Wet joint structure and construction method suitable for prefabricated pavement

A wet-joint, prefabricated technology, applied to pavements, roads, roads and other directions paved with prefabricated blocks, can solve problems such as difficulty in leveling and docking, and achieve improved engineering economy, comfortable and smooth driving, and easy leveling. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in detail below with reference to the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited by the specific embodiments, and the claims shall prevail. In addition, on the premise of not violating the technical solution of the present invention, any modification or change made to the present invention that can be easily realized by those skilled in the art will fall within the scope of the claims of the present invention.

[0037] The construction method of wet joint structure suitable for prefabricated pavement, the construction steps are as follows:

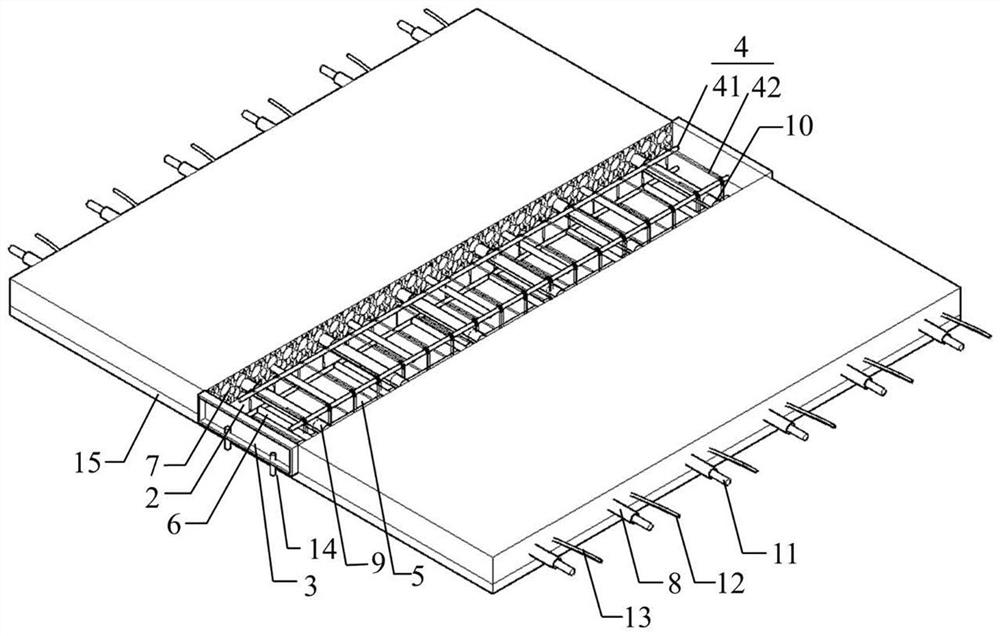

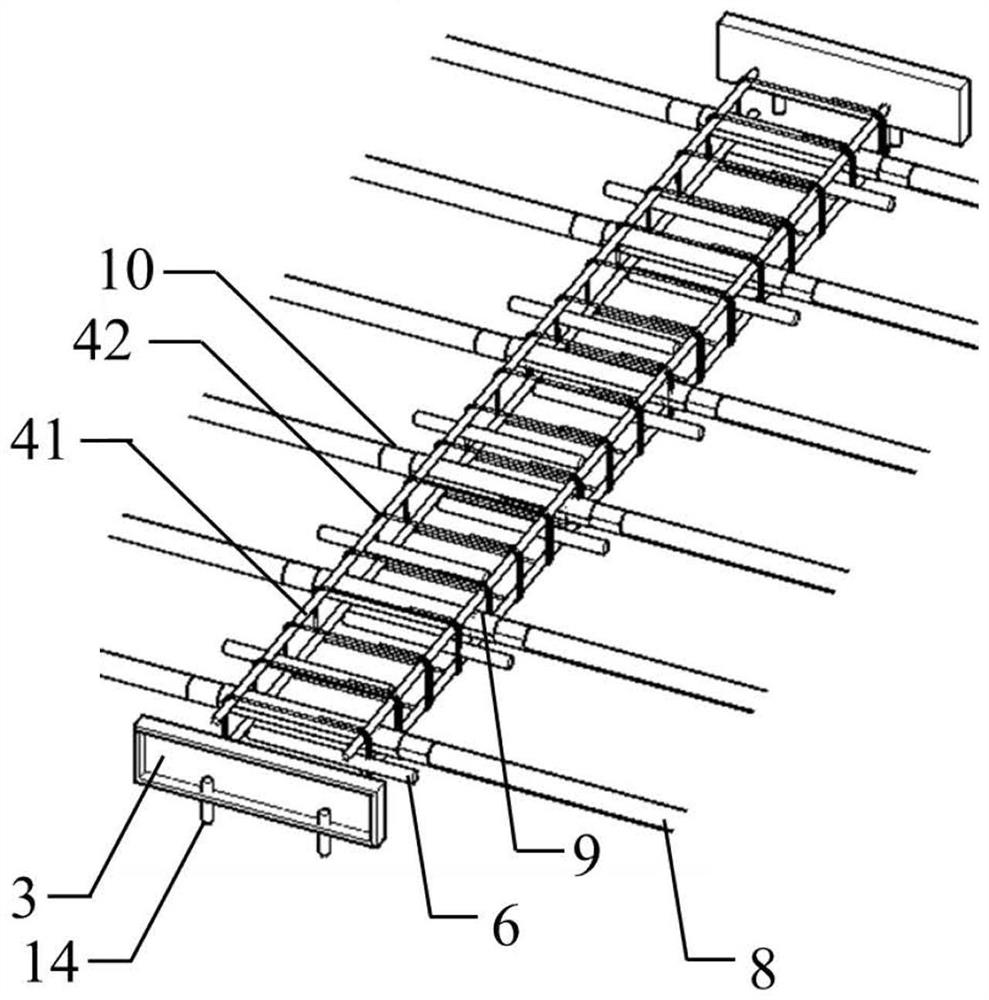

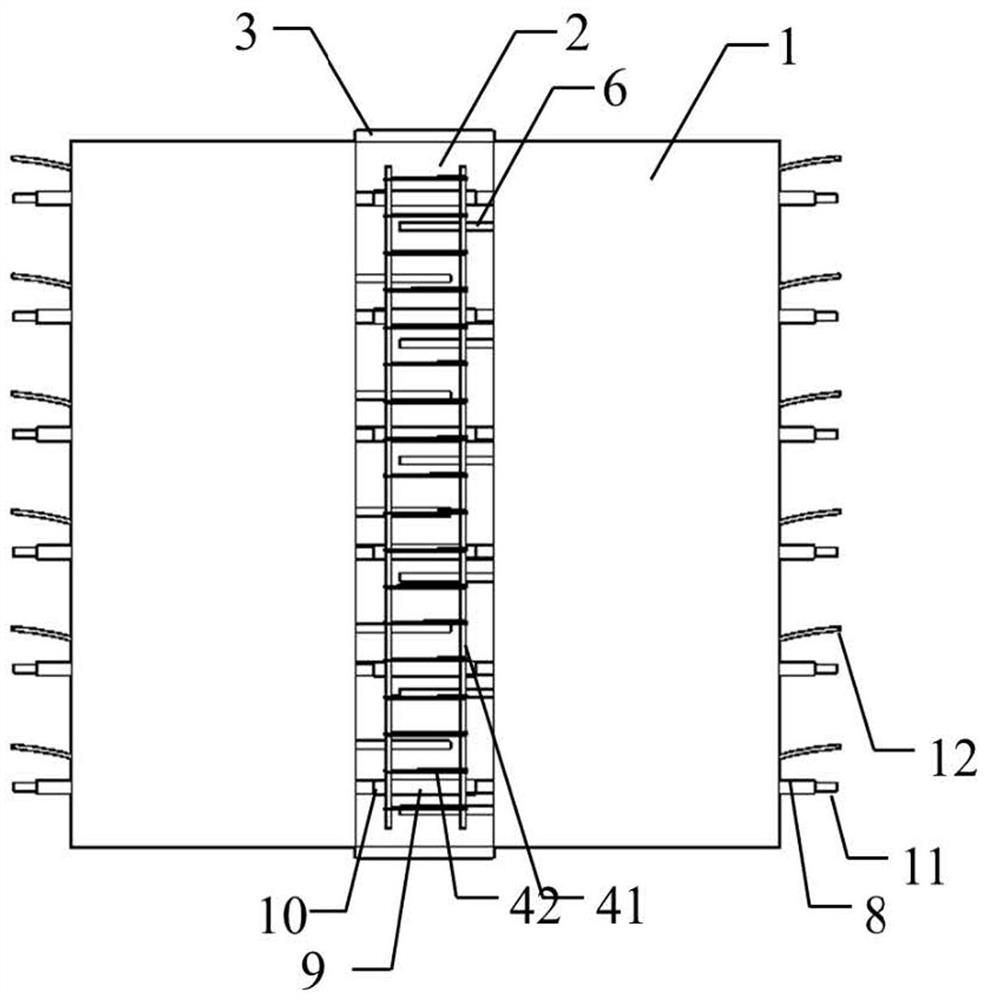

[0038] refer to figure 1 , 2 , showing a wet joint structure suitable for fabricated pavements. The wet joint structure includes cement road slabs, reserved prestressed tunnels, dowel bars, corrugated pipes, structural steel mesh, formwork, and micro-expansion high-performance concrete. The inside of the cement road slab ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com