A Construction Technology of High-grade Concrete Column Foot

A construction technology and concrete technology, which is applied in the processing of building materials, formwork/formwork/work frame, and on-site preparation of building components, etc. Exudation and other problems, to achieve the effect of saving use, good quality and reducing stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with accompanying drawing of description, but protection scope of the present invention is not limited thereto:

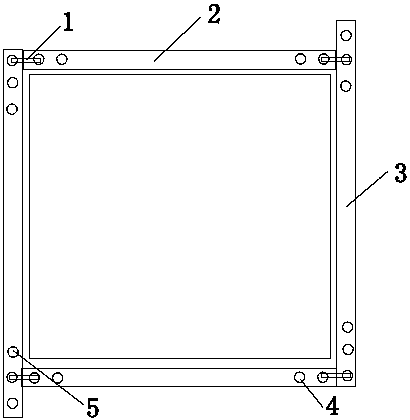

[0040] The construction process of a high-grade concrete column foot of the present invention includes the following steps: binding steel bars→pillar formwork→setting a slurry stop bar→installing isolated steel mesh pieces→concrete pouring and tamping for a primary vibration→concrete pouring and tamping for a second vibration→ After pouring, maintenance and repair → remove the column formwork. If the pouring column is an outer column, after the column formwork and before setting the grout stop strip, the bolts are pre-embedded. Before the side column concrete is poured, pre-embed tie bolts at 100-200mm below the level of the top surface of the floor slab. When preparing the formwork, extend the lower part of the formwork at this position by 300-400mm. When setting up the formwork, fix the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com