Equipment and method for carrying and in-place installation of vertical battens of a building infilled wall

A technology for installing equipment and vertical strips, which is applied in construction, transportation and packaging, building construction, etc., and can solve problems such as high cost, low efficiency, potential safety hazards, and manual handling of strips

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

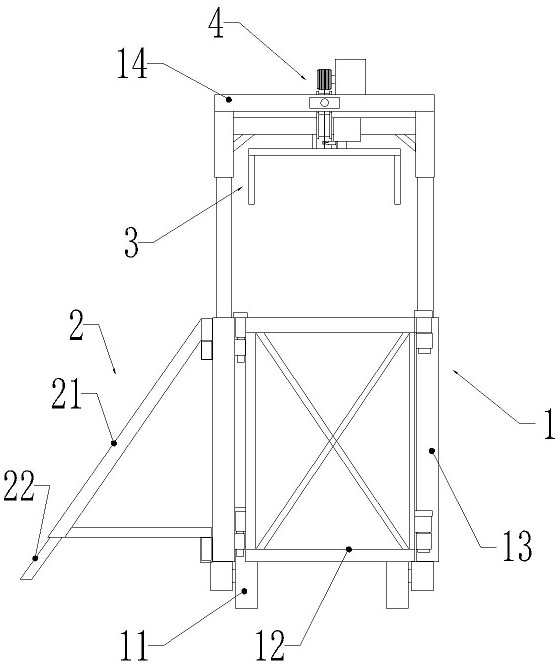

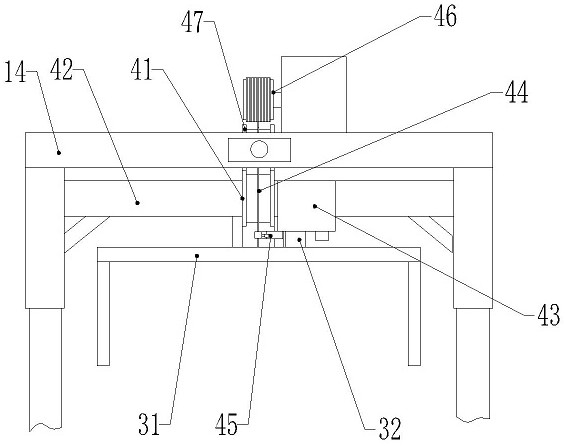

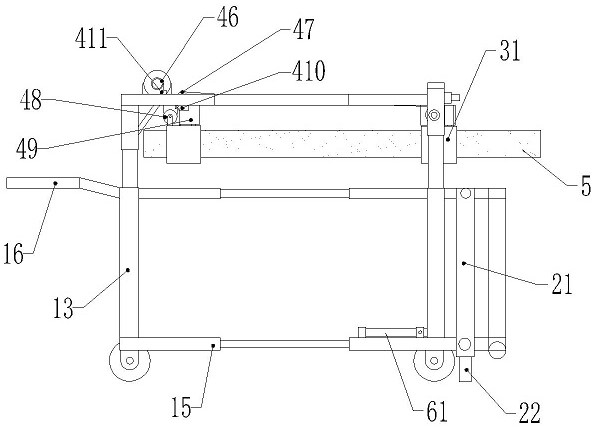

[0068] Such as Figure 1-10 As shown in the figure, a vertical slat transporting installation device for a building filling wall realizes three functions of carrying, positioning and installing a slat 5; it includes a slat transportation system 1, a slat clamping system 3, and a slat Lifting rotation system 4, slat positioning system 6, slat installation system 2 and slat scraping adhesive glue system 7.

[0069] Such as figure 1 , image 3 , Figure 4 with Image 6 As shown, the lath transportation system 1 includes a mobile frame and a lifting support 14 arranged on the mobile frame.

[0070] The mobile frame is assembled by several horizontal support rods 15, several vertical support rods 13 and connecting door body 12; specifically, as figure 1 with image 3 As shown, the cross-section of the mobile frame after the vertical support rod 13 and the horizontal support rod 15 is connected is U-shaped, that is, one of the vertical surfaces is not closed and is in an open ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com