Patents

Literature

110results about How to "With automatic feeding function" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

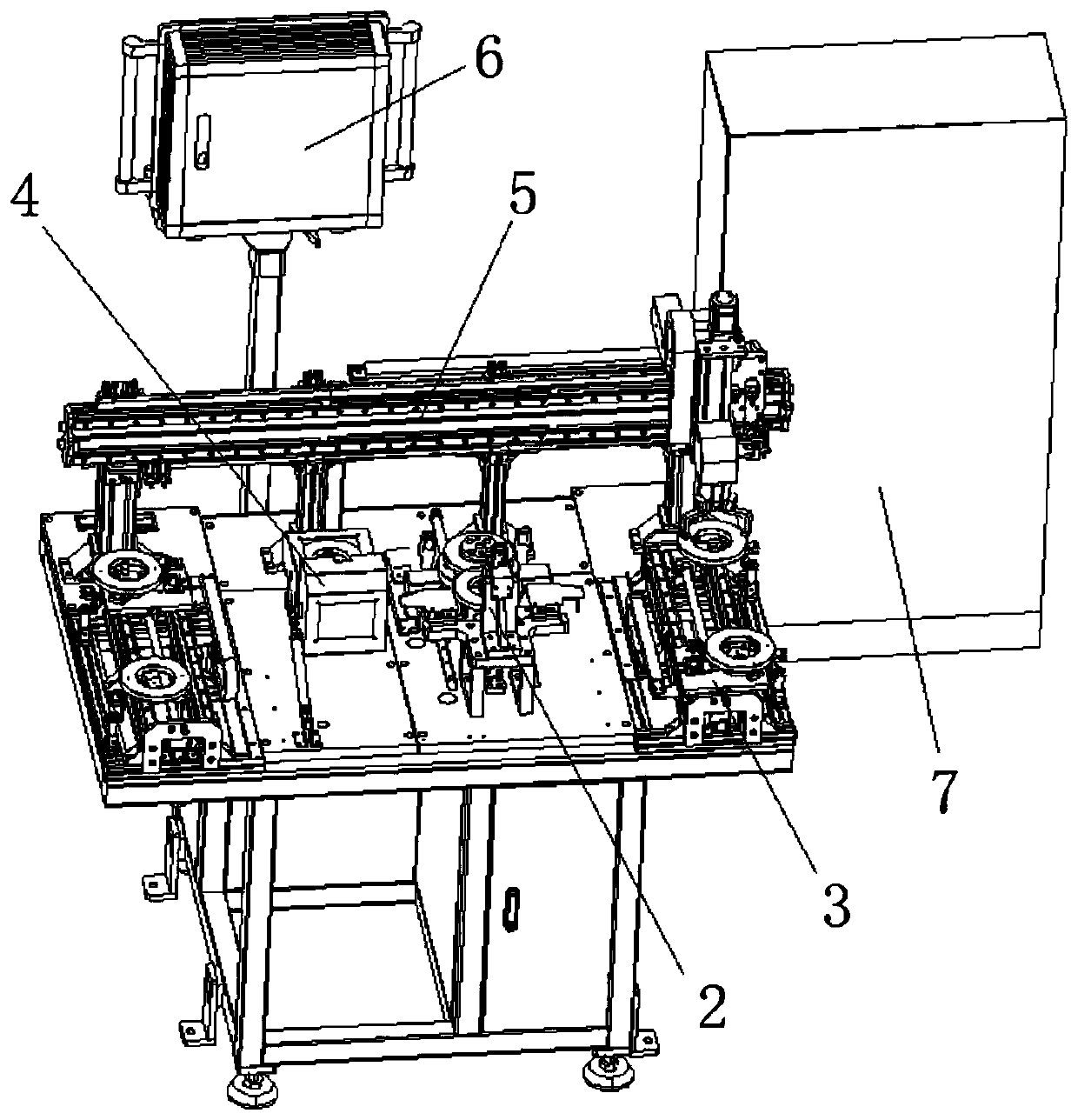

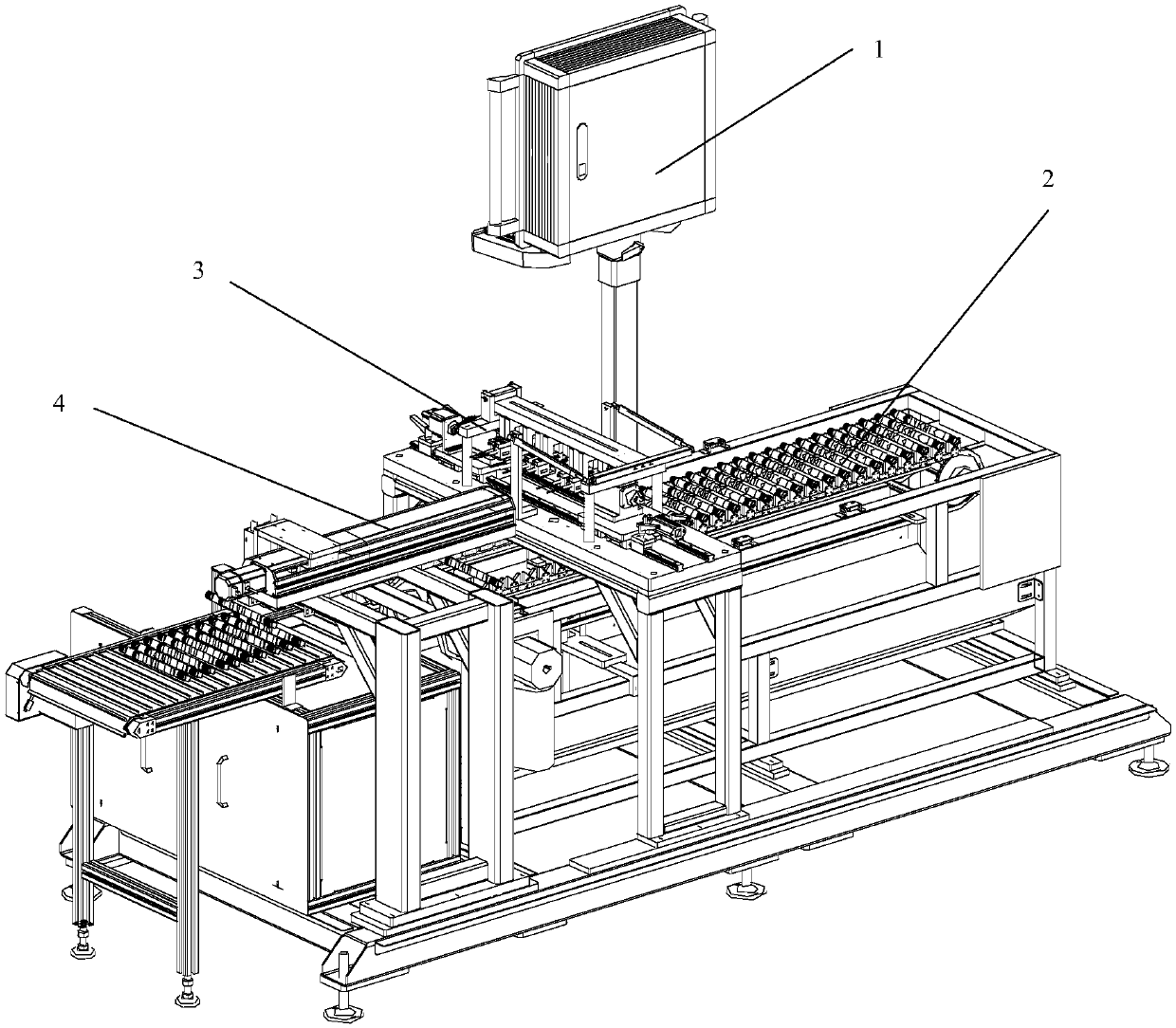

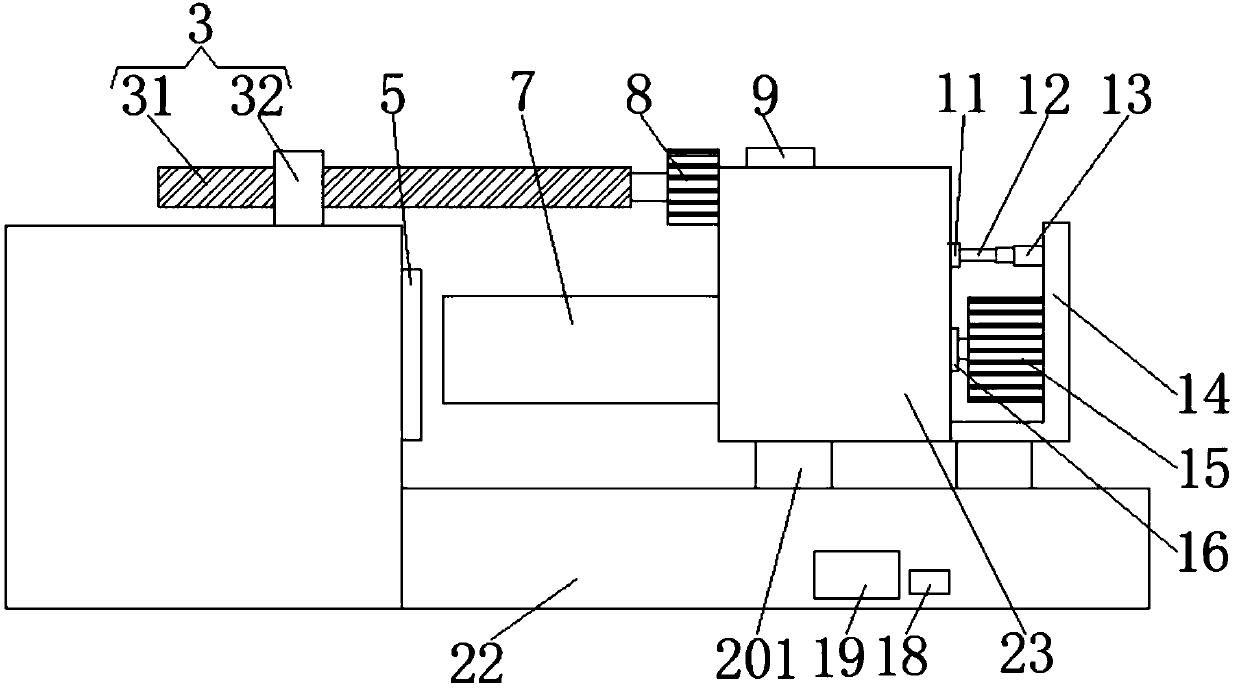

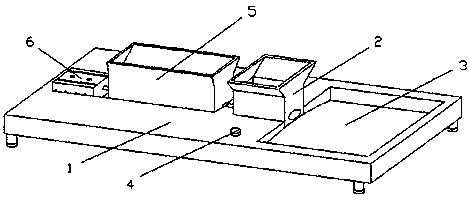

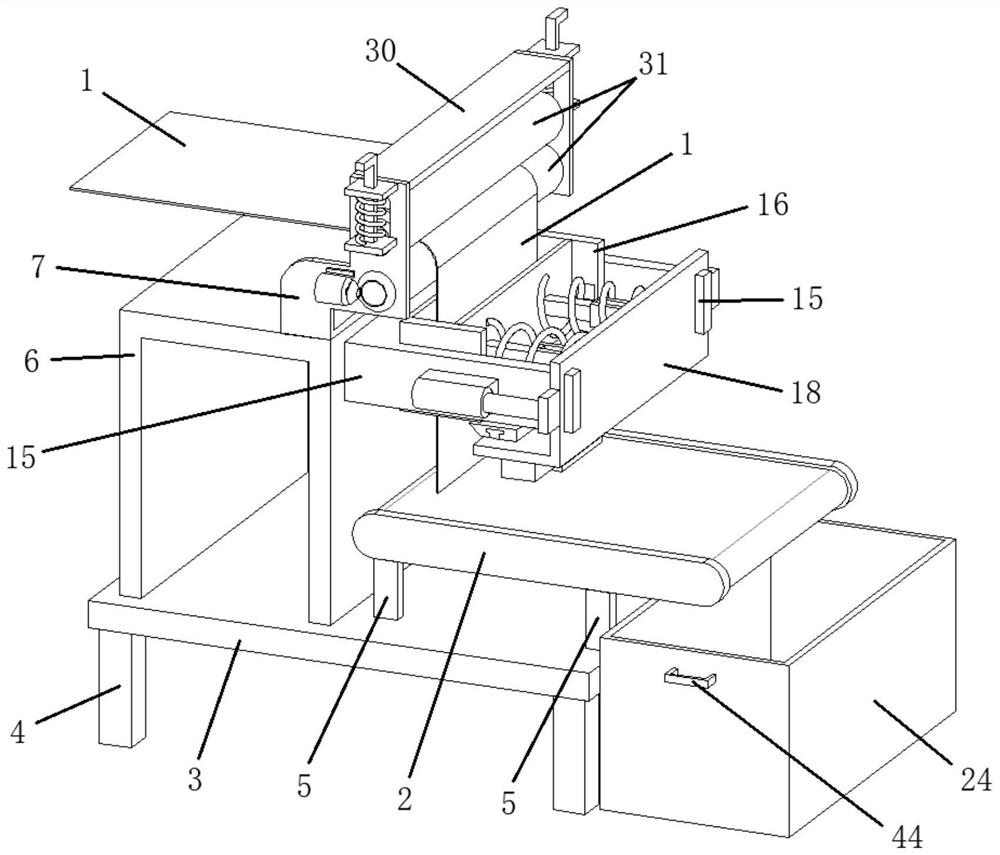

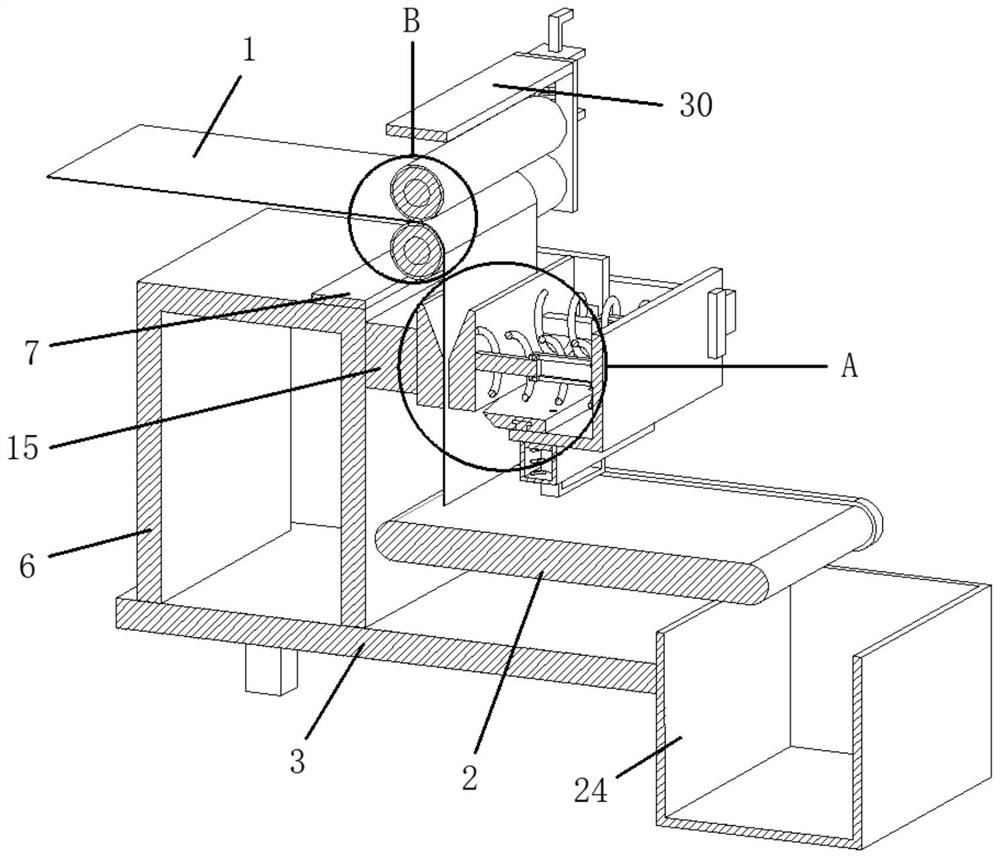

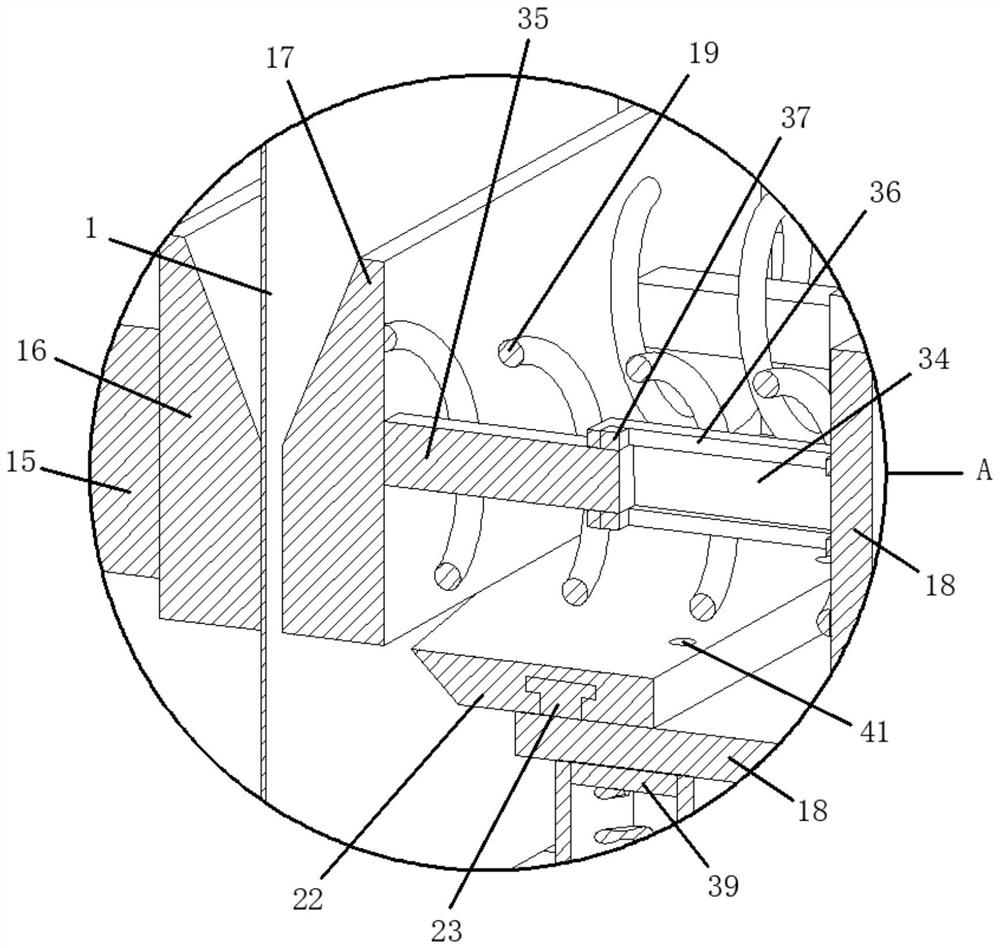

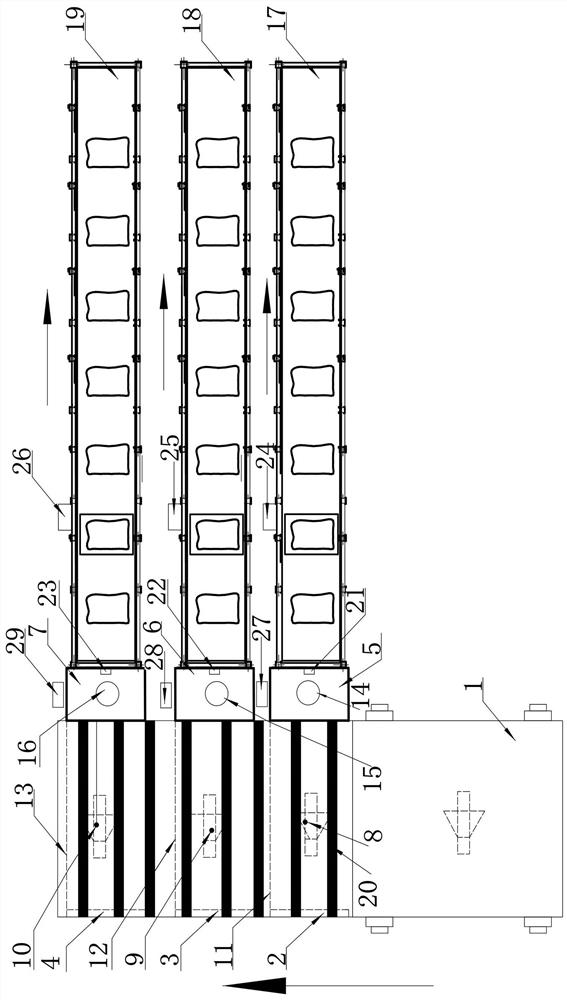

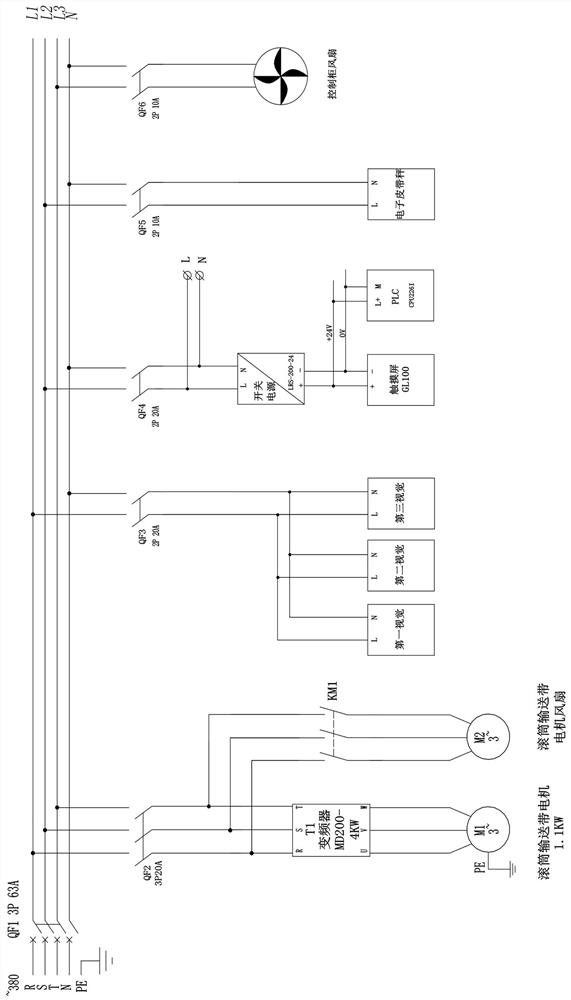

Visual detection equipment of circuit board

InactiveCN103728309ALow costAvoid wasting resourcesOptically investigating flaws/contaminationSortingManipulatorPrinted circuit board

The invention discloses visual detection equipment of a circuit board. The visual detection equipment of the circuit board comprises a bearing plate and a control system, a conveyor trough arranged on the bearing plate, a conveyor belt clamped in the conveyor trough and used for conveying a supplied to-be-detected circuit board, a first visual detection device, a second visual detection device, a finished product collection device and a defective product collection device, wherein the first visual detection device comprises a first CCD (charge coupled device) imaging system and a first blocking mechanism; the second visual detection device comprises a second CCD imaging system and a second blocking mechanism; the finished product collection device is used for collecting finished circuit boards after detection; and the defective product collection device comprises a defective product rejecting manipulator and a defective product collection conveyor belt used for collecting defective products. Compared with the prior art, only one conveyor belt is adopted for the detection process, so that the cost is saved greatly, and the visual detection equipment of the circuit board can perform detection on a first surface and a second surface of the circuit board respectively, the detection covering range is large, and the detection speed is high.

