Special ball valve for oxygen

A technology for ball valves and oxygen, applied in valve details, valve devices, valve housing structures, etc., can solve the problems of enlarged ball activity space and skin shedding, etc., and achieve the effects of improving service life, reducing friction, and stabilizing operating torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

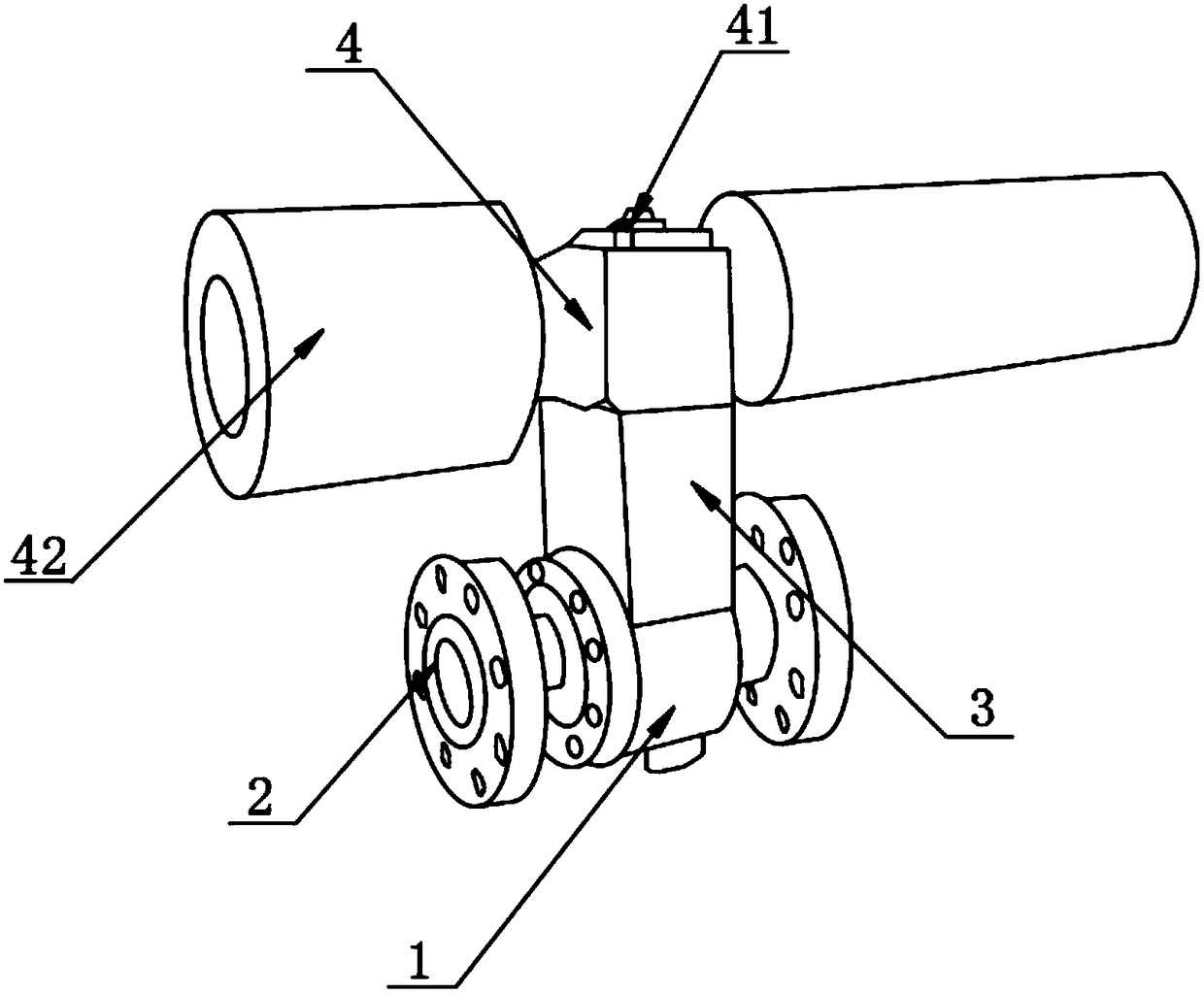

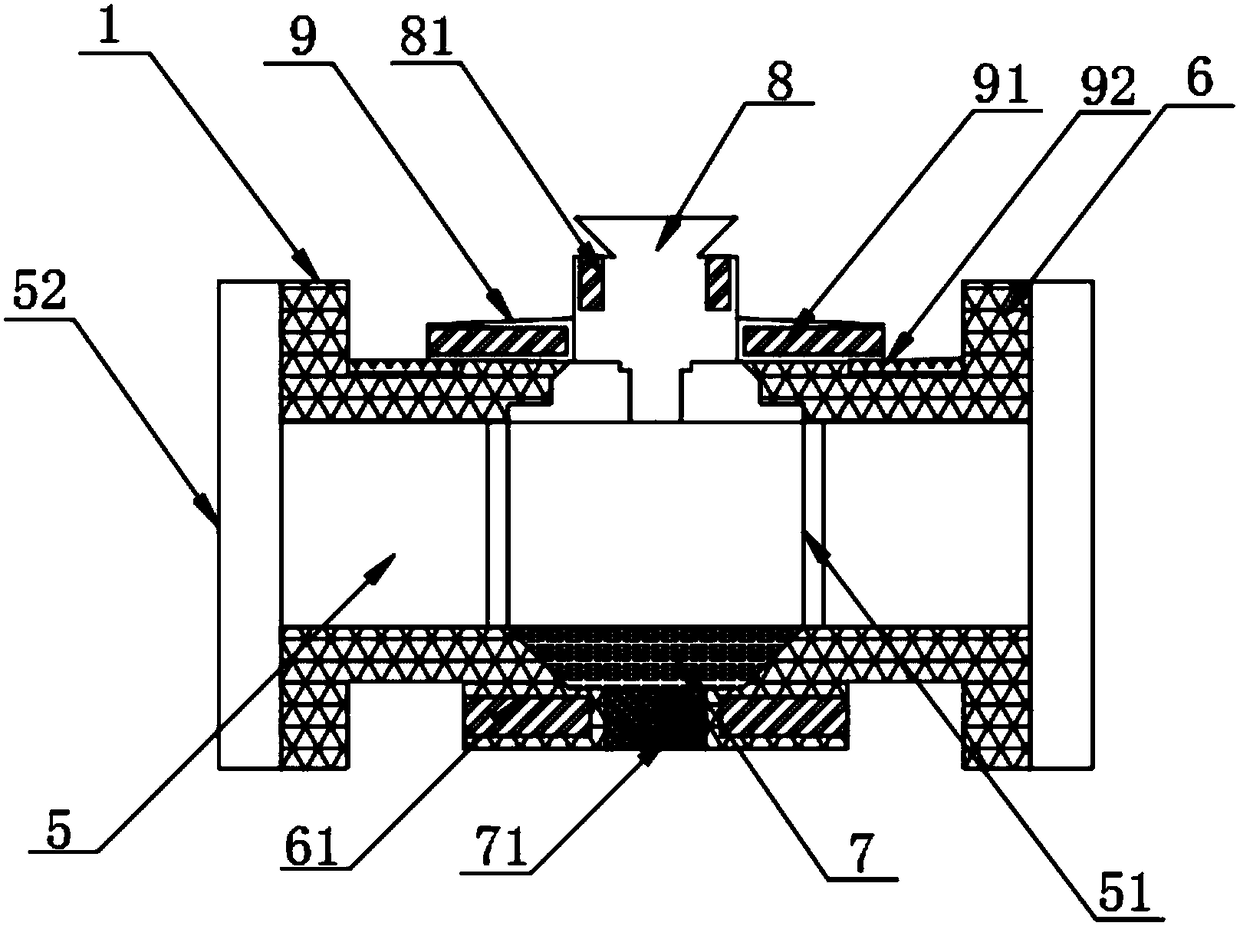

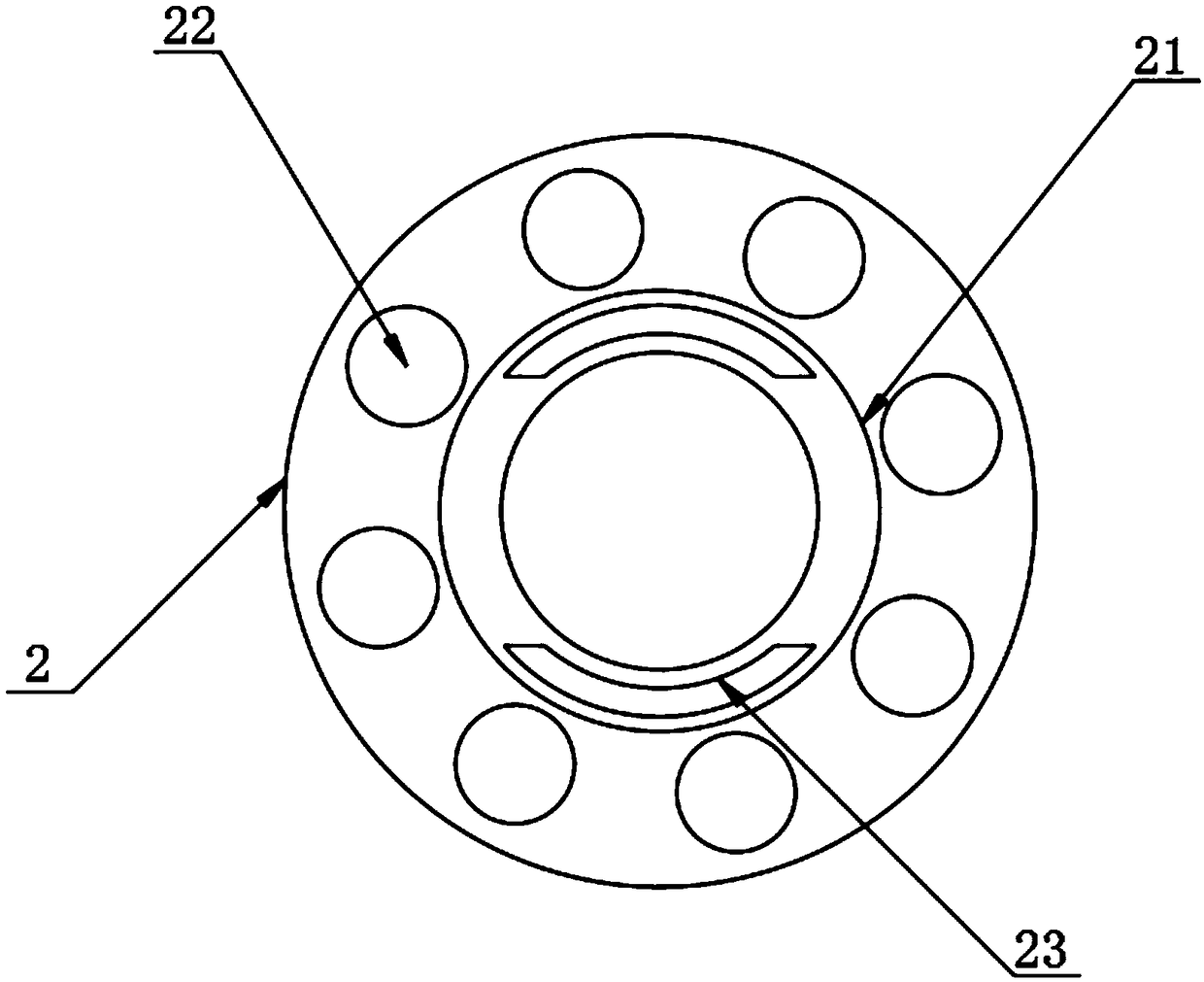

[0024] The present invention provides such Figure 1-4 A special ball valve for oxygen is shown, including a valve body 1, connecting seats 2 are provided on both sides of the valve body 1, a valve stem housing 3 is connected to the top of the valve body 1, and the top of the valve stem housing 3 The actuator 4 is connected, the valve body 1 includes a valve cavity 5 and a valve seat 6, the valve cavity 5 is surrounded by a valve seat 6, the bottom of the valve cavity 5 is provided with a support seat 7, and the support seat 7 It is arranged inside the valve seat 6 , the top of the valve chamber 5 communicates with a valve stem connecting seat 8 , and both sides of the valve stem connecting seat 8 are provided with top fixing seats 9 .

