Component for fabricated building and fabricated building with same

A prefabricated and architectural technology, which is applied to the on-site preparation of building components, building structure, and construction, etc., can solve the problems of high construction difficulty and low construction efficiency, and achieve the advantages of low construction difficulty, convenient construction and reliable connection. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

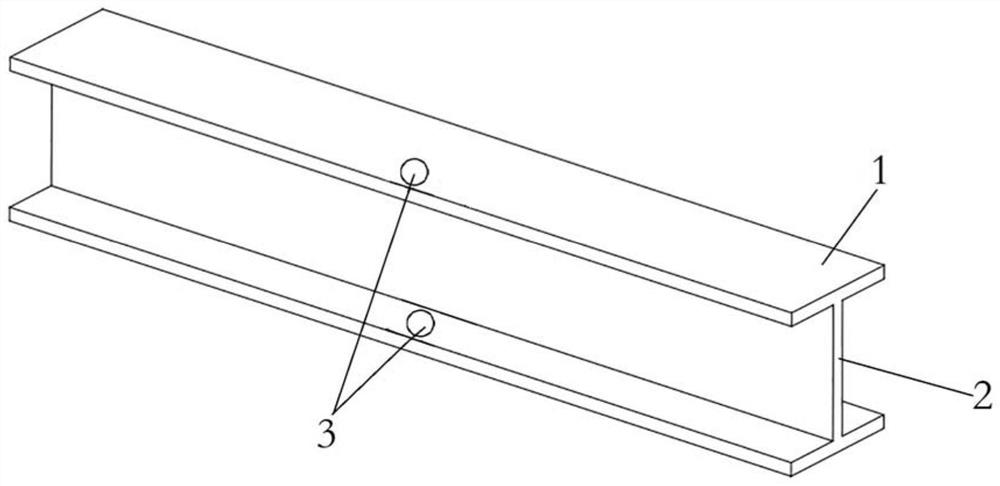

[0034] The prefabricated components provided in this embodiment, such as figure 1 As shown, there is a horizontal plate 1 arranged horizontally and a vertical plate 2 arranged vertically; the horizontal plate 1 has two pieces, which are arranged above and below the vertical plate 2 at intervals; the steel member of this embodiment is H-shaped steel, and the Each of the horizontal plates 1 has a pipeline hole 3 that penetrates up and down, wherein the pipeline hole 3 on the upper horizontal plate 1 and the pipeline hole 3 on the lower horizontal plate 1 are arranged oppositely; the electromechanical pipeline 7 can be directly connected from the pipeline hole 3 through;

[0035] A pipeline hole 3 is set on the horizontal plate 1 of the H-shaped steel. The setting of the pipeline hole 3 prevents the electromechanical pipeline 7 from turning over at the steel member when it is laid vertically along the wall, which reduces the construction difficulty; improves the construction of t...