Owner:GUANGDONG LYRIC ROBOT INTELLIGENT AUTOMATION CO LTD

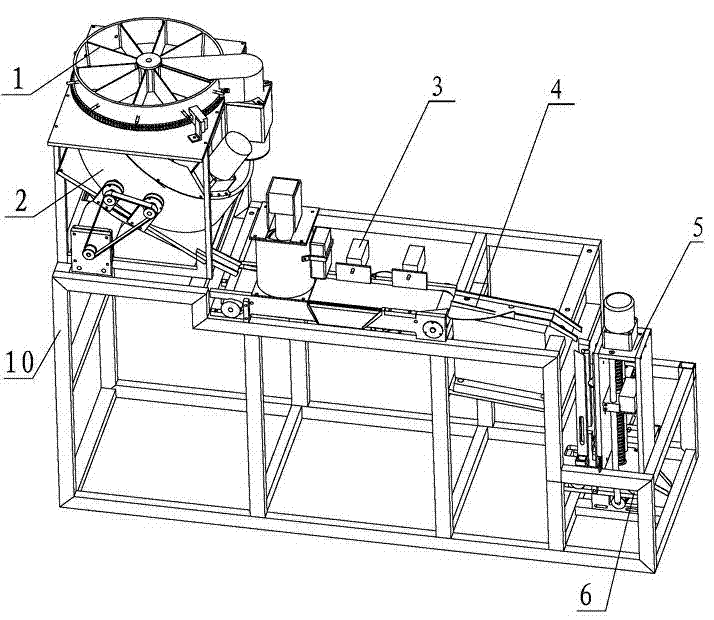

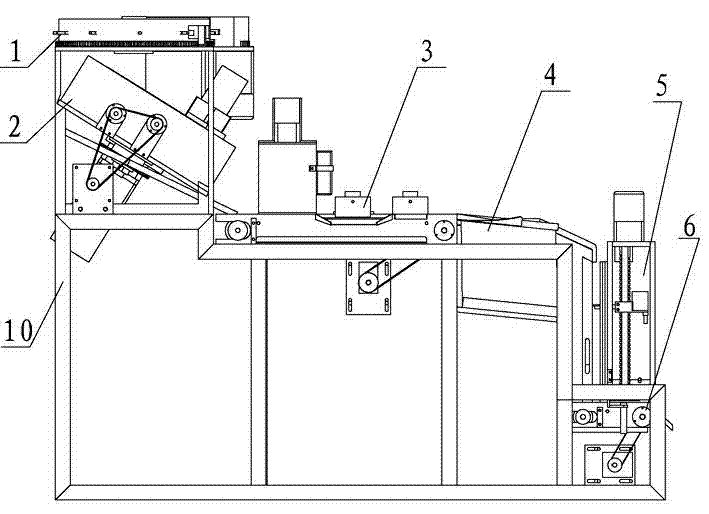

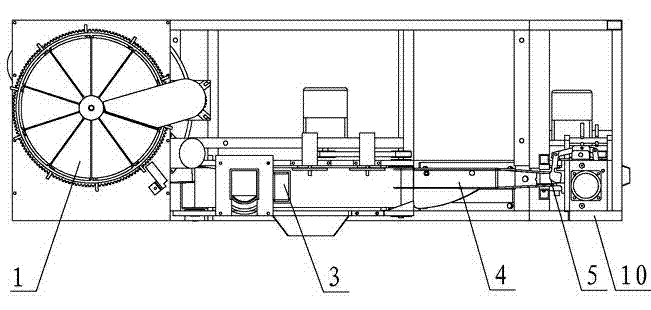

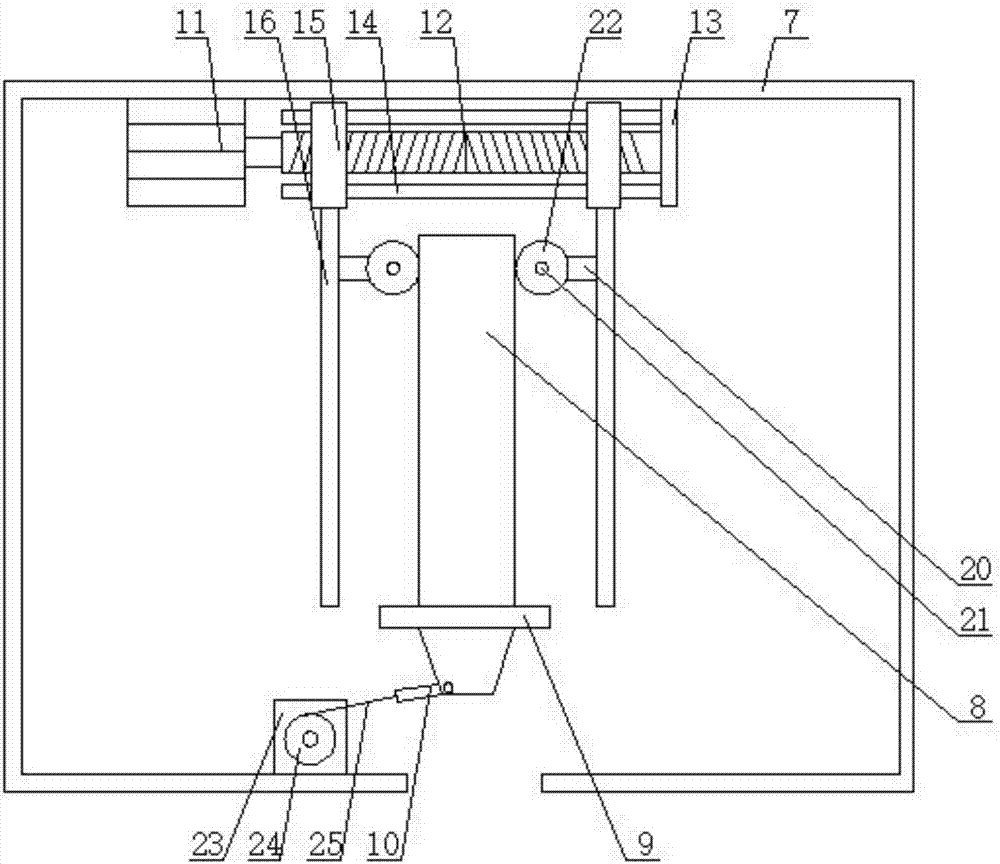

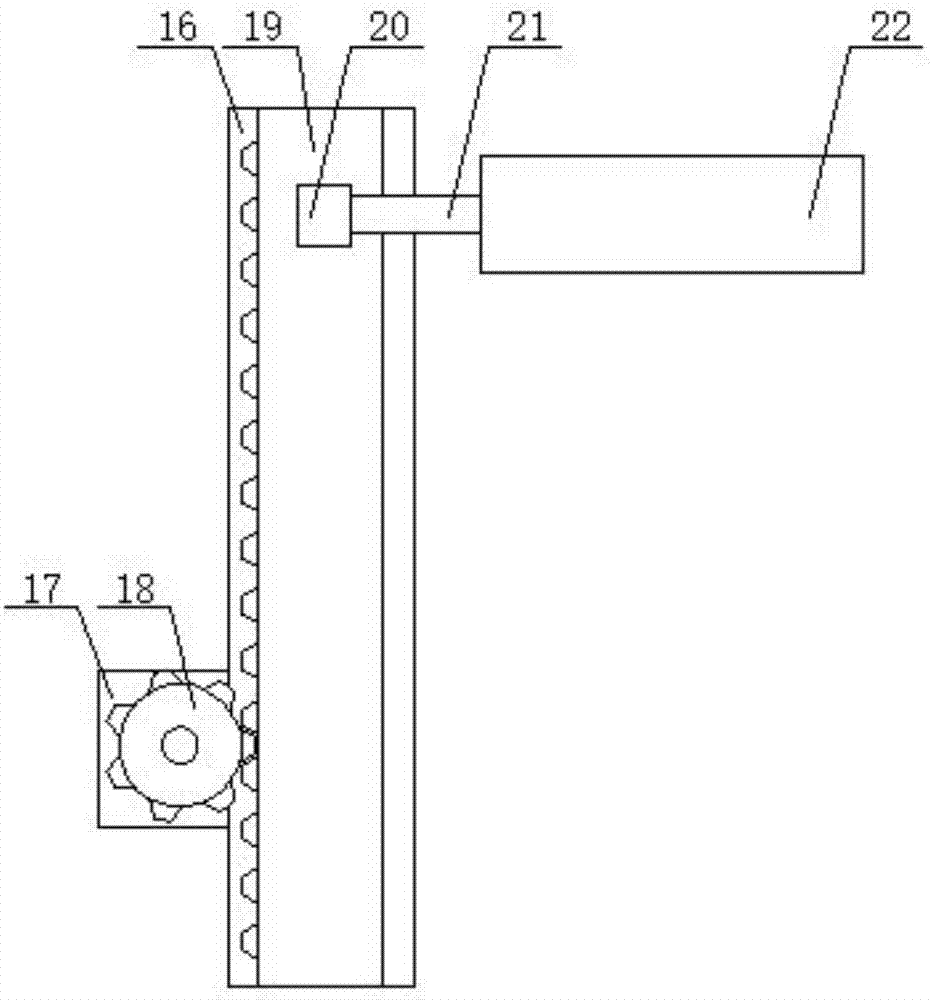

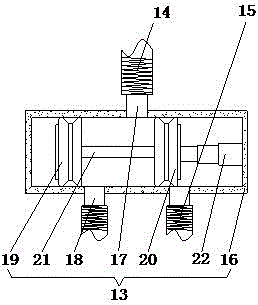

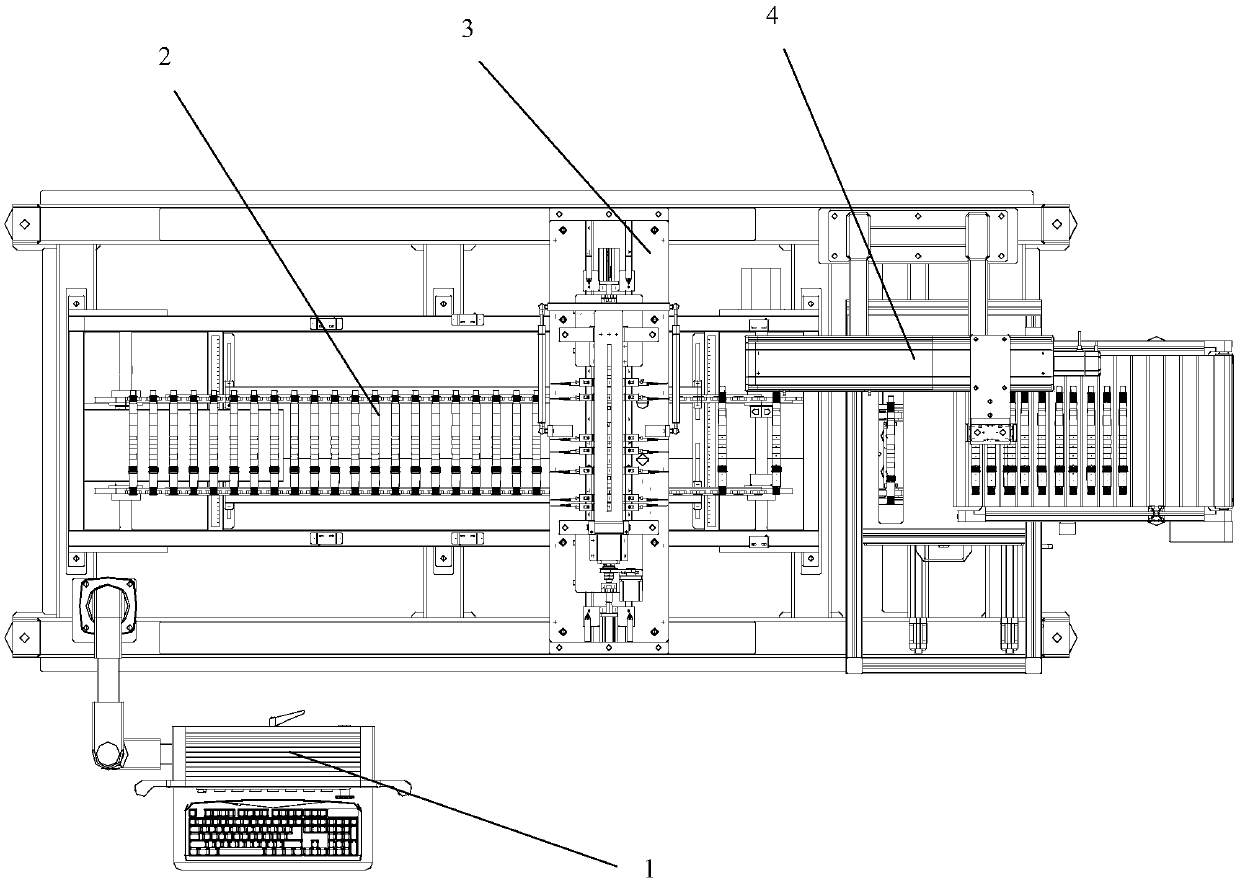

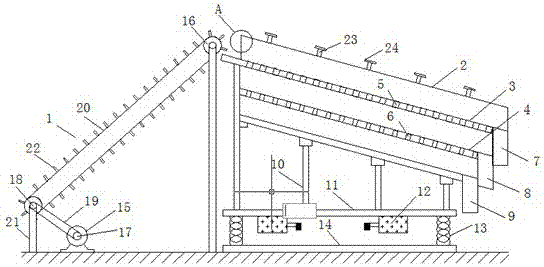

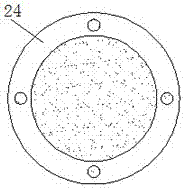

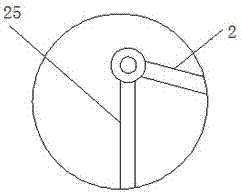

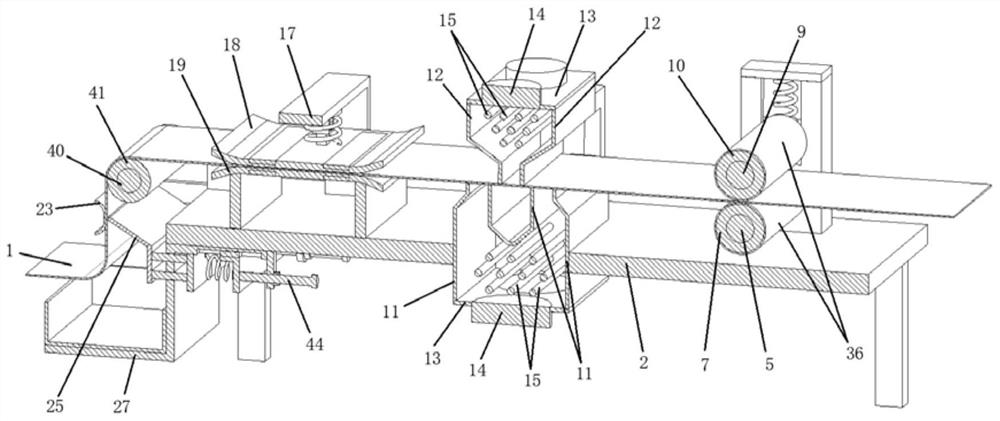

Strip metal auto-screening and integrated feeding device

The invention relates to equipment for processing metals, in particular to a strip metal auto-screening and integrated feeding device which is characterized in that, according to the process flow, a meshed discharging device, a turnplate discharging device, a screening device, an overturn device, an integration device and a feeding device are sequentially arranged on a frame. The strip metal auto-screening and integrated feeding device disclosed by the invention is intelligent and is aimed at solving the disadvantage that strip metal processing equipment in the prior art is insufficient in degree of automation. The strip metal auto-screening and integrated feeding device automatically finishes the operations of single discharging, distinguishing and screening qualified strip metals, revising the front sides and the back sides of the strip metals, collecting qualified strip metals and single feeding.

Owner:XIAOSHAN IND RES INST +1

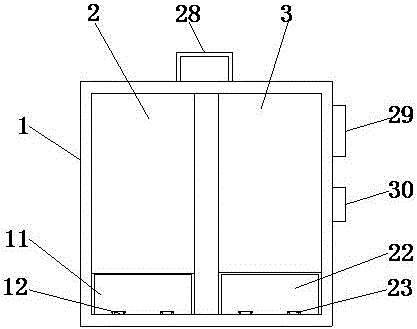

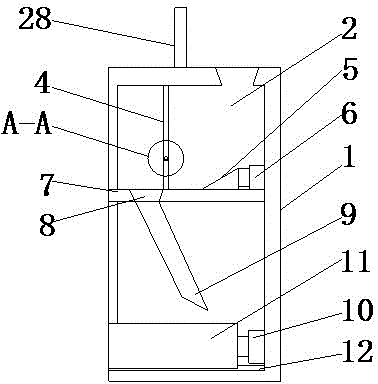

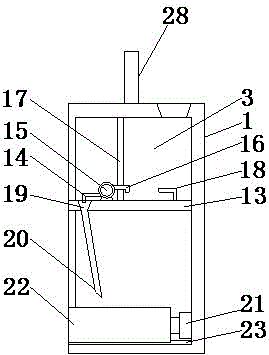

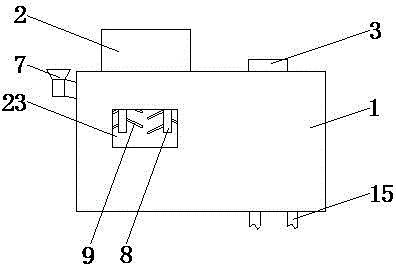

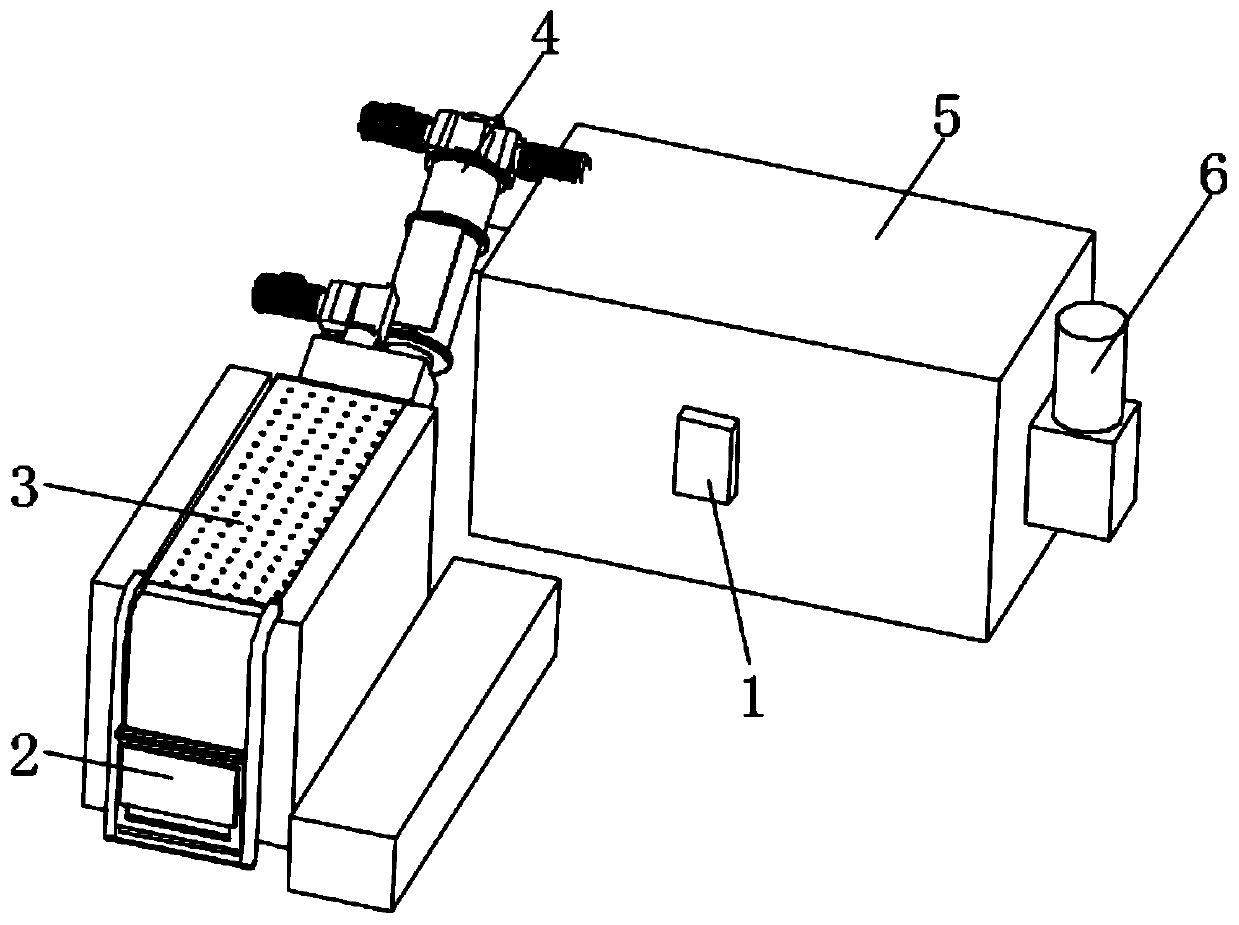

Pet feeder with automatic feeding function

InactiveCN106135042AReduce financial burdenPrevent eatingAnimal watering devicesAnimal feeding devicesPipingStops device

The invention discloses a pet feeder with an automatic feeding function. The pet feeder comprises a box body; a food storing cabin and a water storing cabin are arranged in the box body in sequence from left to right; a first supporting platform is arranged in the food storing cabin; a food stopping device, a food shovel and a first air cylinder are arranged at the top of the first supporting platform in sequence from left to right; the right side of the first air cylinder is fixedly connected with the right side of an inner wall of the box body; the left side of the first air cylinder is fixedly connected with the food shovel; a first through hole is formed in the left side of the first supporting platform. According to the pet feeder with the automatic feeding function, a controller, the first air cylinder, a second air cylinder, the food stopping device, the food box and a timer are arranged, so that the pet feeder can be used for automatically feeding a pet at fixed time; a controller, a heating rod, a water pump, a water pipe, a third air cylinder, a water box and a timer are arranged, so that the effect of automatically feeding water to the pet at fixed time is realized.

Owner:WUXI DONGCHENG BIO TECH CO LTD

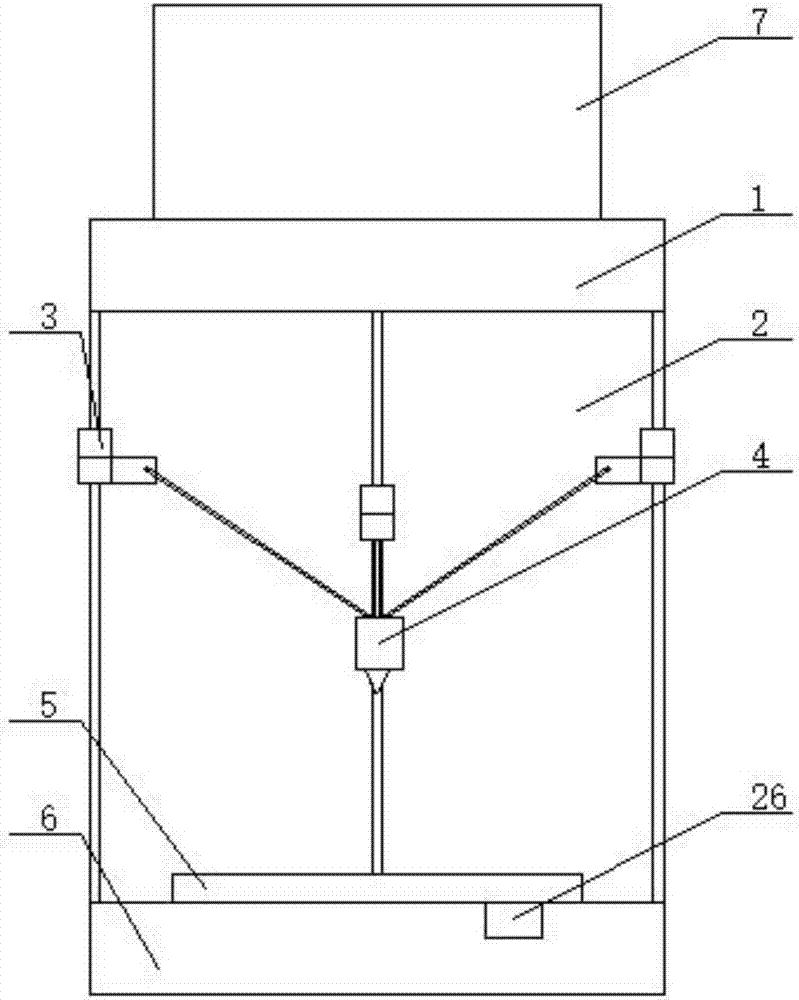

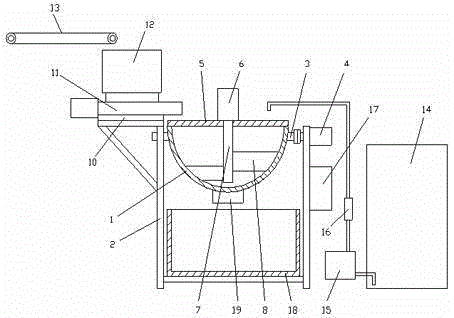

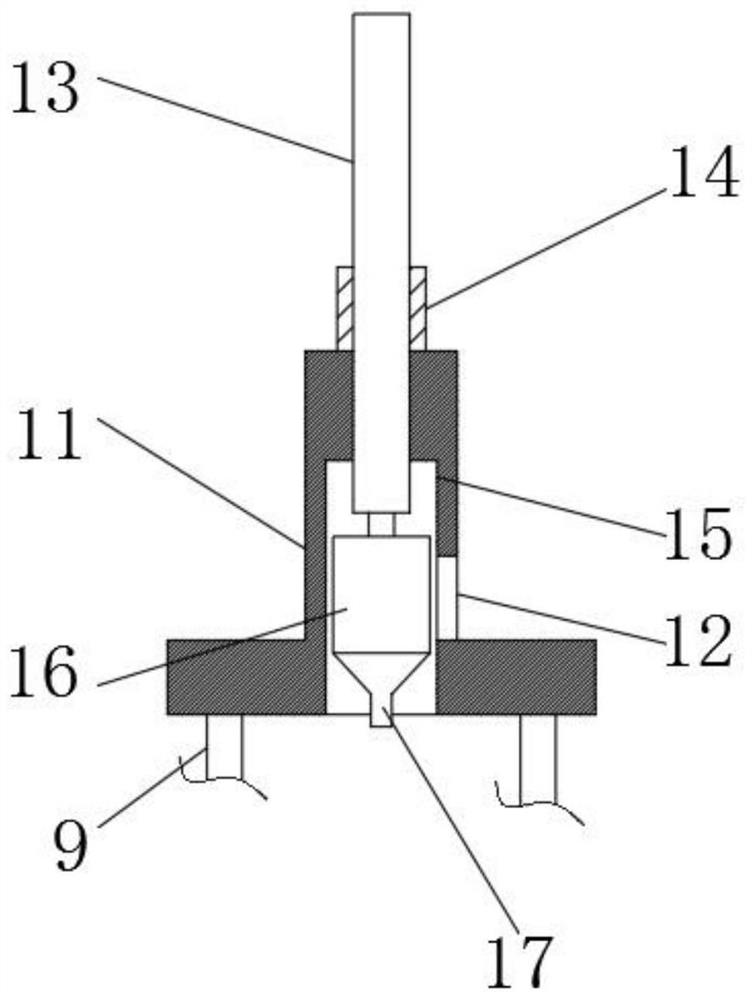

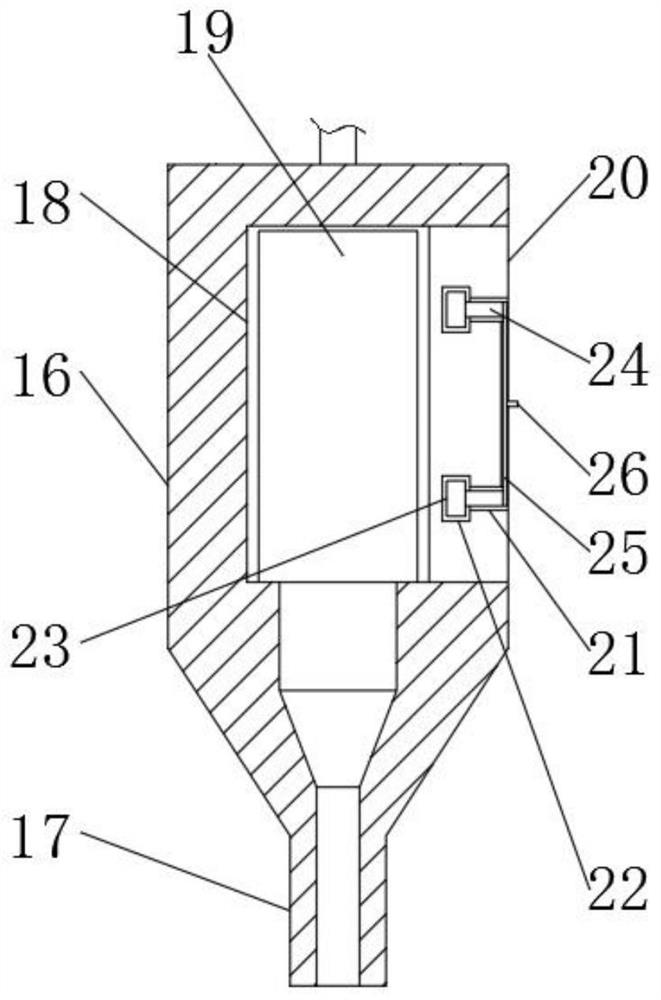

Chocolate 3D printer having automatic feeding function

InactiveCN106922909AWith automatic feeding functionImprove feeding efficiencyAdditive manufacturing apparatusCocoaEngineeringBottle

The invention relates to a chocolate 3D printer having an automatic feeding function. The chocolate 3D printer comprises a material transporting device, a shell, power devices, a spray head, a printing table and a base, wherein the material transporting device also comprises a feeding device, and the feeding device comprises a material storing soft bottle, a regulating mechanism, an extruding mechanism and a switching mechanism; the regulating mechanism comprises a first motor, a screw rod, a fixed block, sliding rods, sliding blocks and regulating rods; the extruding mechanism comprises two extruding assemblies; and the switching mechanism comprises a third motor, a pulley and a steel rope. According to the chocolate 3D printer having the automatic feeding function, when the printer is not loaded with raw materials, a lid at an opening of the material storing soft bottle is automatically opened, rollers extrude the material storing soft bottle, when raw materials in the material storing soft bottle are too few too extrude, the two rollers are close to each other, and the material storing soft bottle is clamped and then is extruded downwards, so that the feeding efficiency is improved; and compared with manual feeding, the manner has the advantages that the situation that chocolate jam pollutes two hands is avoided, besides, time and labor are saved, and the printing efficiency is improved.

