Poultry packaging device with automatic weighing and classifying functions and implementation method thereof

An automatic weighing and poultry technology, applied in packaging, packaging machines, packaged food, etc., can solve the problems of low degree of automation, slow processing speed, low degree of modularization, etc., to facilitate storage and transportation, improve production efficiency, modularization high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

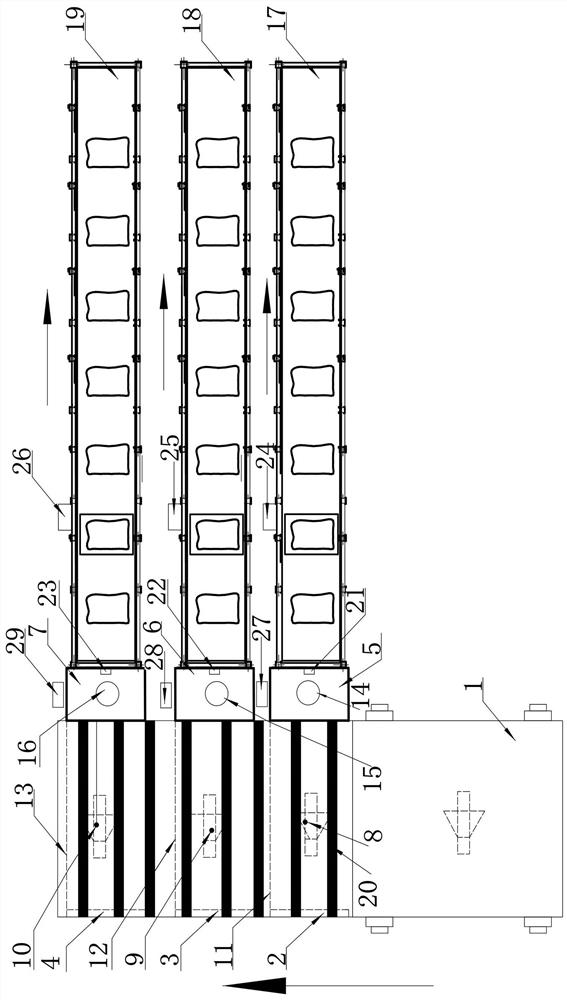

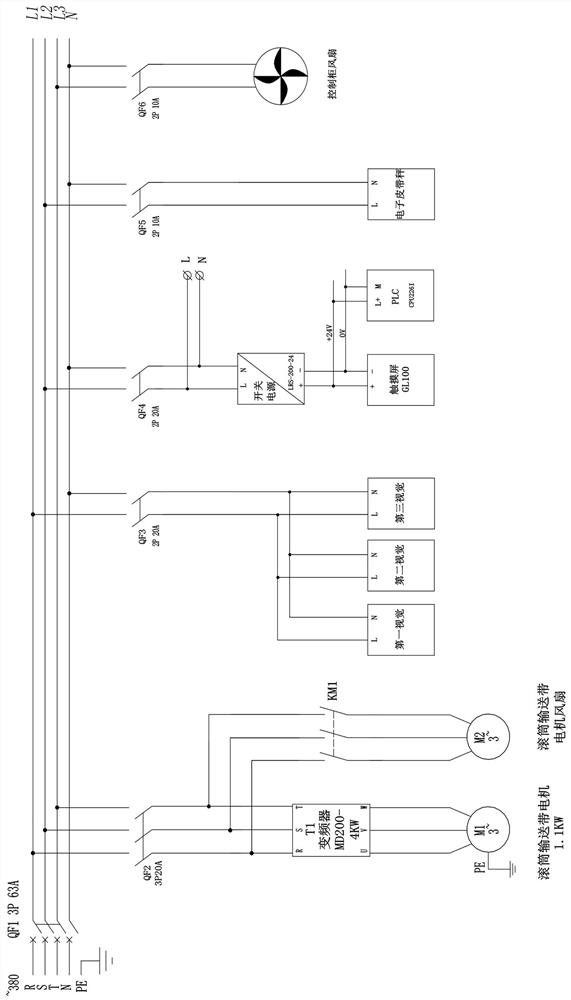

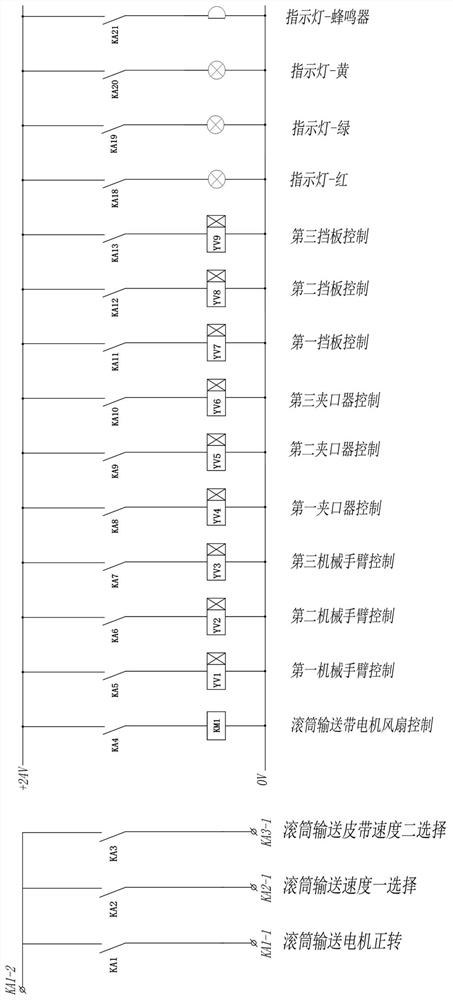

[0075] Embodiment 1, a poultry packaging device with automatic weighing and sorting functions, including a sorting and packaging production line and a control system for the sorting and packaging production line.

[0076] Such as figure 1 As shown, the sorting and packaging production line includes a weighing and sorting mechanism, a conveying and bagging mechanism, and a sealing mechanism.

[0077] The weighing and sorting mechanism sorts the poultry according to the set weight;

[0078] The conveying and bagging mechanism packs poultry of the same specification into bags according to the set quantity, and transports them to the sealing mechanism;

[0079] The sealing mechanism seals the bagged poultry to make the desired finished product.

[0080] The weighing and sorting mechanism includes an electronic belt scale 1, the electronic belt scale 1 is connected with the control system of the sorting and packaging production line through a serial port, and the data of poultry ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com