Novel numerical control flat grinder

A surface grinder, a new technology, applied in the direction of grinding machines, machine tools suitable for grinding workpiece planes, grinding/polishing equipment, etc., can solve the problem of increasing the deformation of the lifting screw 6, affecting the quality of the grinding plane, and affecting the accuracy To achieve the effect of improving feed accuracy and feed speed, ensuring stability and consistency, and improving feed accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

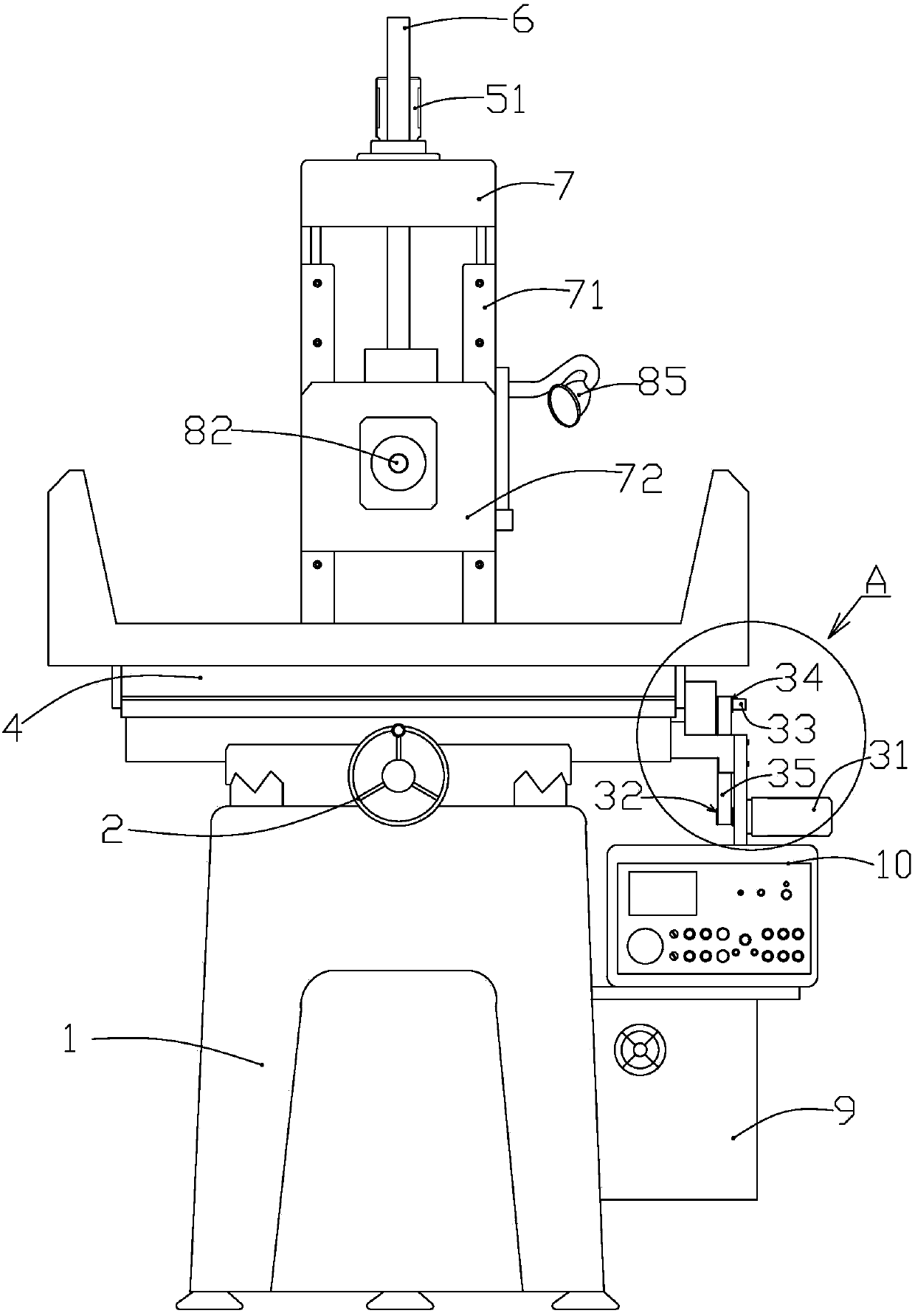

[0027] In order to facilitate the understanding of the technical content of the present invention, it will be further described below in conjunction with the accompanying drawings.

