Method for separating cow milk beta-casein and whey protein at low temperature through microfiltration to simulate composition of human lactoprotein

A whey protein and casein technology, applied in the field of milk powder processing, can solve the problems of reducing the probability of contact between digestive enzymes and protein, reducing protein digestibility, etc., and achieves good application prospects, social and economic benefits, and efficient separation effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0013] A method for preparing a novel functional milk protein ingredient rich in β-casein and whey protein by using skim milk powder as a raw material through low-temperature microfiltration technology. The specific process steps are as follows:

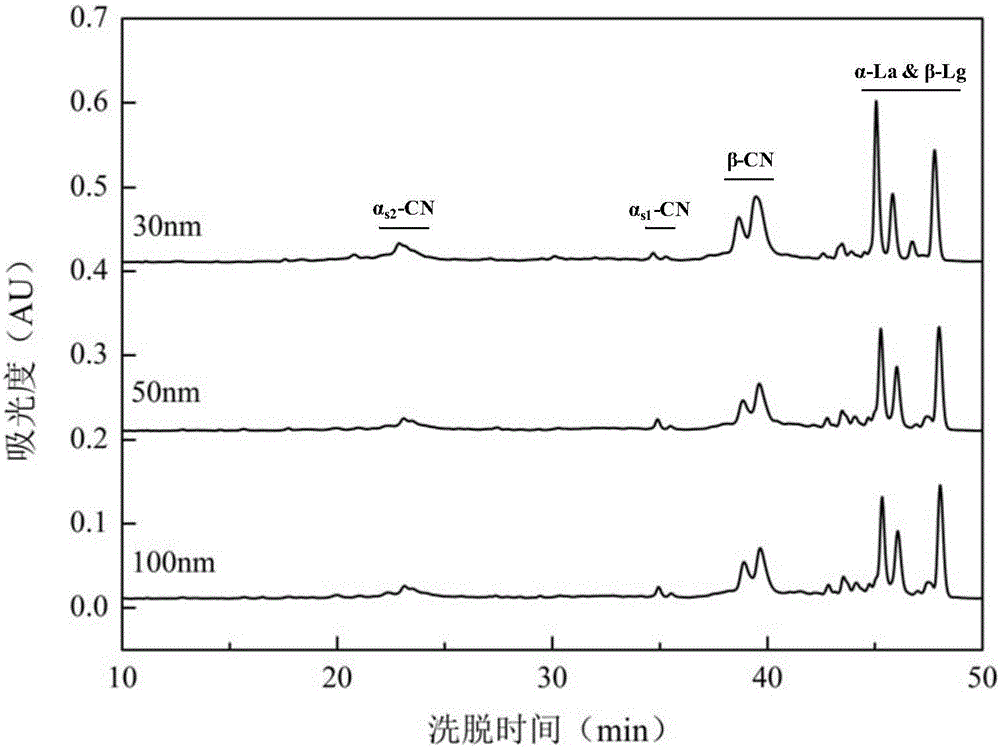

[0014] Take 3 parts of 15kg skimmed milk powder, add 150L of water respectively, stir and dissolve at 50°C for 1 hour, add the obtained complex solution into the liquid storage tank of the microfiltration system, cool its temperature to about 4°C through a low-temperature circulator, and After the equilibrium was stable at this temperature for 1 hour, ceramic membranes with three different pore sizes of 30, 50, and 100 nm were used for microfiltration and concentration. During the microfiltration process, the temperature was still controlled at 4 ° C, and the microfiltration was stopped when the volume of the permeate reached 100 L. The obtained permeate is concentrated by ultrafiltration using an ultrafiltration membrane with a molec...

Embodiment example 2

[0017] A new functional milk protein ingredient rich in β-casein and whey protein is prepared by low-temperature microfiltration technology using whole milk as raw material. The specific process steps are as follows:

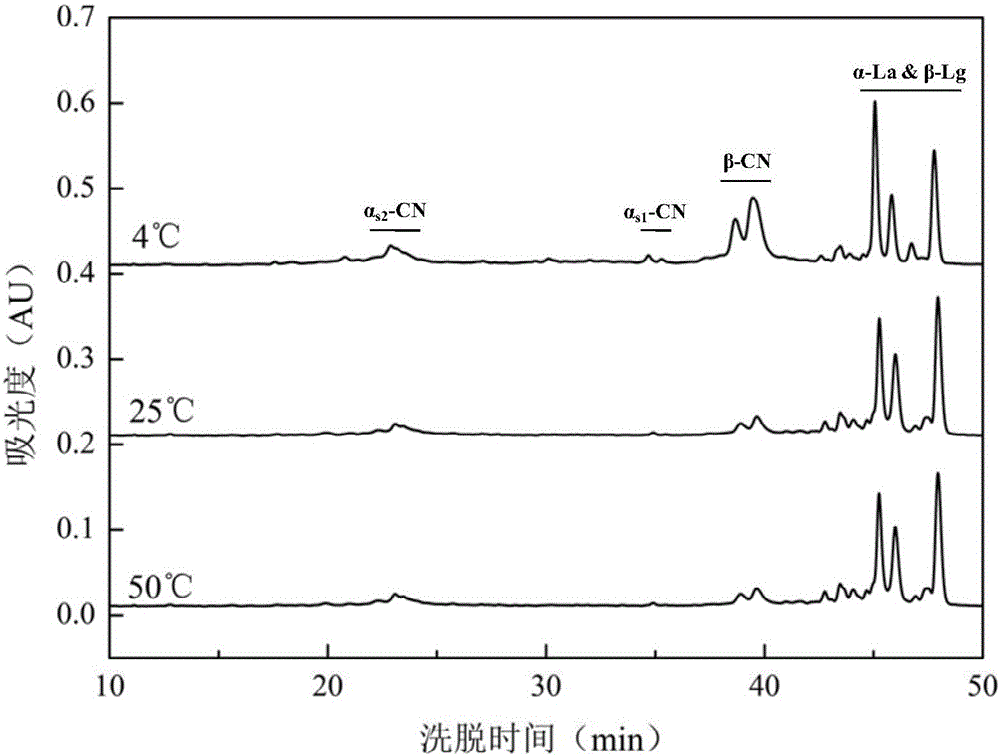

[0018] Take 3 parts of 300L pasteurized whole milk, use a milk fat separator to remove fat, add the obtained skim milk to the liquid storage tank of the microfiltration system, and cool the temperature to 4, 25, and 50°C respectively through a low-temperature circulator After equilibrating and stabilizing at the corresponding temperature for 1 hour, use a ceramic membrane with a pore size of 30nm for microfiltration and concentration. During the microfiltration process, the corresponding temperature is still controlled, and the microfiltration is stopped when the concentration ratio is 3. The obtained permeate is concentrated by ultrafiltration using an ultrafiltration membrane with a molecular weight cut-off of 5kDa at room temperature to remove lactose and mine...

Embodiment example 3

[0021] A new functional milk protein ingredient rich in β-casein and whey protein is prepared by low-temperature microfiltration technology using skim milk as raw material. The specific process steps are as follows:

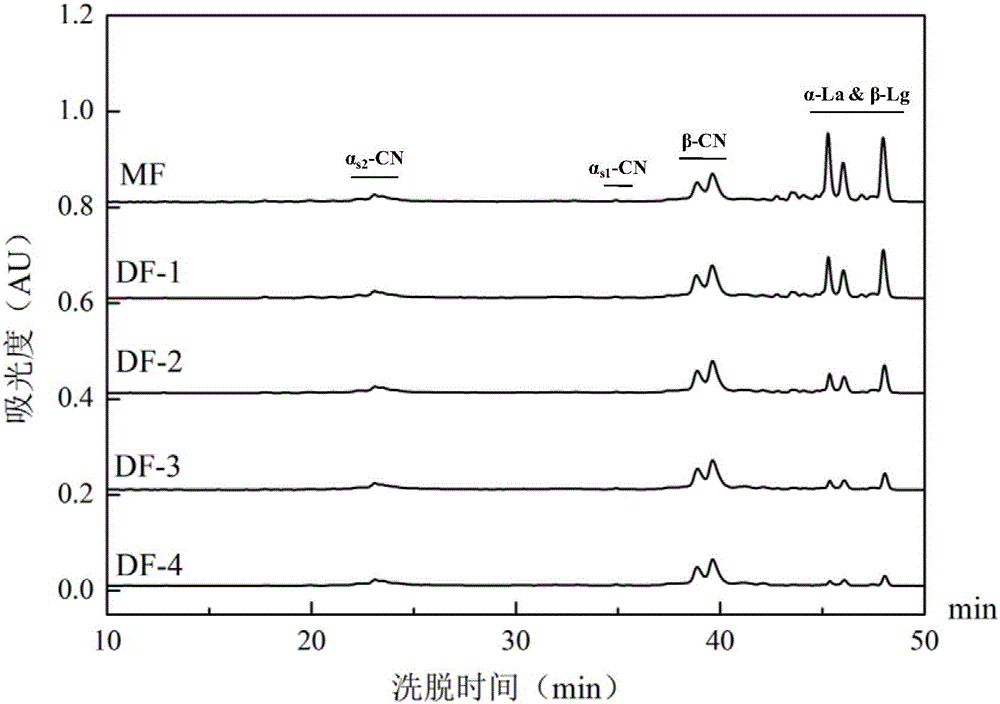

[0022] Take 2 parts of 150L pasteurized skim milk, and use a microfiltration ceramic membrane with a pore size of 30nm to separate at 4°C. The whole process is divided into 1 microfiltration and 4 diafiltrations: the first microfiltration is the concentration and separation of the original skim milk, that is, 150L skim milk is concentrated 3 times, and 100L permeate is collected; the diafiltration operation is at the end of the microfiltration Finally, add water until the original volume of the feed solution is 150L, and continue to concentrate 3 times. Collect the permeate obtained in each stage of separation, and use ultrafiltration membrane with a molecular weight cut-off of 10kDa to carry out ultrafiltration and concentration at room temperature to remove l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com