Integrated device for cutting traditional Chinese medicine

An all-in-one, equipment-based technology that is applied in medical-related fields and can solve problems such as low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

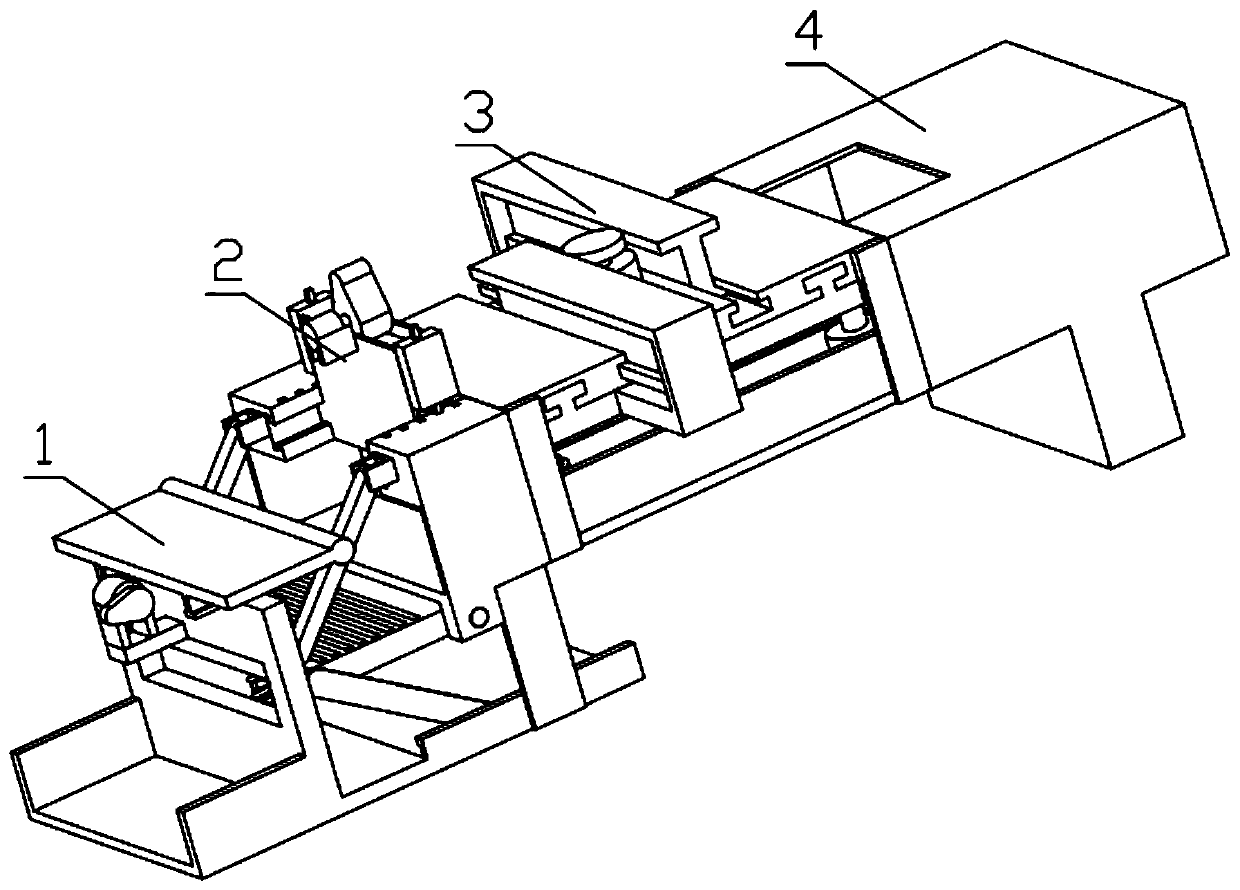

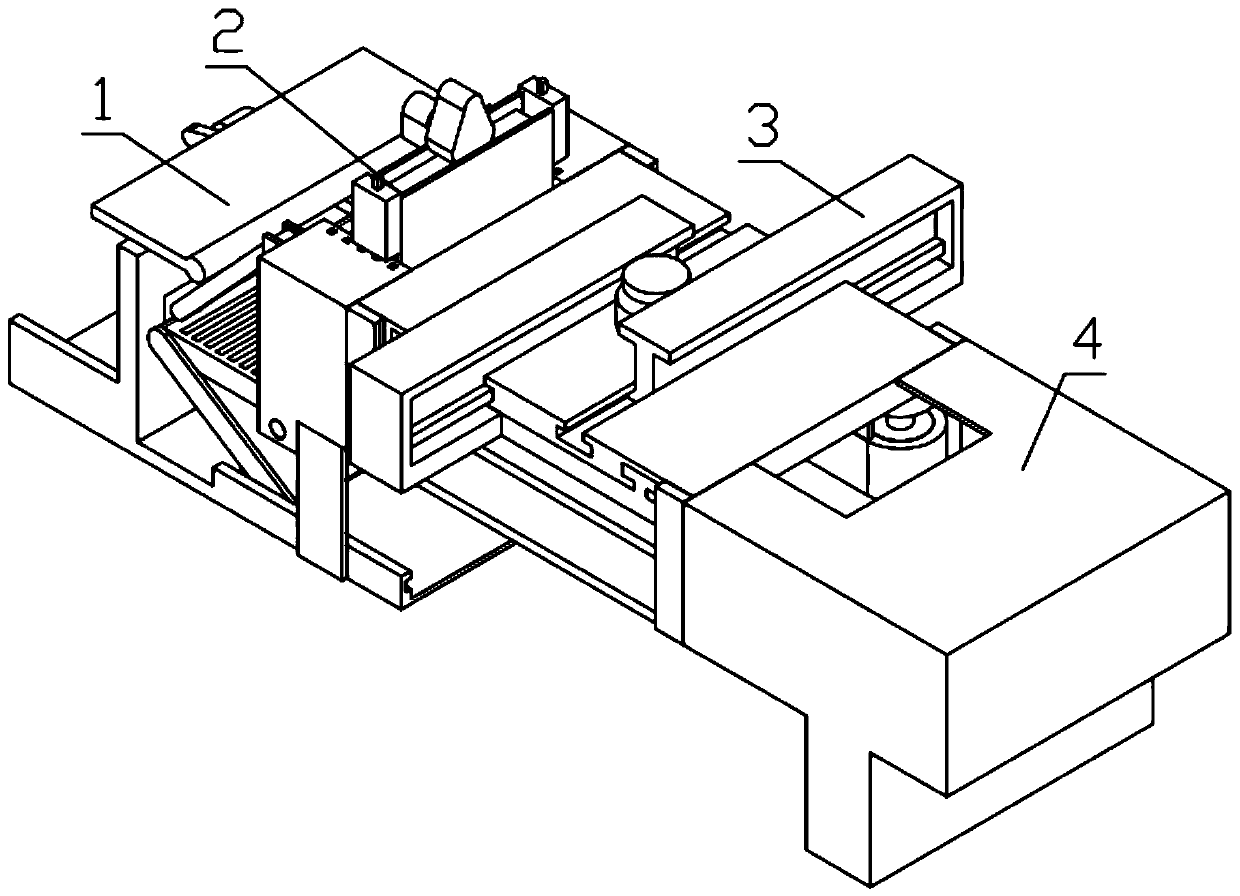

[0036] Combine below figure 1 , 2 , 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13, 14, 15, 16, 17, 18, 19, 20, 21 illustrate this embodiment. , more specifically, it is a traditional Chinese medicine cutting integrated equipment, including a screening mechanism 1, a cutting mechanism 2, a transmission mechanism 3, and a feeding mechanism 4. This equipment has an automatic feeding function, an automatic cutting function, and an automatic screening function. With a variety of adjustment functions to suit different situations. The screening mechanism 1 is connected with the cutting mechanism 2 , the cutting mechanism 2 is connected with the conveying mechanism 3 , and the conveying mechanism 3 is connected with the feeding mechanism 4 .

