Patents

Literature

64results about How to "Low in lactose" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

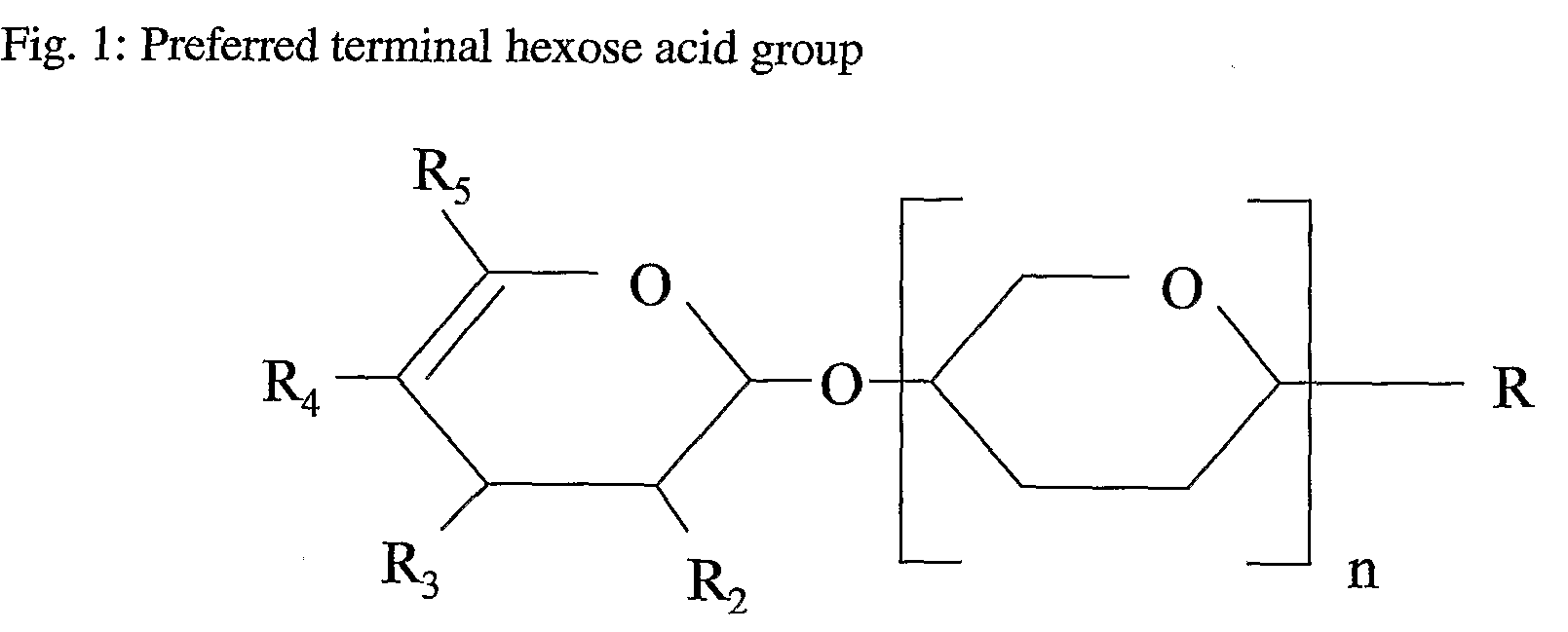

Nutritional Composition Comprising Indigestible Oligosaccharides

ActiveUS20080124323A1Reduce generationRelieve pressureOrganic active ingredientsBiocideDiseaseLactose

The present invention provides a method and composition for the treatment and / or prevention of respiratory tract infection and / or respiratory tract infection disease, said method comprising orally administering a composition to a mammal, said composition comprising a galactose containing indigestible oligosaccharide and at least 5 wt. % digestible galactose saccharide.

Owner:NV NUTRICIA

Process for preparing milk product enhanced with galactooligosaccharide and easily absorbable, and functional milk product prepared therewith

InactiveUS20120040051A1Reduce lactose contentEnhanced with galactooligosaccharideMilk preparationMilk preservationChemistryOligosaccharide

Most milk products in the market are promoted in terms of their nutritional value, rather than the function thereof. For the few products claiming to have a special function, the function comes from substances added to the products rather than from the milk material per se. Some products are claimed to have low lactose content, but there are no milk products in the market that have both low lactose content and high galactooligosaccharide content. The invention is cost effective as compared with milk products with added functional substances. The subject invention relates to a process for production of a milk product enhanced with galactooligosaccharide, characterized in that lactase is used to treat milk raw materials. The subject invention further relates to the milk product of the process of the invention, whose galactooligosaccharide content is at function level.

Owner:V PRODS CORP

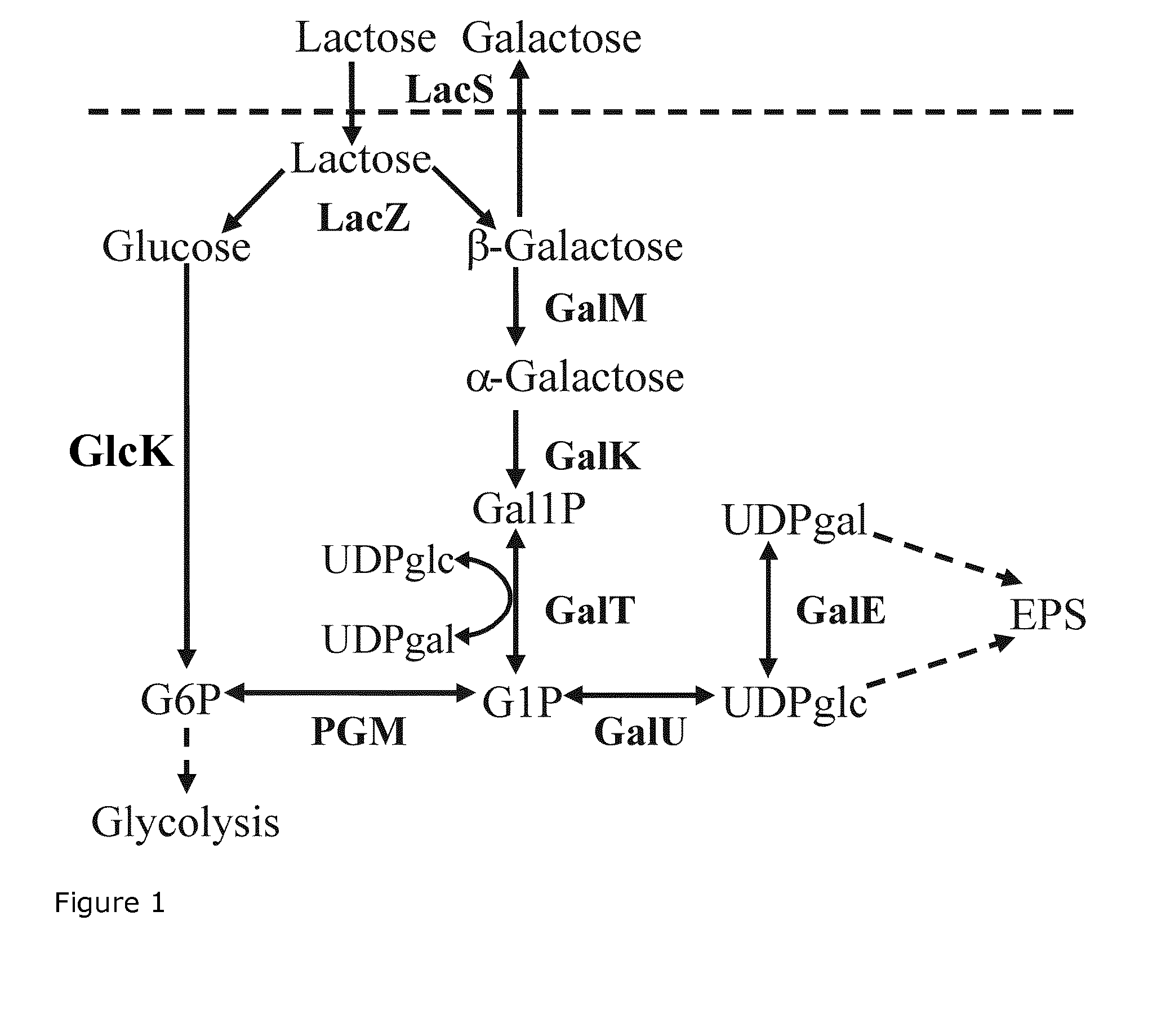

Use of lactic acid bacteria for preparing fermented food products with increased natural sweetness

The dairy industry today faces a problem of providing an alternative to adding sweeteners to fermented milk products in order to achieve the desired sweet taste without the added calories. Furthermore, it would be highly advantageous to establish a method for reducing lactose in fermented milk products to a level which is acceptable for lactose-intolerant consumers. The above problems have been solved by providing mutant Streptococcus thermophilus strains and mutant Lactobacillus delbrueckii subsp. bulgaricus strains that excrete glucose to the milk when the milk is inoculated and fermented with such Streptococcus thermophilus strains and Lactobacillus delbrueckii subsp, bulgaricus strains. Thus, the present invention relates to strains of Streptococcus thermophilus and Lactobacillus delbrueckii subsp, bulgaricus which secrete glucose to the milk substrate during fermentation, as well as to mixed cultures comprising the Streptococcus thermophilus strains and the Lactobacillus delbrueckii subsp, bulgaricus strains, starter cultures comprising the strains and dairy products manufactured with the cultures. The present method also relates to use of the strains for decreasing the lactose content of a fermented food product and for boosting growth of the probiotic BB-12®.

Owner:CHR HANSEN AS

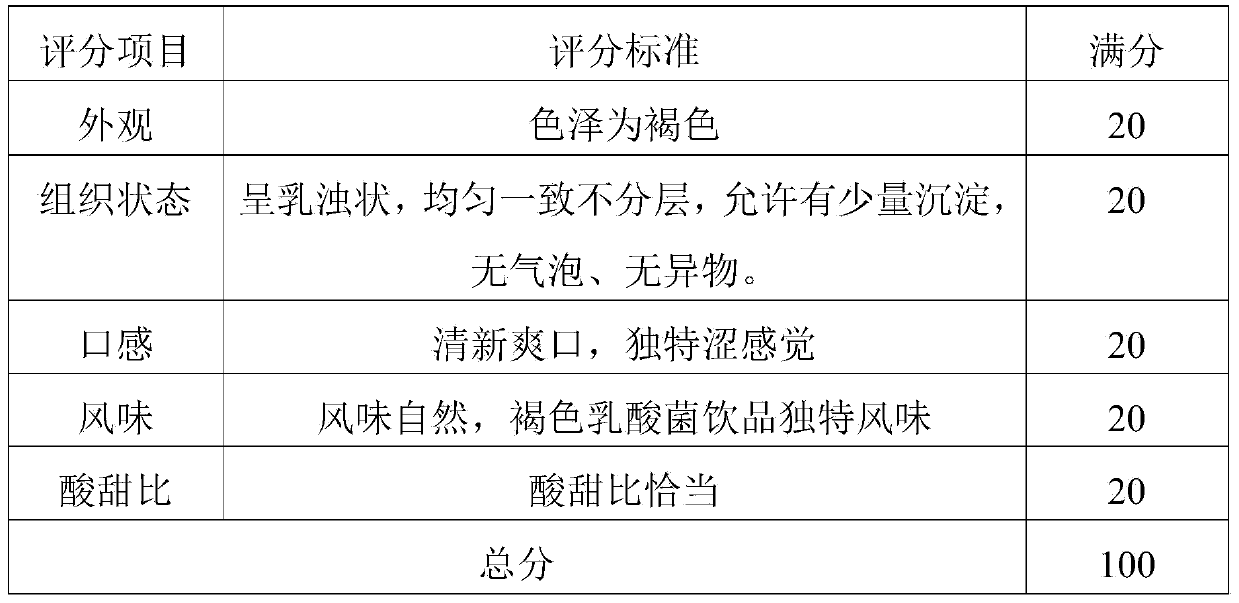

Low-sugar brown lactobacillus drink and preparation method thereof

The invention discloses a low-sugar brown lactobacillus drink and a preparation method thereof. The preparation method comprises the following steps: (1) mixing raw milk with lactase, and standing to obtain mixed liquid; (2) producing Maillard reaction of the mixed solution to obtain browned liquid; (3) cooling the browned liquid, fermenting, and cooling to obtain a fermented milk base material; (4) mixing sugar water liquid with the fermented milk base material, and homogenizing to obtain the low-sugar brown lactobacillus drink, wherein the sugar water liquid is prepared by mixing water with an additive A, sterilizing and cooling. According to the preparation method, lactose is decomposed by a bio-enzyme technology, and the effect of the Maillard reaction can be achieved without addition of reducing sugar, such as exogenous glucose; the low-sugar brown lactobacillus drink is relatively natural and mild in mouth feel, and an emulsifier can be reduced and even is no longer used according to the actual situation.

