Irregularly widened arched section tunnel construction device and construction method

A tunnel construction, irregular technology, applied in tunnels, tunnel linings, shaft equipment and other directions, can solve the problems of poor applicability of general equipment, difficult construction and other problems, to reduce construction complexity, shorten construction period, and high applicability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

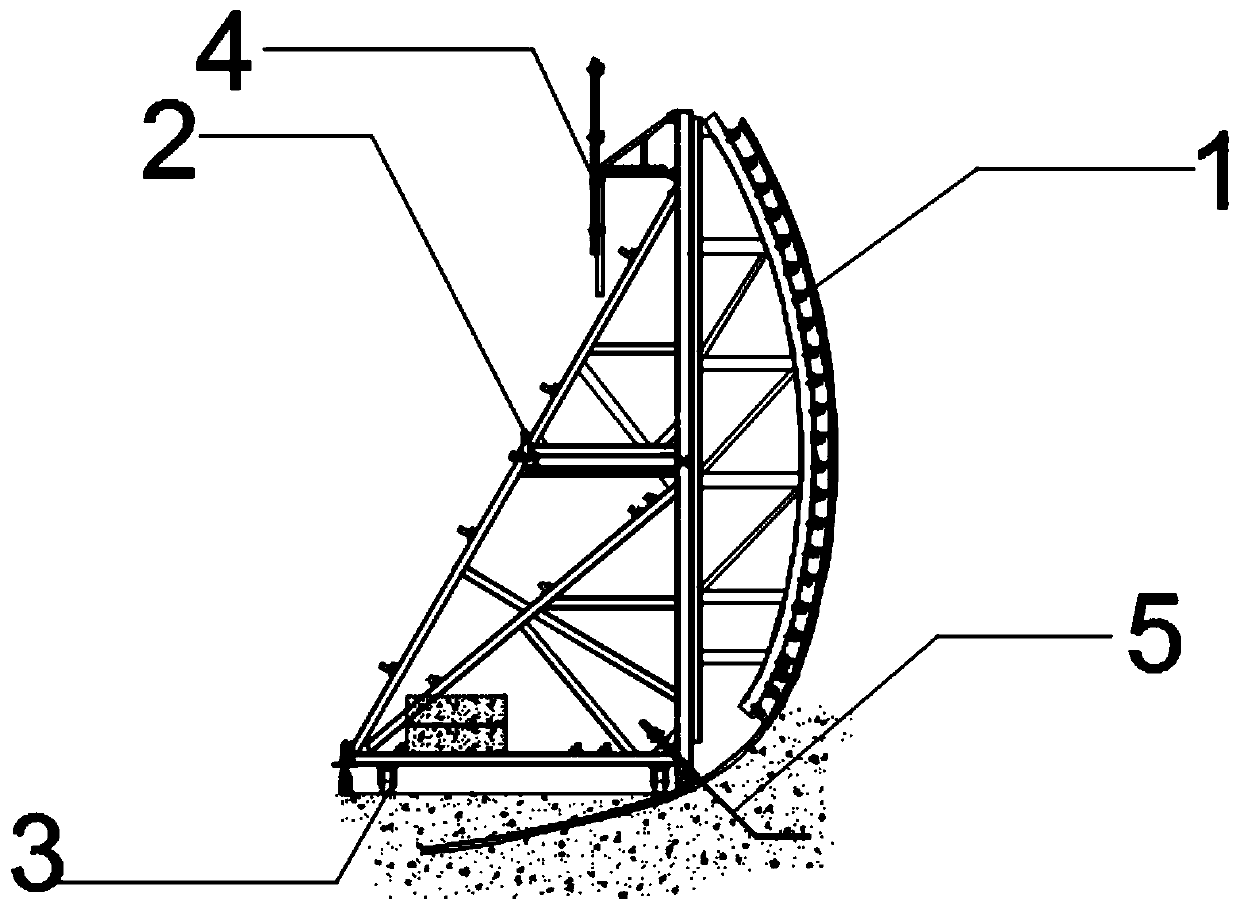

[0052] like figure 1 As shown, the irregular widening section mobile side wall formwork construction device and construction method include a panel system 1 and a support system 2. The panel system 1 is set on one side of the support system 2, and the lower end of the support system 2 is provided with a universal wheel 3. The upper end of the triangular support 211 is provided with a working platform 4 . The working platform 4 is provided with a scaffolding board. The bottom edge of the trapezoidal support 212 is provided with anchor bolts 5 pre-embedded in the concrete floor at right angles to the bottom.

