Commercial food processor

A food processor, commercial technology, applied in applications, home appliances, kitchen appliances, etc., can solve the problems of reduced service life, incompleteness, loud noise, etc., to achieve the effect of convenient installation and disassembly, saving operation time, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

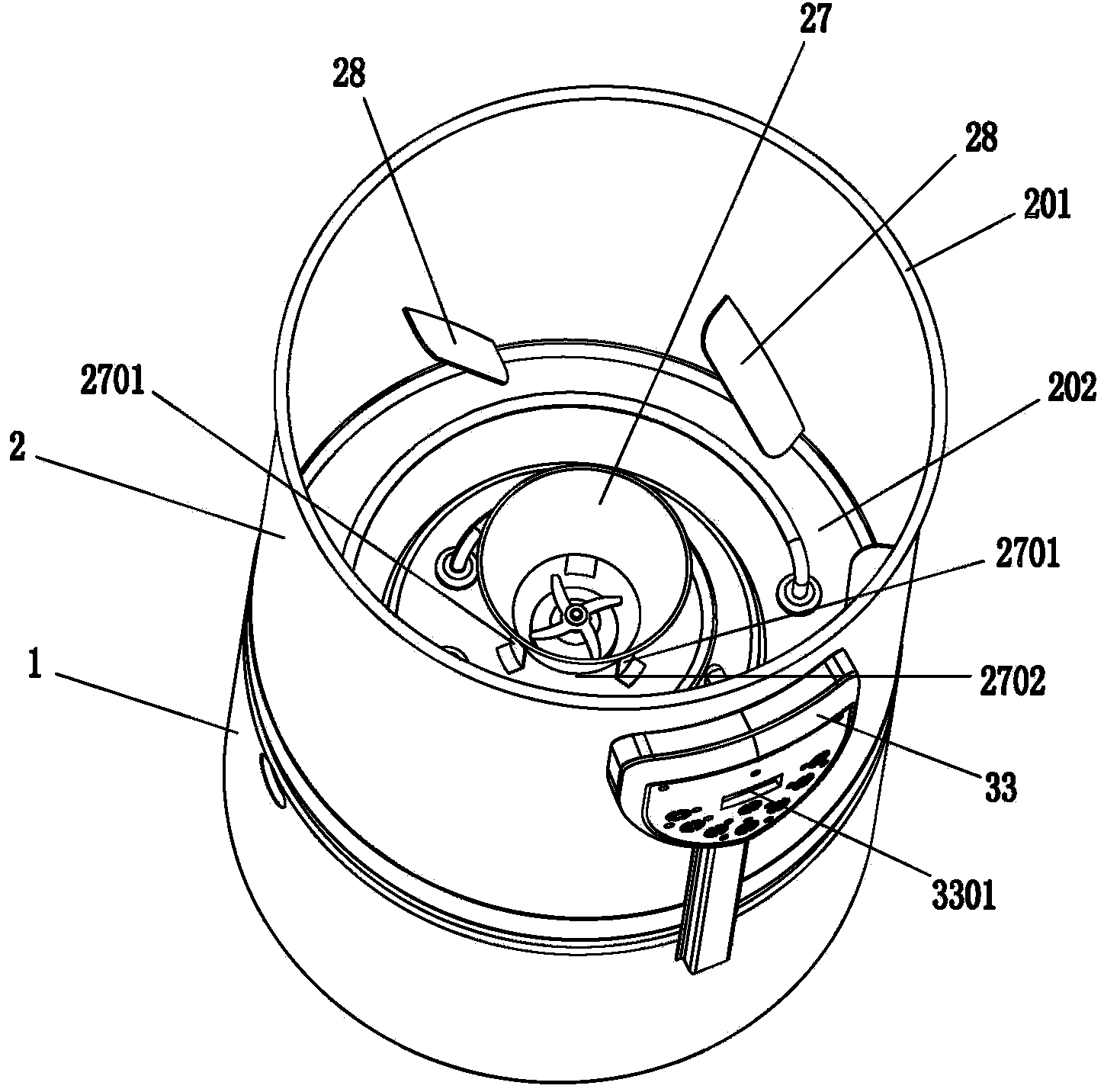

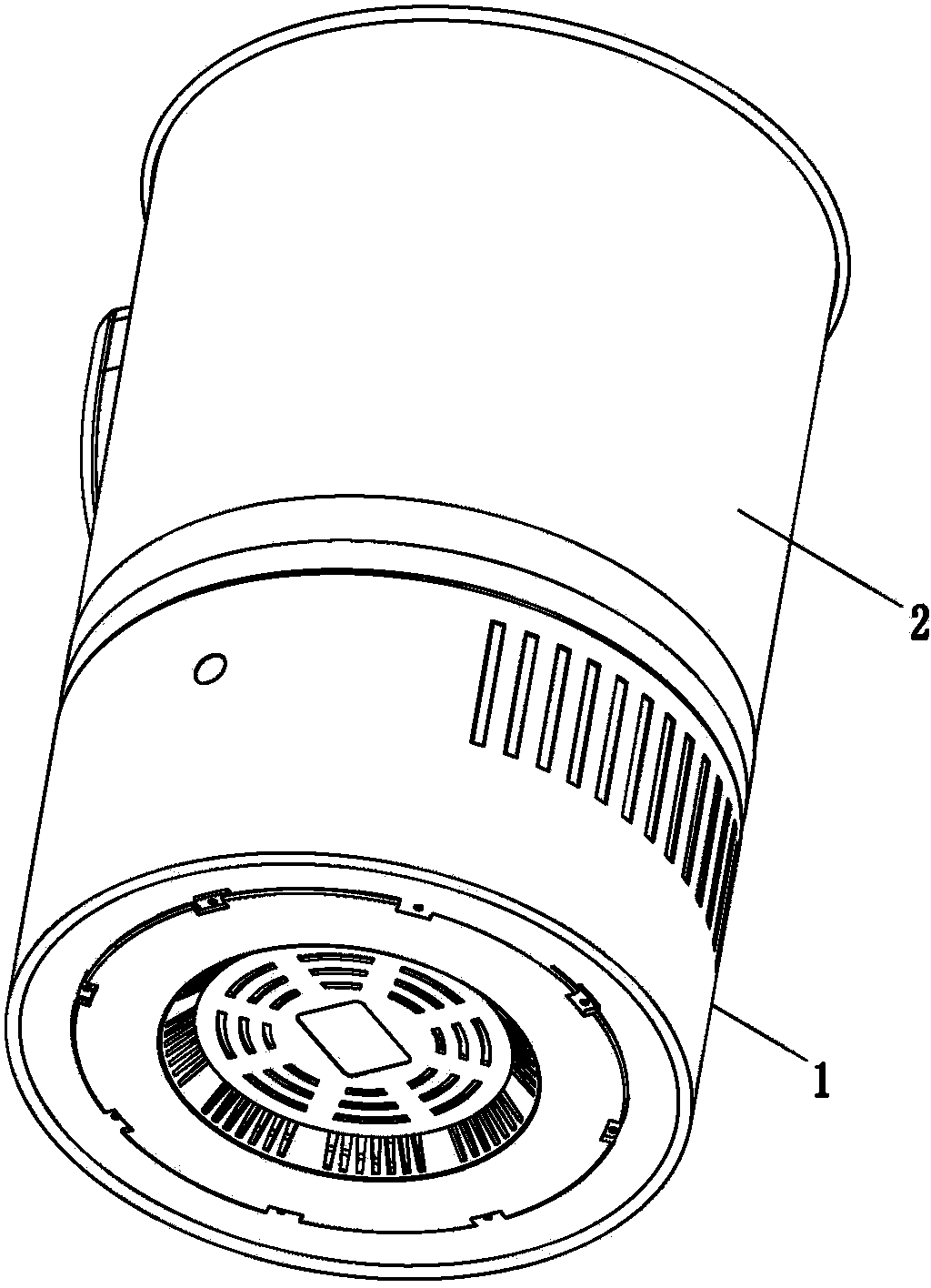

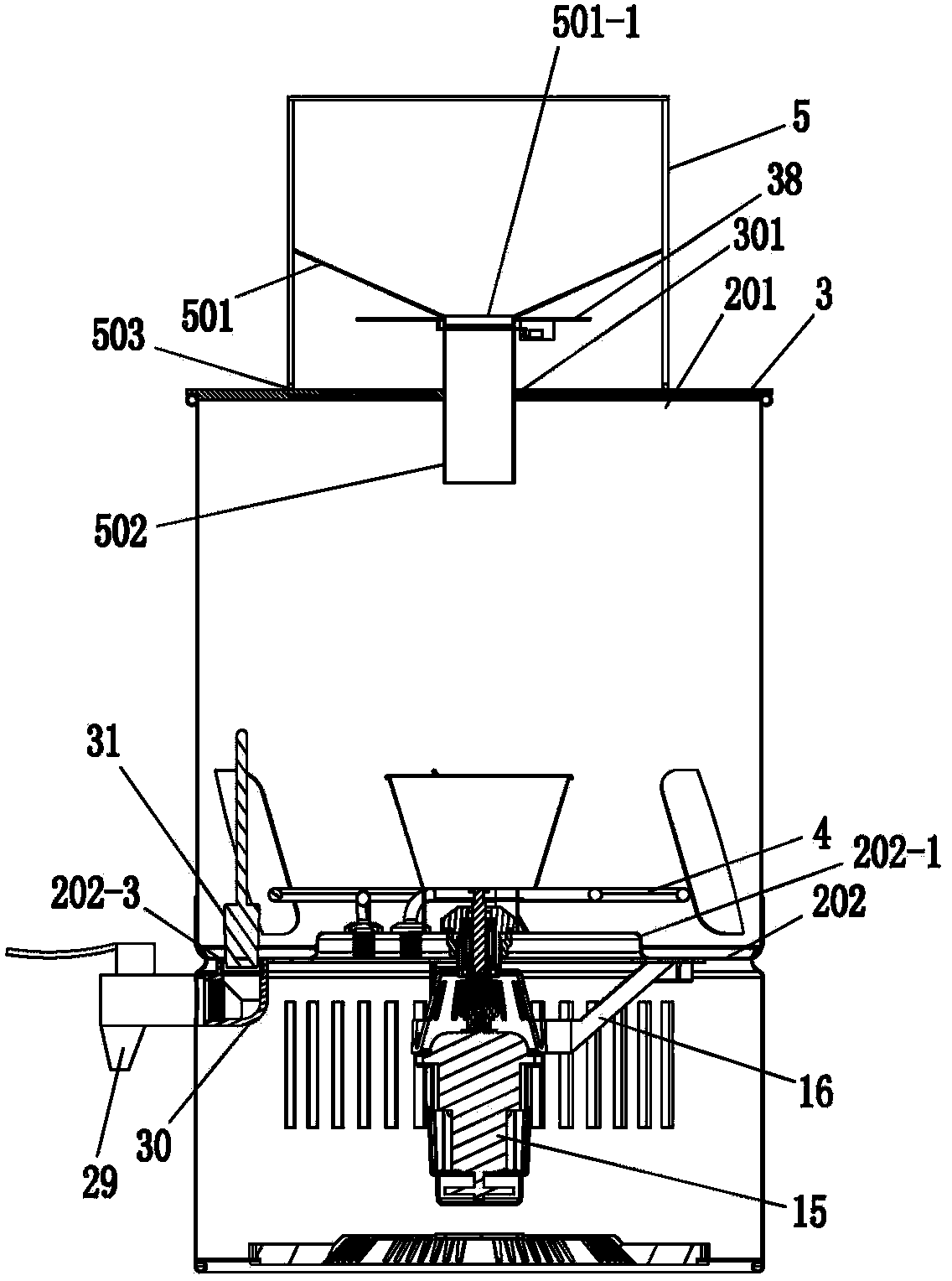

[0032] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0033] Such as Figure 1 to Figure 2 As shown, a commercial food processing machine includes a base 1, a barrel body 2 is connected to the base 1, a barrel cover 3 is provided on the top opening 201 of the barrel body 2, a driving device is fixed inside the base 1, and a barrel body 2 is mounted on a bottom plate 202. A heating pipe 4 is connected, and it is characterized in that a timing feeding container 5 is detachably installed on the barrel body 2, and a funnel body 501 is arranged in the timing feeding container 5, and the funnel hole 501-1 on the funnel body 501 is connected with a The funnel tube 502, the bucket cover 3 is provided with a bucket cover feed hole 301 suitable for the insertion of the funnel tube 502, and the timing feeding container 5 is seated on the bucket cover 3 through the bottom edge 503;

[0034] The inside of the funnel t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com