Owner:BRIGHT DAIRY & FOOD CO LTD

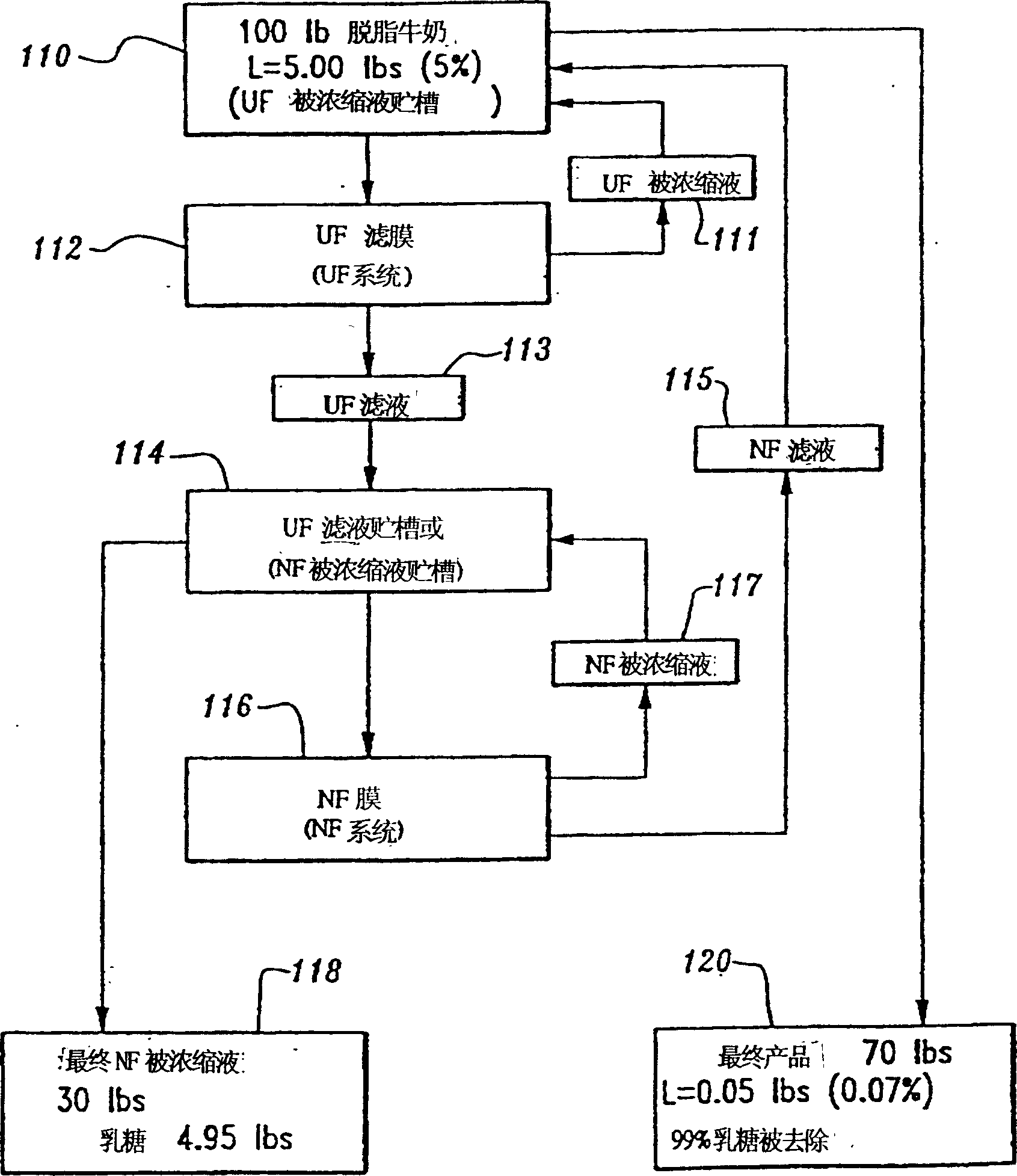

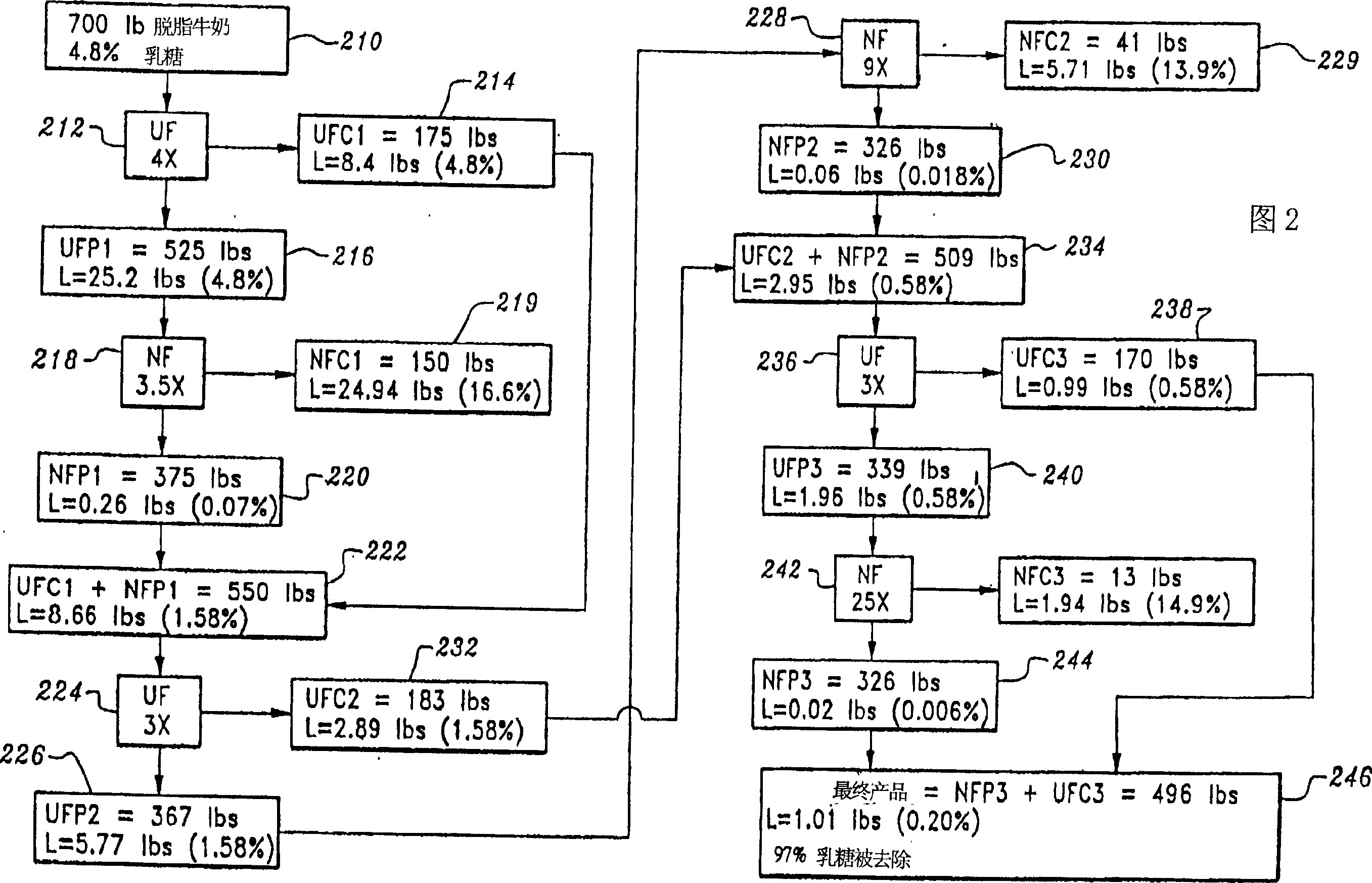

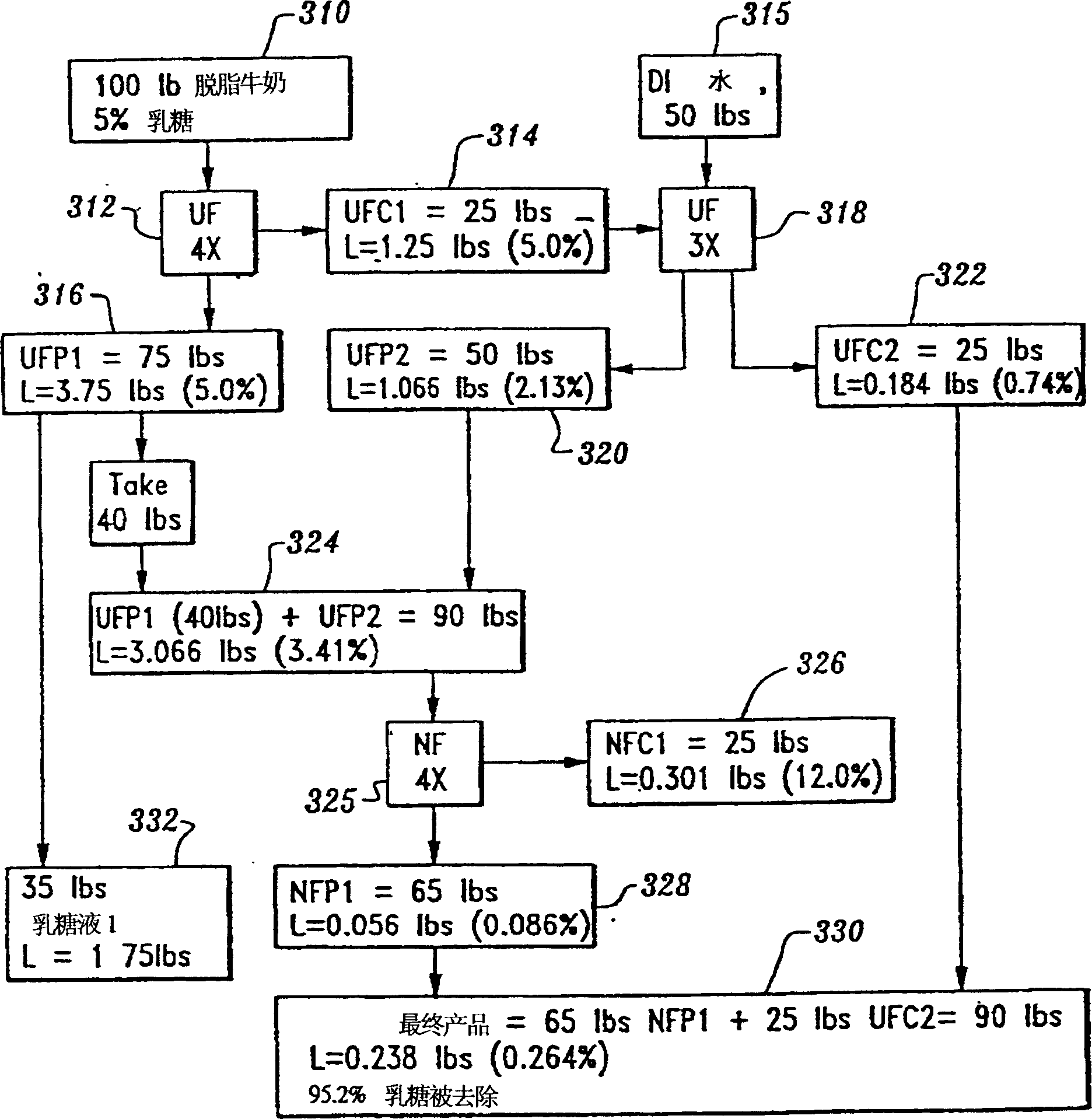

Delactose dairy product and its preparing method

A dairy product without lactose is prepared from milk through ultra-filtration to obtain a concentrated liquid A and a filtrate A, nano-filtering of said filtrate to obtain a concentrated liquid B and a filtrate B, and adding the concentrated liquid A to the filtrate B. It is suitable for the patients of diabetes and obesity.