[0025] Both the valve body 1 and the connecting seat 2 are made of hard alloy material, the valve cavity 5, the valve seat 6 and the valve stem connecting seat 8 are integrated, and the surfaces of the valve cavity 5 and the valve seat 6 are a...

Embodiment 2

[0030] The valve stem housing 3 is sleeved with a valve stem 31 inside, and the outer side of the valve stem housing 3 is surrounded by an actuator connecting plate 32, and the bottom of the actuator connecting plate 32 is provided with a filler 33, and the filler 33 set for low leakage skimming combined packing.

[0031] The actuator 4 is provided with a hydraulic pump inside, and the output shaft of the hydraulic pump is connected to the valve rod 31 in a transmission manner. The executive switch 41 is arranged on the top of the actuator 4 , and the executive connection seat 42 is arranged on both sides of the actuator switch 41. , the execution connection seat 42 is made of PEI material.

[0032] Beneficial effects of this embodiment: the ball and the valve stem 31 are connected through cylindrical pins and adopt interference fit. After the connection, the ball and the valve stem are approximately integral, which completely guarantees the concentricity of the ball and the v...

Embodiment 3

[0034] A fixed seat 71 is arranged between the support seat 7 and the valve seat 6, and the fixed seat 71 is composed of springs. Both sides of the fixed seat 71 are provided with valve seat connection holes 61, and the valve seat connection holes 61 is arranged inside the valve seat 6 .

[0035] The valve stem connection seat 8 is provided with a through hole inside, and the through hole is matched with the valve stem 31 , and the valve stem connection seat 8 is provided with a valve stem connection hole 81 at the top of both sides of the inner wall.

[0036] The top fixing seat 9 is arranged on the top of the valve seat 6 and is fixedly connected with the valve stem connecting seat 8. The inside of the top fixing seat 9 is provided with a fixing seat connection hole 91, and the outside of the top fixing seat 9 is provided with an electrostatic connection export assembly. 92 , the electrostatic connection lead-out component 92 is arranged on the top of the valve seat 6 .

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com