Owner:福建省速卖通电子商务有限公司

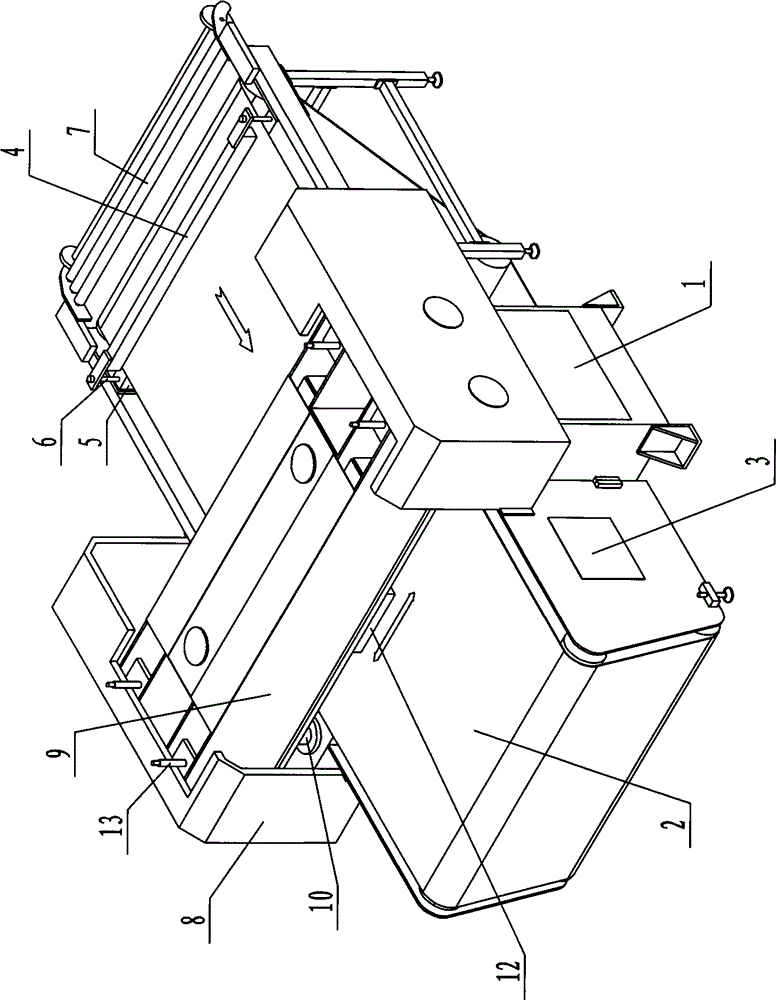

Full-automatic knife die transverse moving circulation belt type cutting machine

ActiveCN104385372AWith automatic feeding functionConvenient horizontal die-cuttingMetal working apparatusBall screwDrive motor

The invention discloses a full-automatic knife die transverse moving circulation belt type cutting machine. The full-automatic knife die transverse moving circulation belt type cutting machine comprises a rack, wherein the rack is provided with a conveyor belt control device, a material pressing plate is arranged above the front end of a conveyor belt, two sides of the material pressing plate are respectively connected with piston rods of two air cylinders, a stamping plate is arranged between two connecting blocks, the stamping plate is arranged on the rack through a stamping air cylinder and a guiding post in a supporting way, the stamping plate is provided with a knife die through a knife die clamping block, a knife die balance regulating device comprises four knife die regulating rods, the lower ends of the four knife die regulating rods are respectively in threaded connection with four lower connecting sleeves, the upper end of each of the four knife die regulating rods is sequentially provided with an upper connecting sleeve, a chain wheel and an upper pressing plate from bottom to top, four chain wheels are connected with each other through a chain, the stamping plate is internally provided with a ball screw which is mutually matched with the knife die clamping block, and one end of the ball screw is connected with a driving motor which is arranged on the stamping plate.

Owner:JIANGSU KUNTAI MACHINERY

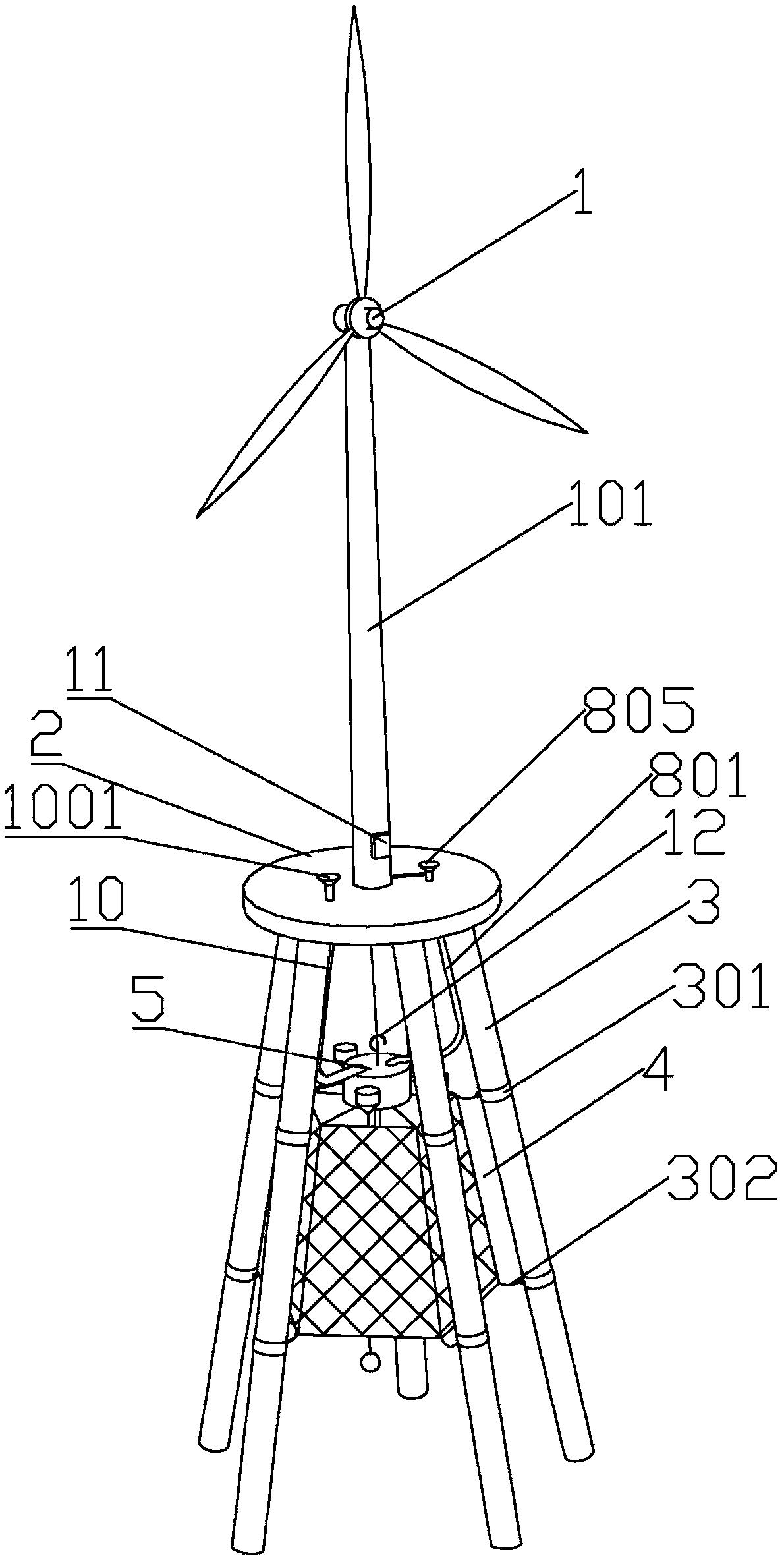

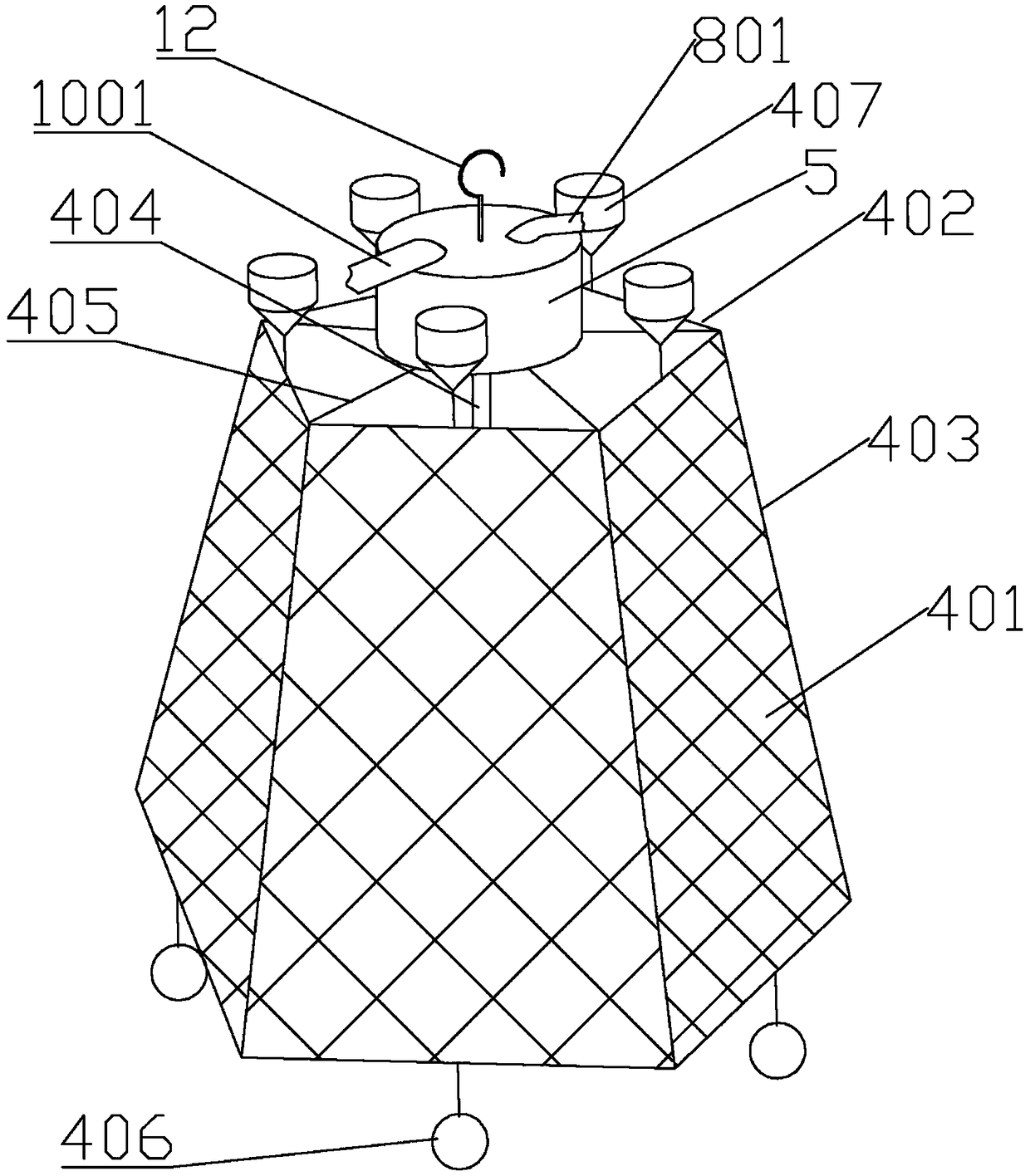

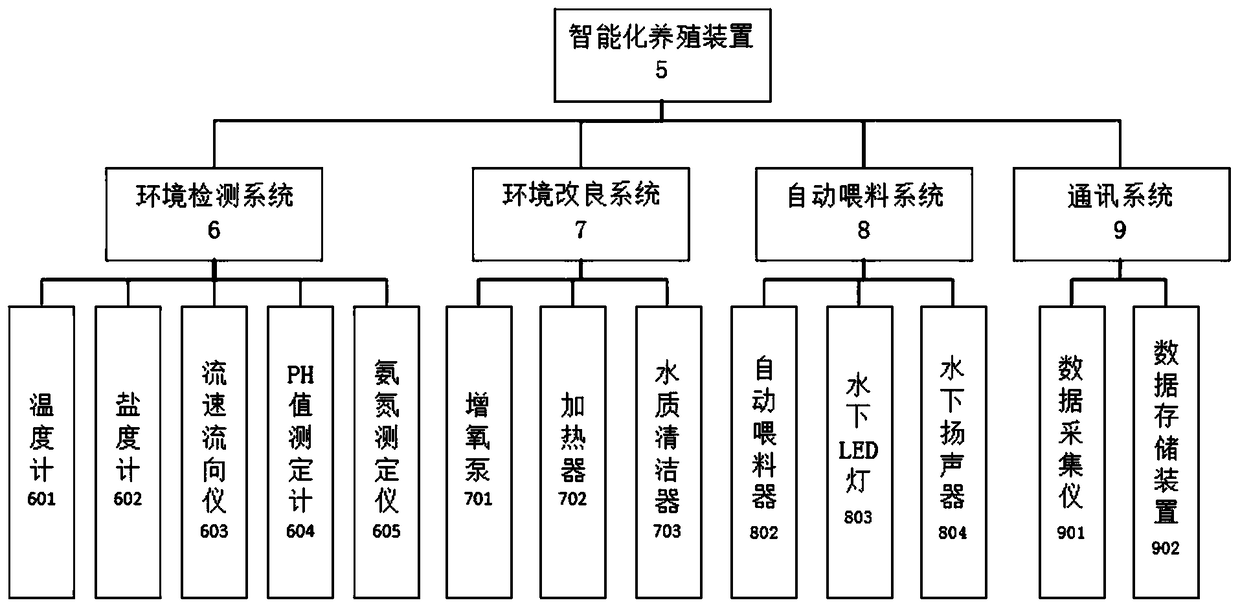

Culture net cage equipment based on high-pile cushion cap foundation of offshore wind turbine

PendingCN109076997ALow costReduce current velocityWind energy with electric storageFinal product manufactureElectricityAquatic product

The invention provides culture net cage equipment based on a high-pile cushion cap foundation of an offshore wind turbine to solve the problem of the high cost of separate development construction ofoffshore wind power equipment and net cage culture equipment in the prior art. An aquaculture net cage culture intelligent breeding system combines an offshore wind turbine support structure, reducesthe total cost of construction, production and operation, and improves the efficiency of the use of marine resources. The structure of the equipment comprises a wind power generator, a cushion cap, apile foundation structure and a culture net cage, the wind power generator is arranged on the top of a high-pile cushion cap, the culture net cage is arranged on the pile foundation structure, the culture net cage is provided with an intelligent culture device, and the wind power generator supplies power for the intelligent culture device.

Owner:POWERCHINA HUADONG ENG COPORATION LTD

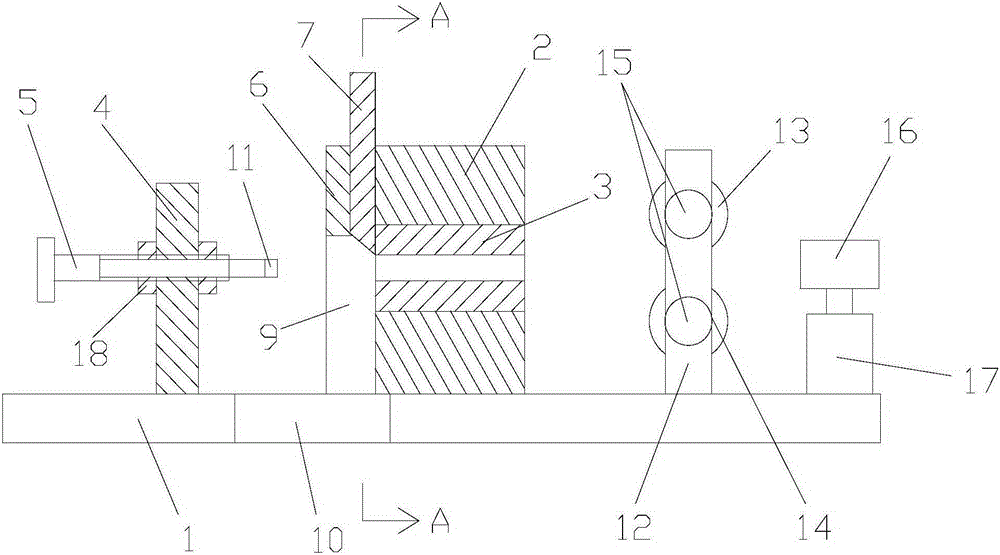

Steel bar punching and blanking machine with automatic feeding function

InactiveCN105215465AWith automatic feeding functionSimple structureNibbling shearing machinesShearing machine accessoriesPunchingSteel bar

The invention discloses a steel bar punching and blanking machine with the automatic feeding function. The steel bar punching and blanking machine comprises a base, a locating device, a cutter device and a feeding device. The cutter device comprises a cutter holder and a return spring. The feeding device comprises a pressure sensor, vertical clamping rollers and horizontal clamping rollers. In work, a steel bar manually penetrates a locating hole of a locating sleeve through the vertical clamping rollers and the horizontal clamping rollers, and the steel bar is pushed by the feeding device to move forwards; after the front end of the steel bar abuts against the pressure sensor, a controller controls a press head of a hydraulic machine to move downwards to push a cutter to move downwards, and the steel bar is then punched at the stipulated length; and after the steel bar is punched, the cutter returns to the original position upwards under the effect of the return spring, and meanwhile short-section materials generated after punching operation fall into a collecting device through a discharging groove and a discharging hole. The steel bar punching and blanking machine with the automatic feeding function is simple in structure, punching operation is easy and convenient, the automatic feeding function is achieved, and production efficiency is high.

Owner:CHONGQING CHANGZHAN MACHINERY

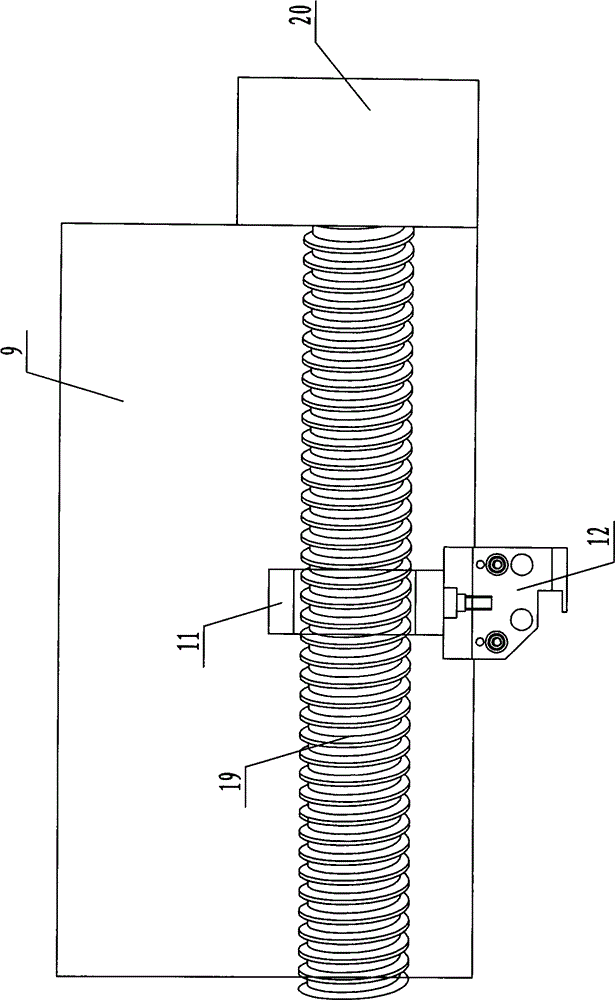

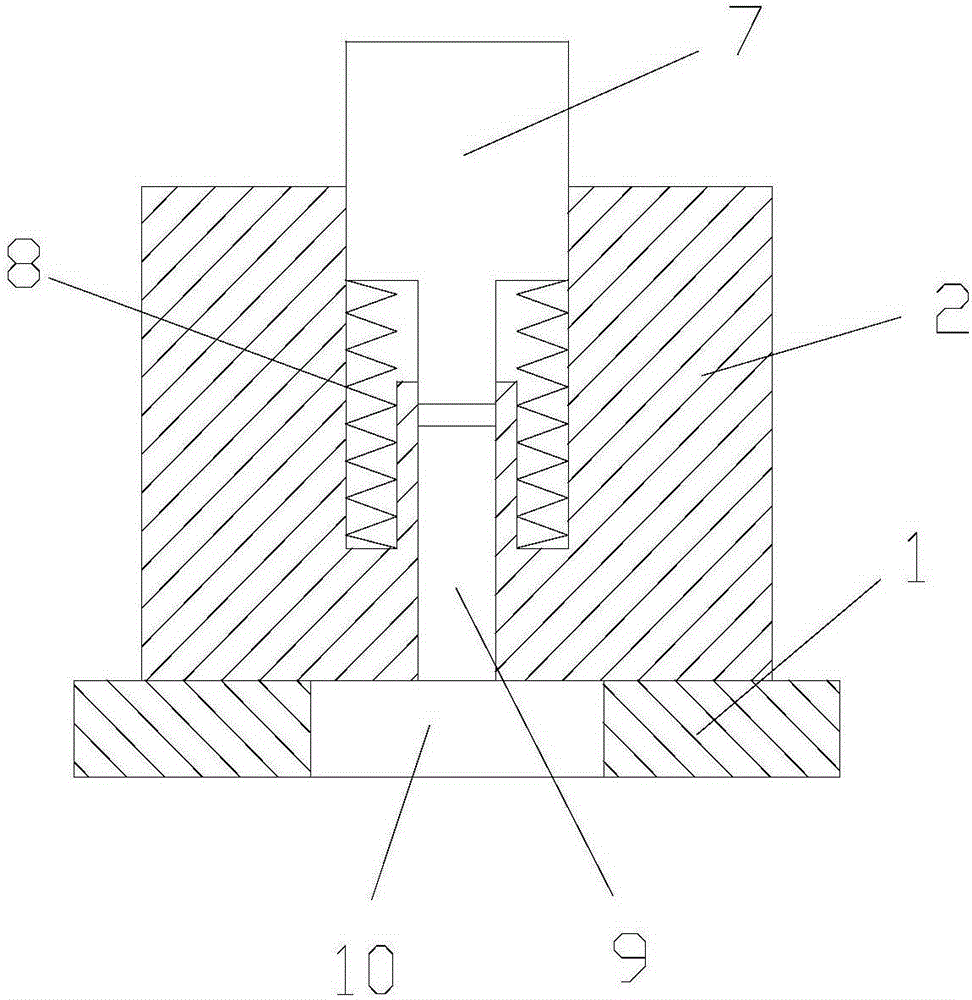

Steel pipe cutting machine with automatic feeding function

InactiveCN106001734AWith automatic feeding functionEasy to useTube shearing machinesMetal working apparatusMotor driveDrive wheel

The invention discloses a steel pipe cutting machine with an automatic feeding function. The steel pipe cutting machine comprises a bottom plate. A feeding device and a cutting device are fixedly connected to the upper surface of the bottom plate. The cutting device is located on one side of the feeding device. According to the feeding device, a first connecting rod is fixedly connected to the front face of a first supporting plate, and the upper surface of the first connecting rod is fixedly connected with the surface of a double-shaft motor through a second connecting rod. According to the steel pipe cutting machine with the automatic feeding function, by the arrangement of the feeding device, two output shafts of the double-shaft motor drive a first feeding wheel and a driving wheel to rotate in the forward direction respectively, the driving wheel drives a driven wheel to rotate through a conveying belt, a second feeding wheel rotates in the forward direction, and thus steel pipes placed among the first feeding wheel, the second feeding wheel and a third feeding wheel move towards the cutting device, so that manual steel pipe conveying is not needed, the strength of workers is saved, and the steel pipe cutting machine is more convenient to use.

Owner:无锡博成洋超声设备有限公司

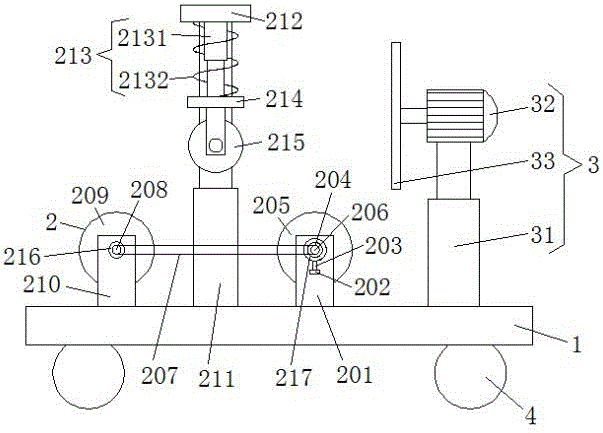

Automatic-feeding ore screening device for ore machine

InactiveCN107185819AWith automatic feeding functionNovel structureSievingConveyorsEngineeringUltimate tensile strength

The invention discloses an automatic-feeding ore screening device for an ore machine. The automatic-feeding ore screening device for the ore machine comprises a feeding device body and a screening device body. The screening device body is inclined. A first screening plate and a second screening plate are arranged in the screening device body. The first screening plate is located on the top of the second screening plate. The first screening plate and the second screening plate are provided with first screening holes and second screening holes correspondingly. Conveying rollers are connected through a conveying belt. The bottoms of the conveying rollers are provided with an installation frame. The conveying belt is further provided with feeding plates. A feeding baffle is hinged to the top of the left side face of the screening device body. The top end of the conveyer belt extends into the feeding baffle. The automatic-feeding ore screening device for the ore machine is novel in structure and convenient to operate, achieves automatic feeding, greatly lowers the labor intensity and improves the screening quality.