Owner:王永强

Process for preparing a functional fermented milk product with low acidity and containing a low content of lactose and enhanced with galactooligosaccharides and Bifidobacterium, and functional fermented milk product prepared therewith

InactiveUS20140227393A1Low in lactoseIncrease GOS contentMilk preparationButtermilkBifidobacteriumLactose

The present invention relates to a process for preparing a functional fermented milk product with low acidity and containing a low content of lactose and enriched with galactooligosaccharide and Bifidobacterium, and functional fermented milk product prepared therewith. The process is characterized by converting lactose in milk materials to galactooligosaccharide before subjecting the milk materials to lactic fermentation. The process is further characterized by adding fructooligosaccharide to milk materials before subjecting the milk materials to lactic fermentation; the addition of fructooligosaccharide promotes growth of Bifidobacterium during lactic fermentation and increases the amount of galactooligosaccharide in the final product.

Owner:V PRODS CORP

Low-lactose nutrition fortification milk for children and its production method

InactiveCN102511547ALow in lactoseSolve the problem of physical discomfortMilk preparationNutrientChemistry

The invention relates to a low-lactose nutrition fortification milk for children and its production method. The low-lactose nutrition fortification milk is prepared from the following raw materials: 100 kg of raw mil, 50 to 200 g of lactase with an activity of no less than 2000 NLU / g, 100 to 500 g of an emulsifier, 30 to 50 g of taurine, 60 to 100 mg of vitamin A, 1 to 4 mg of vitamin D, 1 to 2 g of ferric pyrophosphate in terms of the Fe element, 0.5 to 1 g of zinc citrate in terms of the Zn element and 20 to 44 g of fish oil. The production method comprises the steps of enzyme hydrolysis of lactose in the raw milk for preparation of low lactose raw material milk, mixing of nutrients and the emulsifier for preparation of material liquid to be sterilized and pasteurization, filling and examination of a product. According to the invention, lactose in the raw milk is degraded into micro-molecular galactose and glucose which are favorable for digestion and absorption, which enables problems caused by lactose intolerance to be avoided; meanwhile, the nutrient elements vitamins, minerals, fish oil (containing DHA and ARA) promoting development of intelligence and the like are added into the low lactose raw milk obtained after lactose degradation; therefore, a foodstuff suitable for growth and development of children is produced. A hydrolysis conversion rate of lactose is 97 to 99% in the invention.