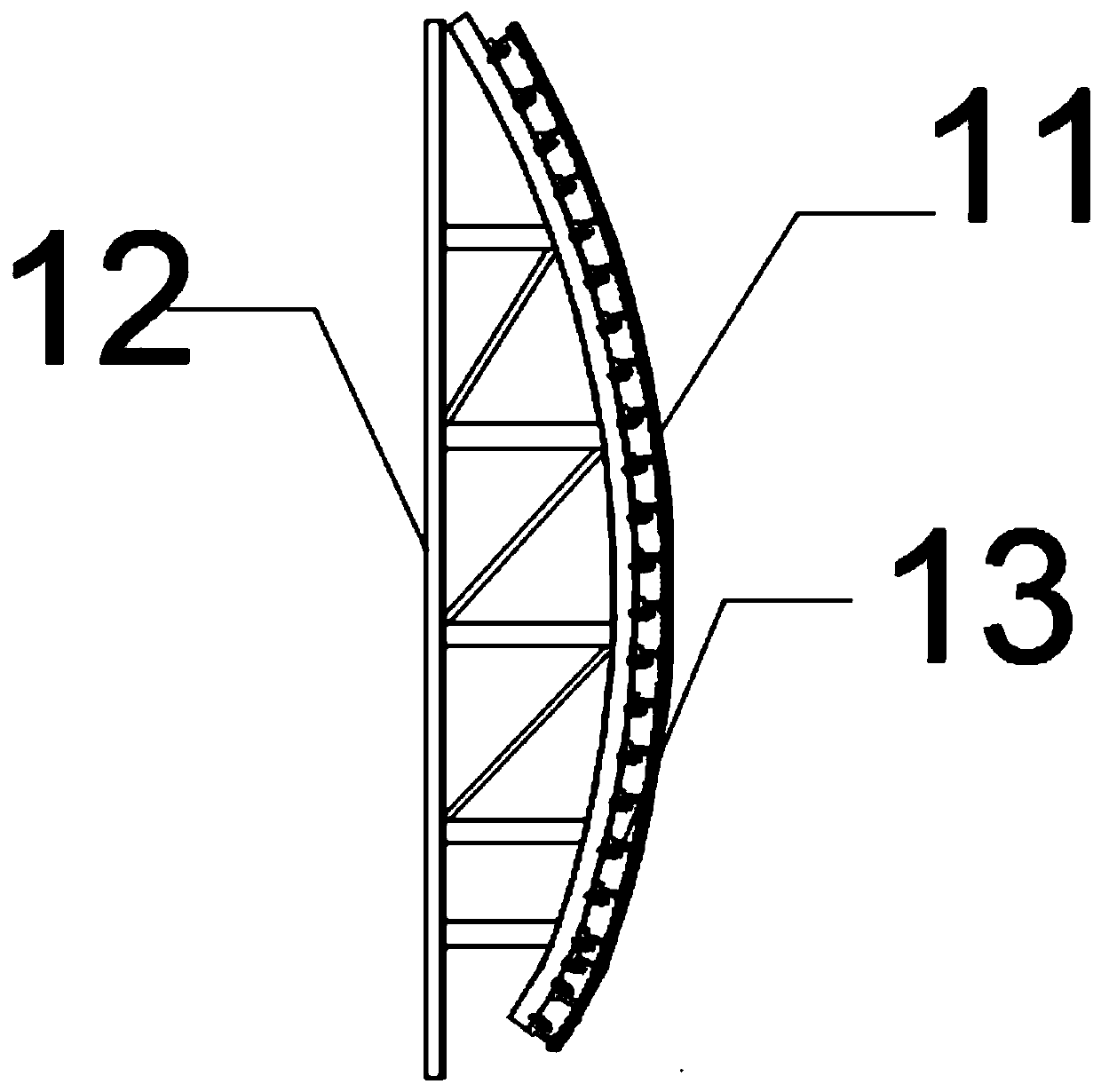

[0053] like Figure 4~5 As shown, the support system 2 includes three supports 21, the supports 21 are arranged side by side in rows, the supports 21 include a triangular support 211, a trapezoidal support 212, and an adjustment support 213, the triangular support 211 is a 3600mm standard section, and the trapezoidal support 212 is a 3200mm heightening section The shape...

Embodiment 2

[0067] like figure 1 As shown, the irregular widening section mobile side wall formwork construction device and construction method include a panel system 1 and a support system 2. The panel system 1 is set on one side of the support system 2, and the lower end of the support system 2 is provided with a universal wheel 3. The upper end of the triangular support 211 is provided with a working platform 4 . The working platform 4 is provided with a scaffolding board. The bottom edge of the trapezoidal support 212 is provided with anchor bolts 5 pre-embedded in the concrete floor at right angles to the bottom.

[0068] like Figure 4~5 As shown, the support system 2 includes three supports 21, the supports 21 are arranged side by side in rows, the supports 21 include a triangular support 211, a trapezoidal support 212, and an adjustment support 213, the triangular support 211 is a 3600mm standard section, and the trapezoidal support 212 is a 3200mm heightening section The shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com