[0028] The X-axis, Y-axis and Z-axis involved in the present invention correspond to figure 2 The shown left and right, front and rear, and up and down directions are not intended to limit the technical solution of the present invention.

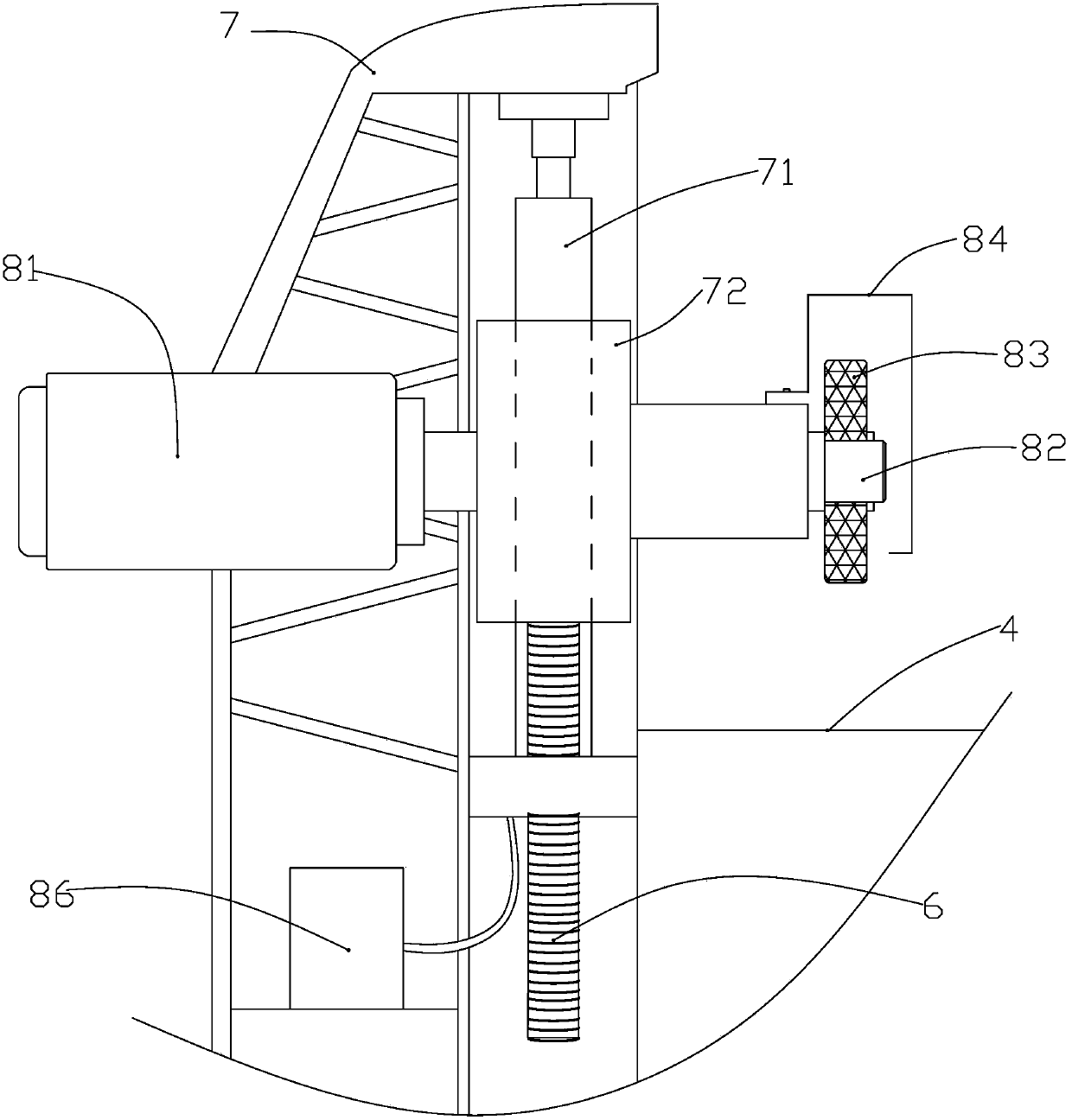

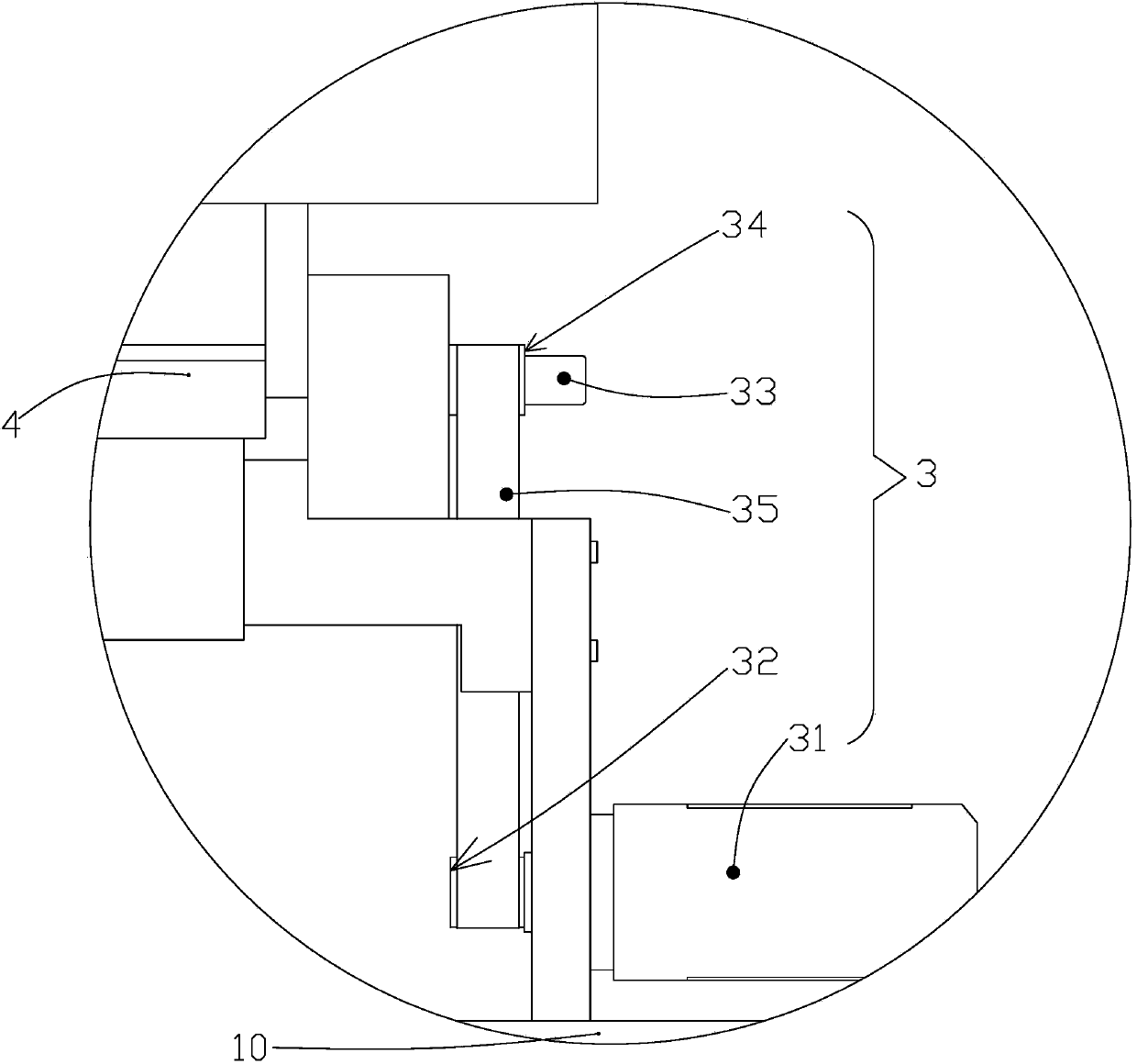

[0029] Such as Figures 2 to 4 As shown, a new type of CNC surface grinder, including a bed 1, a Y-axis front and rear feeding device of the worktable, a X-axis left and right feed motor device 3 of the worktable, a worktable 4, a column 7, a lifting screw 6, and a guide block 72 And the guide rail 71 that cooperates with guide block 72, main shaft motor 81, main shaft 82 and the grinding head 83 that is installed on the main shaft 82 ends, Z-axis lifting drive device 5, machine tool motor control box 9 and with this machine tool motor control box 9 through ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com