Owner:TAICANG QINFENG ADVERTISEMENT & MEDIA CO LTD

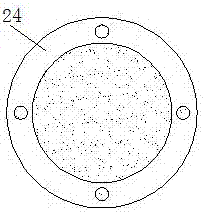

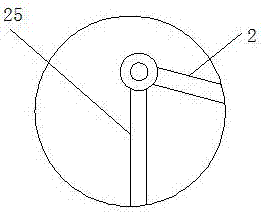

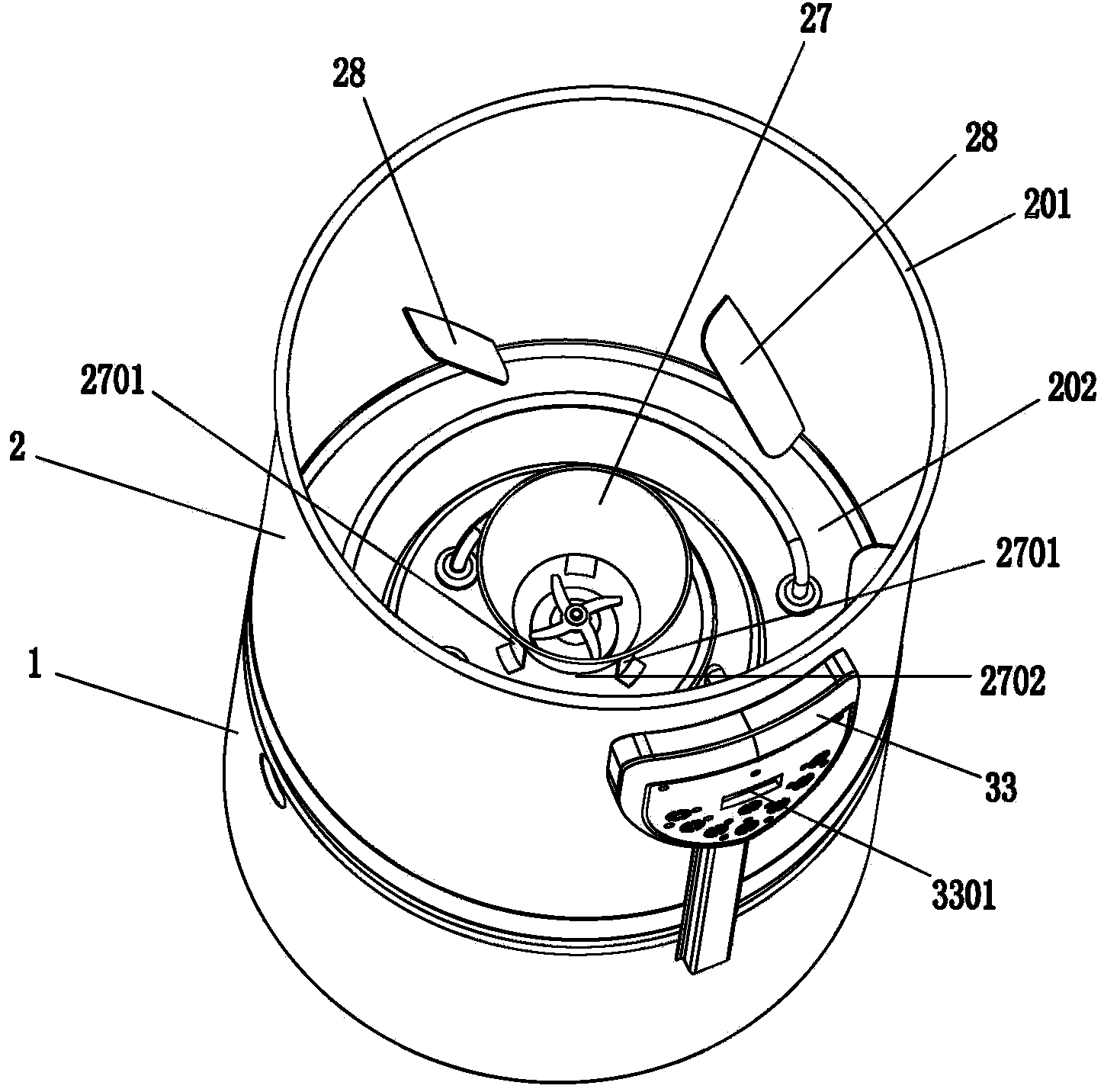

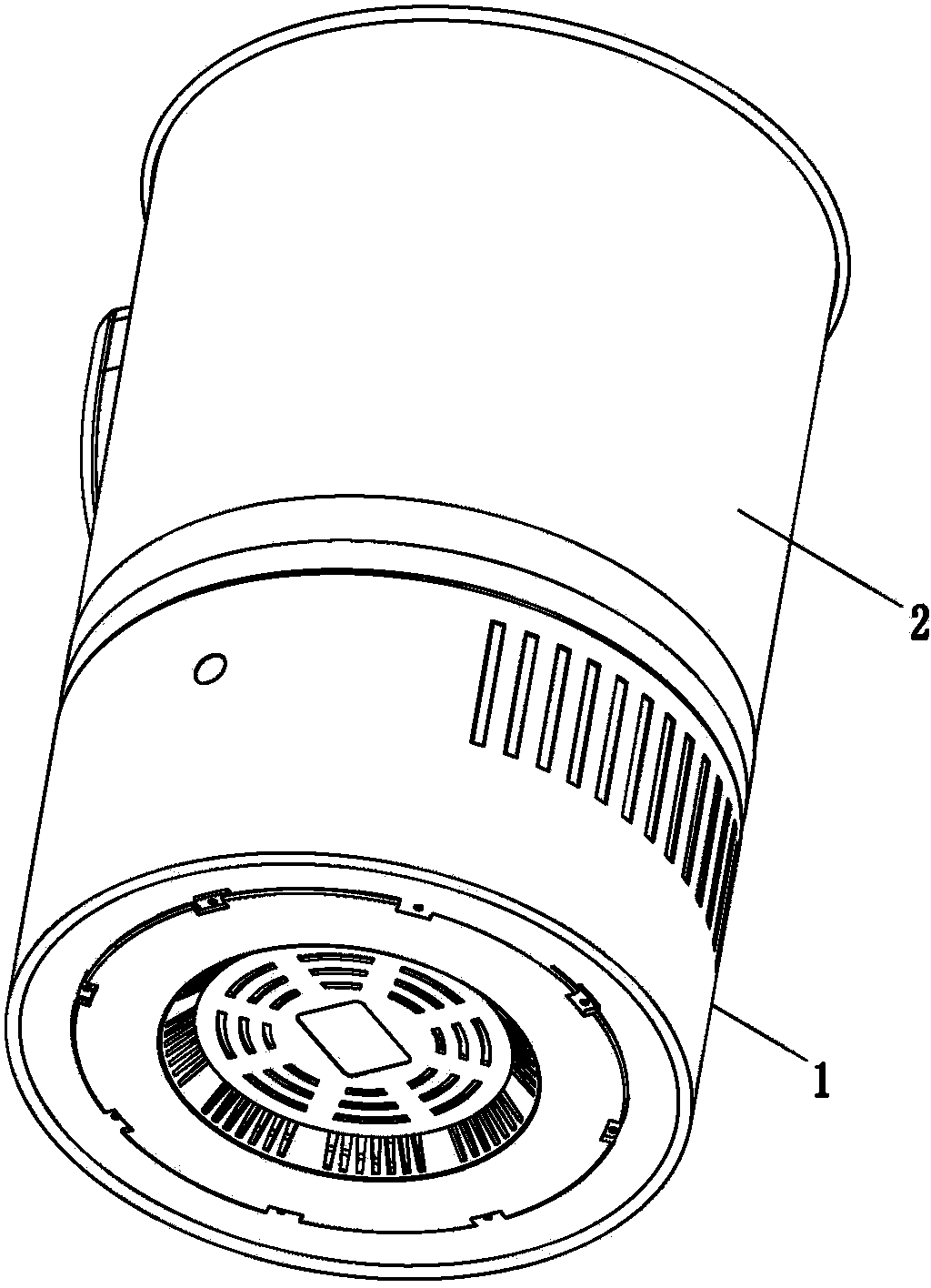

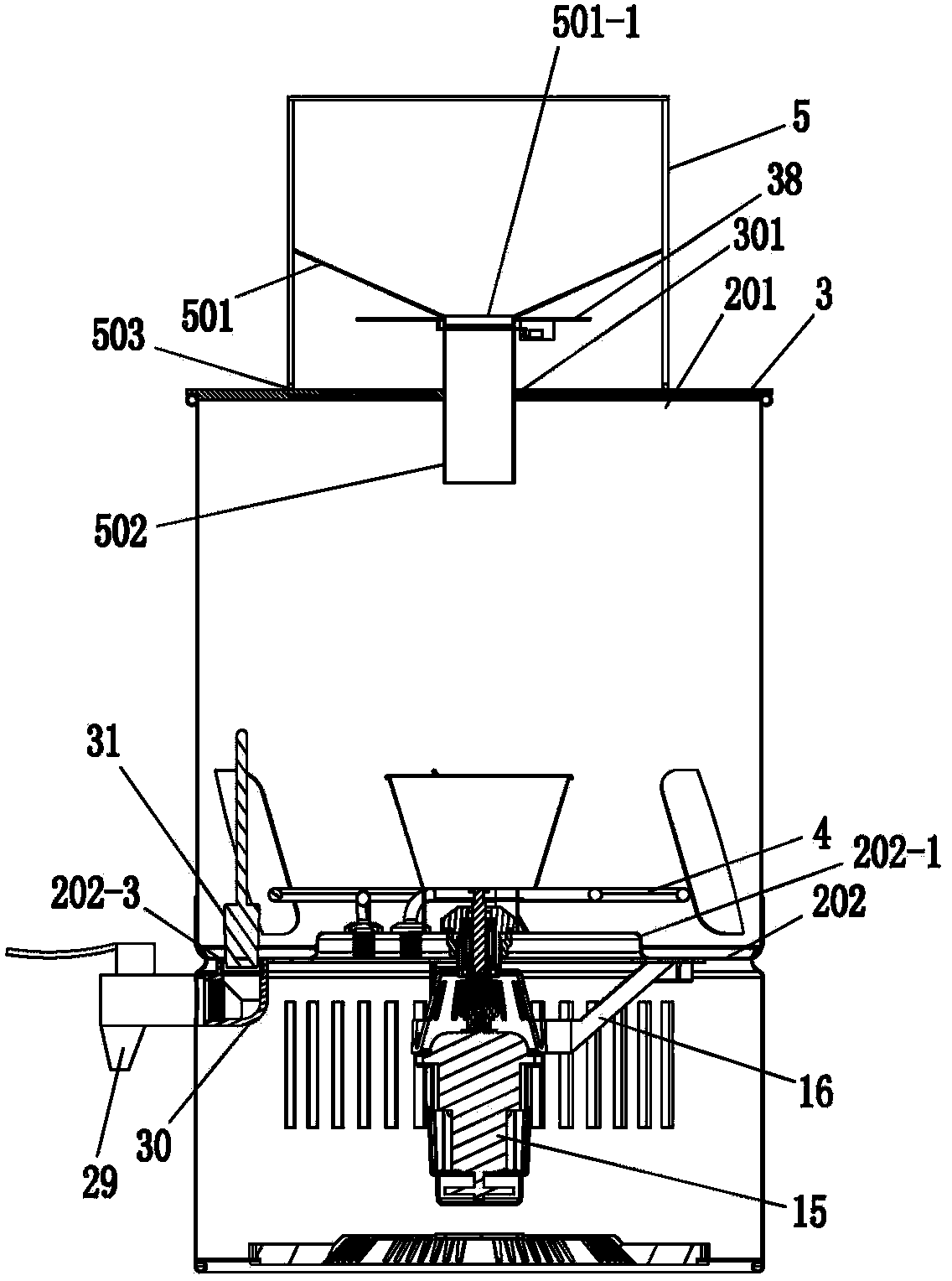

Commercial food processor

The invention discloses a commercial food processor. The commercial food processor comprises a base, wherein a barrel body is connected to the base, a barrel cover covers an opening in the top of the barrel body, a driving device is fixed in the base, a heating pipe is connected to a base plate of the barrel body, a timed feeding container is detachably installed on the barrel body, a funnel body is arranged in the timed feeding container, a funnel hole in the funnel body is connected with a funnel pipe, a barrel cover feeding hole suitable for the funnel pipe to be inserted in is formed in the barrel cover, and the timed feeding container is seated on the barrel cover through the bottom edge; a rotary shaft transversely penetrates through the funnel pipe and is arranged in the funnel pipe, a material blocking switch plate is connected to the rotary shaft, the driving device further comprises a bearing sleeve, a locking nut, an upper coupler, a lower coupler and a motor, a cross-shaped buffer glue part is arranged between the upper coupler and the lower coupler, and four buffer supporting arms on the buffer glue part stretch to the space between an upper rotating claw side face and a lower rotating claw side face which are adjacent to each other. The commercial food processor is simple and reasonable in structure, low in noise and ideal in crushing effect, and foods better in flavor can be made.