Embodiment 2

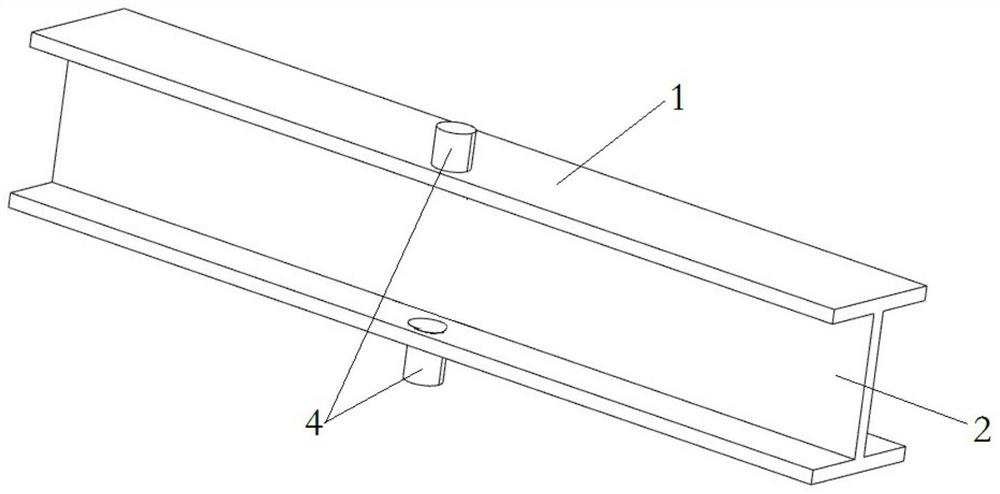

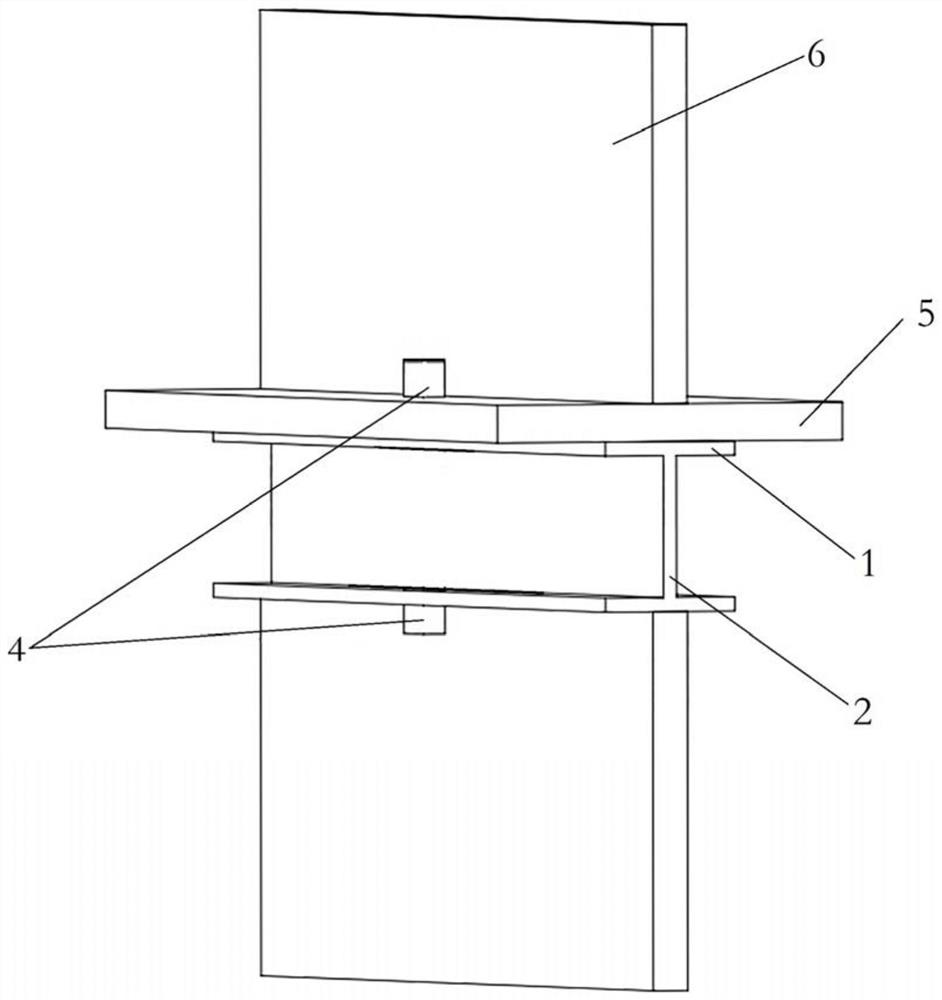

[0039] The prefabricated building provided in this embodiment includes the component for the prefabricated building described in Embodiment 1; this embodiment uses H-shaped steel as the component for the prefabricated building; image 3 As shown, casings 4 are arranged in the pipeline holes 3 of the H-shaped steel, and a structural floor 5 is horizontally erected above the H-shaped steel. equal to 5 cm, preferably 5 cm.

[0040] like Figure 4 As shown, a wall panel 6 is arranged above the structural floor 5 and below the H-shaped steel, and the H-shaped steel is used as a beam to connect the wall panel 6 and the structural floor 5 or connect the wall panel 6 and the wall panel 6;

[0041] like Figure 5 As shown, the electromechanical pipeline 7 is laid along the vertical direction of the wallboard 6. When the electromechanical pipeline 7 passes through the H-shaped steel, the electromechanical pipeline 7 passes through the pipeline hole 3 of the H-shaped steel, effectively...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com