Automatic three-side synchronous grinding grinder

A technology of grinding and grinding department, applied in the direction of grinding machine, grinding bed, grinding machine tool parts, etc., can solve the problems of large cost adjustment, installation time, low work efficiency, high labor intensity, etc., and increase the use of Range, high processing efficiency, and productivity-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with accompanying drawing:

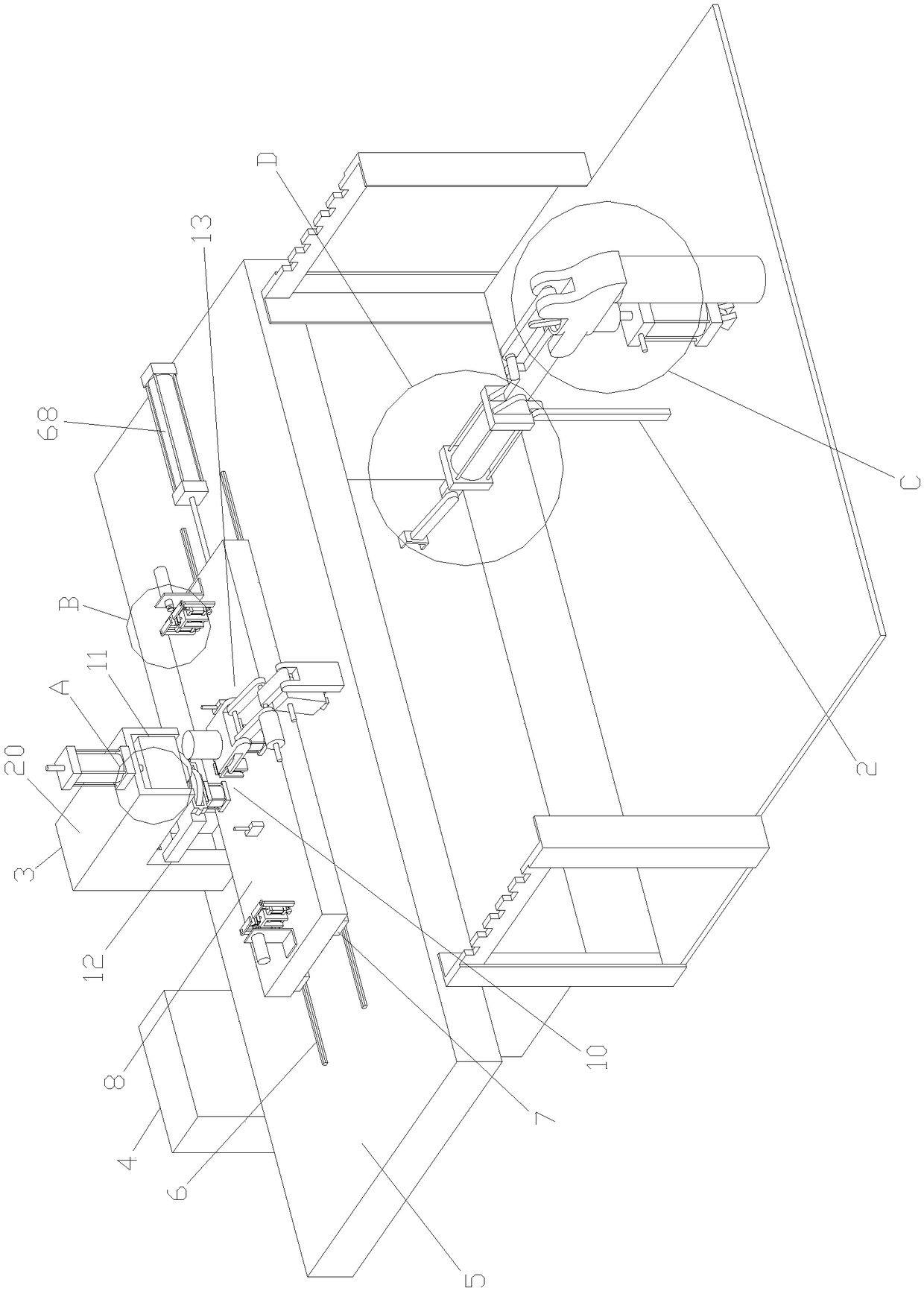