Owner:中山市惠尔普斯电器有限公司

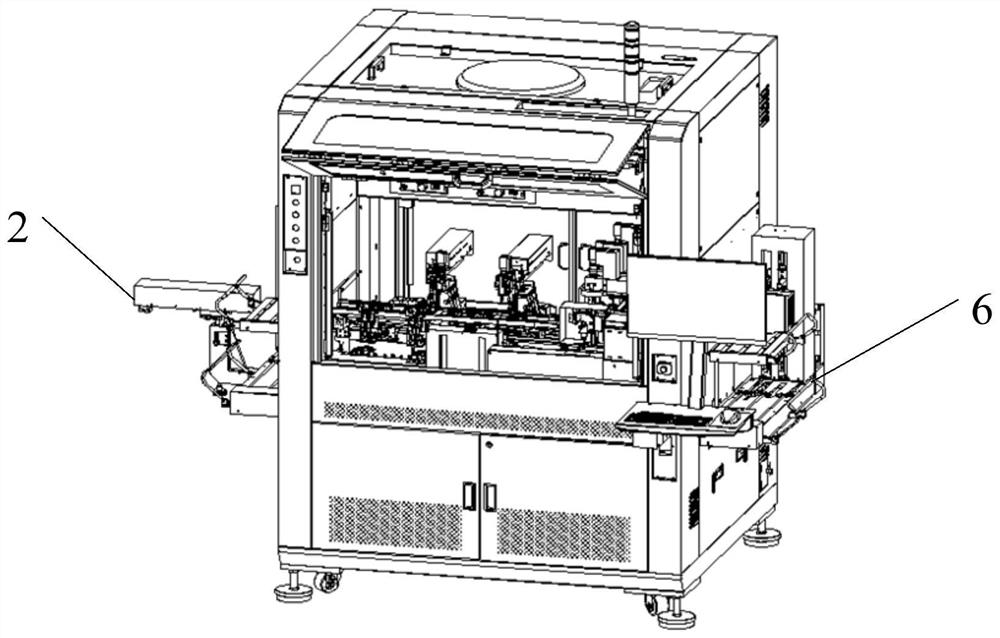

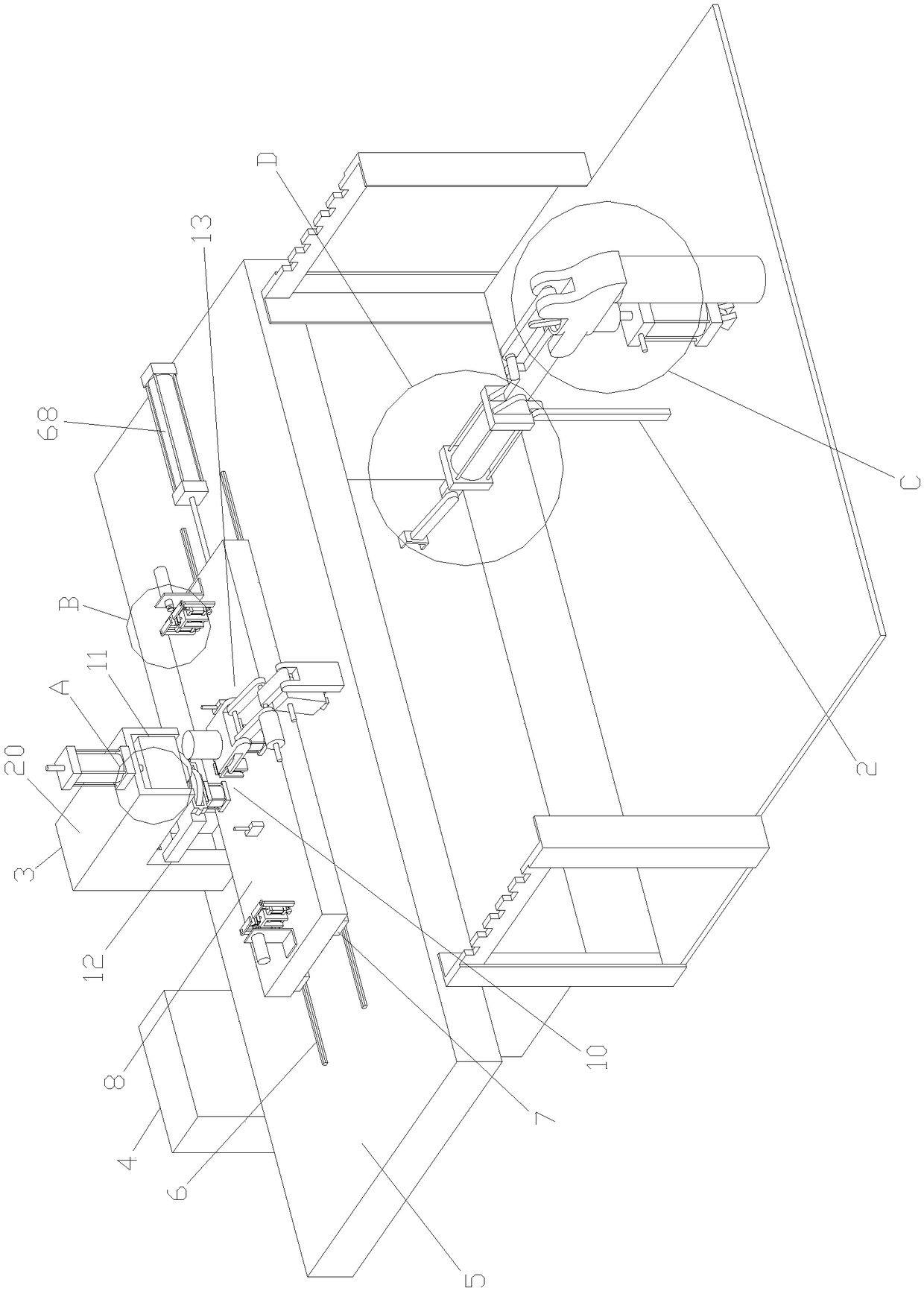

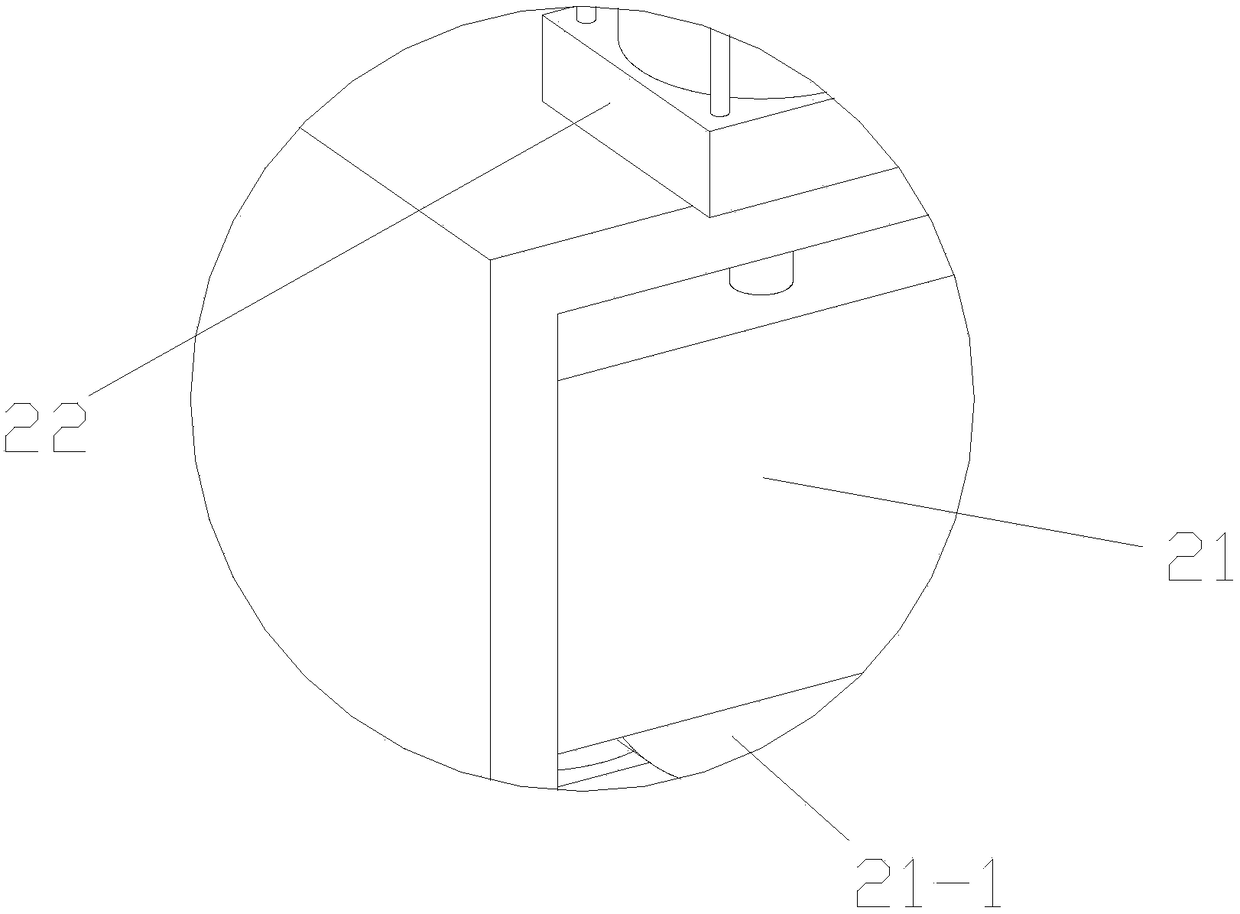

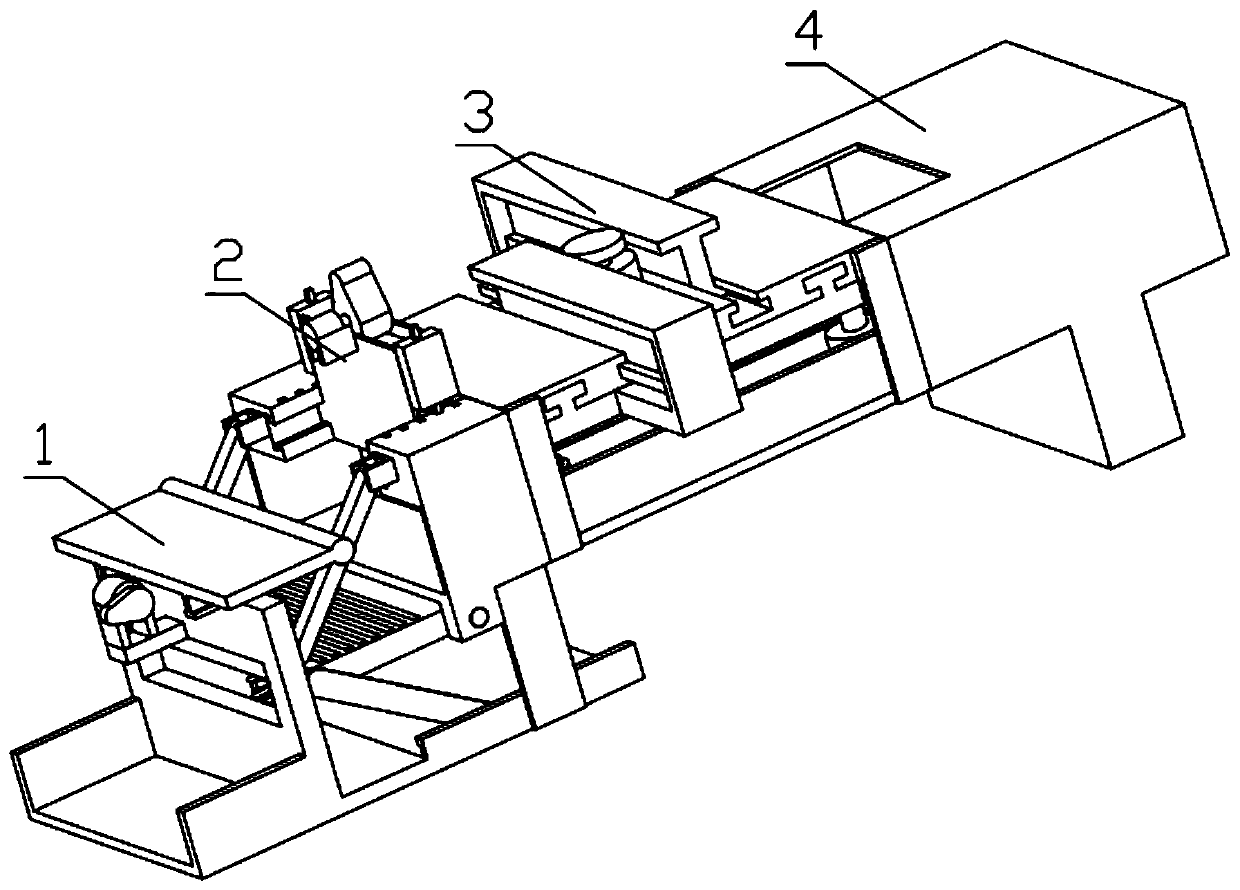

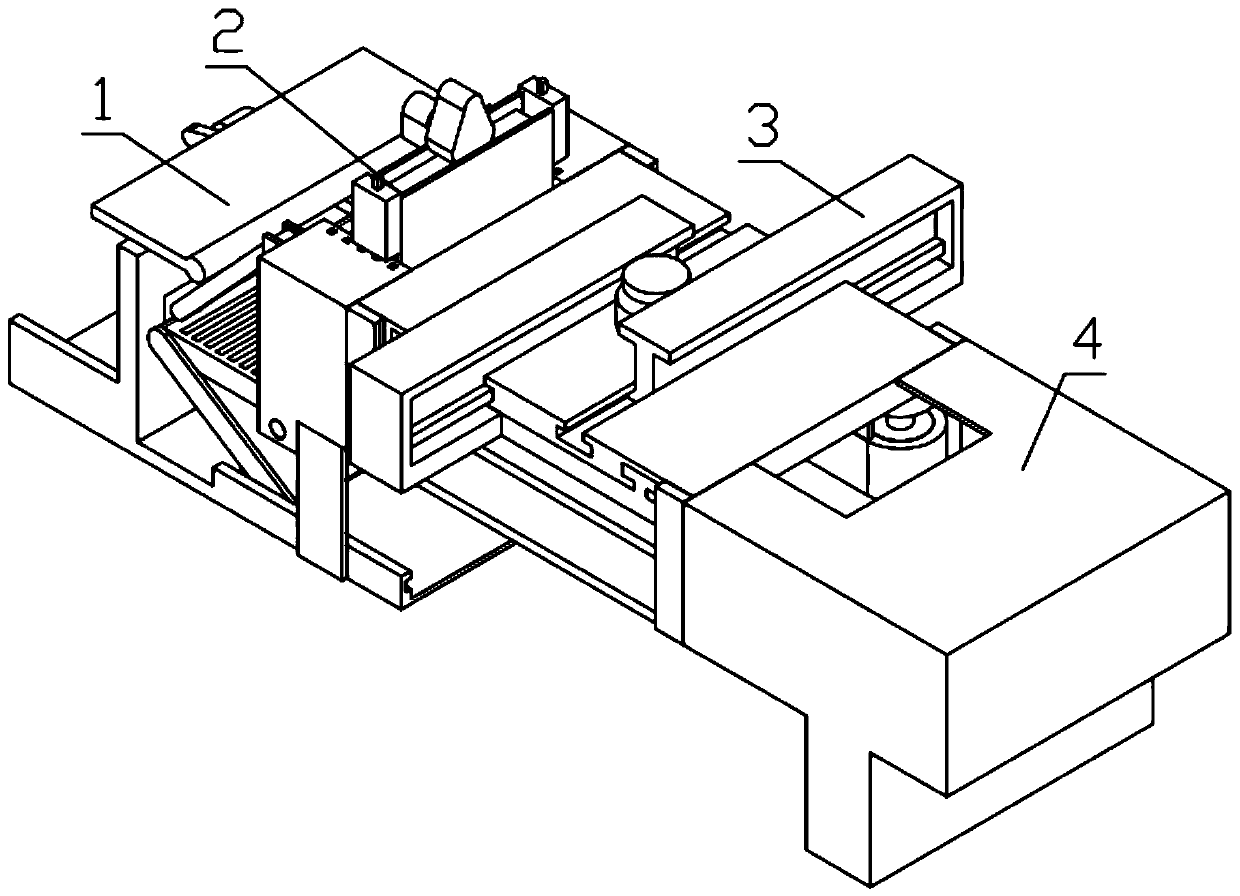

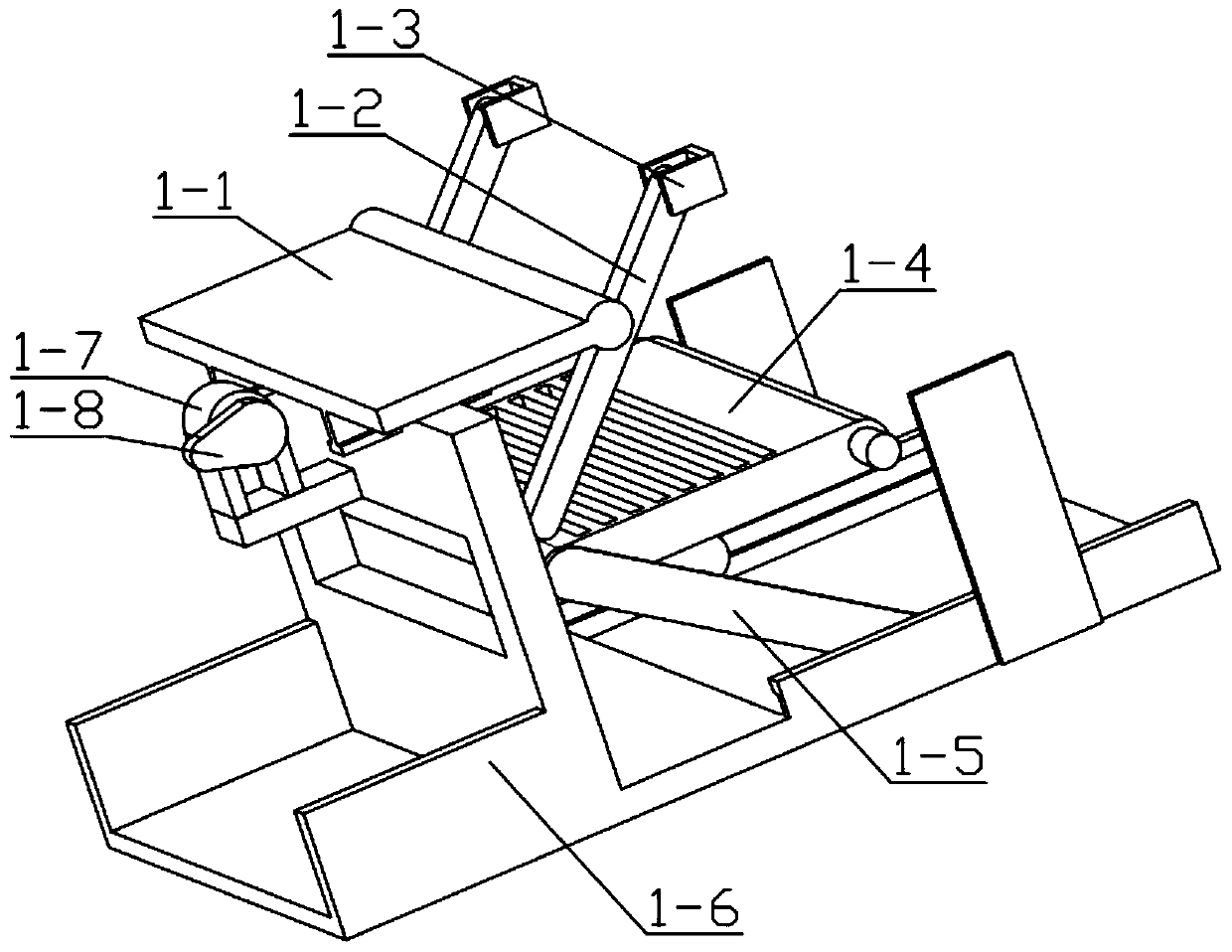

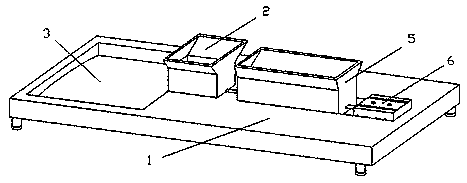

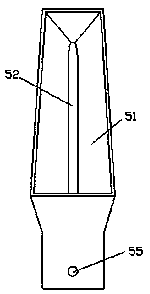

Single-channel laminating assembly equipment for mobile phone camera module

PendingCN111889318AFit and assemble high efficiencyEasy to mass produceLiquid surface applicatorsMaterial gluingCamera lensEngineering

The invention discloses single-channel laminating assembly equipment for a mobile phone camera module. The single-channel laminating assembly equipment comprises a conveying track, a substrate feedingdevice, a glue dispensing device, a camera lens feeding device, a picking and laminating device, and a finished product discharging device, wherein the substrate feeding device, the glue dispensing device, the camera lens feeding device, the picking and laminating device, and the finished product discharging device are arranged along the conveying track; a glue dispensing and adsorbing platform and a laminating and adsorbing platform are arranged in the conveying track; the glue dispensing device is arranged to correspond to the glue dispensing and adsorbing platform; the picking and laminating device is arranged to correspond the laminating and adsorbing platform; and the conveying track is used for receiving substrates pushed by the substrate feeding device, sequentially conveying the substrates to the glue dispensing and adsorbing platform and the laminating and adsorbing platform, and pushing an assembled camera to the finished product discharging device. The single-channel laminating assembly equipment realizes the full-automatic operation of feeding and laminating assembly of the substrates and camera lenses and finished product discharging, and the high-efficiency laminating assembly, meets the requirements of high precision, and is beneficial to mass production.

Owner:深圳中科软件科技有限公司

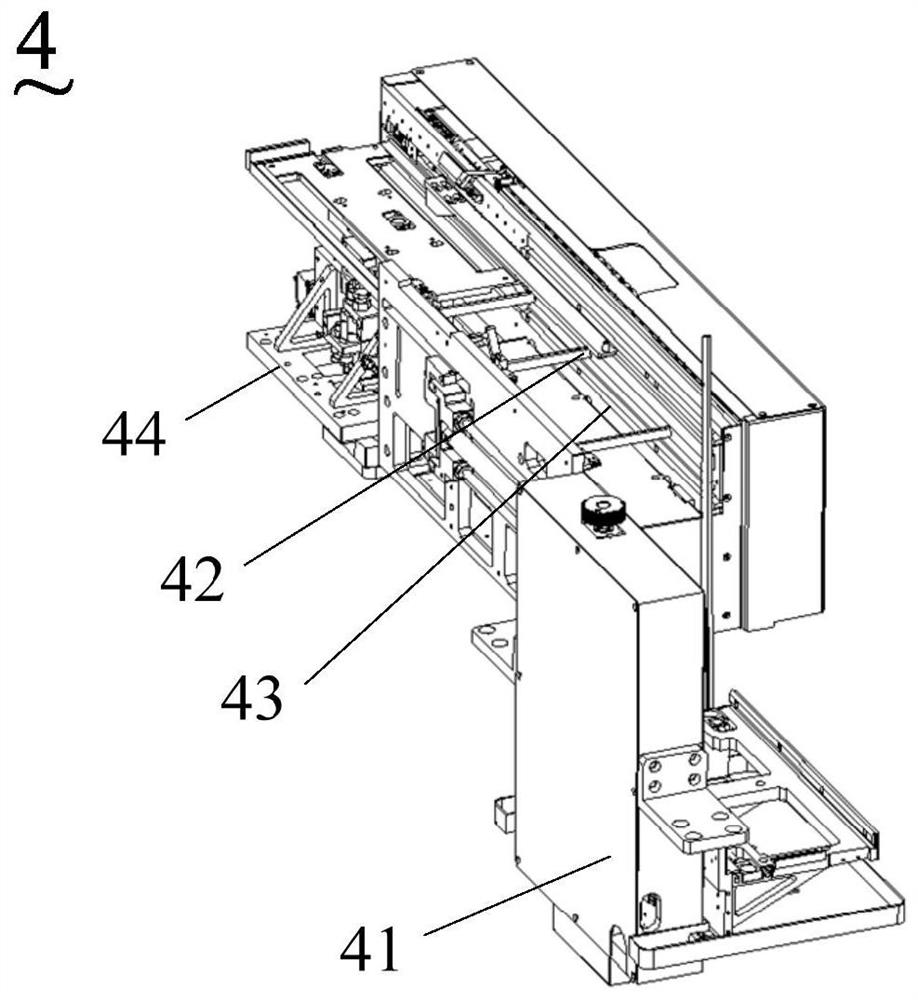

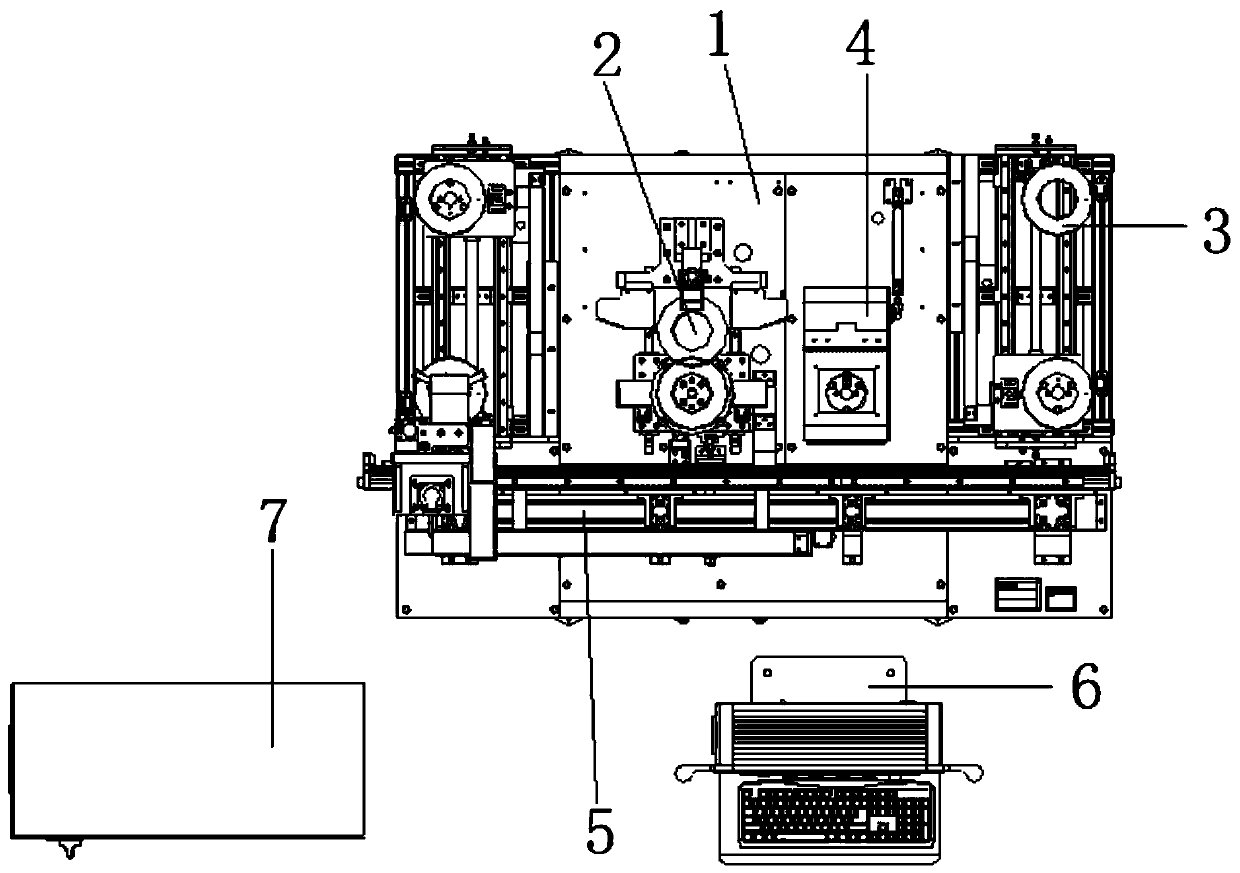

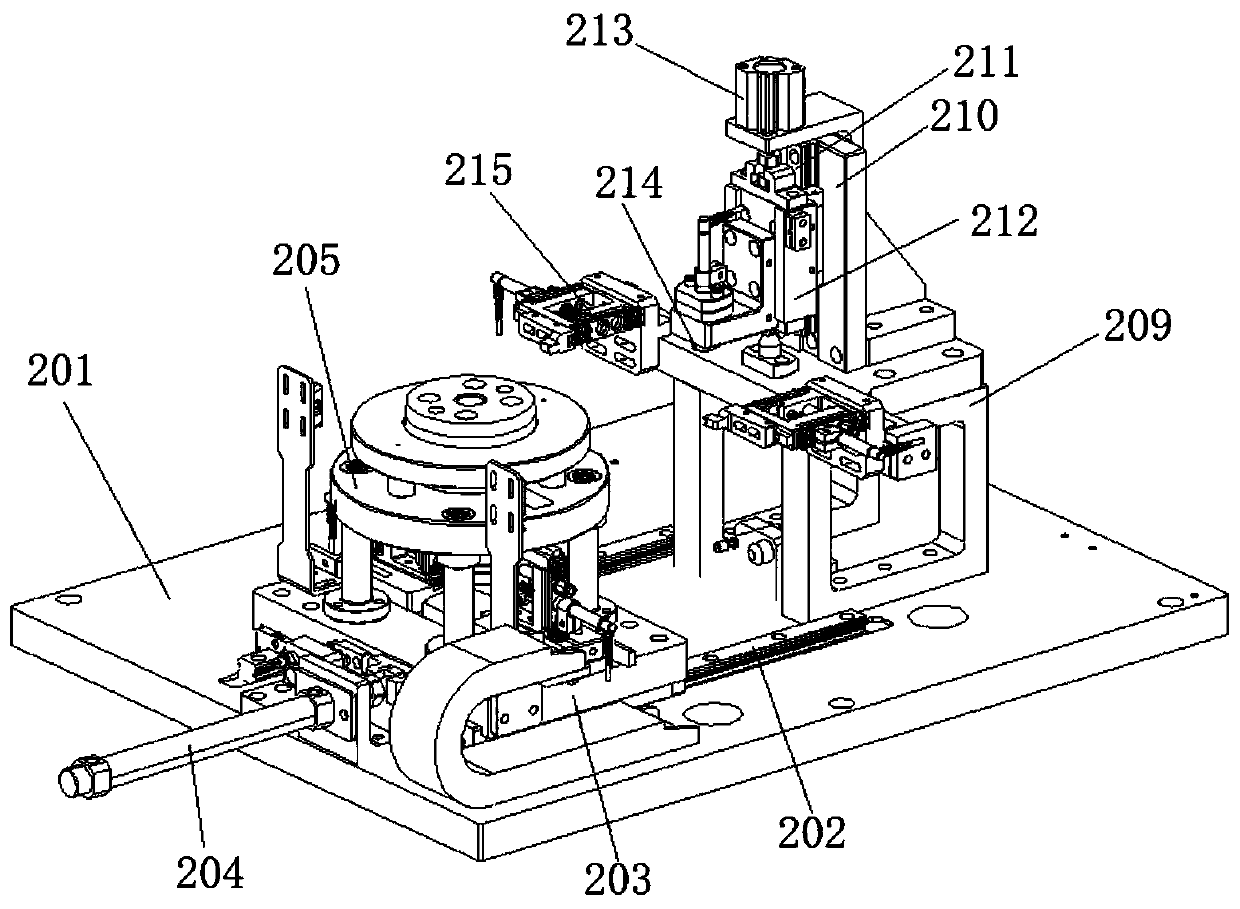

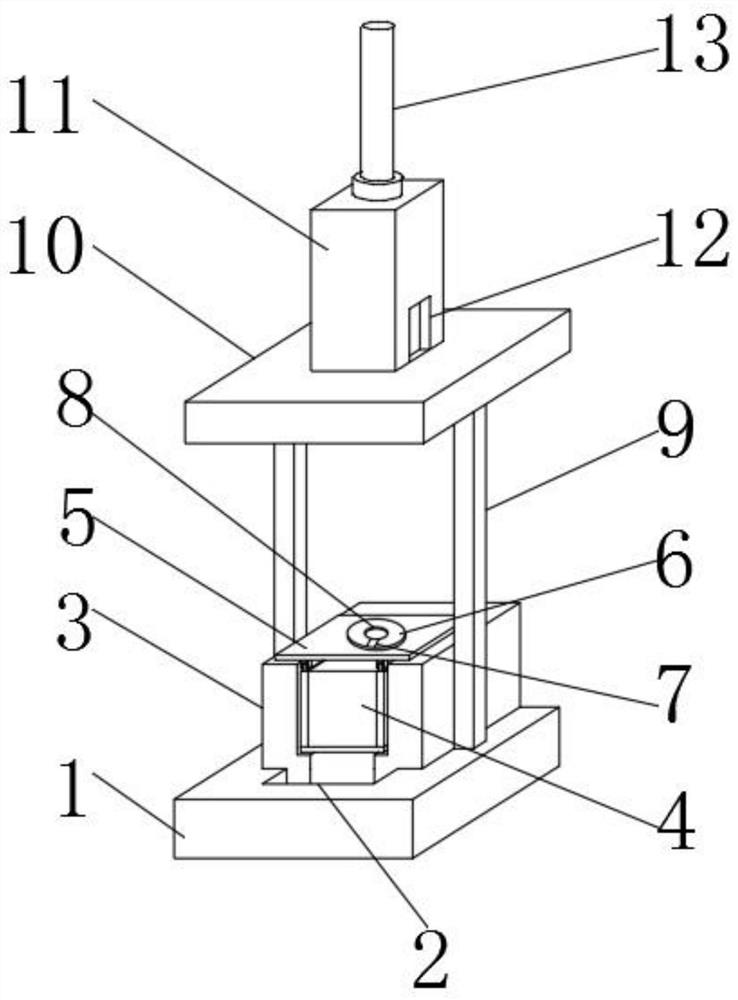

Gear part detector

PendingCN110388888ASave operating timeConvenient automatic knife adjustmentMeasurement devicesProduction linePersonal computer

The invention provides a gear part detector, comprising a frame, and a group mounted on the frame and consisting of an automatic measuring portion, an automatic loading and unloading portion, a calibrating portion and a carrying portion, wherein the automatic measuring portion comprises a gear positioning structure and a measuring structure which are used for automatically positioning and measuring a workpiece; the measuring structure comprises at least three groups of sensors for measuring the inner diameter, the outer diameter and the height of a gear respectively; the sensors send the measured data to an industrial personal computer; the automatic loading and unloading portion comprises a loading portion and an unloading portion; the loading portion conveys a workpiece to be detected; the unloading portion conveys detected qualified workpieces; and unqualified workpieces are returned from the loading portion along the original path. The gear part detector can be directly connected to a production line, is convenient for a processing machine tool to automatically adjust a cutter and automatically give a processing abnormal alarm, reduces the production cost and labor intensity and saves manpower.

Owner:无锡恩梯量仪科技有限公司

Pet feed stirring and feeding device

InactiveCN106135030AGuaranteed normal feedingEasy feedingAnimal feeding devicesEngineeringHigh pressure

Owner:WUXI DONGCHENG BIO TECH CO LTD

Dried tofu stirring device with automatic feeding function

InactiveCN105233731ARealize automatic stirringRealize nestingRotary stirring mixersMixer accessoriesBiochemical engineeringScrew conveyor

The invention discloses a dried tofu stirring device with an automatic feeding function. The dried tofu stirring device comprises a stirring device, a dried tofu adding device and a seasoning adding device, wherein the stirring device comprises a stirring chute, a frame, a first motor, a second motor, a stirring shaft and a stirring blade; the dried tofu adding device comprises an electronic weighting instrument, a spiral conveyer, a hopper and a belt conveyor; the seasoning adding device comprises a sauce cylinder, a pump and a flow meter; the dried tofu stirring device further comprises a controller for controlling the first motor, the second motor, the belt conveyor, the spiral conveyer and the pump; detecting signals of the electronic weighting instrument and the flow meter are input to the controller. The dried tofu stirring device with the automatic feeding function has the advantages that automatic stirring and discharging are realized, the stirring working efficiency is high, the labor intensity is low, automatic charging is realized and the working efficiency of the dried tofu production is further increased.