Owner:SHANDONG DEYI DAIRY IND

Nutritional composition

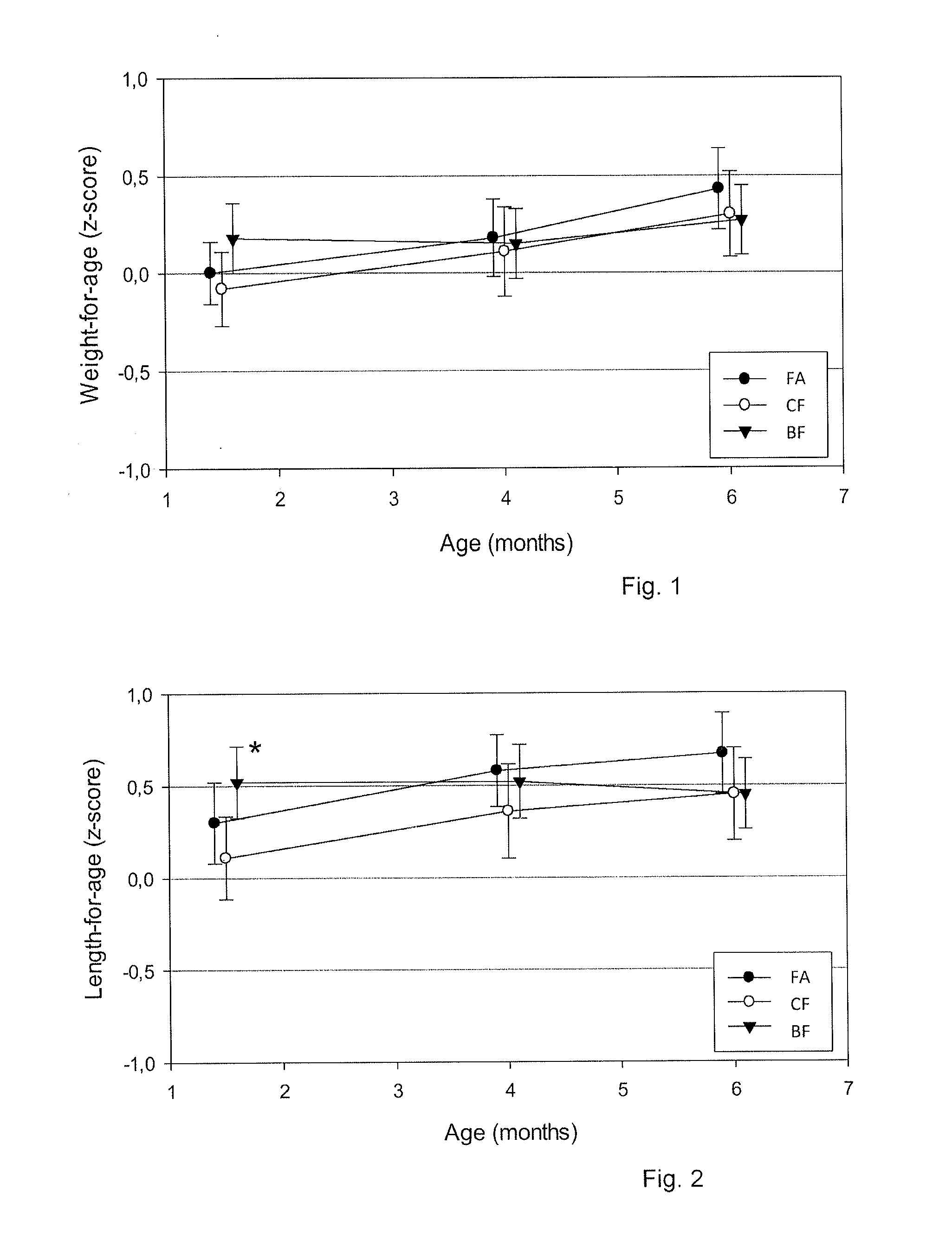

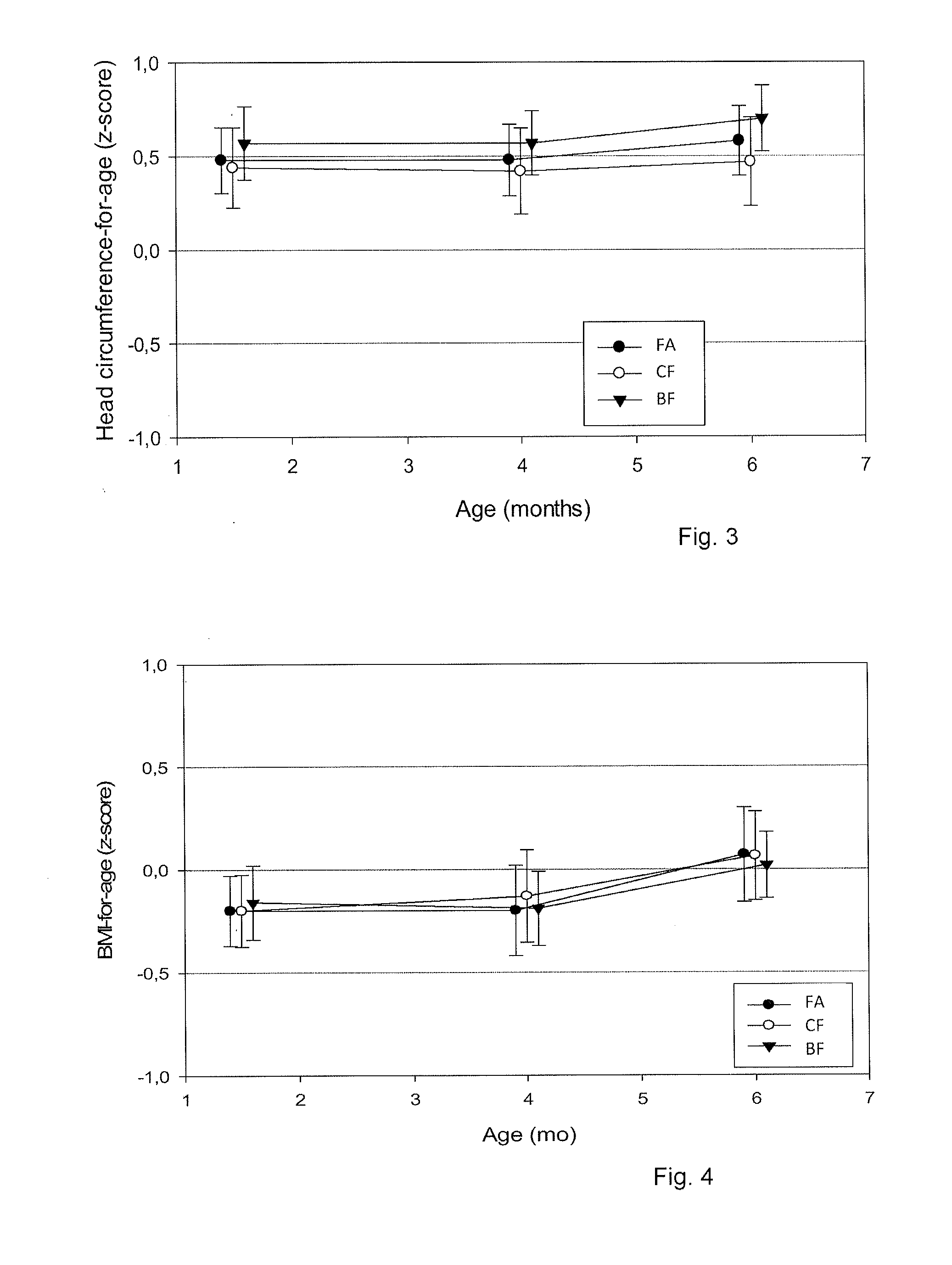

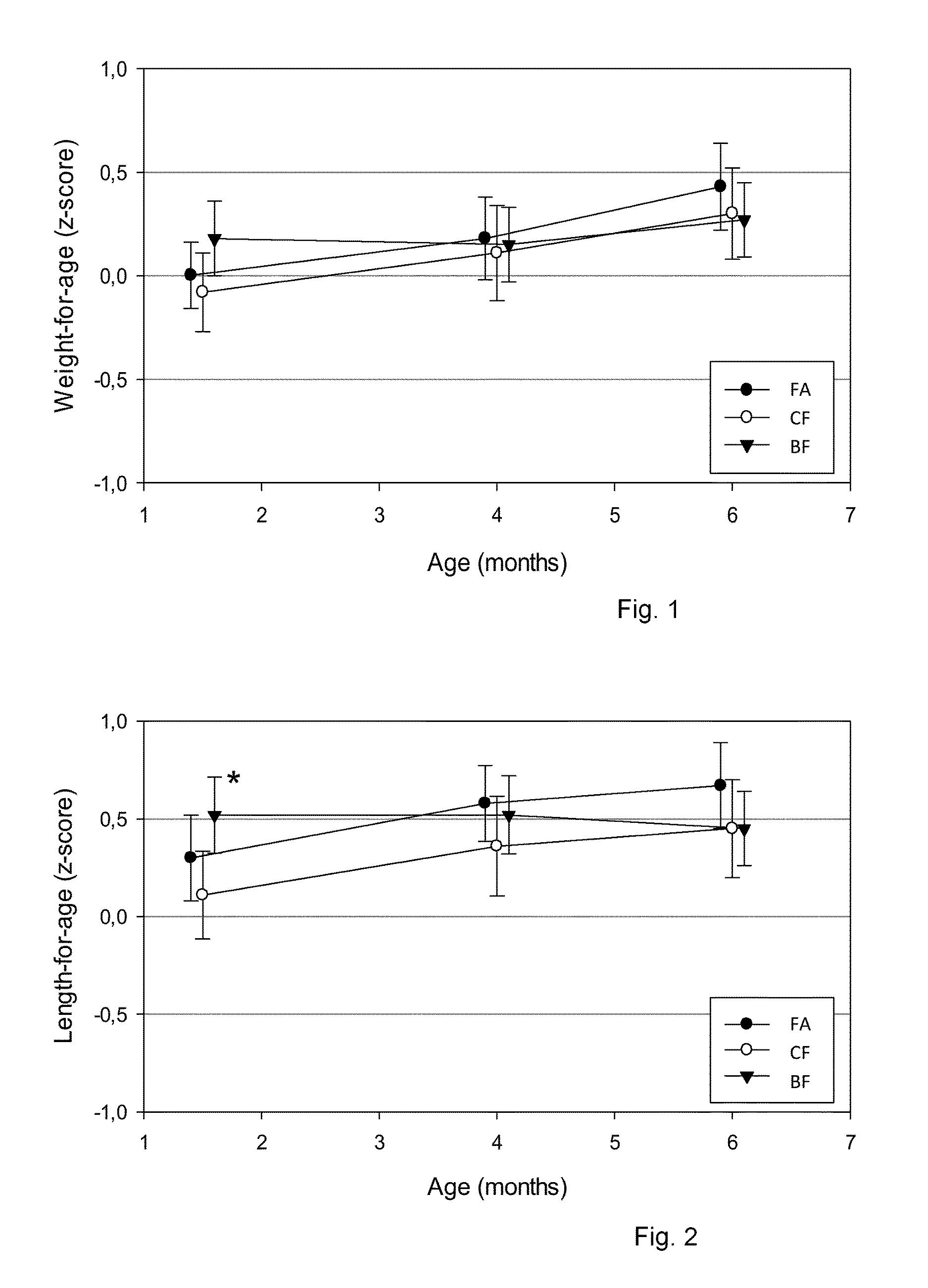

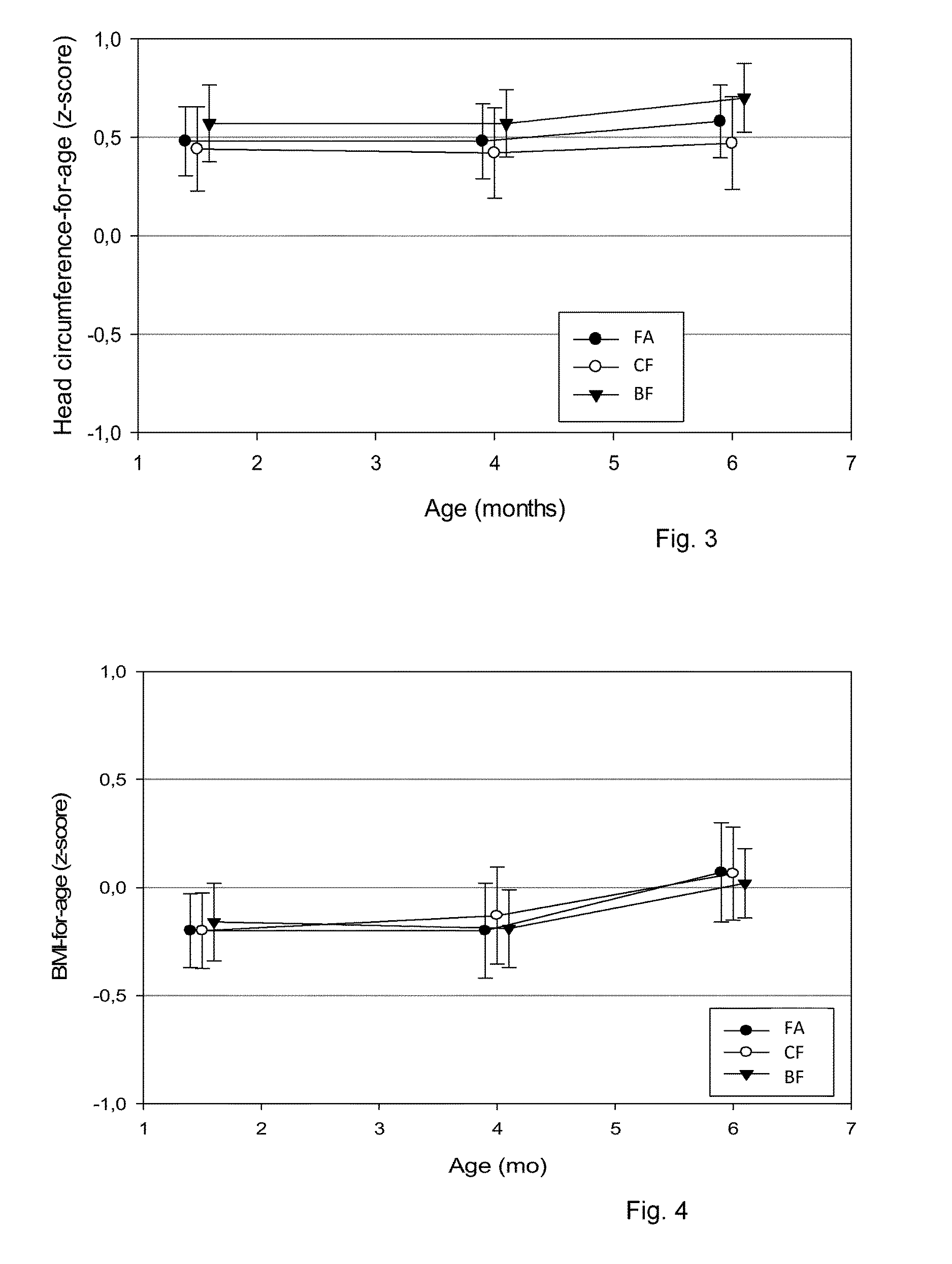

InactiveUS20150079225A1Less developed self-regulationRapid weight gainSugar food ingredientsAnimal feeding stuffAdditive ingredientCholesterol

A nutritional composition having a total energy content of 67 kcal / 100 ml or lower and including: a protein content which is 1.25 g / 100 ml or lower, an energy content from protein of 7.2-8.4% of the total energy content of the nutritional composition, an energy content from fat which is at least 49% or more of the total energy content of the nutritional composition, a medium chain fatty acid content comprising 8 to 10 carbons which is less than 3 wt % of total amount of fatty acids, a sialic acid content of 10-25 mg / 100 ml, a cholesterol content of 5-10 mg / 100 ml, and a sphingomyelin content of 9-15 mg / 100 ml is disclosed.

Owner:HERO

Modified Whey Powder and Process for Producing the Same

InactiveUS20080193623A1Reduce contentReduce moisture absorption performanceMilk preparationFlexible container closureIon exchangeWhey permeate

The present invention relates to a process by which whey permeates or blends thereof can be converted to a modified whey powder (MWP) having low mineral content, low hygroscopicity, and advantageous organoleptic properties using a combination of ion-exchange demineralization and crystallization. The modified whey powder thus obtained is suitable for dry applications in the production of food products. Furthermore, the present invention relates to a modified whey powder (MWP) obtainable by said process and to products comprising said modified whey powder (MWP), such as confectionery, biscuits, and powdered soft drinks.