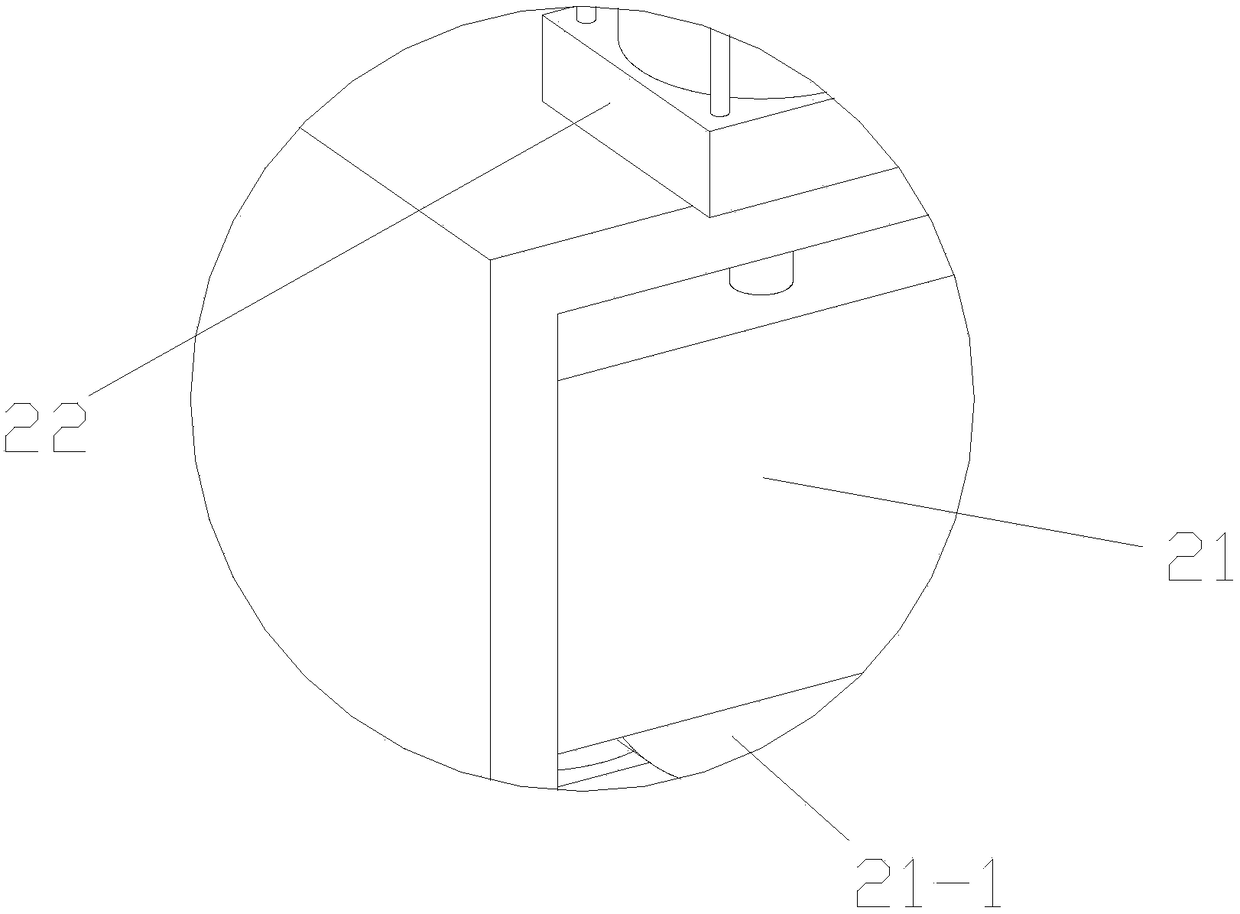

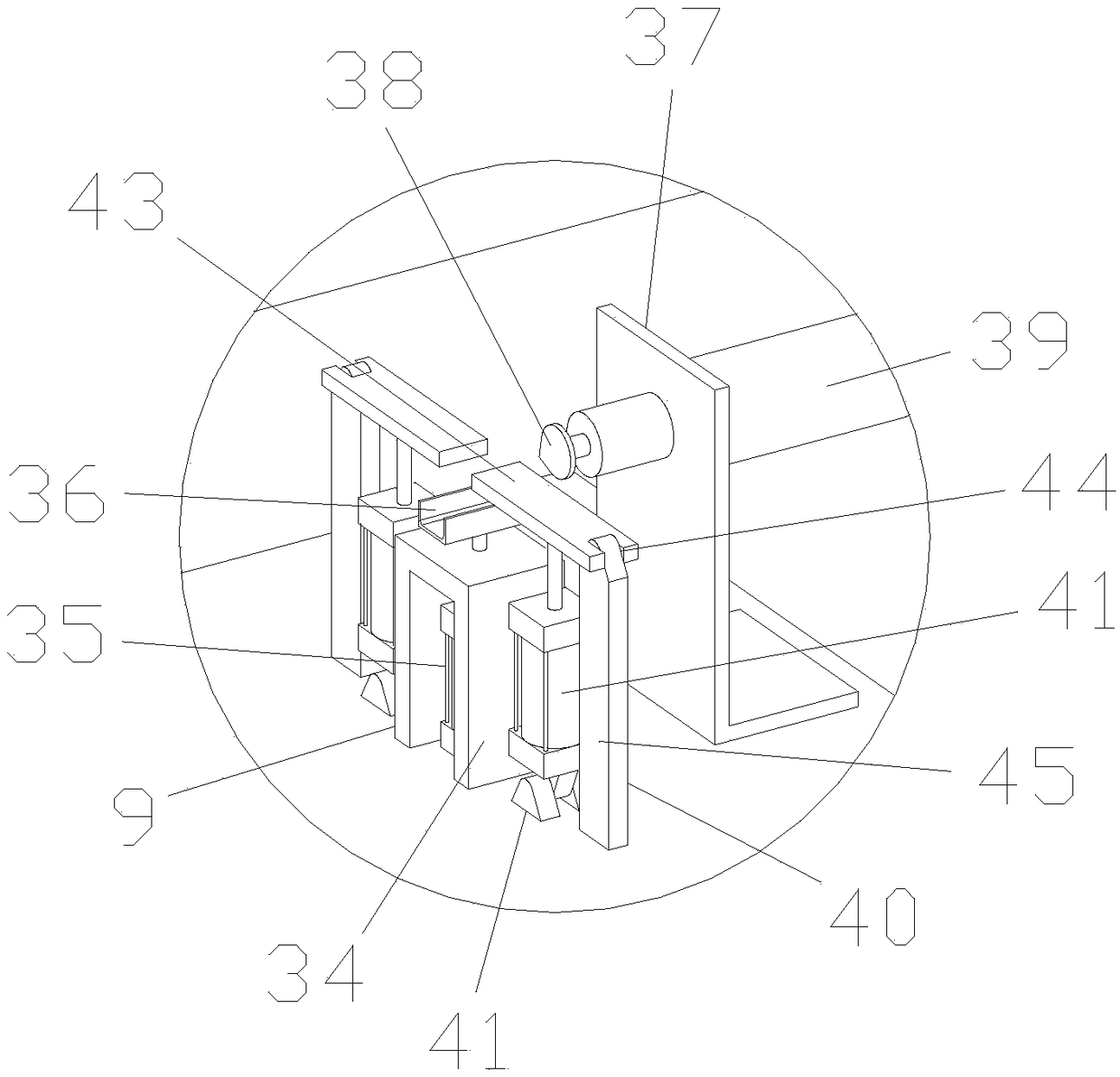

[0029] Referring to the accompanying drawings: This automatic three-sided synchronous grinding machine includes a frame body 1 for placing slide rails, a conveying device 2 placed at the rear end of the frame body 1, a grinding device 3 placed at the front end of the frame body 1, and a control conveying device 2. The control device 4 of the grinding device 3, the grinding device 3 includes a body 5, a pair of first slide rails 6 mounted on the body 5, and a first sliding block slidably connected to the first slide rails 6 7. The workbench 8 installed on the first slider 7 is driven by the eighth cylinder 68. The workbench 8 is provided with an installation unit 9, and the upper, front and rear ends of the installation unit 9 are provided with grinding wheel units. 10. The grinding wheel unit 10 is provided with a main grinding section 11 placed on the upper end of the inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com