Owner:CHONGQING YUPAI AGRI PROD DEV

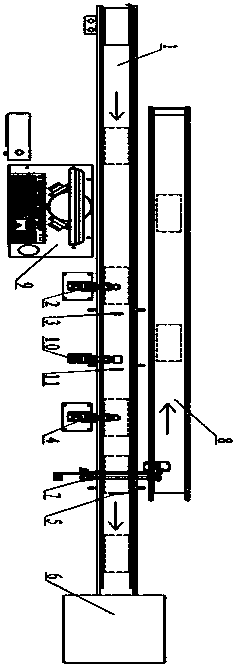

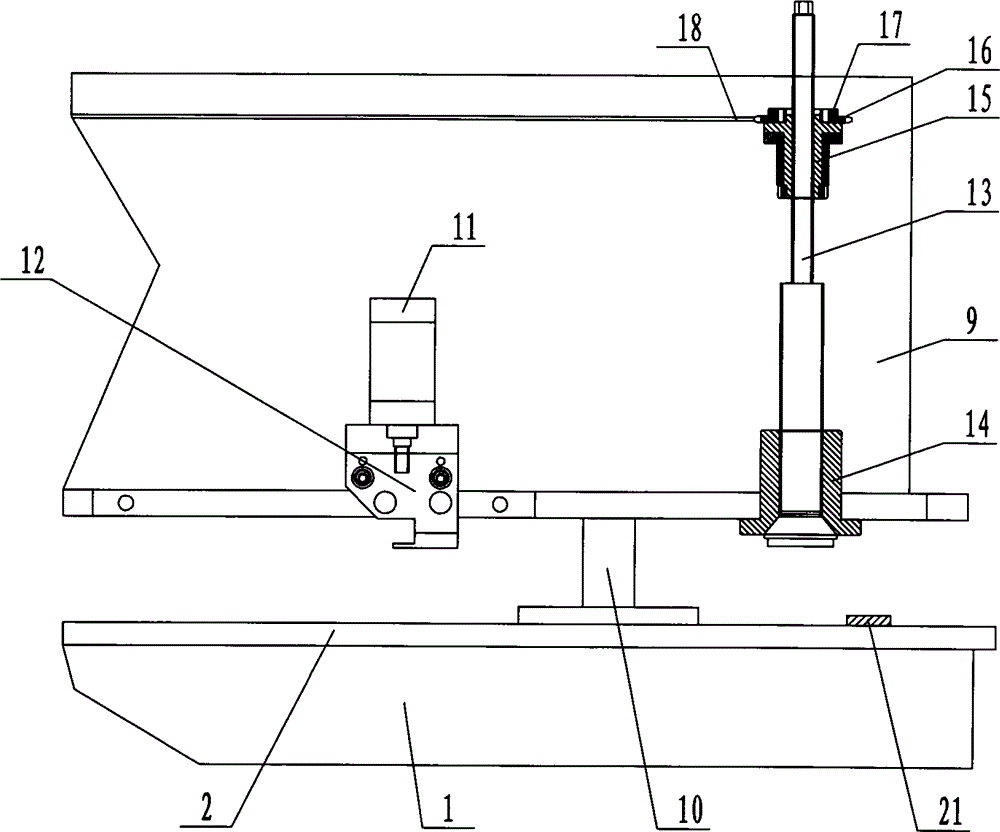

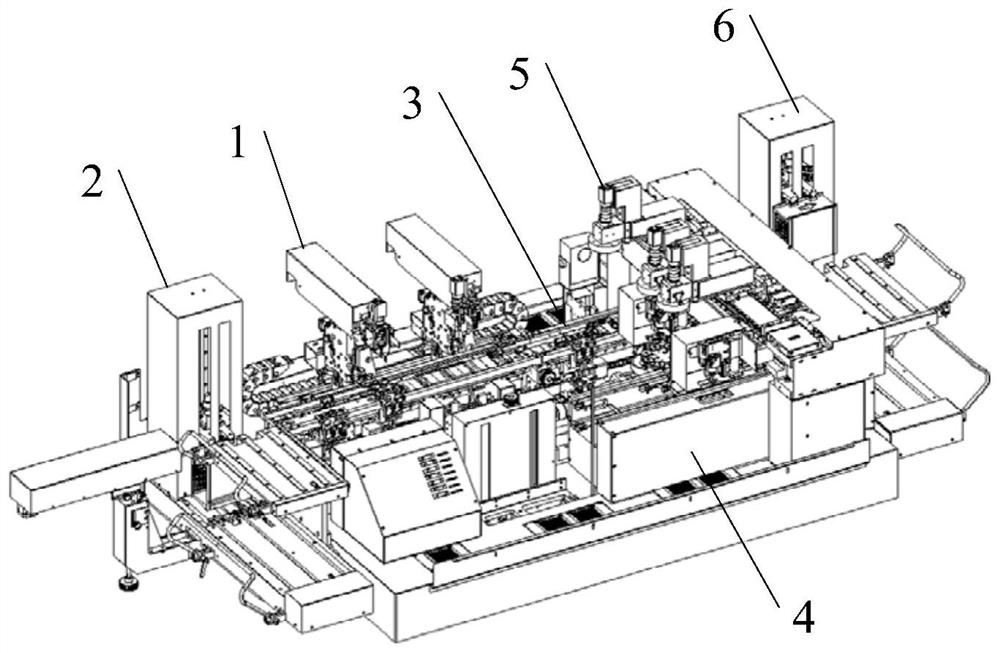

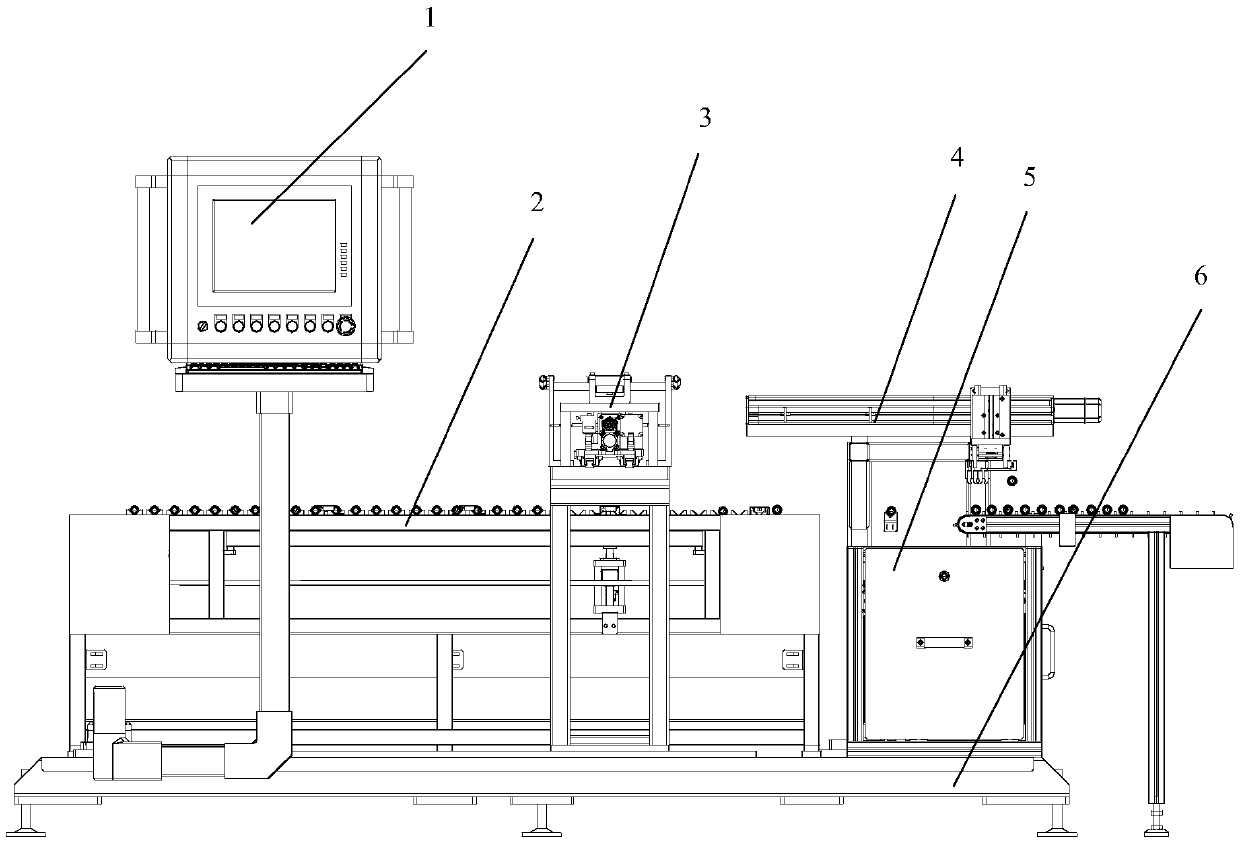

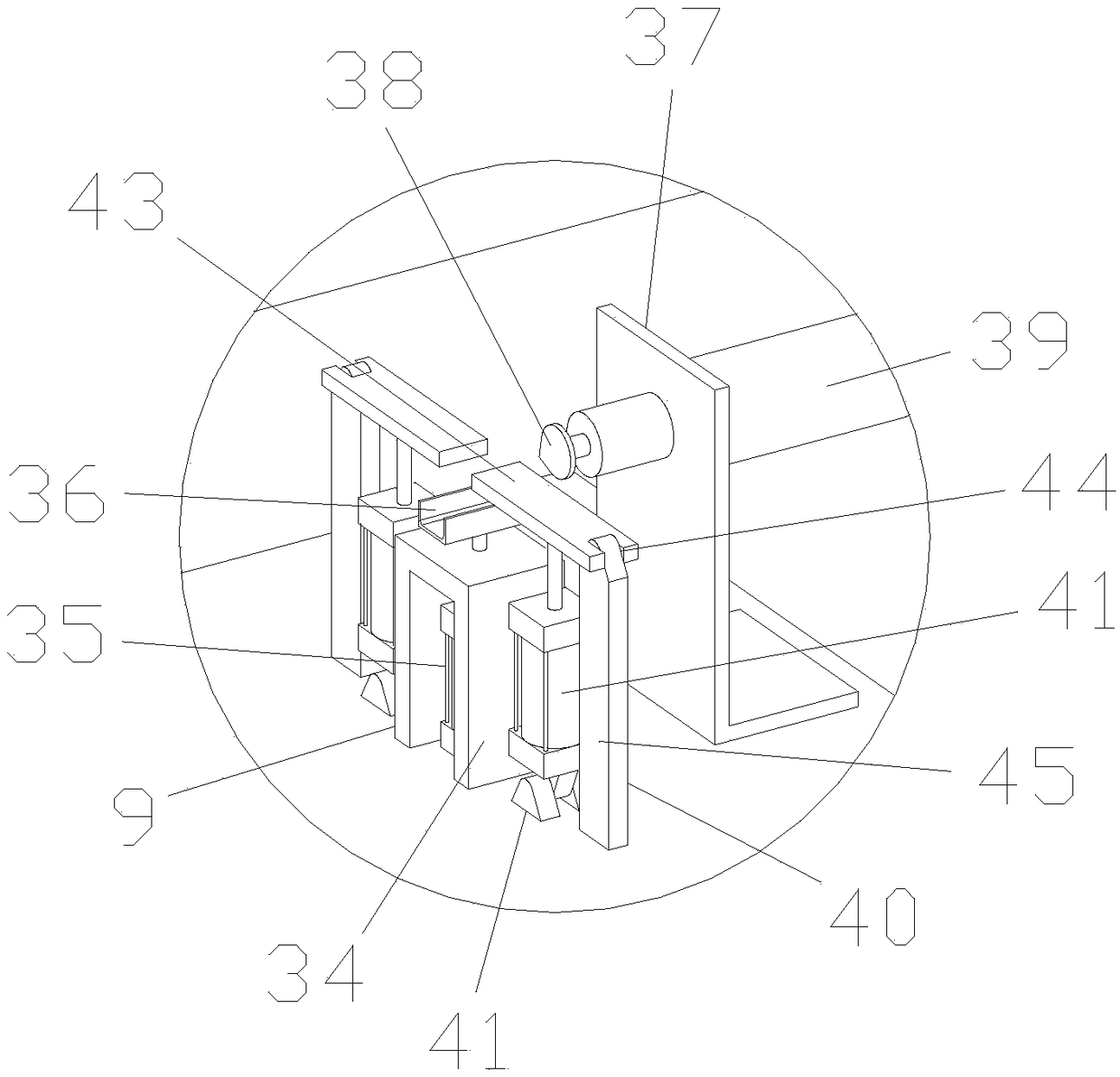

Long-shaft type part detection machine

The invention provides a long-shaft type part detection machine. The long-shaft type part detection machine comprises an automatic roller line, an automatic detection part, an automatic sorting part,an unqualified material box, and a peripheral frame, wherein the automatic roller line is fixedly arranged on the peripheral frame; the automatic detection part is fixedly arranged on the automatic roller line; the unqualified material box is fixedly arranged on the peripheral frame; the automatic sorting part is separately arranged at one side of the automatic detection part; the automatic rollerline is a chain type roller table structure, and a plurality of V-shaped supporting blocks are arranged on the automatic roller line; the automatic detection part has a positioning structure and a measurement structure and is used for automatically positioning, clamping and detecting a workpiece; and the automatic sorting part has a mechanical arm structure, is used for grasping the workpiece according to the judgment result, and placing the workpiece in an automatic qualified part path or the unqualified material box located below the mechanical arm structure. The long-shaft type part detection machine solves the problems in the prior art that the traditional long shaft measurement requires manual operation, has low degree of automation and low efficiency, and is not suitable for rapid mass production.

Owner:无锡恩梯量仪科技有限公司

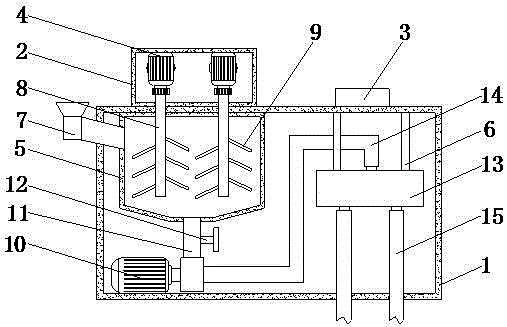

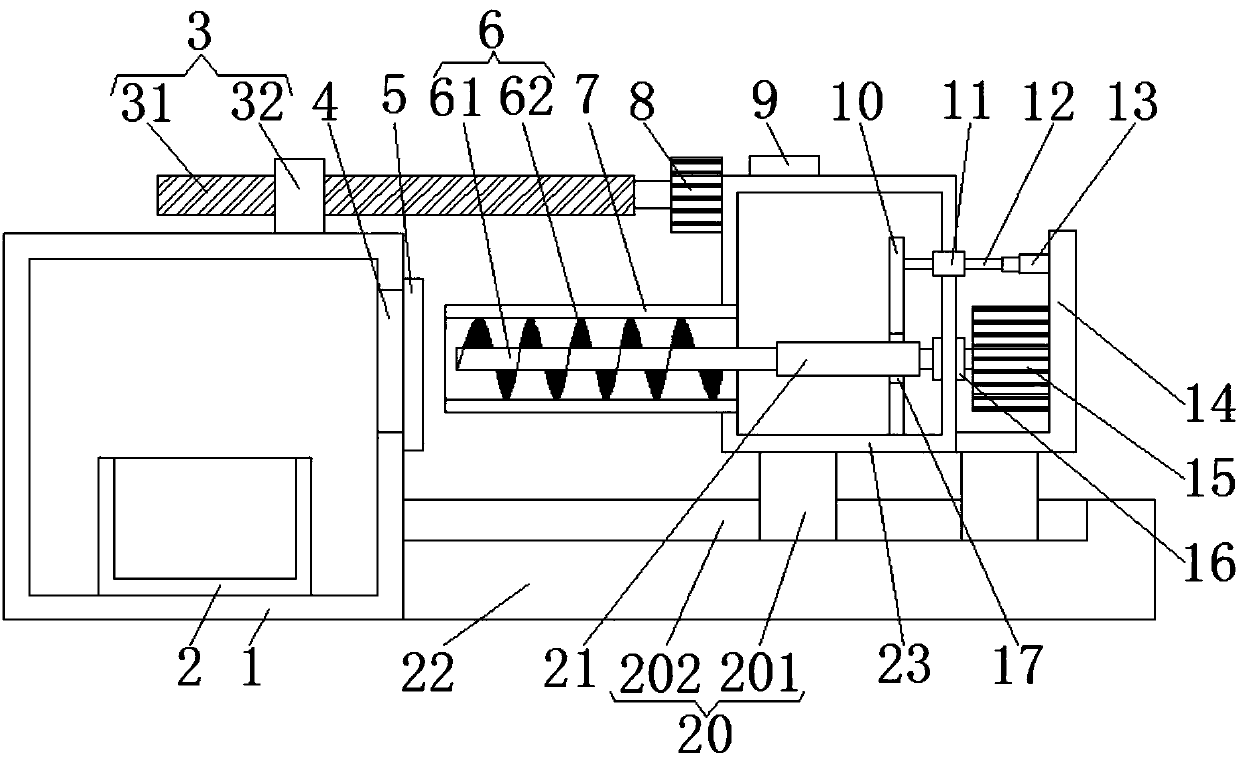

Novel energy boiler having automatic feeding function

InactiveCN107588418ASave time and effortImprove work efficiencySolid fuel combustionLump/pulverulent fuel feeder/distributionCombustion chamberEngineering

The invention discloses a novel energy boiler having an automatic feeding function. The novel energy boiler comprises a boiler body, the lower surface of the inner wall of the boiler body is fixedly connected with the lower surface of a combustion chamber, the right side of the boiler body is provided with a first through hole, a cover plate is disposed at the position of the boiler body corresponding to the first through hole, and the upper surface of the boiler body is fixedly connected with the lower surface of a moving device. According to the novel energy boiler having the automatic feeding function, by arrangement of a control panel, a first motor, a second motor, an electric push rod, a sliding rod, a sliding sleeve, a bearing, a sliding block and a chute, workers add fuel into a casing through a feeding port. When the boiler body needs fuel, the workers open the cover plate, so that a fixing rod drives a spiral blade to rotate to make fuel in a discharging barrel pushed outsidethe discharging barrel, the fuel falls into the combustion chamber, the boiler body achieves automatic feeding, time and physical power of the workers are saved, and workers' work efficiency is improved.

Owner:成都课迪科技有限公司

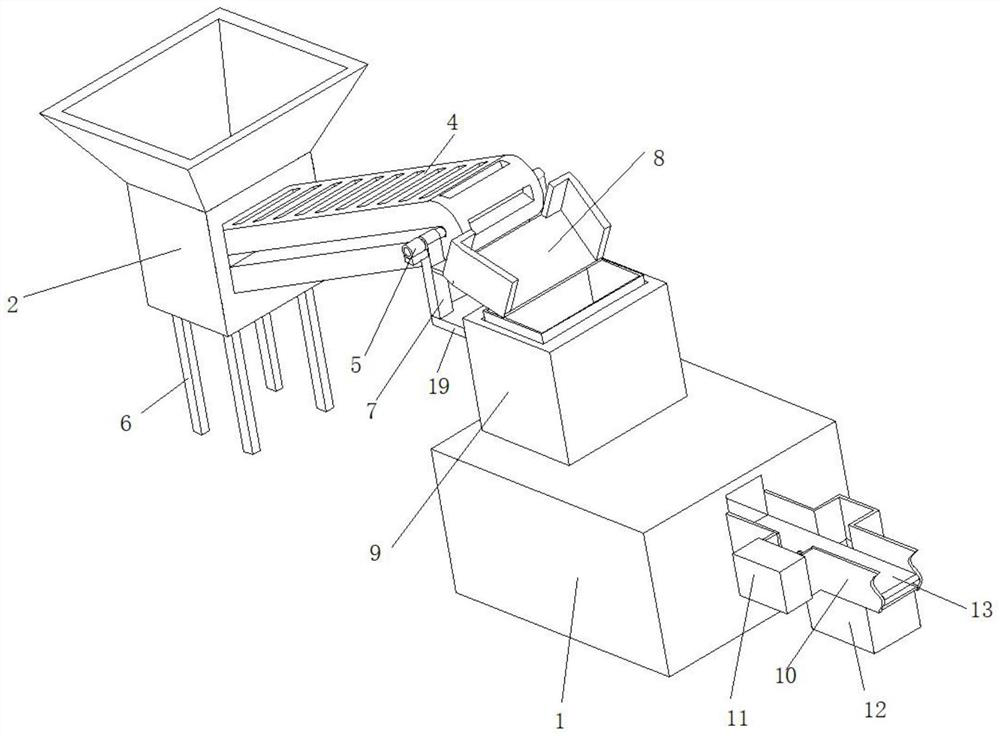

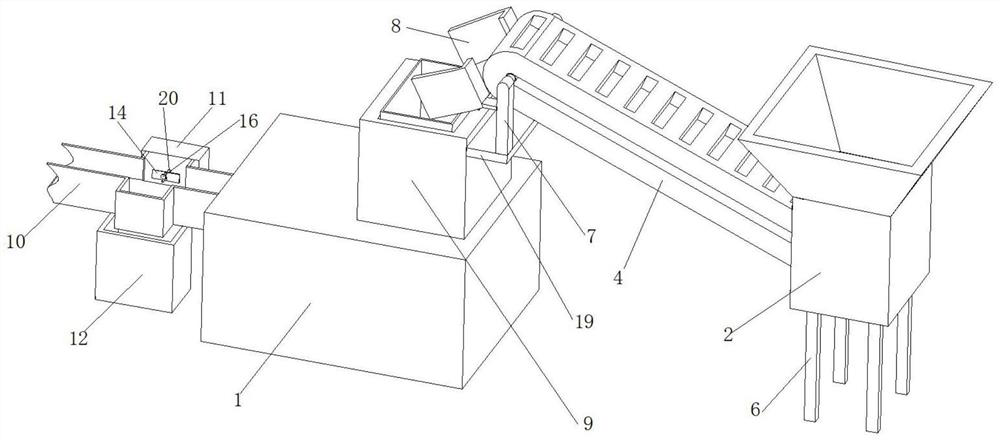

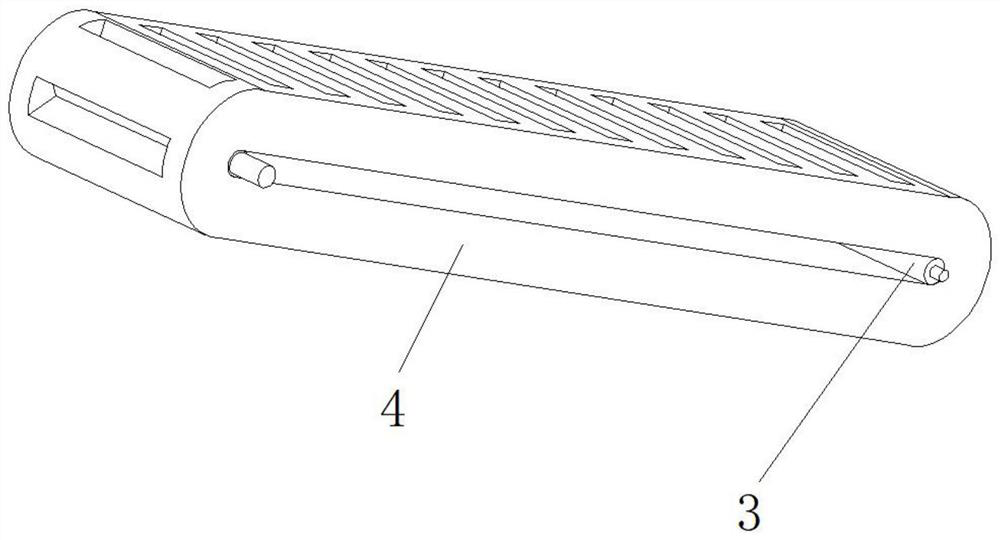

Ore screening device for ore machine and with automatic feeding function

InactiveCN106944336AWith automatic feeding functionNovel structureSievingScreeningEngineeringUltimate tensile strength

The invention discloses an ore screening device for ore machinery with an automatic feeding function, which comprises a feeding device body and a screening device body, the screening device body is arranged obliquely, and a first A sieving plate and a second sieving plate, the first sieving plate is located on the top of the second sieving plate, and the first sieving plate and the second sieving plate are respectively provided with a first sieving hole and a second sieving hole. Two screening holes, the conveying rollers are connected by a conveying belt, the bottom of the conveying roller is provided with a mounting frame, the conveying belt is also provided with a feeding plate, and the top of the left side of the screening device body is hinged with a The feeding baffle, the top end of the conveyor belt extends to the feeding baffle. The invention is an ore screening device for ore machinery with automatic feeding function, which has novel structure, convenient operation, realizes automatic feeding, greatly reduces labor intensity, and improves screening quality.

