Mould for preparing H-shaped concrete pile

A technology for concrete piles and moulds, which is applied in the direction of moulds, mold trays, manufacturing tools, etc., can solve the problems that hinder the opening of existing moulds, and achieve the effects of easy cleaning and maintenance, simple structure, and strong driving force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

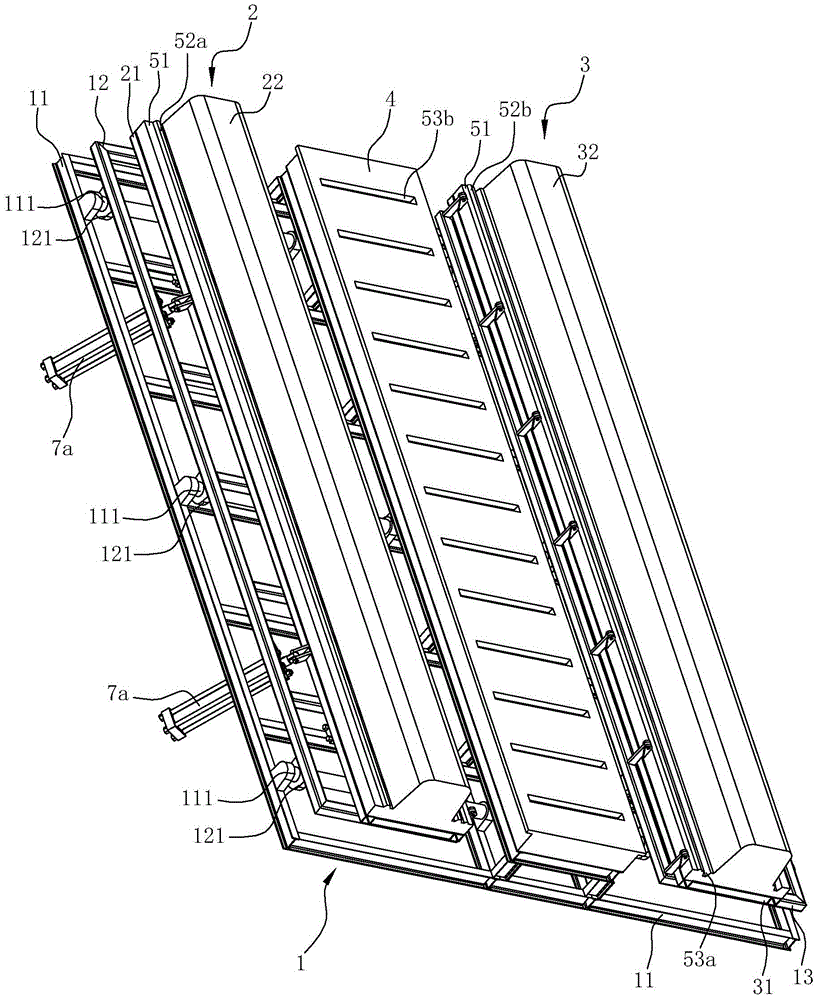

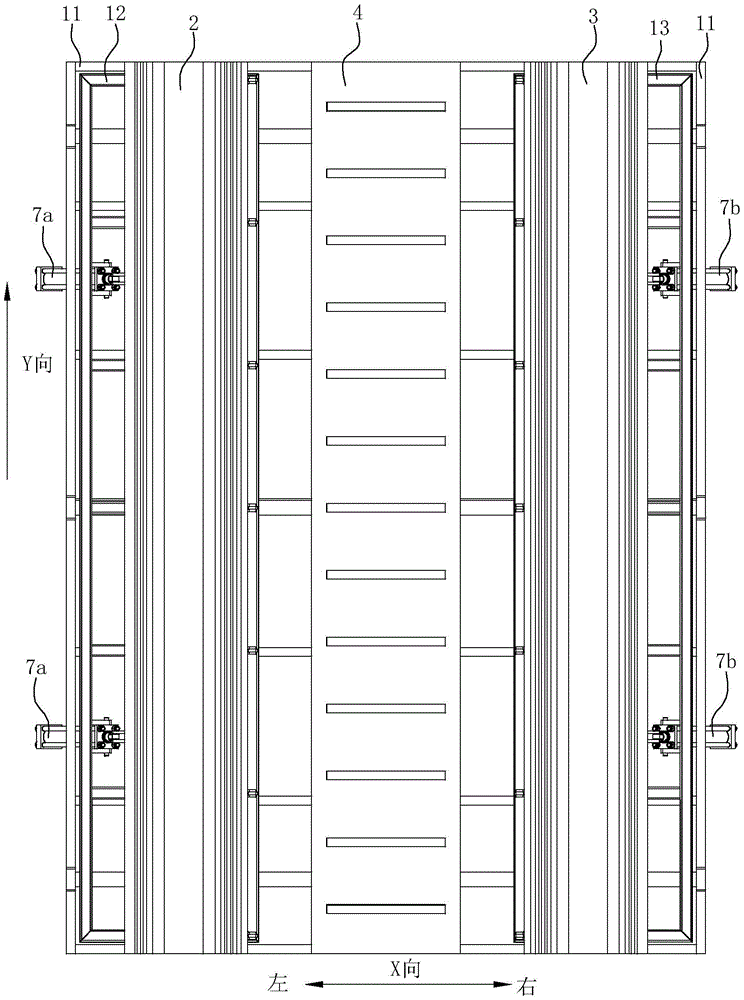

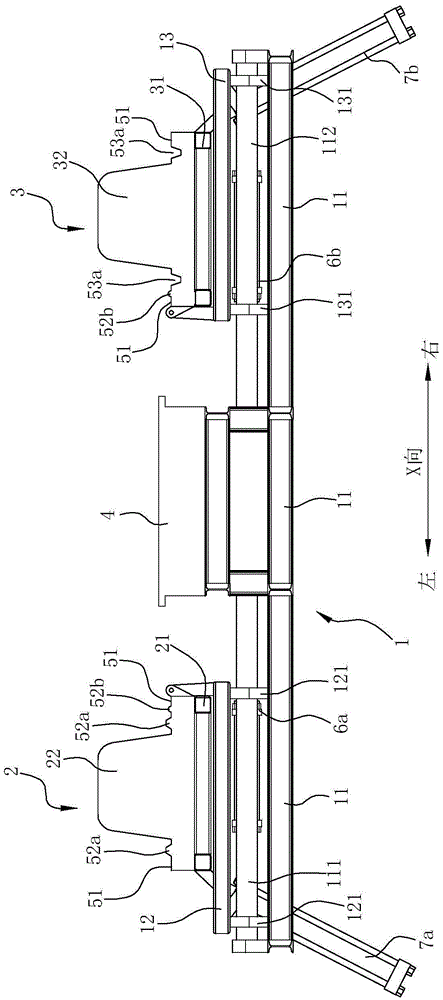

[0032] Such as Figure 1-11 Shown is the first embodiment of the present invention.

[0033]A mold for preparing H-shaped concrete piles, including a frame body 1, a left formwork 2, a right formwork 3 and a lower formwork 4, the left formwork 2 and the right formwork 3 are driven by a driving structure and can be turned over and together with the lower formwork 4 Together, they form a cavity 5 that matches the shape of the H-shaped concrete pile. In actual production, various concave-convex structures need to be set on the flange of the H-shaped concrete pile to facilitate engineering needs, but the cross-section of the pile body is still roughly H. shape. The left formwork 2 is composed of the left side plate 21 and the left module 22 fixedly connected, the right formwork 3 is composed of the right side plate 31 and the right module 32 fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com