Load shedding sound barrier unit and sound barrier thereof

A sound barrier and sound absorption screen technology, applied in construction, noise absorption devices, etc., can solve problems such as concrete cracking, sound barrier bolt loosening, and safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

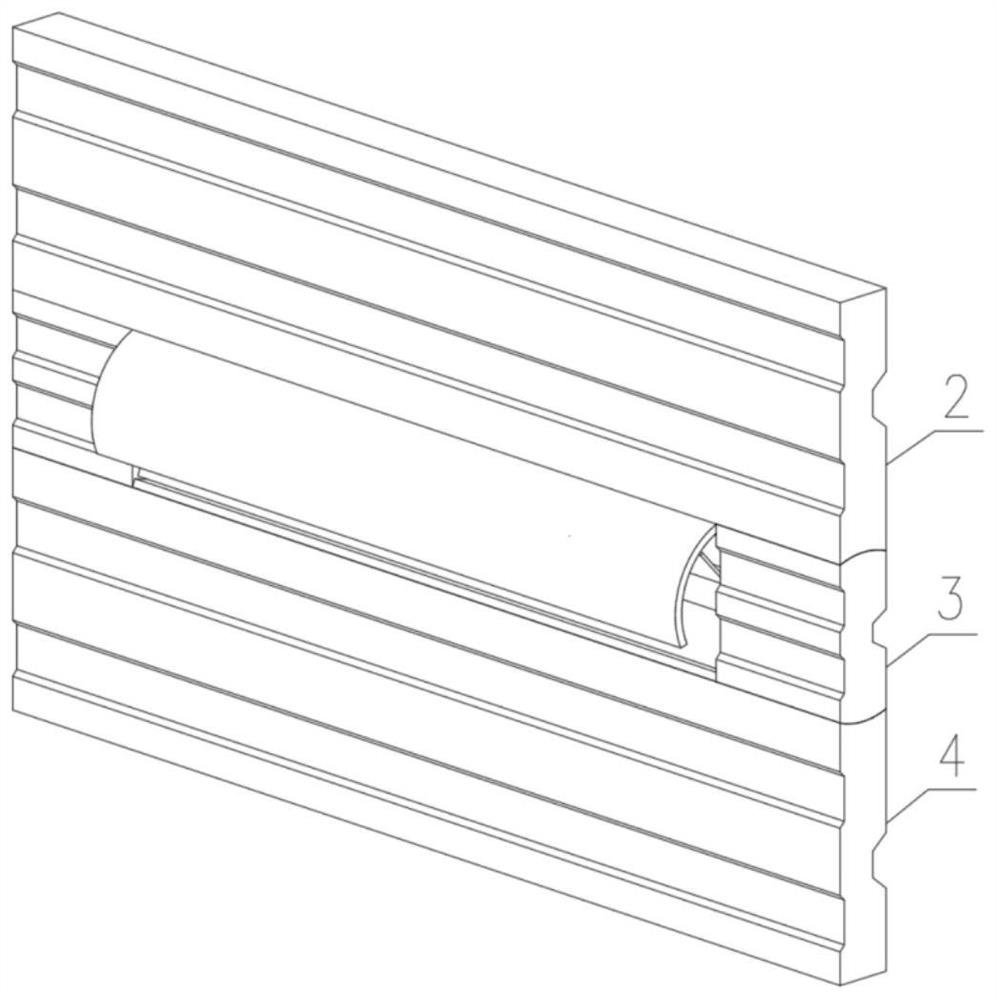

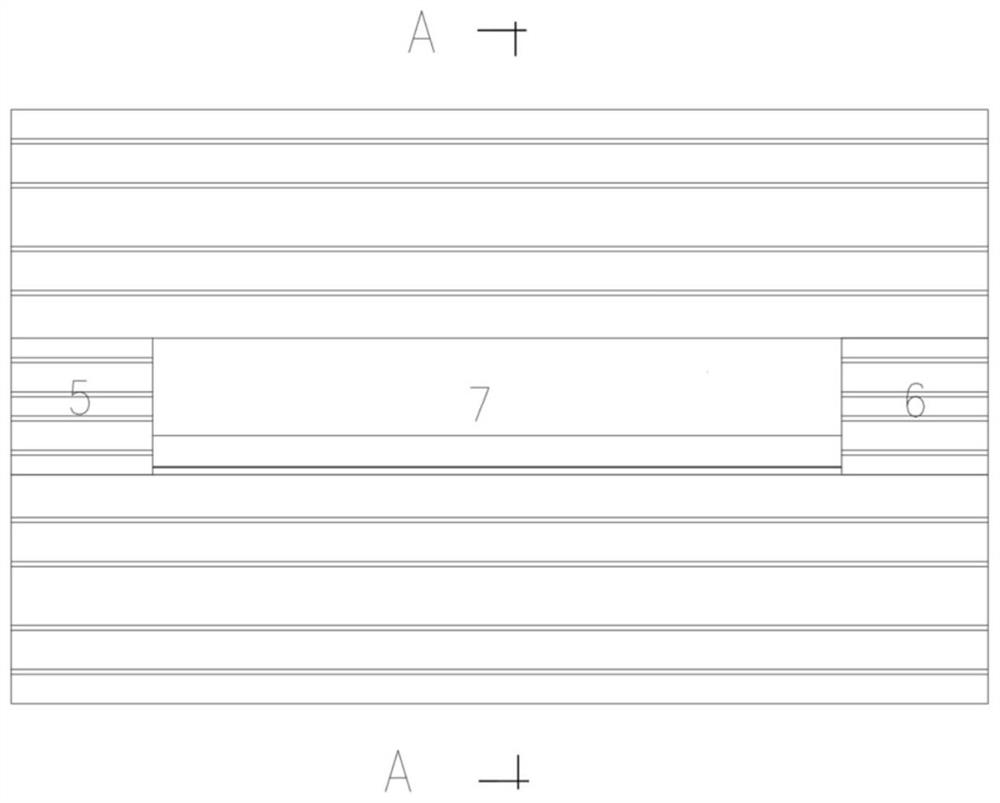

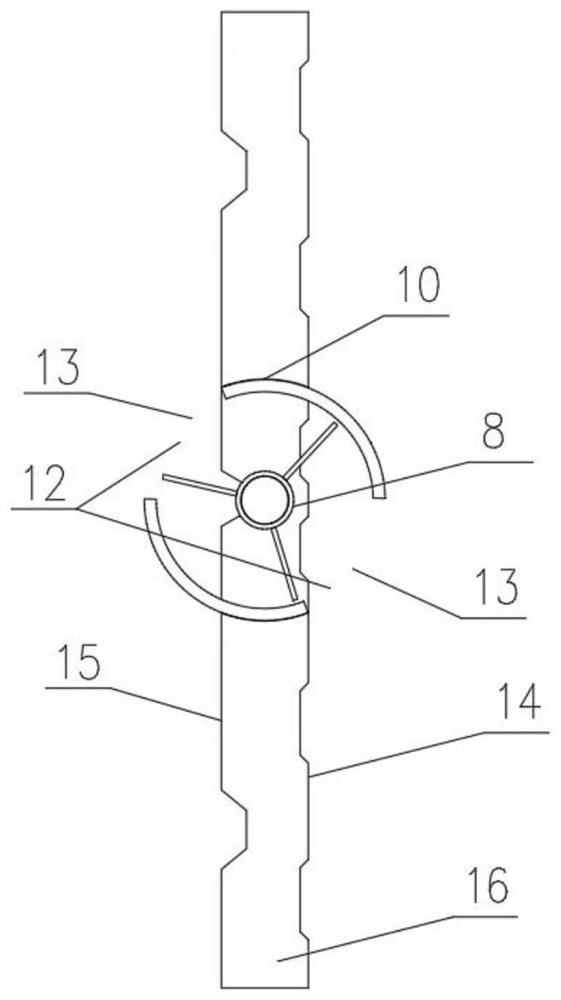

[0037] like Figure 1-4As shown in the figure, a load shedding sound barrier unit of this embodiment includes a load shedding sound absorbing screen body, and the load shedding sound absorbing screen body includes an upper screen body 2 arranged in sequence from top to bottom along the vertical direction, a load shedding sound absorbing screen body, and a load reducing sound absorbing screen body. Unit structure 3 and lower screen body 4. The load reducing unit structure 3 includes a left screen body 5 , a right screen body 6 and a load reducing structure 7 located between the left screen body 5 and the right screen body 6 . The load reducing structure 7 includes a runner 8 and an outer cylinder 10 . The runner 8 includes a rotating shaft 9 and three impellers 11. The two ends of the rotating shaft 9 are respectively connected with the left screen body 5 and the right screen body 6 of the same height at both ends and can be freely rotated. 11 is evenly arranged on the outer ...

Embodiment 2

[0052] A load shedding sound barrier unit of this embodiment is different from Embodiment 1 in the size of the load shedding unit structure 3 and the material of the sound barrier screen body.

[0053] In this embodiment, the height of the sound barrier unit is 3 meters and the length is 2 meters, and a load reducing unit structure with an outer cylinder diameter of 400 mm and a length of 1.5 meters is used.