Owner:XIAOGAN QISIMIAOXIANG CULTURAL MEDIA

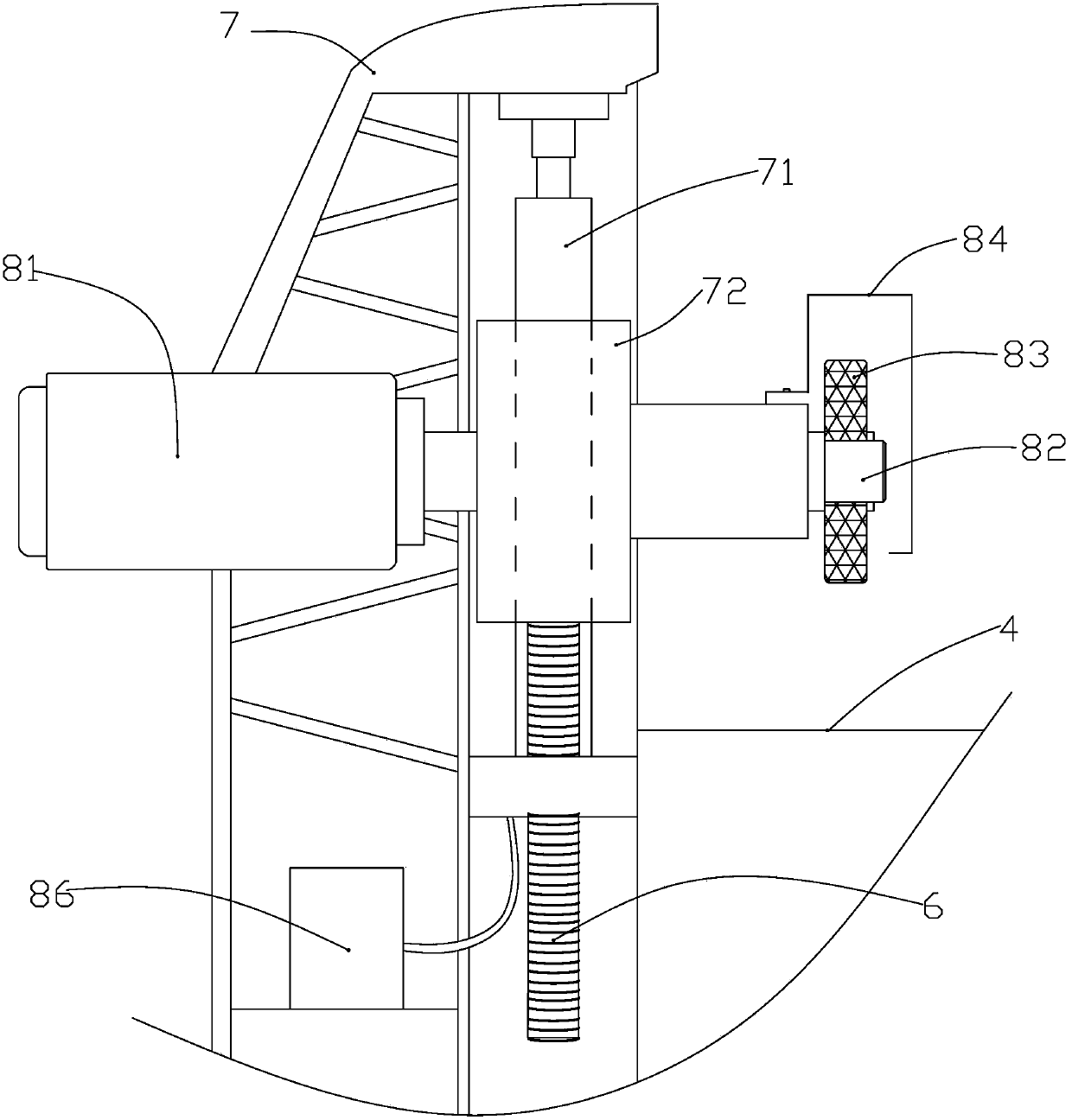

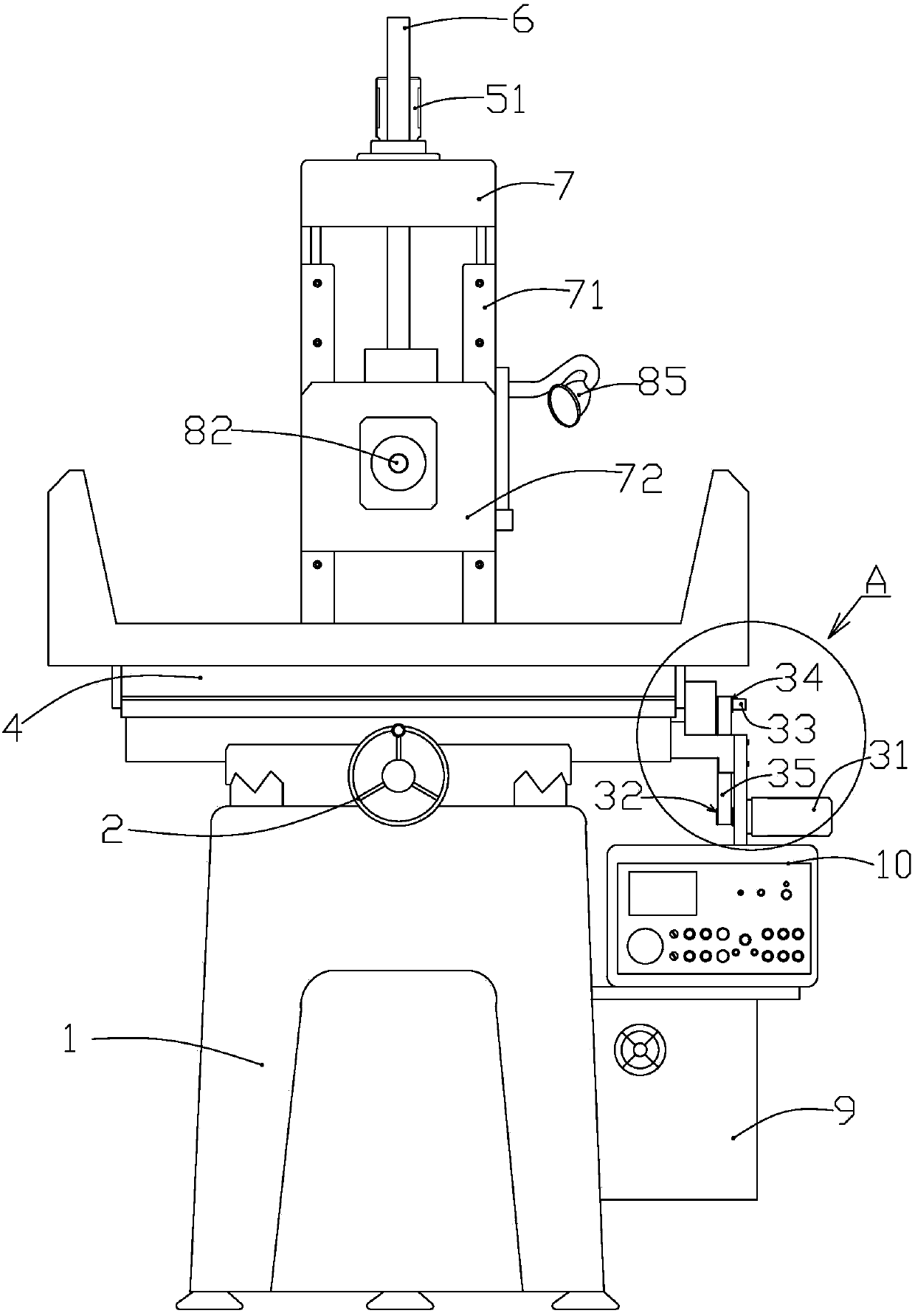

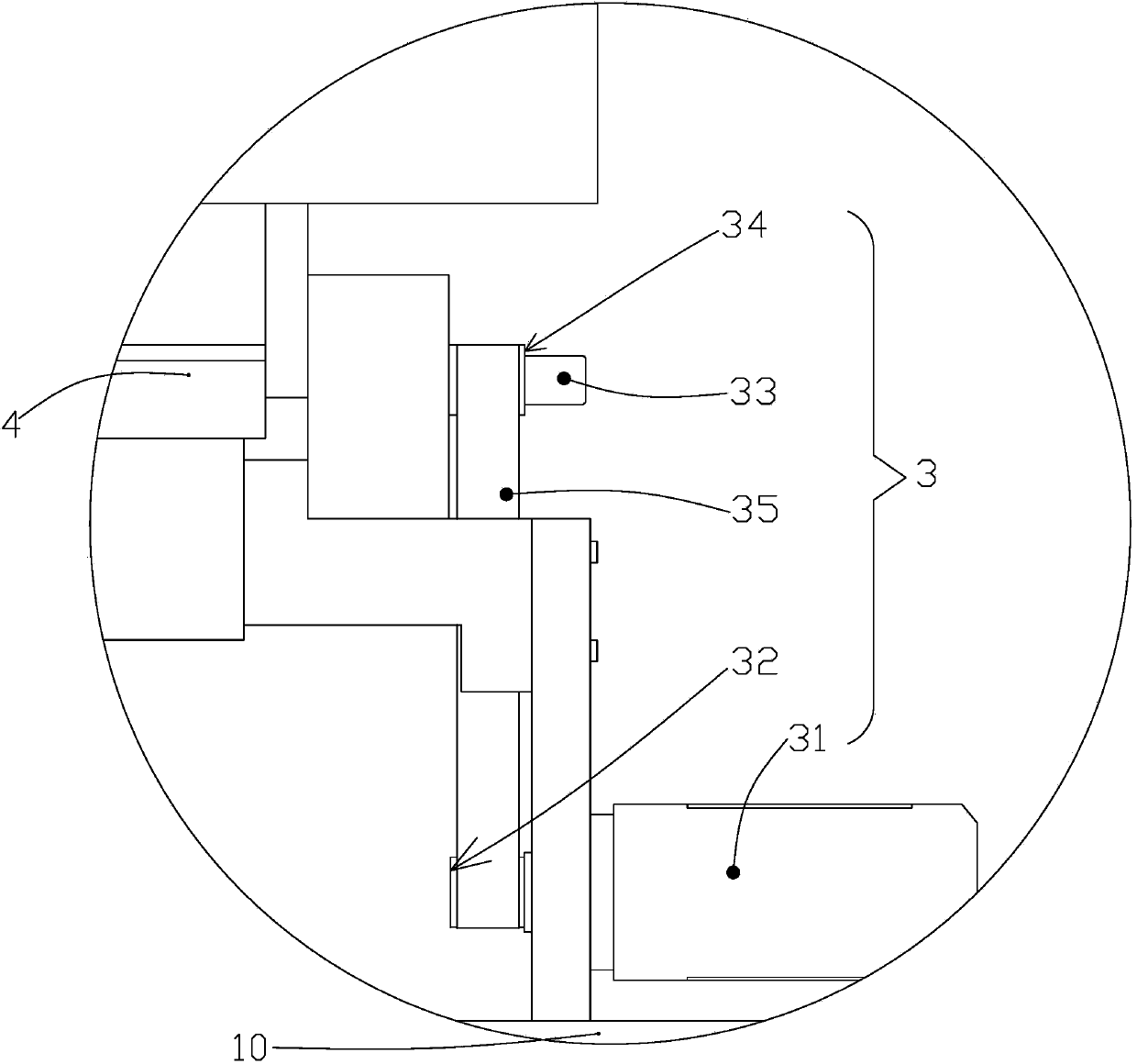

Novel numerical control flat grinder

InactiveCN103465126AImprove accuracyIncrease feed ratePlane surface grinding machinesNumerical controlMotor control

The invention provides a novel numerical control flat grinder and has the function of matching a servo motor with a synchronical toothed belt to realize automatic feeding of an X shaft and a Z shaft. A guide block adopts a pull-up type to drive a spindle motor to move up and down. With the novel numerical control flat grinder, the existing general wedge type column is changed to a square column in shape, and tool motor control cabinet and control panel connected with each other are arranged in the novel numerical control flat grinder to realize a CNC (computer numerical control) function. The novel numerical control flat grinder has automatic feeding function, improves production efficiency, reduces labor strength, improves feeding accuracy, guarantees production stability and integrity, increases feeding accuracy and feeding speed of lifting lean screws, prolongs service life of the lifting lean screws, improves rigidity of column structure, and further guarantees feeding accuracy.

Owner:LINQING QIYA MACHINERY

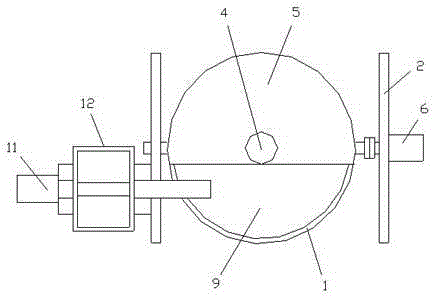

Automatic three-side synchronous grinding grinder

ActiveCN108608266AImprove processing efficiencyImprove stabilityGrinding carriagesGrinding feedersProduction rateEngineering

The invention discloses an automatic three-side synchronous grinding grinder. The grinder comprises a support used for arranging rails, a conveying device arranged at the rear end of the support, a grinding device arranged at the front end of the support, and a control device used for controlling the conveying device and the grinding device. The automatic three-side synchronous grinding grinder provided by the invention is high in machining efficiency and good in using stability, grinding portions in three directions are utilized for grinding the slide rails synchronously, in addition, the three grinding portions are adjustable, thus, the distance of slide rails of different sizes can be controlled, the using range of the equipment is expanded, furthermore, the grinder further has an automatic feeding function, zero labor can be achieved, the cost is lowered, the production rate is increased, and the grinder deserves popularization.

Owner:LISHUI VOCATIONAL & TECHN COLLEGE

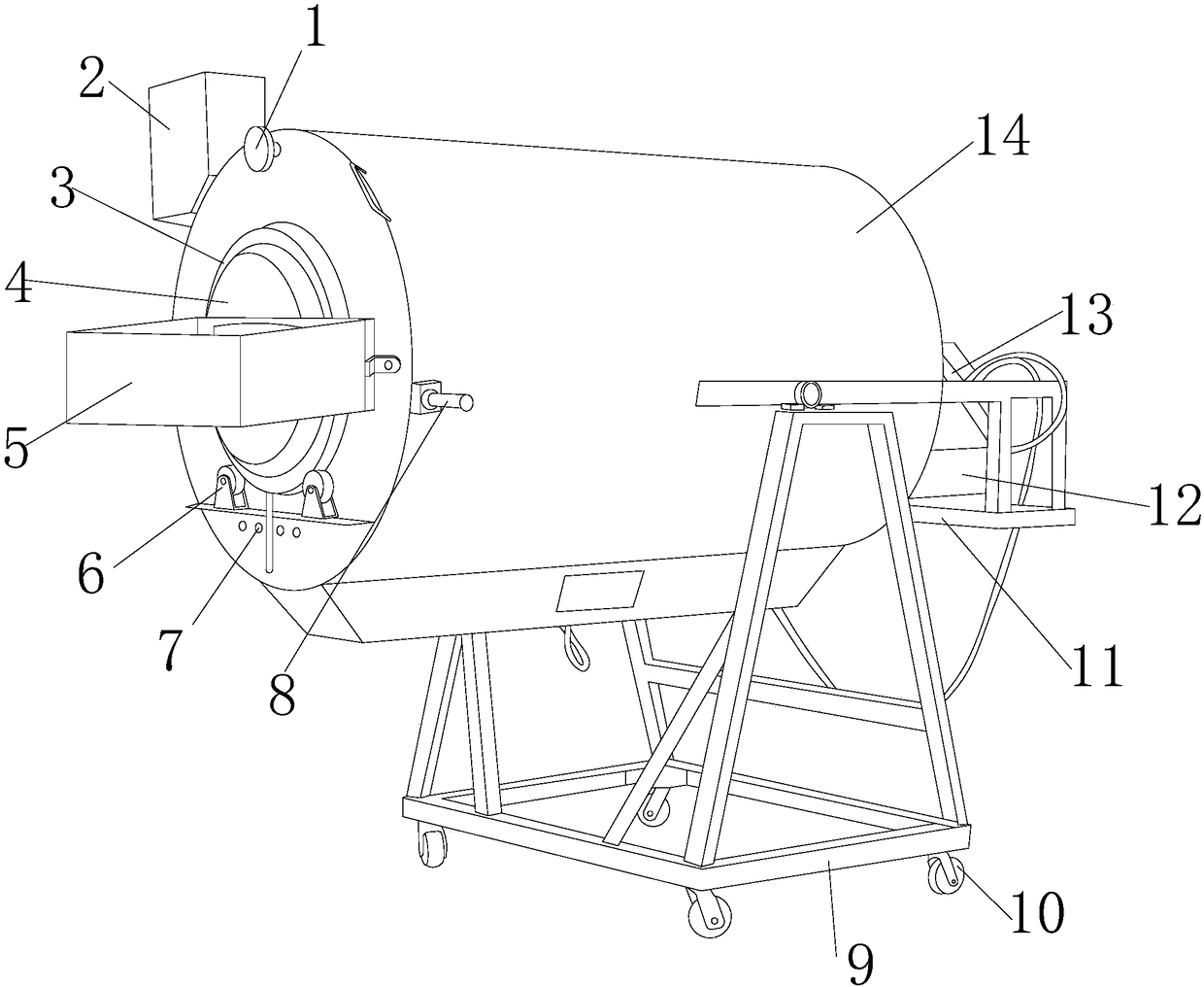

Fully-automatic fixation machine for tea leaf processing and production

PendingCN108244279AReduce tensionReduce workloadPre-extraction tea treatmentElectric machineryFully automatic

The invention discloses a fully-automatic fixation machine for tea leaf processing and production. The structure of the fully-automatic fixation machine for tea leaf processing and production comprises a temperature meter, an intelligent controller, a rolling drum, a through hole, an automatic feeding device, towing wheels, air holes, a handle, a base, full-brake caster wheels, a motor bracket, amotor, a conveyor belt and an outer cylinder, wherein the full-brake caster wheels are mounted on four feet of the bottom of the base; the number of the full-brake caster wheels is four, and the full-brake caster wheels form a rectangular structure; the outer sides of the outer cylinder are connected with the two inner sides of the top of the base in a mechanical connection manner; and the rollingdrum which cooperates with the outer cylinder in a clearance manner penetrates through the inside of the outer cylinder. The fully-automatic fixation machine for tea leaf processing and production disclosed by the invention has the beneficial effects that the automatic feeding device is arranged on the fully-automatic fixation machine, so that the function of automatic feeding is achieved; and manual feeding is not needed, and automatic feeding can be effectively achieved, so that the workload of an operator is greatly reduced, and work efficiency can be improved.

Owner:万欣宇

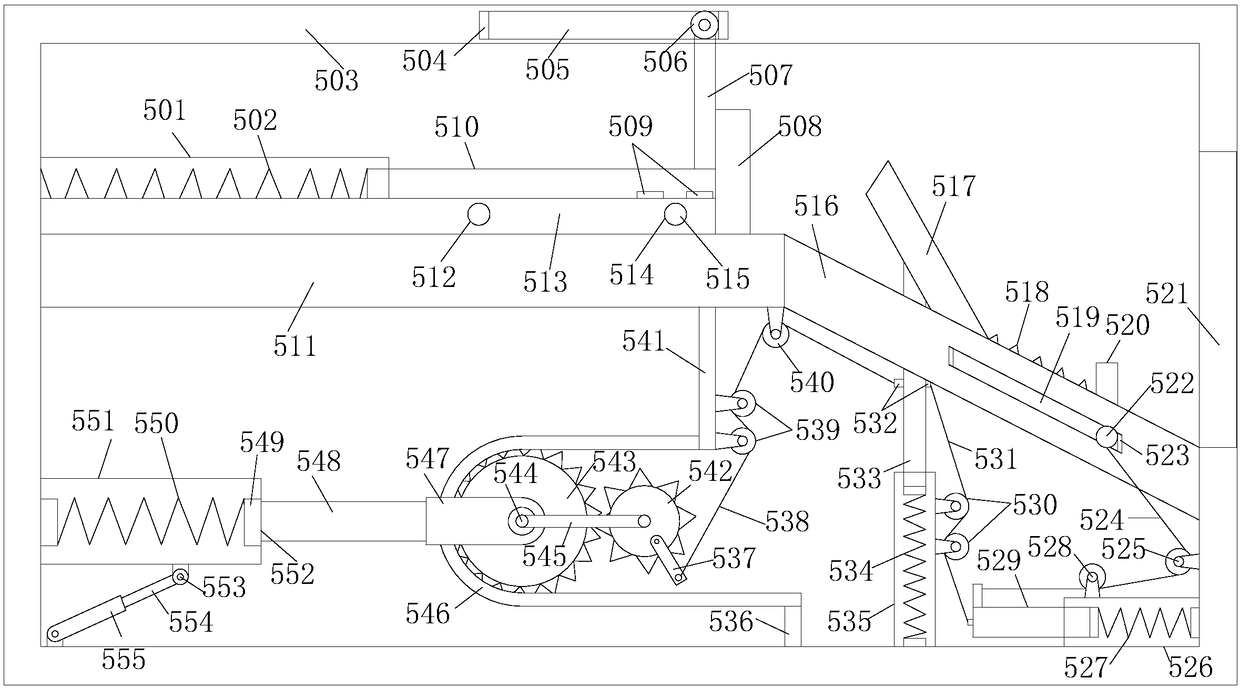

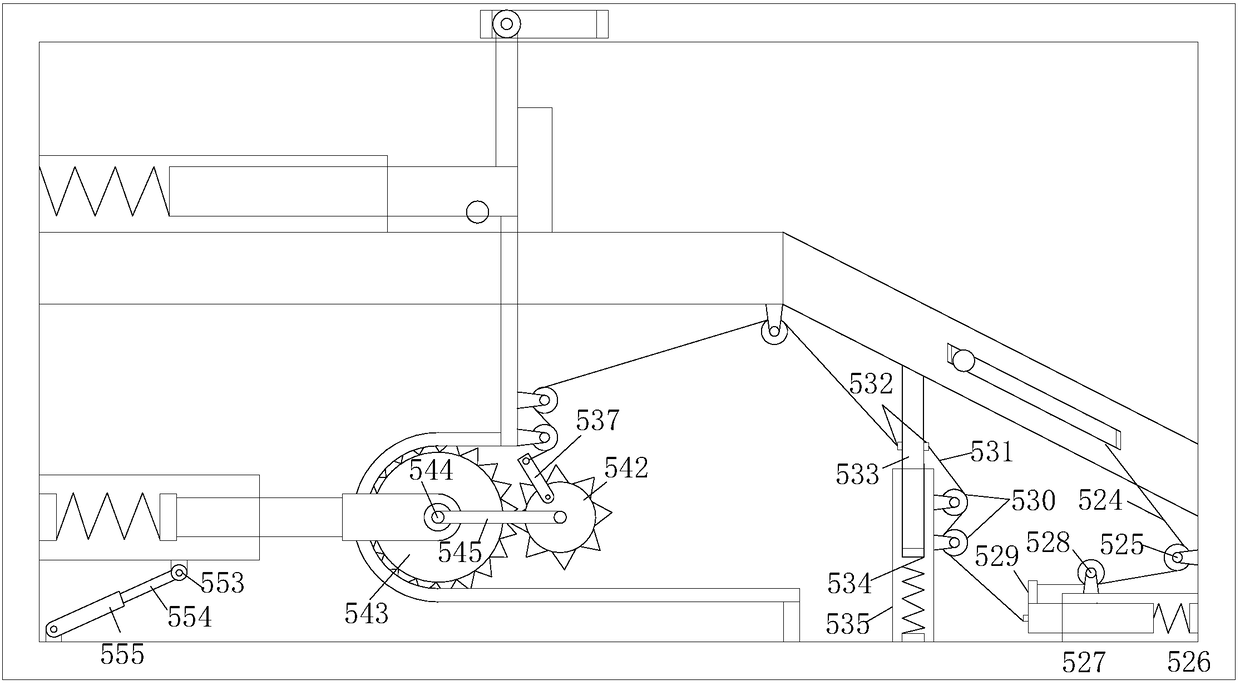

Integrated device for cutting traditional Chinese medicine

ActiveCN110421600AWith automatic feeding functionWith automatic cutting functionSievingScreeningMechanical engineeringMedical treatment

The invention relates to medical treatment, in particular to an integrated device for cutting traditional Chinese medicine. The device comprises a screening mechanism, a cutting mechanism, a conveyingmechanism and a discharging mechanism. The device has an automatic feeding function, an automatic cutting function, an automatic screening function, and also has multiple adjusting functions so as toadapt to different situations. According to the device, the screening mechanism is connected with the cutting mechanism, the cutting mechanism is connected with the conveying mechanism, and the conveying mechanism is connected with the discharging mechanism.

Owner:重庆天江一方药业有限公司

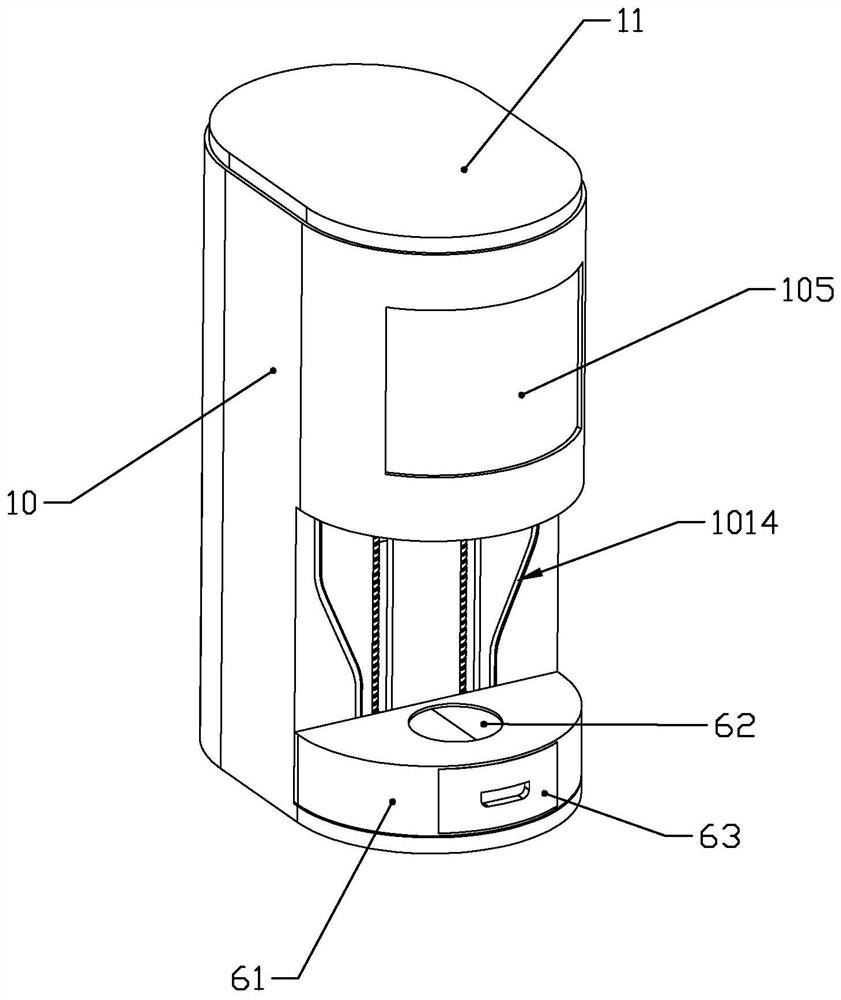

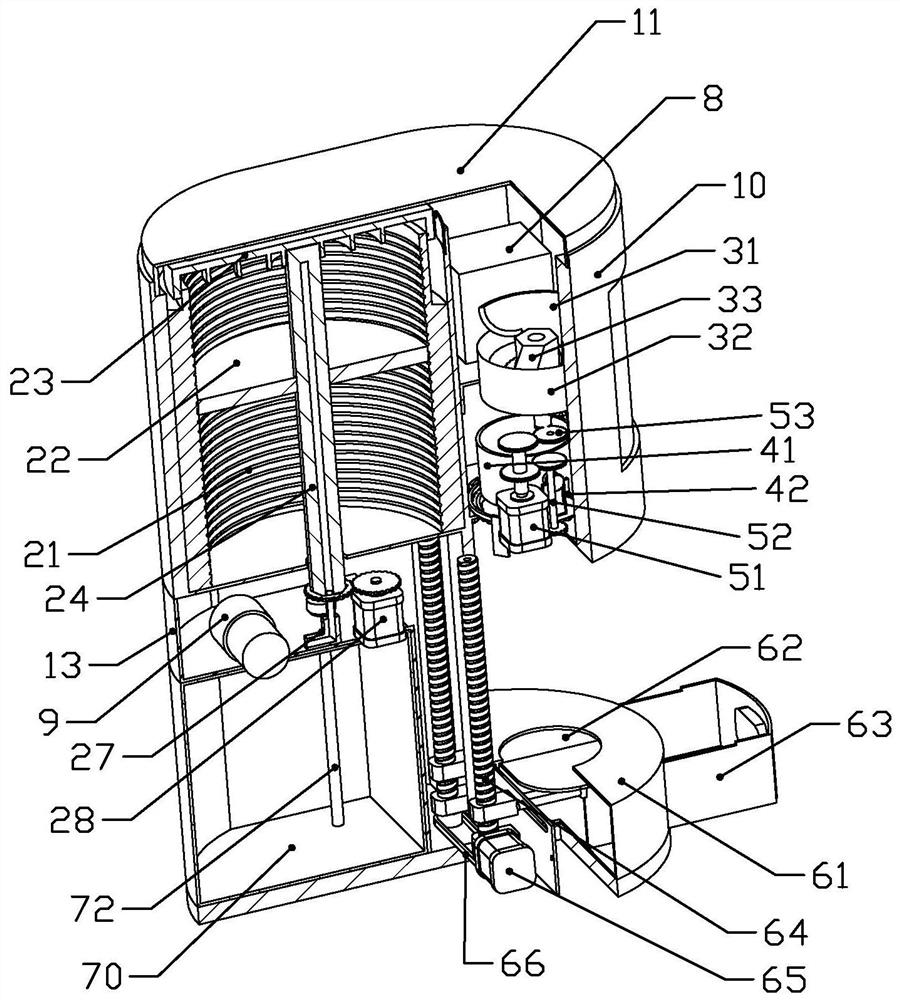

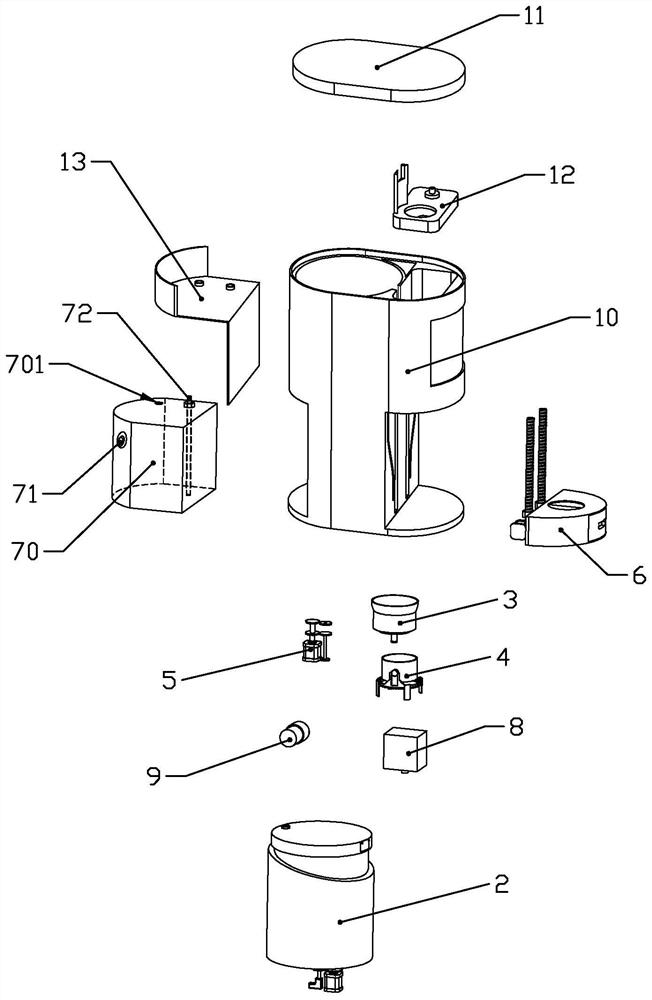

Full-automatic coffee machine

InactiveCN112107226AEasy to storeTo achieve the purpose of automatic feedingBeverage vesselsAgricultural engineeringAir pump

The invention discloses a full-automatic coffee machine, and belongs to the technical field of small household appliances. The full-automatic coffee machine comprises a shell; a filter cup, a grindingassembly and a water tank are installed in the shell; a charging barrel is fixedly connected into the shell; a feeding assembly used for conveying coffee beans in the charging barrel into the grinding assembly is installed in the shell; an air pump for pressurizing the water tank to supply water into the filter cup is fixedly connected into the shell; and an air inlet of the air pump communicateswith the interior of the charging barrel. The full-automatic coffee machine has a coffee bean storage function, and a low-pressure low-oxygen environment can be formed in the charging barrel, so thatthe coffee bean storage time is prolonged; an automatic feeding function is achieved, and coffee beans can be automatically added into a conical grinding hopper according to the coffee demand; and the filter screen cleaning function is achieved, a filter screen can be automatically cleaned, undissolved residues are flushed away, and filtering of the filter screen is smooth all the time. An automatic process is mostly adopted, and the functions of coffee grinding, coffee brewing, cleaning and the like are automatically completed through a touch panel selection function.