Owner:KRAFT FOODS R & D INC

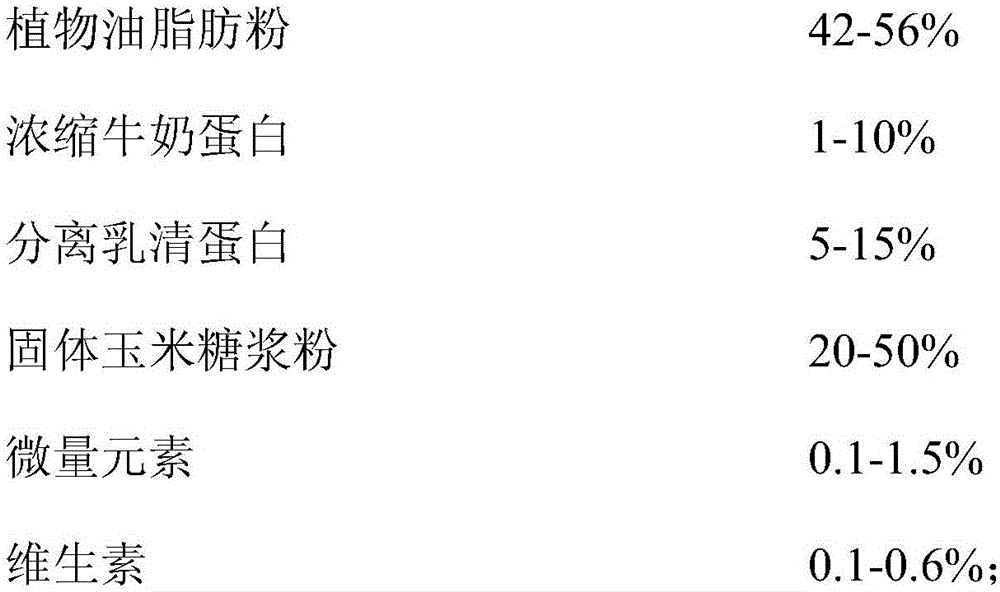

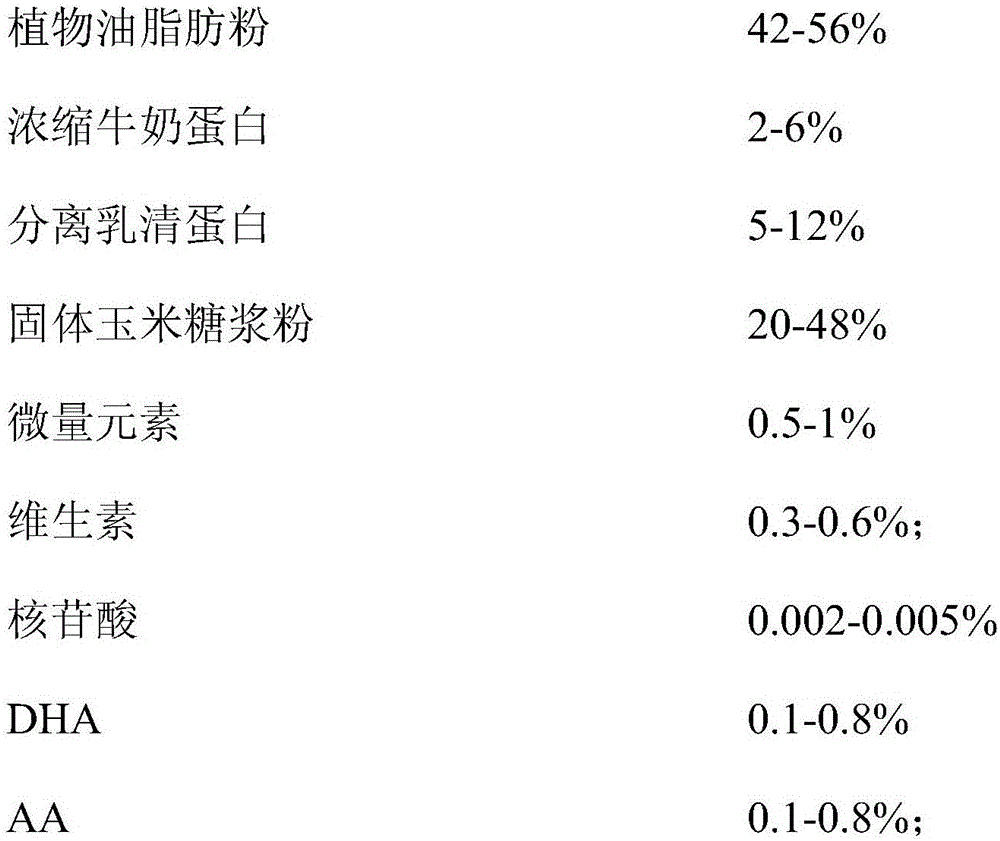

Lactose-free infant formula milk powder and preparation method thereof

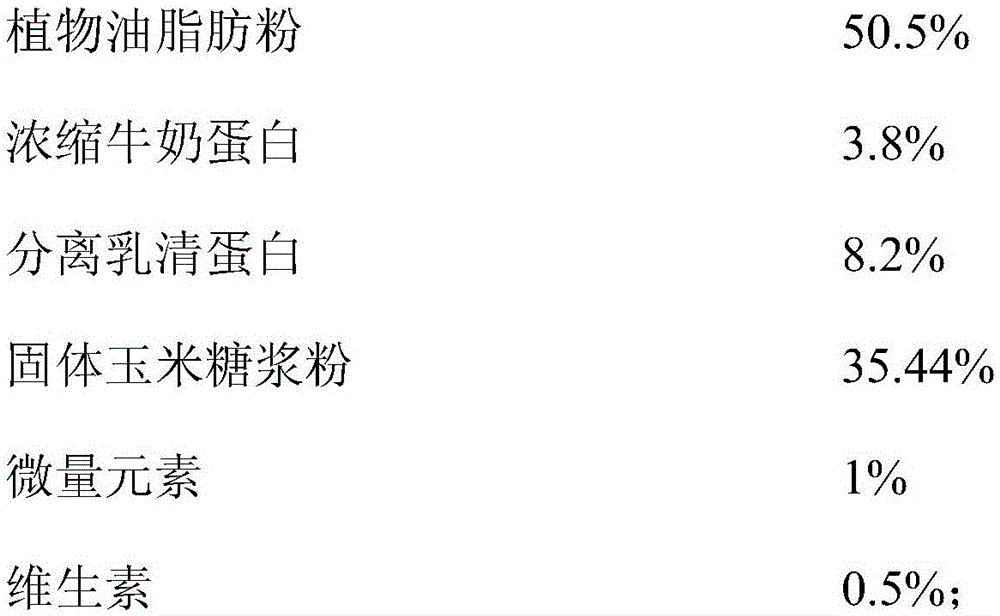

The invention relates to the technical field of food ingredients, specifically to a lactose-free infant formula milk powder for special medical use and a preparation method thereof. A special medical condition is primary or secondary lactose intolerant babies. The lactose-free infant formula milk powder mainly comprises the following ingredients (by weight): 35-70% of plant oil fatty powder, 1-10% of concentrated milk protein, 3-15% of separated whey protein, 20-50% of solid corn syrup powder, 0.1-5% of trace elements and 0.1-5% of vitamins, wherein sum of contents of the ingredients is no more than 100%, and content of lactose is less than 0.5g / 100g. The lactose-free infant formula milk powder contains 30 vitamins and trace elements which are essential to infants daily, linoleic acid, alpha-linolenic acid / aliphatic acid combination, DHA, AA and nucleotide, and lactose content meets requirements of GB25596-2010 on lactose content of lactose-free formula milk powder. In comparison with a common formula milk powder (containing lactose), the product meets health requirements of lactose intolerant lactose-free infants.

