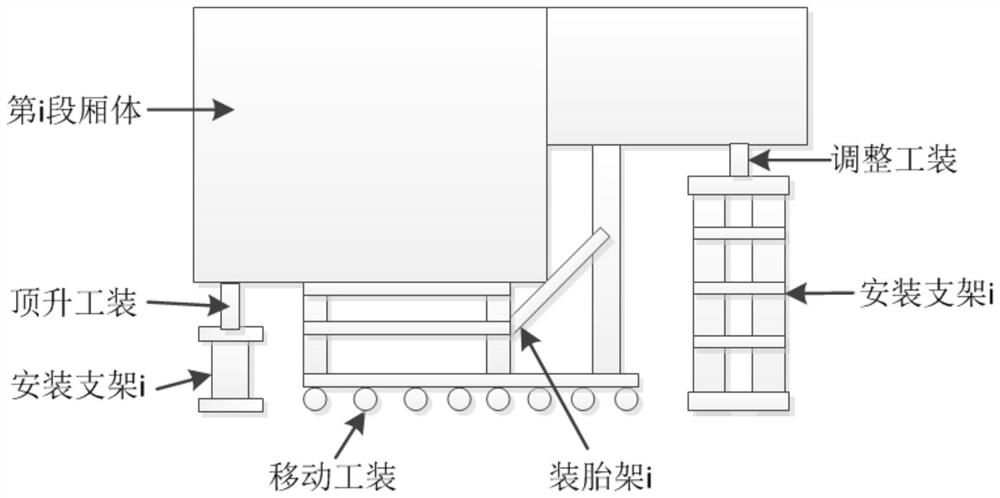

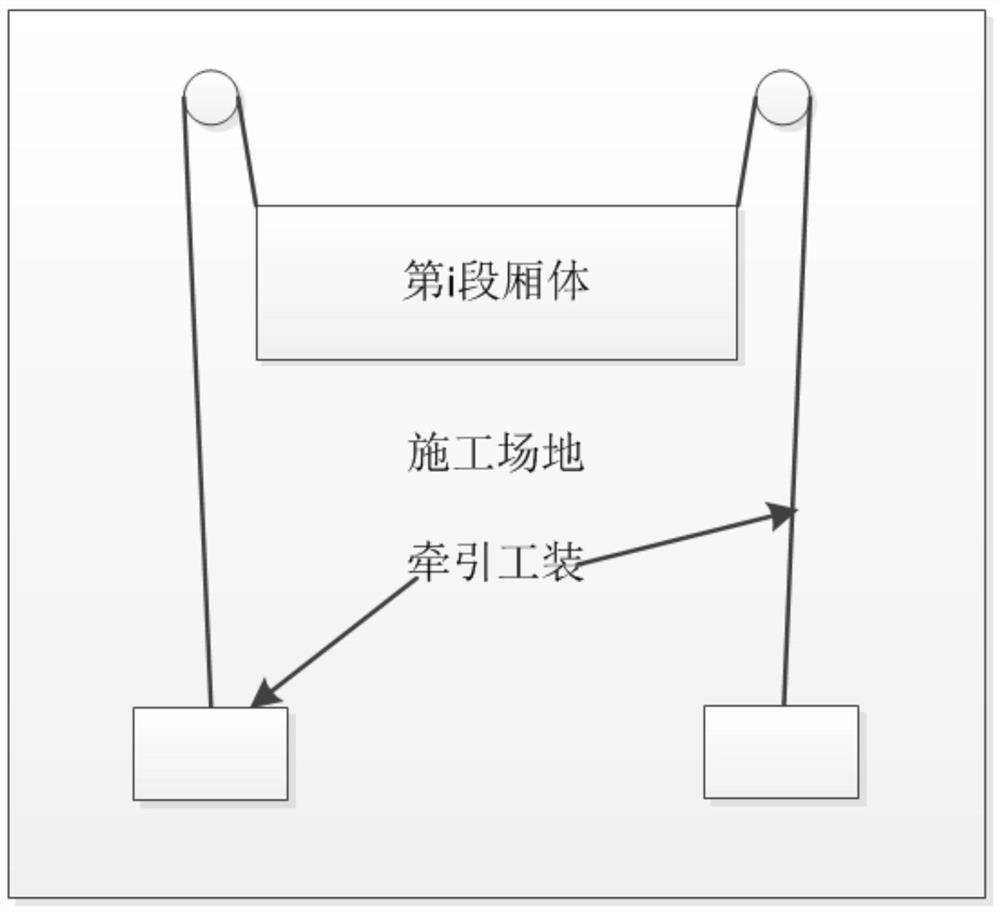

[0061] combined with Figure 1-2 , a method for assembling a ship-bearing compartment of a ship lift, the method comprising the following steps:

[0062] (1) Divide the ship-bearing compartment to be assembled into N sections of compartments, which are recorded as the i-th compartment, N≥2, N is an integer, and i takes a value from 1 to N;

[0063] (2) The car body components that form the i-th section of the car body are fixed by the assembled tire frame i of the i-th section of the car body, arranged into the shape of the i-th section of the car body, and assembled to form the i-th section of the car body;

[0064] (3) Set up the installation bracket in the shape of the i-th section of the car body at the designated position, denoted as the installation bracket i;

[0065] (4) Transfer the i-th section of the car body to the installation bracket i;

[0066] (5) Step (2) to step (4) is repeated for each section of the car body until i=N;

[0067] (6) The N sections of the bo...

Embodiment 2

[0076] This embodiment proposes a method for assembling the ship-bearing compartment of the ship lift, which can be improved on the basis of Embodiment 1 as follows: the step (2) includes:

[0077] (2-1) Carry out the marking work for the erection of car body components;

[0078] (2-2) according to the shape of the i-th section car body, the assembled tire frame i of the i-th section car body is set up;

[0079] (2-3) hoisting the car body components of the i-th section car body to the assembled tire frame i;

[0080] (2-4) Assembling and splicing the car body components of the i-th section car body into the i-th section car body;

[0081] (2-5) Repeat step (2-1) to step (2-4) for the car body components of each section of car body until i=N.

[0082] Marking the erection of the car body components is conducive to subsequent confirmation of the hoisting and assembly positions of the car body components of the i-th section of the car body. The car body components of the sect...

Embodiment 3

[0104] This embodiment proposes a method for assembling the ship-bearing compartment of the ship lift, which can be improved on the basis of Embodiment 1 and Embodiment 2 as follows: the step (3) includes:

[0105] (3-1) According to the bottom shape of the i-th section of the box body, make and assemble the mounting bracket i of the i-section box body;

[0106] (3-2) Set jacking tooling and adjusting tooling on the top of the mounting bracket i;

[0107] (3-3) Steps (3-1) to (3-2) are repeated until i=N.

[0108] According to the bottom shape of the i-th section of the car body at the predetermined position of the construction site, make and assemble the corresponding installation bracket i, the installation bracket i corresponds to the shape of the bottom of the i-th section of the box body, which is beneficial to the difference in the shape of the i-th section of the box body, To better realize the stable placement of the i-th section of the box body, set jacking tools suc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com