specific Embodiment approach 2

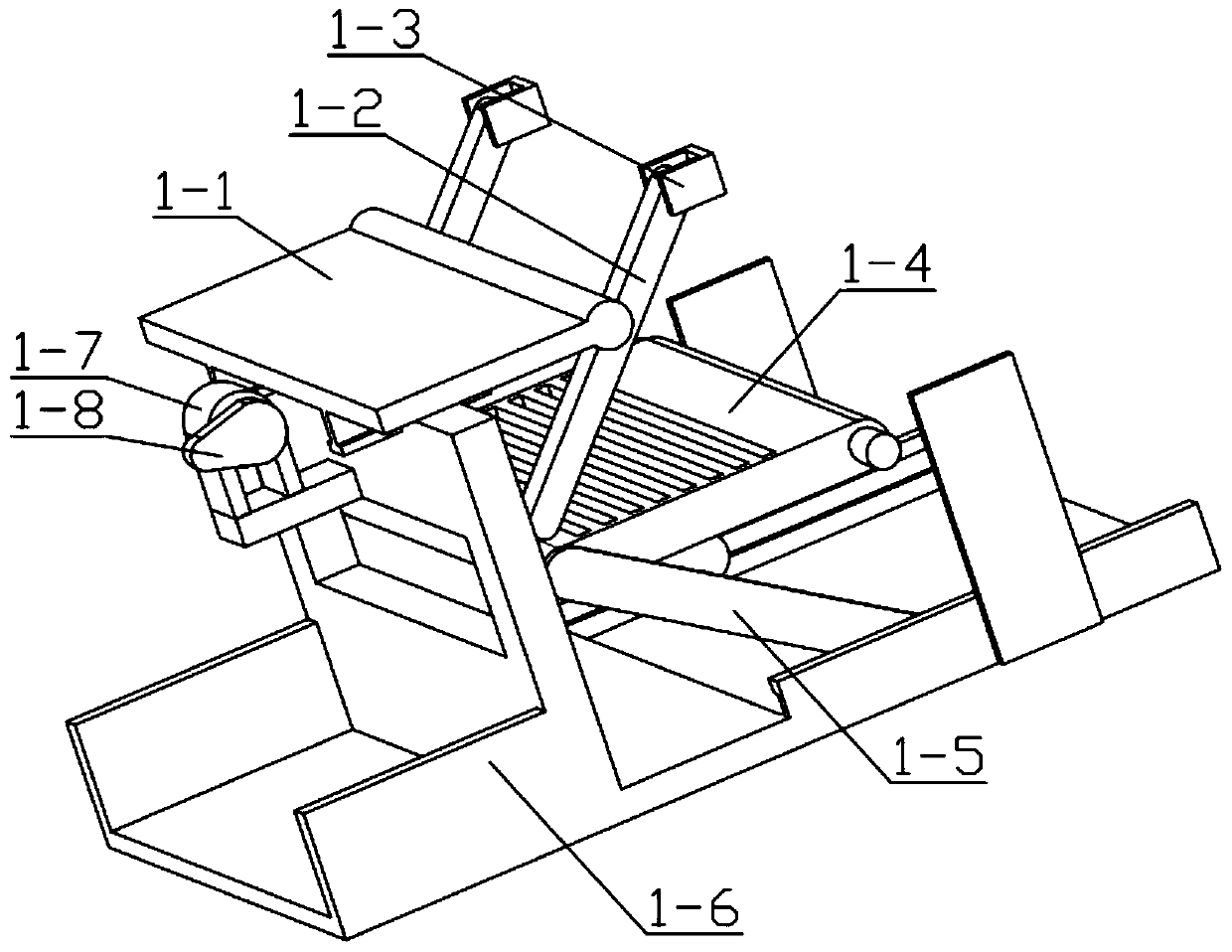

[0038] Combine below figure 1 , 2. To further illustrate, the screening mechanism 1 includes a horizontal pressing plate 1-1, a side pressing bar 1-2, a hinged U-shaped piece 1-3, a sieve plate 1-4, a material separating plate 1-5, and a bottom bracket 1- 6. Motor 1-7 for extrusion, cam 1-8 for extrusion, return spring 1-9, horizontal pressure plate 1-1 is connected with side pressure rod 1-2, and side pressure rod 1-2 is connected with hinged U-shaped piece The 1-3 phases are hinged, the side pressure rod 1-2 is in contact with the sieve plate 1-4, the sieve plate 1-4 is hinged with the distribution plate 1-5, and the gap between the distribution plate 1-5 and the bottom bracket 1-6 Connection, the bottom bracket 1-6 is fixedly connected with the extrusion motor 1-7, the extrusion motor 1-7 is fixedly connected with the extrusion cam 1-8, and the return spring 1-9 is fixed with the bottom bracket 1-6 Connection, the return spring 1-9 is fixedly connected with the distribut...

specific Embodiment approach 3

[0041] Combine below figure 1 , 2 . To further illustrate, the cutting mechanism 2 includes a housing 2-1, a locking assembly 2-2, a cutting motor 2-3, a cutting cam 2-4, a cutting knife 2-5, a knife housing 2-6, and a knife connection The spring 2-7, the shell 2-1 is connected with the clamping component 2-2, the clamping component 2-2 is connected with the knife shell 2-6, and the knife shell 2-6 is connected with the cutting knife 2-5 through a through hole gap , cutting knife 2-5 is fixedly connected with knife connecting spring 2-7, and knife connecting spring 2-7 is fixedly connected with knife housing 2-6, and knife housing 2-6 is fixedly connected with cutting motor 2-3, and cutting motor 2 -3 is fixedly connected with the cutting cam 2-4, the cutting cam 2-4 is in contact with the cutting knife 2-5, the sieve plate 1-4 is hinged with the shell 2-1, and the shell 2-1 is connected with the bottom bracket 1- 6 fixed connection; the shell 2-1 is provided with a square ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com