Owner:无锡超科食品有限公司

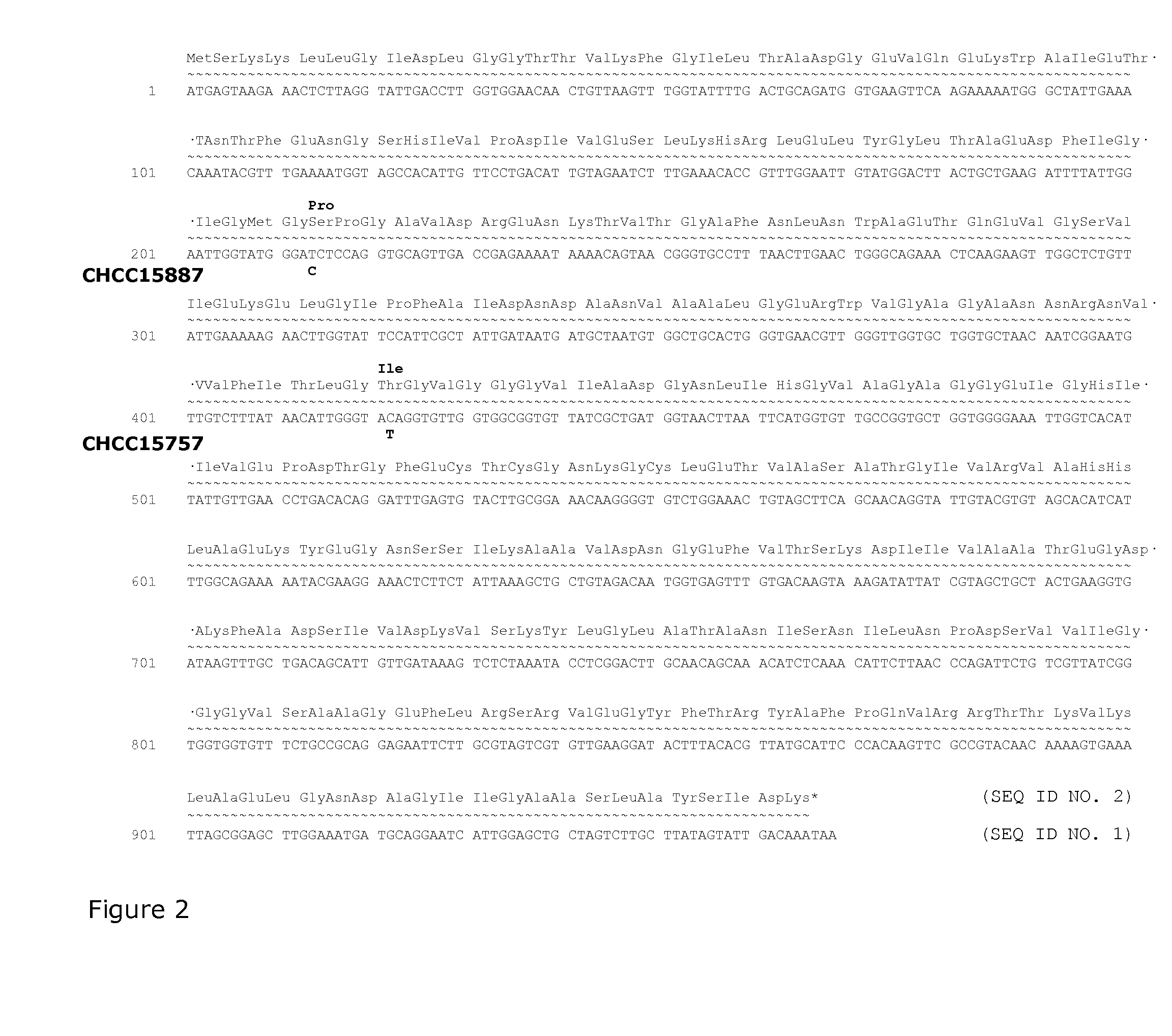

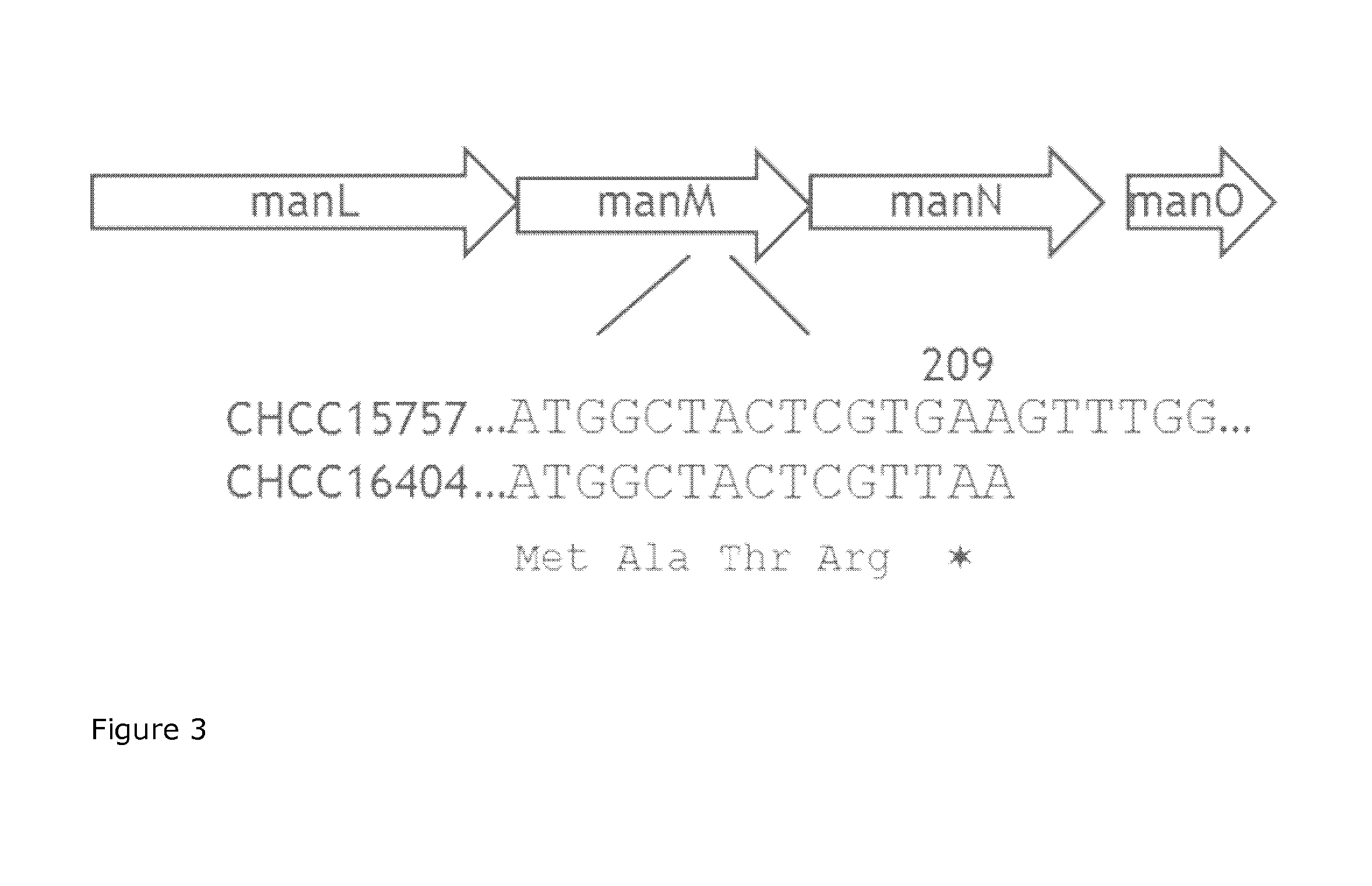

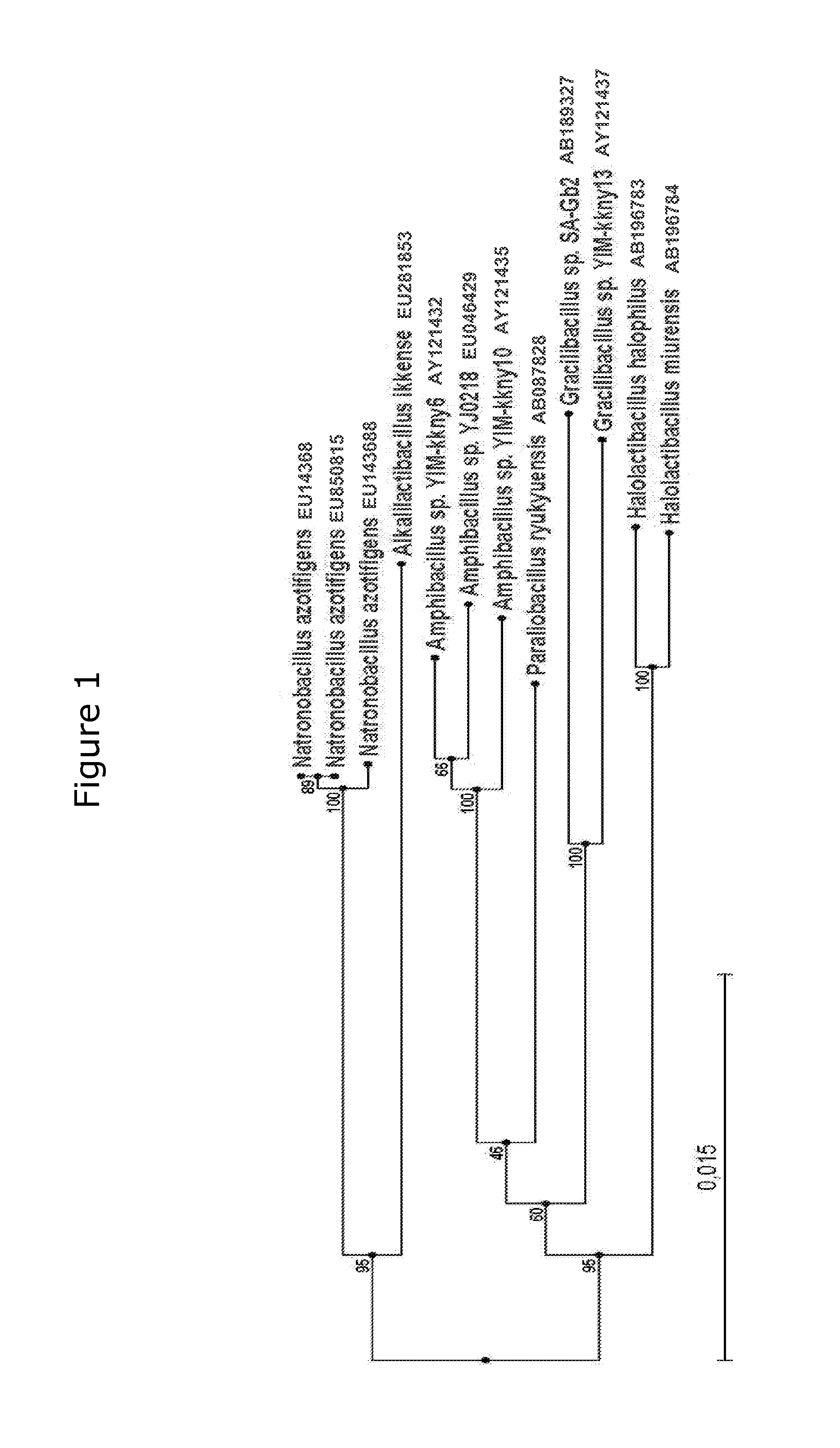

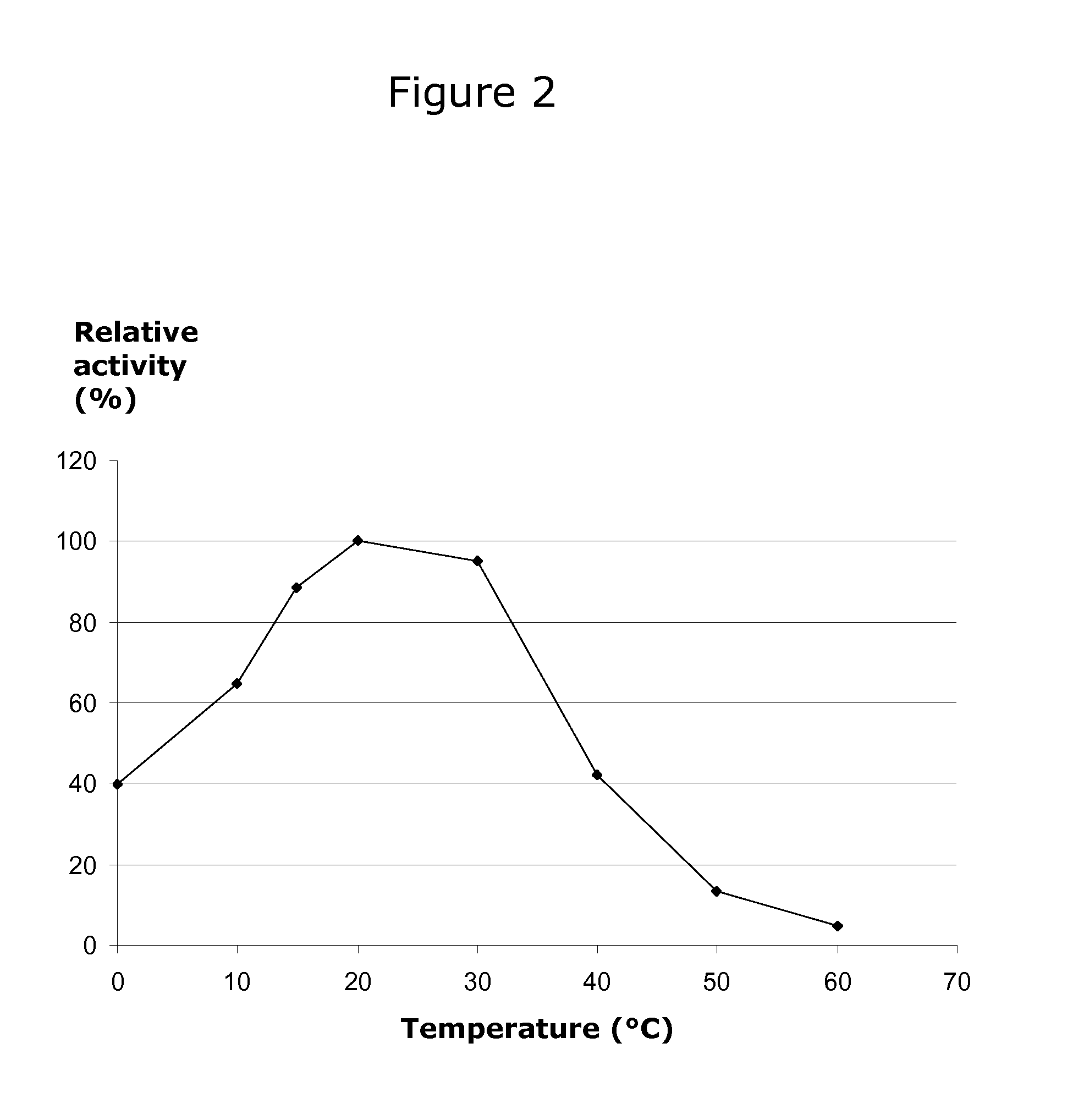

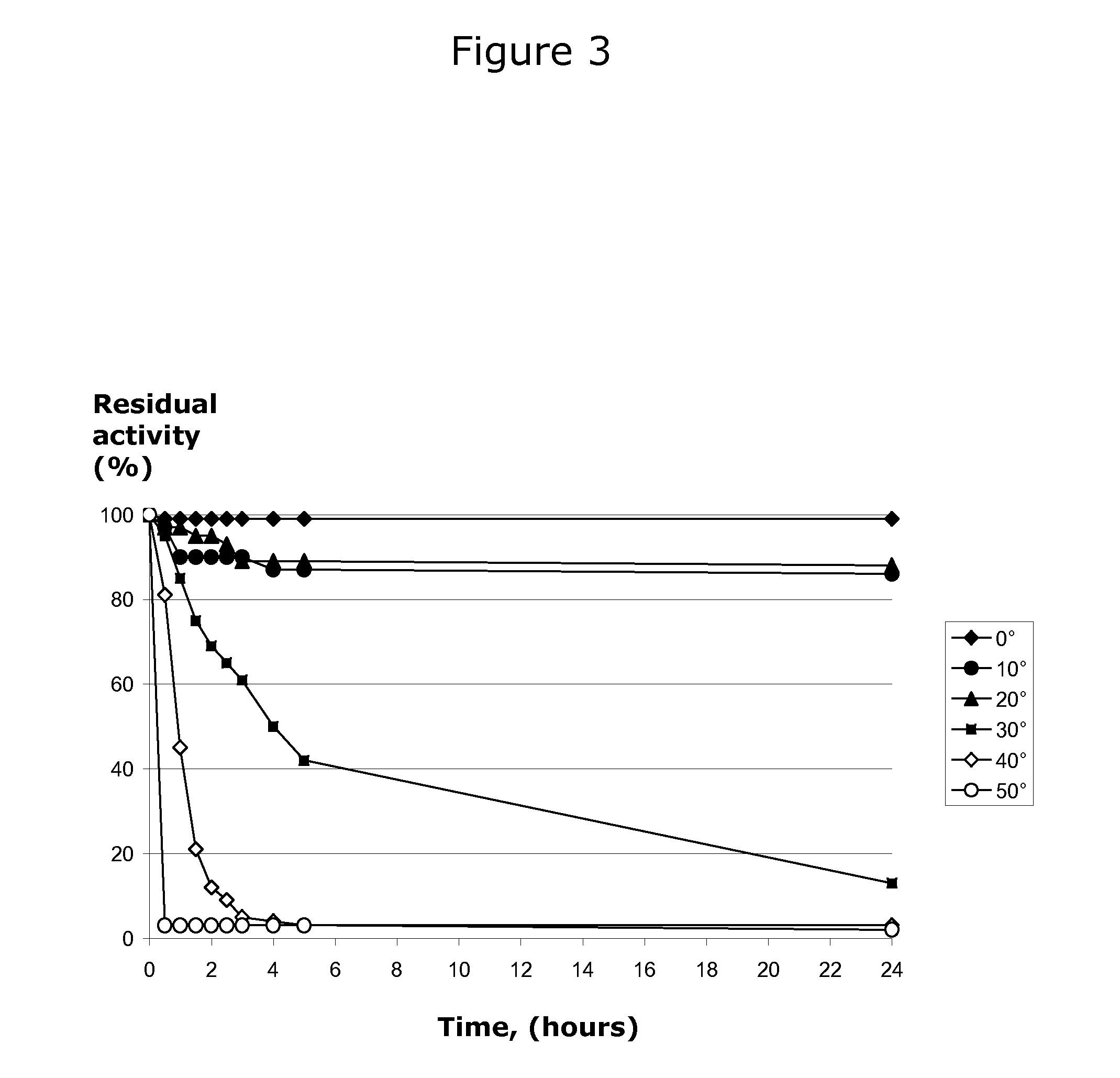

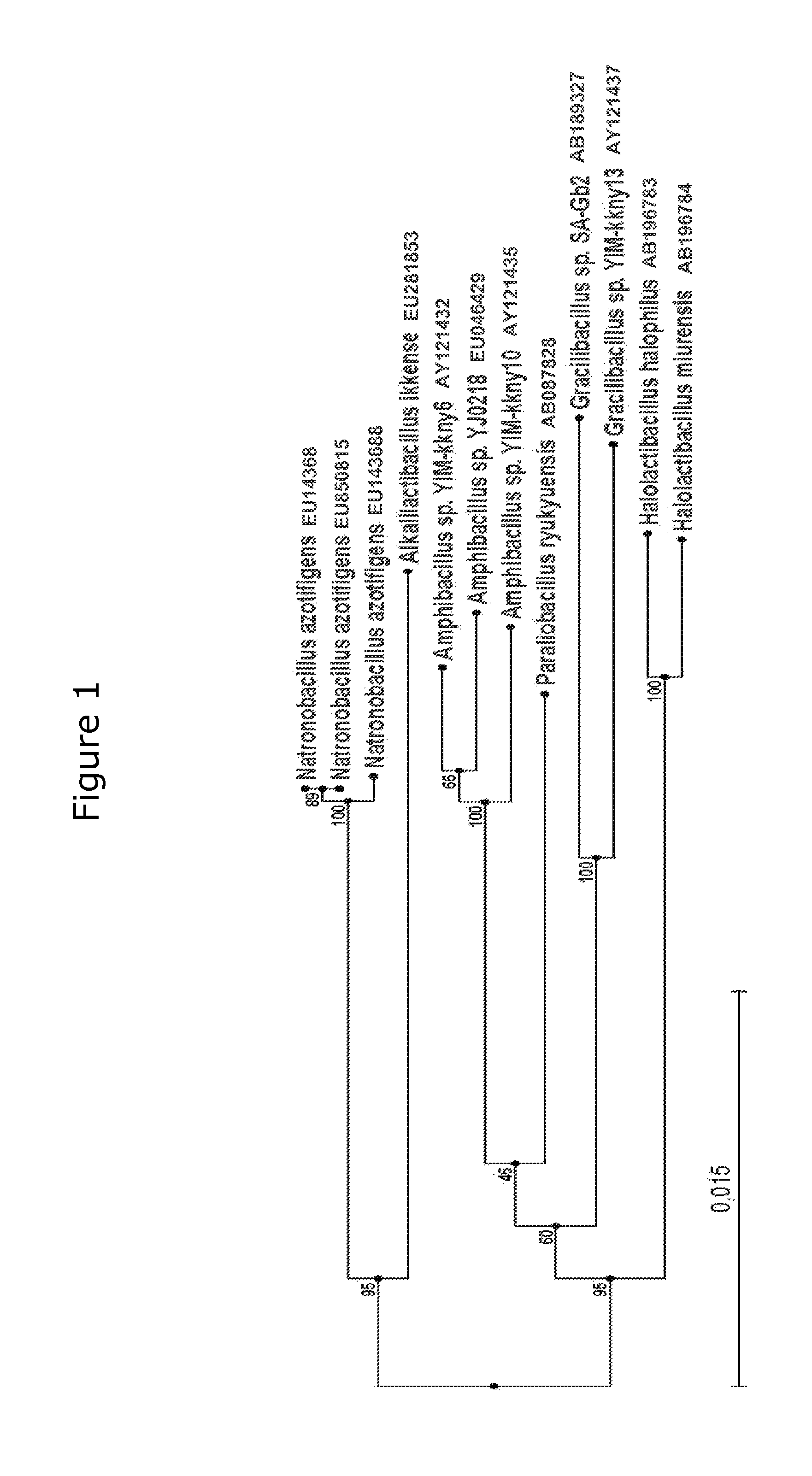

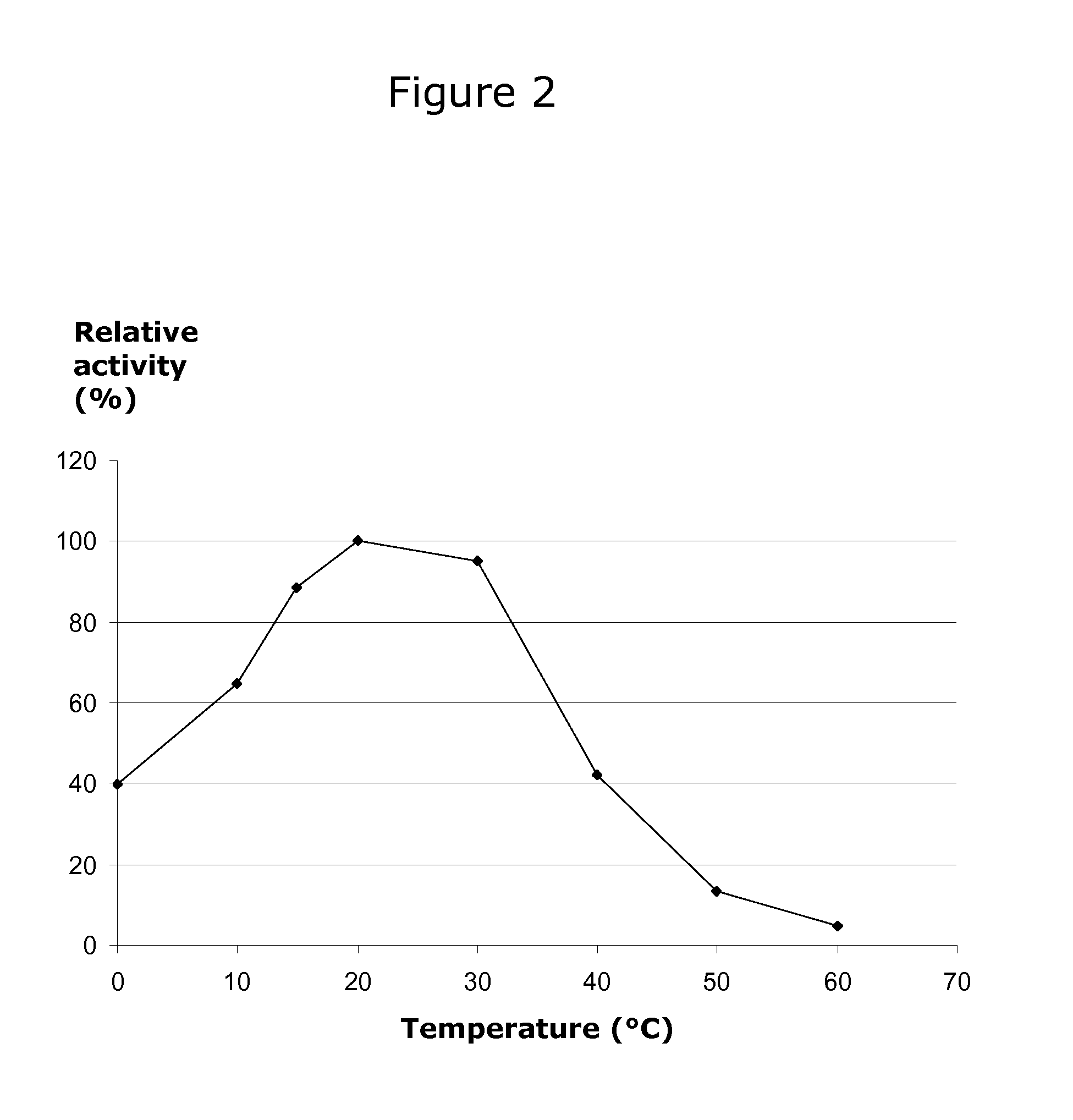

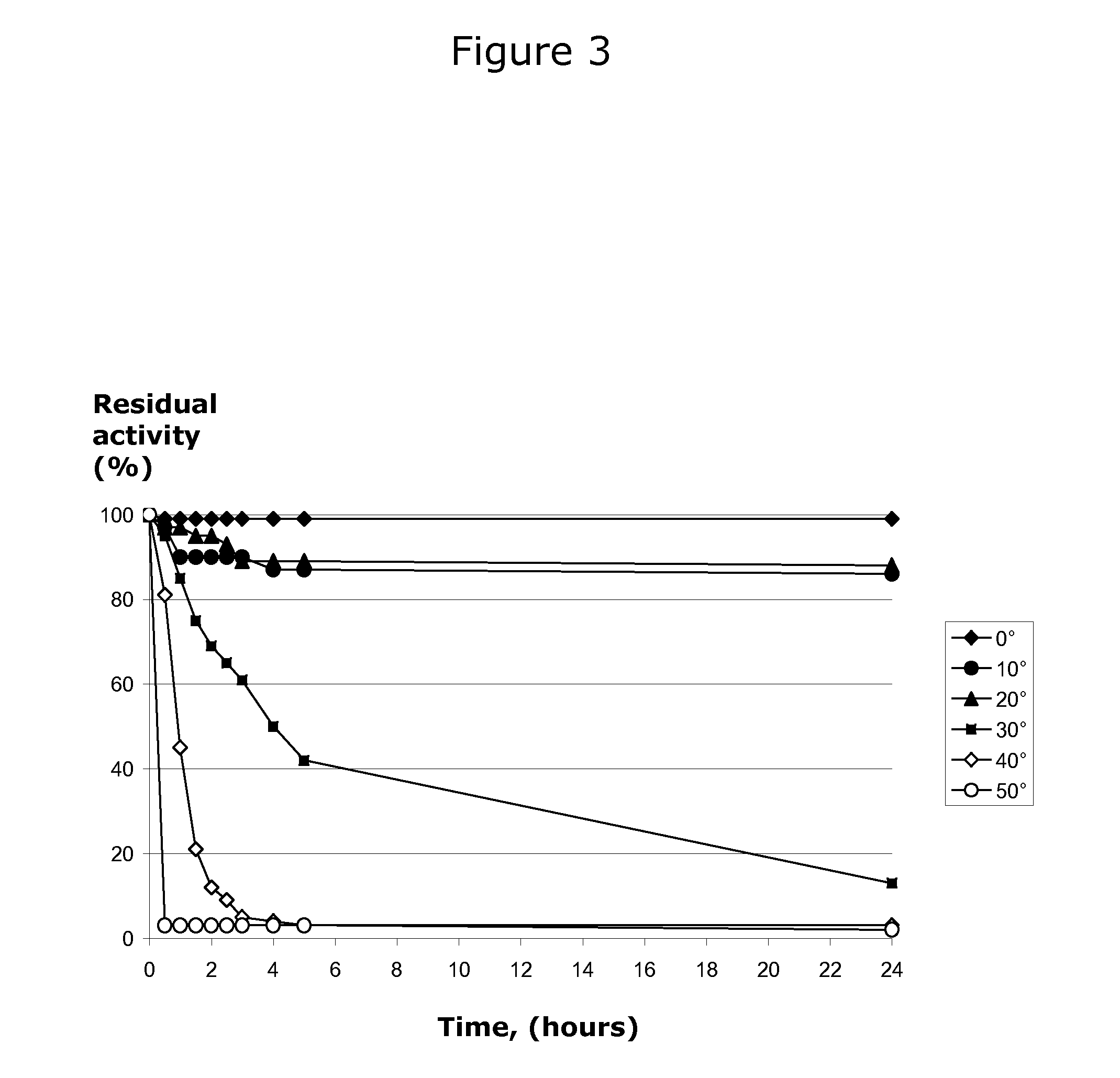

Cold-active beta-galactosidase, a method of producing same and use of such enzyme

A novel cold-active beta-galactosidase is enzyme specific for lactose. The enzyme is thus useful in e.g. the food industry for catalyzing at low temperatures the hydrolysis of lactose disaccharide into its constituent monosaccharides, glucose and galactose. A method produces the cold-active beta-galactosidase by recombinant DNA technology.

Owner:COLDZYMES APS

Milk replacer capable of preventing flatulence of lamb, starter feed and feeding method

InactiveCN106107074AGood dispersionEasy feedingFood processingAnimal feeding stuffDiseaseAnimal science

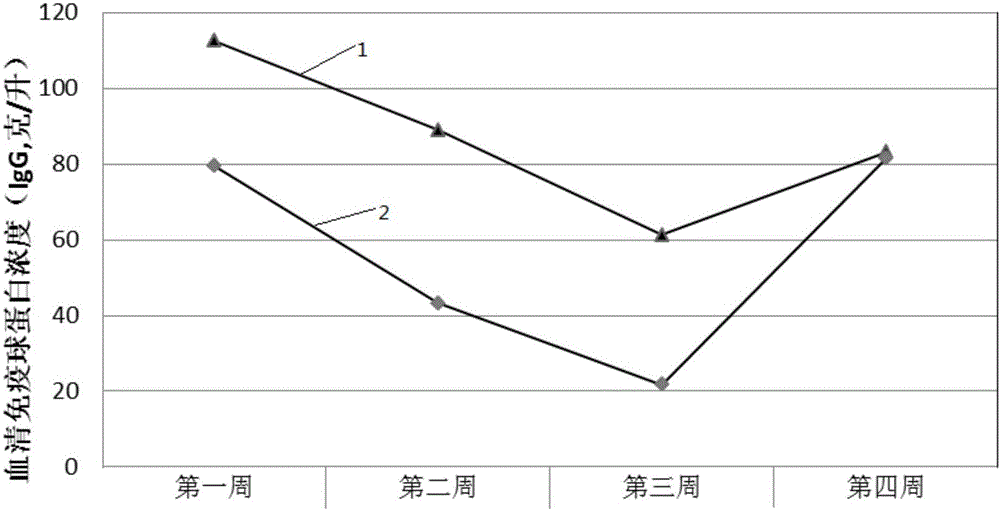

The invention relates to a lamb milk replacer, a lamb starter feed and a preparing method, relates to a method of feeding lamb by using the lamb milk replacer and the lamb starter feed, and belongs to the technical field of cultivation in animal husbandry. The lamb milk replacer is mainly composed of the following raw materials in parts by weight: 40-50 parts of whey protein concentrate, 6-15 parts of glucose, 6-10 parts of puffed rice, 3-8 parts of egg powder, 20-30 parts of palm oil fatty powder, 0.5-1.5 parts of coconut oil fatty powder, and 0.1-0.2 part of premix feed. The lamb starter feed is prepared by