[0054] The load shedding sound barrier unit may be a non-metallic sound barrier unit. The upper screen body 2, the lower screen body 4, the left screen body 5 and the right screen body 6 are all composed of a sound absorption panel 14, a sound insulation backboard 15 and an internal sound absorption layer 16, and the overall thickness is 80mm-120mm.

[0055] The sound-absorbing panel 14 adopts a glass fiber reinforced plastic perforated plate, the plate thickness is 3.5 mm, the aperture is 4-5 mm, and the opening rate is about 15%. The sound insulation back plate 15 is ...

Embodiment 3

[0061] like Figure 5 As shown, a load shedding sound barrier according to an embodiment of the present invention includes several load shedding sound barrier units 1 of Embodiment 1 and several H-shaped steel uprights 17 . A plurality of the load shedding sound barrier units 1 are connected to each other through the H-shaped steel uprights 17 to form the load shedding sound barrier. The H-shaped steel uprights 17 are arranged at equal distances from each other. After the H-shaped steel uprights 17 are fixed, the load-reducing sound barrier unit 1 is inserted between the H-shaped steel uprights 17 and placed on the upright support plate 18. to be fixed.

[0062] The height of the load shedding sound barrier should make the sensitive building in the sound shadow area to achieve good insertion loss, or set according to the acoustic design requirements of the noise reduction target of the sensitive building; 17 is a span) is 1.5m ~ 2.5m, and the screen thickness of the load she...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Plate thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com