Owner:李昆娟

Device for inserting barbecue stick into sausage

InactiveCN109042811AReduce labor intensityWith automatic feeding functionMeat processing devicesEngineeringAutomation

The invention discloses a device for inserting a barbecue stick into sausage. The device comprises a base, a barbecue stick inserting mechanism and a sausage feeding box, wherein the barbecue stick inserting mechanism is mounted on the base; the sausage feeding box is arranged on the front side of the barbecue stick inserting mechanism; a finished product groove is formed in the front face of thesausage feeding box; a switch is arranged on a side surface of the sausage feeding box; the barbecue stick inserting mechanism consists of a barbecue stick box and an air cylinder; a cylinder shaft ofthe air cylinder is used as a pushing rod which provides an acting force for the barbecue stick to be inserted into the sausage. The device for inserting the barbecue stick into the sausage, disclosed by the invention, can easily insert the barbecue stick into the sausage and replaces manual operation so as to reduce the labor intensity; the device has the functions of automatically feeding and automatically inserting the barbecue stick and is high in degree of automation.

Owner:北海智联投资有限公司

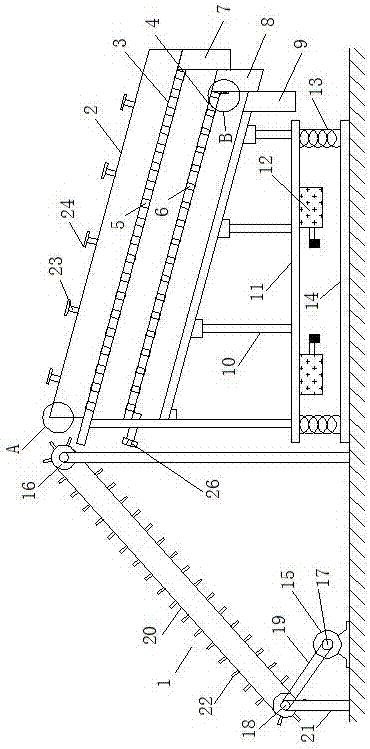

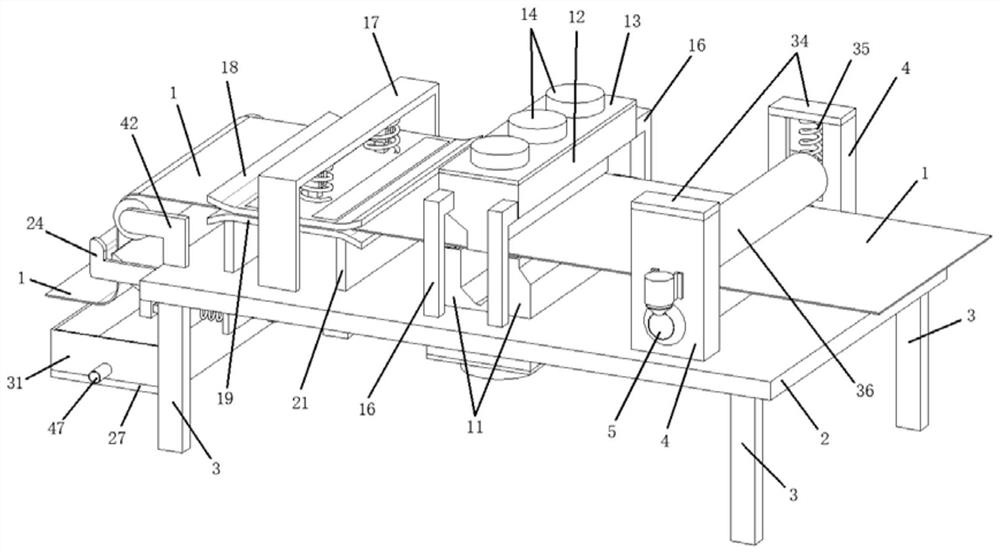

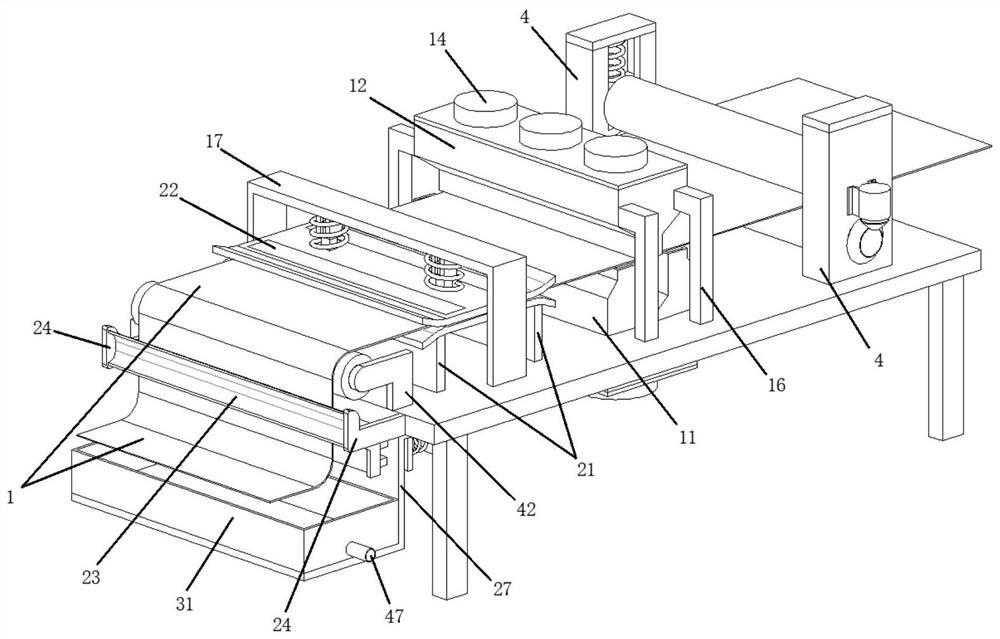

Double-sided drying equipment for polyester fabric production and processing

ActiveCN112647228AAvoid looseImprove stabilityLiquid/gas/vapor removal by squeezingTextile shapingPolyesterPolymer science

The invention relates to the technical field of cloth processing, in particular to double-sided drying equipment for polyester fabric production and processing. The double-sided drying equipment comprises polyester fabric, a processing table plate is arranged on one side of the polyester fabric, a plurality of supporting legs are fixedly arranged on one side of the processing table plate, two fixing columns are fixedly arranged on one side of the processing table plate, a driving shaft is arranged on one side of the processing table plate, through holes are formed in one sides of the fixing columns, the driving shafts are rotationally connected to the inner sides of the through holes, motors are arranged on one sides of the driving shafts and fixedly connected to one sides of the fixing columns, and transmission devices are arranged between the motors and the driving shafts. By arranging a feeding barrel, a pressing barrel, an automatic pressing device, a double-opening drying cover, a single-opening drying cover, the air inlet fan, an electric heating pipe, an upper ironing plate, a lower ironing plate, a spring A, a constant-temperature electric heating block, a water squeezing plate and a water squeezing frame, and the double-sided drying equipment for polyester fabric production and processing has the functions of automatic continuous processing, double-sided automatic drying, automatic ironing, automatic dewatering, squeezing force adjusting and the like.

Owner:吴江保利化纺有限公司

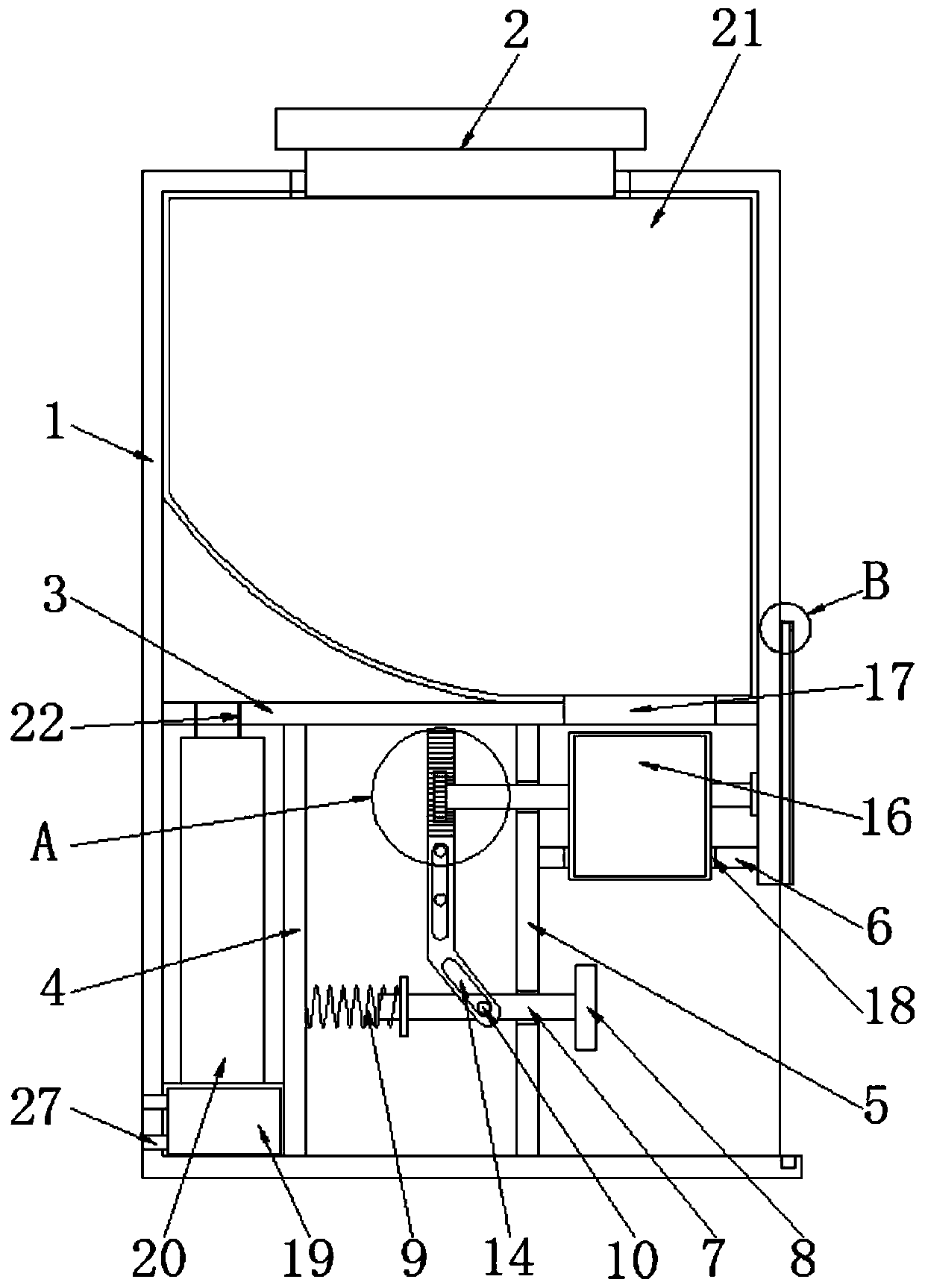

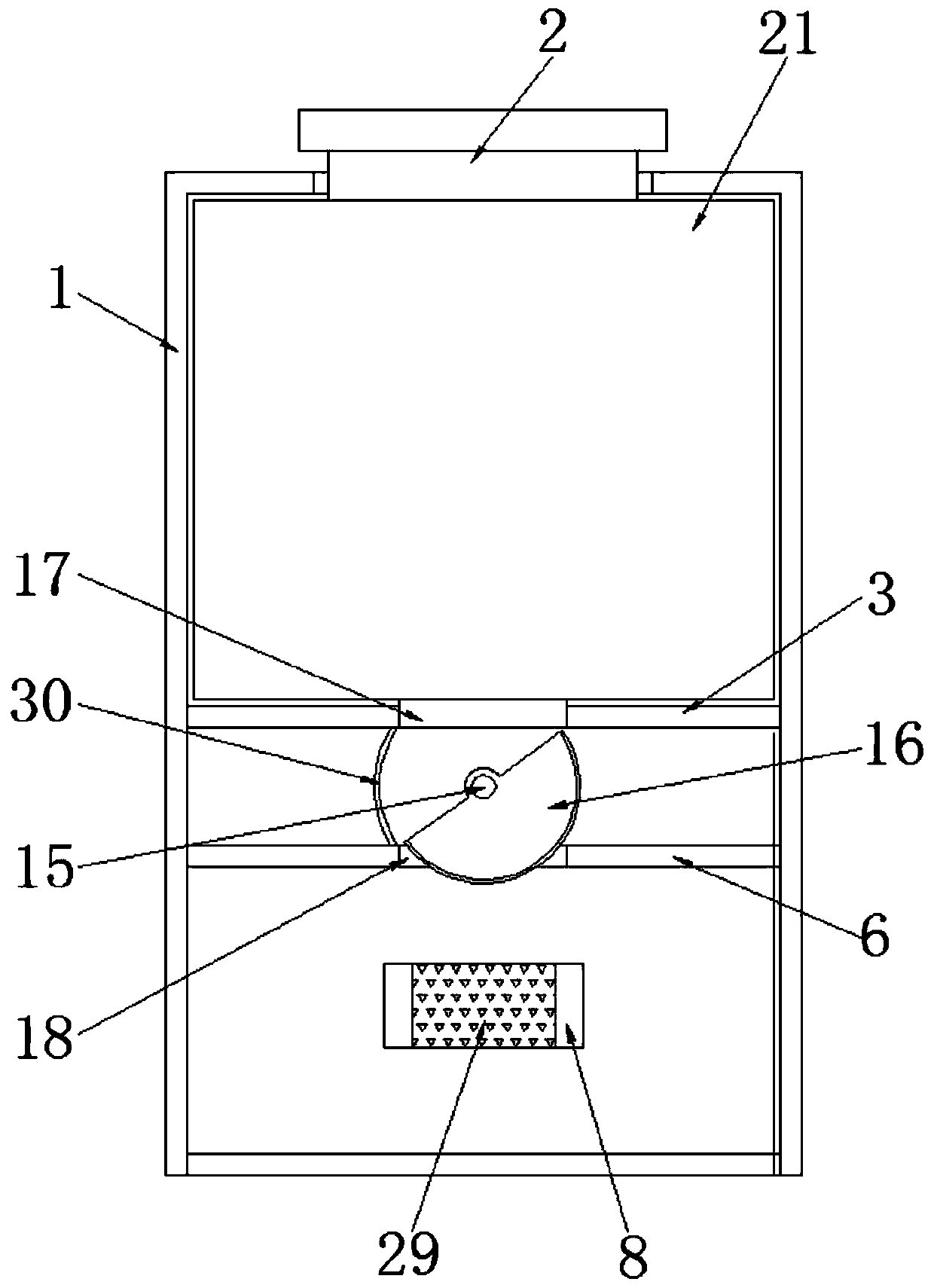

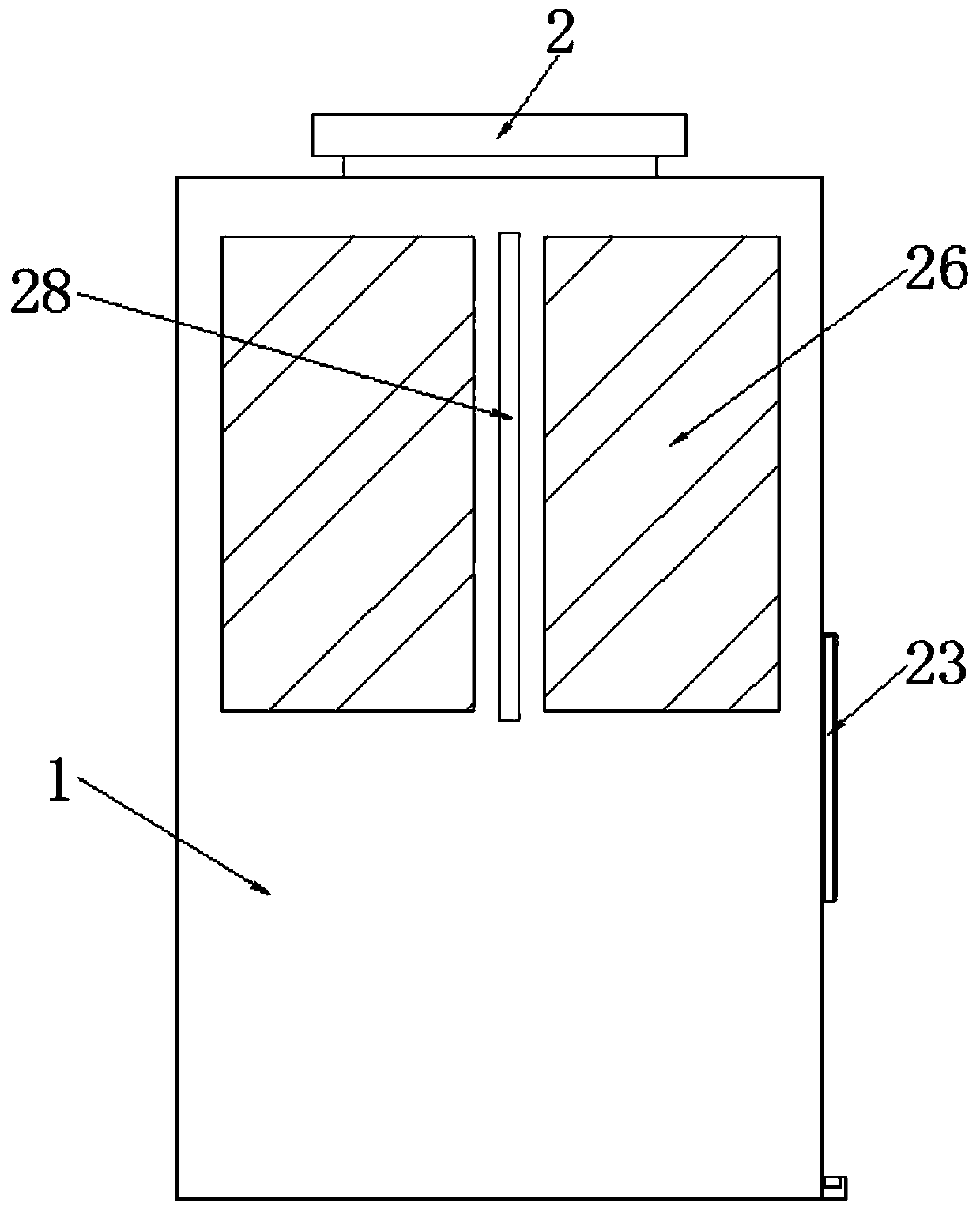

Tea box with automatic feeding function

InactiveCN109795807AWith automatic feeding functionReduce unsanitary conditionsRacksPowdered material dispensingEngineeringExtrusion

The invention discloses a tea box with an automatic feeding function, and relates to the technical field of automatic feeding functions. The tea box comprises a box body and a box cover, the top of the box body is connected with the bottom of the box cover in a threaded mode, and the inner surface of the box body is fixedly connected with a first partition plate. According to the tea box with theautomatic feeding function, a movable plate is arranged inside a second supporting plate, by extruding the movable plate, a rack and a gear shaft are driven to rotate, thus a semicircle sleeve fixed to the surface of the gear shaft is driven to rotate, the semicircle sleeve is rotated to open a second falling opening, thus tea leaves in the semicircle sleeve fall from a first falling opening intoa teacup, extrusion of the movable plate is released, a spring is used for making the movable plate move to the left, the movable plate is used for driving the rack to move upwards, thus the second falling opening is closed by the semicircle sleeve, the tea leaves fall from the first falling opening into the semicircle sleeve and are poured quantitatively, the unsanitary situation of the tea leaves taken by hands is reduced, and the taste of tea is greatly enhanced.

Owner:河南发明哥知识产权代理有限公司

Organic garbage treatment integrated equipment

PendingCN110976485AVersatilePrevent proliferationSolid waste disposalTransportation and packagingProcess engineeringOil water

The invention discloses organic garbage treatment integrated equipment. The equipment comprises a garbage can lifting device, a conveying device, an oil-water separation device and a fermentation box;the garbage can lifting device is composed of a hydraulic drive elevator; pretreatment equipment is arranged at the top end of the garbage can lifting device; the feeding opening of the garbage can lifting device is a trapezoidal hopper; the conveying device is installed on a sorting platform and is composed of a sorting conveying belt; one end of the conveying device is communicated with the discharging opening of the pretreatment equipment, and the other end of the conveying device is communicated with the oil-water separation device; the oil-water separation device is composed of a pulverizer and a spiral squeezing conveyor; and one end of the spiral squeezing conveyor is communicated with the discharging end of the pulverizer. The organic garbage treatment integrated equipment is lowin later-period operation cost, complete in function and high in integration degree and can be widely popularized and used in various industries.

Owner:JIANGSU QINGSHI TECH

Cloth cutting device capable of replacing blade for textile fabric processing

ActiveCN112853723APrevent movementQuick disassemblySevering textilesHydraulic cylinderStructural engineering

The invention relates to the technical field of fabric, in particular to a cloth cutting device capable of replacing a blade for textile fabric processing. The cloth cutting device comprises the fabric and a conveyor belt, wherein a working table plate is arranged on one side of the fabric, a plurality of supporting legs are fixedly arranged on one side of the working table plate, a plurality of supporting rods are fixedly arranged on one side of the conveyor belt, the other end of each supporting rod is fixedly connected to one side of the working table plate, an inverted-U-shaped frame is fixedly arranged on one side of the working table plate, a Z-shaped hollow frame is fixedly arranged on one side of the inverted-U-shaped frame, and a driving shaft is arranged on one side of the Z-shaped hollow frame. Through arrangement of the driving shaft, a servo motor, a driving discharging barrel, a pressing shaft, a movable hole, a driven pressing barrel, a U-shaped clamping base, a sliding clamping base, an L-shaped sliding frame, a spring, a telescopic hydraulic cylinder, a bevel edge cutter and a T-shaped fixing strip, the automatic cutting device has the functions of automatic feeding, accurate feeding, automatic cutting, deviation prevention, convenience in blade replacement, automatic collection and the like.

Owner:苏州帛乐纺织有限公司

High-speed bottle unscrambling method with automatic feeding and detecting functions for cosmetic packaging

InactiveCN112429689AWith automatic feeding functionWith detection functioConveyorsControl devices for conveyorsEngineeringBottle

The invention relates to the technical field of bottle unscramblers, and discloses a high-speed bottle unscrambling method with automatic feeding and detecting functions for cosmetic packaging. A high-speed bottle unscrambler comprises a bottle unscrambler main body, a bottle storage hopper, a conveying belt, an ultrasonic flaw detector, a push plate and other structures, wherein a first supporting frame is fixedly connected to the ground on the left side of the bottle unscrambler main body, the bottle storage hopper is fixedly connected to the top of the first supporting frame, a connecting rod is movably connected to one side of the bottom end of an inner cavity of the bottle storage hopper, and the other end of the connecting rod is fixedly connected with the middle of one end of a rotating wheel. According to the high-speed bottle unscrambler with automatic feeding and detecting functions and the bottle unscrambling method of the high-speed bottle unscrambler, through the arrangement of springs, a supporting tank can slowly move in an inner cavity of a bottle containing bin, the falling distance of bottles conveyed by the conveying belt is very short, damage to the bottles canbe effectively reduced, the resilience force of the springs can drive the supporting tank to return to the initial position, and the conveying belt can conveniently convey the bottles in the bottle storage hopper into the bottle storage bin again.

Owner:程庆花

Intermediate frequency furnace with automatic feeding function

The invention discloses an intermediate frequency furnace with an automatic feeding function, which comprises a base, a waste groove, a machining table, a locking block and a limiting block, wherein the waste groove is formed in the base, the machining table is installed on the base, a turnover mechanism is arranged on the machining table, a supporting plate is connected to the turnover mechanism, a smelting furnace is installed on the supporting plate, a casting opening is formed in the smelting furnace, a smelting cavity is formed in the smelting furnace, and a first supporting column is installed on the base. According to the intermediate frequency furnace with the automatic feeding function, the lifting box capable of ascending and descending is arranged, when secondary feeding is conducted on the smelting cavity, the lifting box conveys raw materials to the position right above the smelting cavity through ascending and descending, a first overturning plate and a second overturning plate are opened through rotation of a winding roller, the raw materials fall into a feeding hopper from a storage box, and the materials are accurately added into the smelting cavity through the feeding hopper, so that the feeding process is automatically completed, the feeding convenience is improved, and the danger is reduced.

Owner:丹阳市建晟精密机械科技有限公司

Poultry packaging device with automatic weighing and classifying functions and implementation method thereof

ActiveCN114506520AHigh degree of automationIncrease productivityPackaging automatic controlSortingElectric machineryProcess engineering

The invention discloses a poultry packaging device with an automatic weighing and classifying function, and belongs to the technical field of sorting and packaging equipment, the poultry packaging device comprises a sorting and packaging production line and a control system of the sorting and packaging production line, the sorting and packaging production line comprises a weighing and sorting mechanism, a conveying and bagging mechanism and a sealing mechanism, sorting the poultry according to the set weight; the conveying and bagging mechanism is used for bagging the poultry with the same specification according to a set number and conveying the bagged poultry to the sealing mechanism; the sealing mechanism is used for sealing the bagged poultry to obtain required finished products; the control system of the sorting and packaging production line comprises a power module, a relay control module, a motor driving module and a PLC module, the PLC module is connected with the relay control module and the motor driving module, and the power module supplies power to all the modules.

Owner:SHANDONG VOCATIONAL ANIMAL SCI & VETERINARY COLLEGE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com