the following raw materials in parts by weight: 30-40 parts of barley, 30-40 parts of corn, 5-20 parts of oat, 3-10 parts of molasses, 10-18 parts of bean pulp, and 0.15 part of ligustrum lucidum ait. According to the products and the lamb feeding method, the weight and the average daily gain of the lamb are remarkably increased, the serum antibody concentration of the lamb is remarkably improved, and an obvious effect is achieved for improving the disease resistance and the survival rate of the lamb.

Owner:BEIJING SANYUAN HEFENG ANIMAL HUSBANDRY

Reduced fat and carbohydrate cultured dairy product and process for manufacturing such cultured dairy product

InactiveUS20050084593A1Reduce fatLow in lactoseMilk preparationOther dairy technologyButterfatCompound (substance)

A reduced fat and carbohydrate, cultured dairy product includes ultra filtered (UF) raw skim milk, water, a fat source, a protein source, and a predetermined amount of live and active cultures (LAC). A process for manufacturing this product includes providing UF skim milk, adding water and a fat source to obtain a first combination; adding a protein source to the first combination to form a second combination; adding a predetermined amount of LAC to the second combination; and placing the second combination, in a container to culture at a temperature of about 40.6° C. for about 4-5 hours or until the pH of the second combination is less than or equal to about 4.65. The first combination may include non-fat milk solids in a range of about 4.5%-6.4% by weight, total solids in a range of about 8.9%-10.5% by weight, and butterfat in a range of 0.44%-2.20% by weight.

Owner:HP HOOD

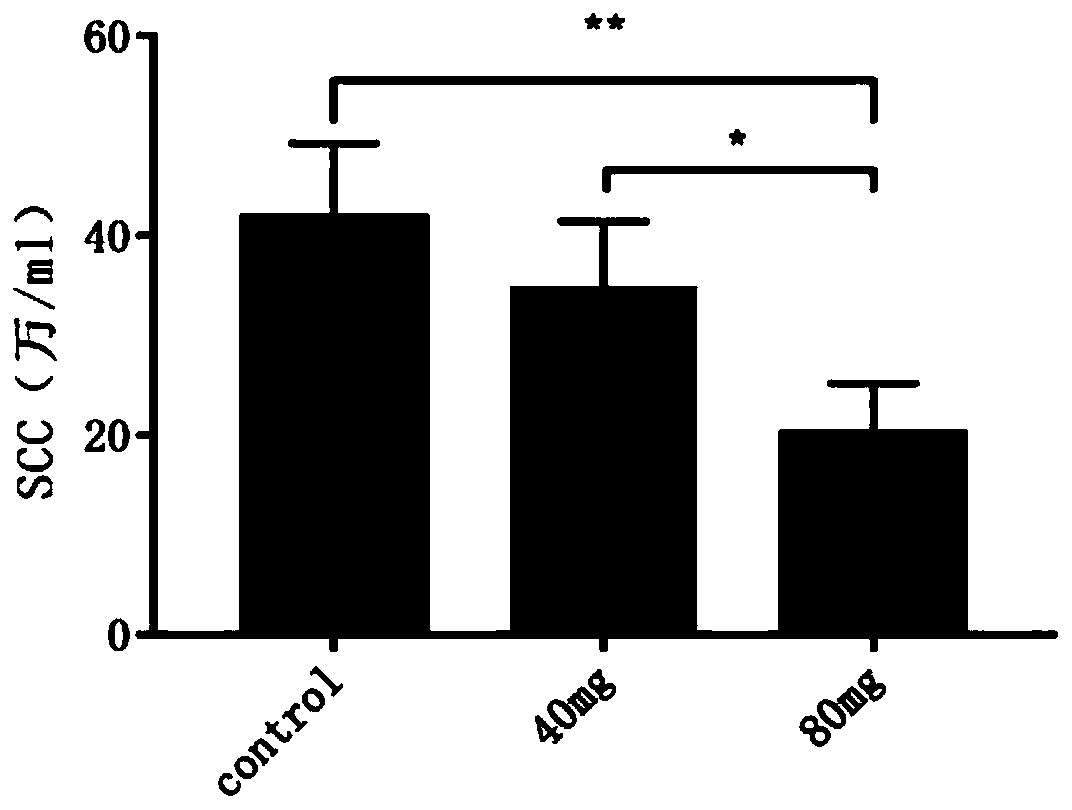

Application of rumen bypass melatonin in improvement of ruminant rumen microbial flora structure and improvement of milk quality

ActiveCN110447778ALow in lactoseImprove milk qualityOrganic active ingredientsDigestive systemSomatic cellStomach

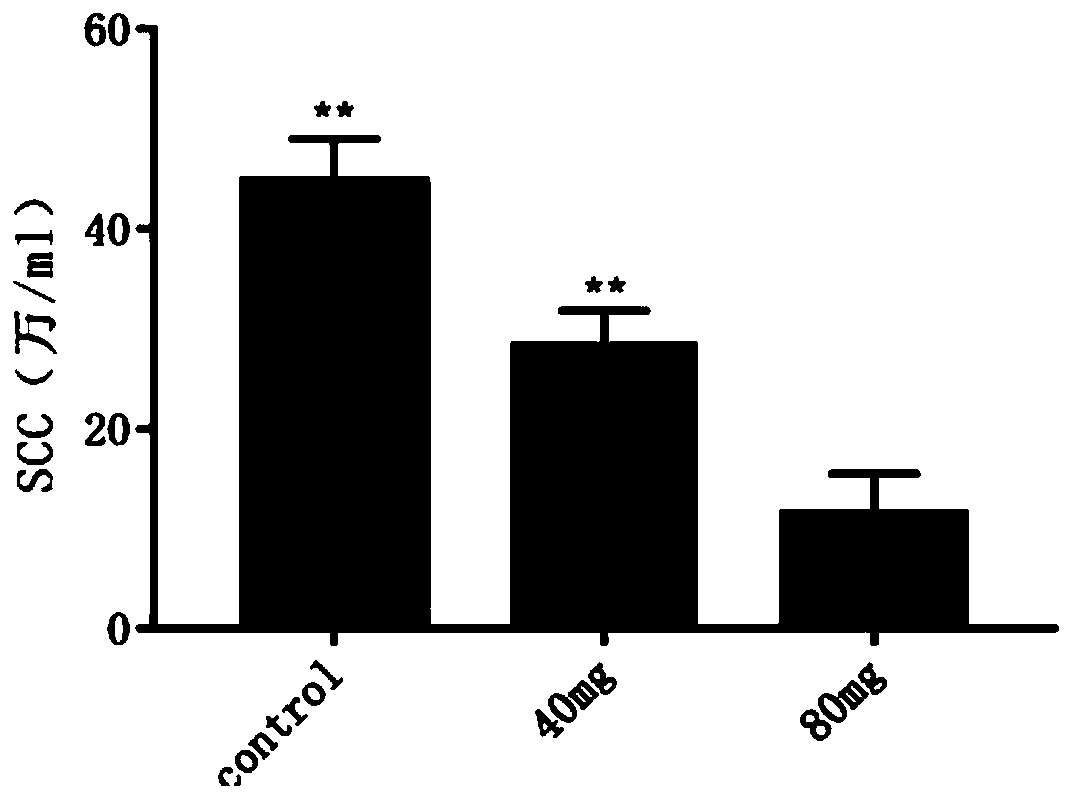

The invention provides application of rumen bypass melatonin in improvement of the milk quality and improvement of a ruminant rumen microbial flora structure. According to the application, it is discovered that after melatonin is prepared into the rumen bypass melatonin, a ruminant is orally fed with the rumen bypass melatonin, the somatic cell number of cows is lowered, the somatic cell number ofthe cows can be lowered to 200-400 thousand / mL from 400-700 thousand / mL, the content of milk protein, milk fat and dry substances in milk is obviously increased, the content of lactose in the milk islowered, the milk quality is obviously improved, and in addition, according to the application, it is also discovered that the residual rumen bypass melatonin in the rumen can also improve the abundance of flora in the rumen.

Owner:CHINA AGRI UNIV

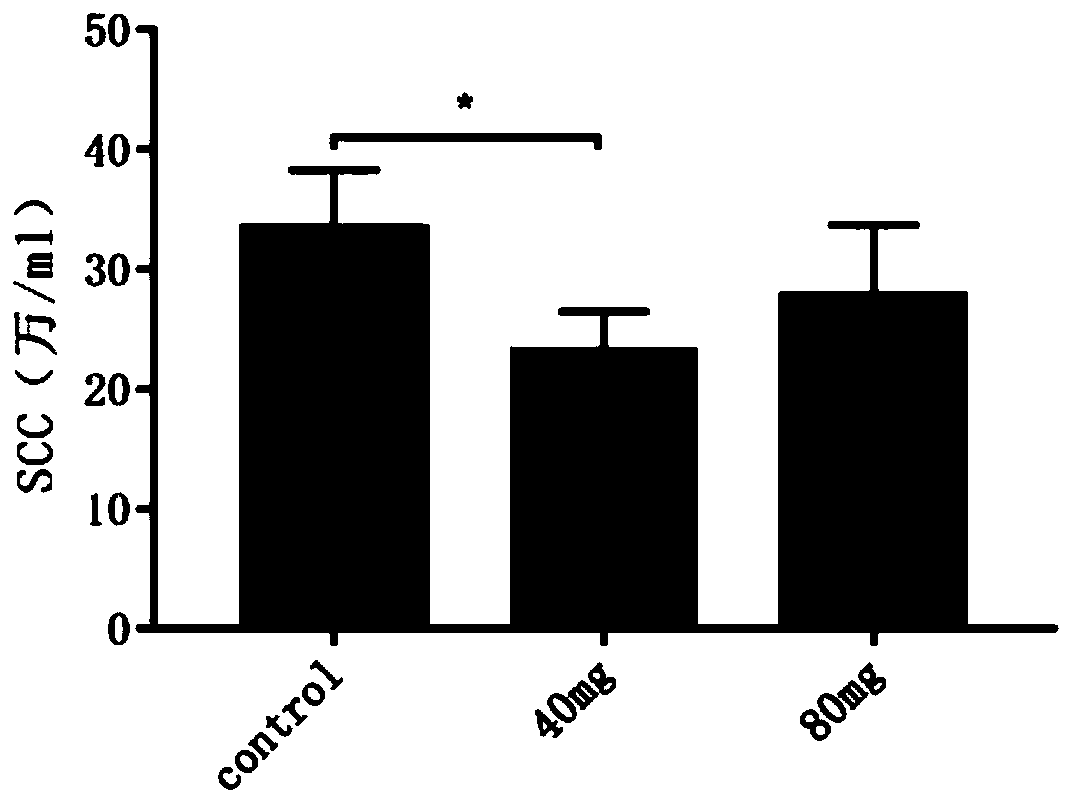

Component-reconstituted thick milk and preparation method thereof

The invention discloses a component-reconstituted thick milk, and belongs to the technical field of dairy product processing. The protein content of the thick milk is 5-9% wt, and the fat content of the thick milk is 5-20% wt. The invention also discloses a preparation method of the thick milk, which comprises the following steps: (1) concentrating and separating the raw milk by using an RO (reverse osmosis) membrane or an evaporator to obtain a no.1 concentrated solution and a no.1 permeate; (2) performing centrifugal separation and online fat standardization on the raw milk to obtain skimmed milk and single cream; concentrating and separating the skimmed milk by using a UF / NF forward osmosis membrane to obtain a no.2 concentrated solution and a no.2 permeate; dividing the no.2 permeate into two parts, and respectively adding a stabilizer and buffer salt to obtain no.4 permeate and no.5 permeate; and dividing the single cream into two parts, and respectively adding an emulsifier and the enzymolysis milk fat to obtain no.3 single cream and enzymolysis milk fat-single cream; and (3) mixing, emulsifying and shearing the no.1 concentrated solution, the no.2 concentrated solution, the no.4 permeate, the no.5 permeate, the no.3 single cream and the enzymolysis milk fat-single cream to obtain a semi-finished product, and performing post-treatment to obtain the thick milk.

Owner:宁夏塞尚乳业有限公司

Rectal cancer nutritious food and preparation method thereof

InactiveCN108936597AImprove clearanceReduce clearanceFood ingredient functionsBiotechnologyNutritional status

The present invention belongs to the technical field of nutritious foods, and especially relates to a rectal cancer nutritious food and a preparation method thereof. The rectal cancer nutritious foodcontains nutrient elements including proteins, fat, carbohydrate, vitamins, minerals, ginkgo flavonoids and phytosterol. The nutritious food provided by the invention can provide sufficient and comprehensive nutrients for the organism, more importantly, the food enhances the barrier function of intestinal mucosa, better accords with the metabolic physiological state, facilitates the protein synthesis and metabolism regulation of the organism, promotes the recovery of intestinal function and form, prevents bacteria and toxin translocation, obviously reduces the occurrence of intestinal source infection, and is an effective way to improve the nutritional status of chemotherapy patients. The food has a certain improvement effect on the nutritional status of chemotherapy patients with middle or advanced rectal cancer, can reduce adverse reaction of patients, and can effectively improve the immunity of patients.

Owner:SHANDONG UNIV OF TECH +1

Low-calorie and easy-to-brew portable quinoa meal replacement powder

The invention discloses a low-calorie and easy-to-brew portable quinoa meal replacement powder, which belongs to the technical field of food processing. The meal replacement powder has the advantagesof low calorie and rich nutrition, only 323.6kcal, 3.8g of fat and 44.9g of carbohydrate are contained per 100g of meal replacement powder disclosed by the invention, and 25g of protein, 9.9g of dietary fibers, 52.8mg of sodium and 598.0mg of calcium are contained per 100g of meal replacement powder disclosed by the invention. According to the invention, by controlling the grain size of quinoa powder, sequentially extruding the quinoa powder under 50 DEG C, 90 DEG C, 110 DEG C and 130 DEG C, controlling the water activity of the quinoa powder and controlling the amount of the quinoa powder added in the meal replacement powder, the solubility of the meal replacement powder disclosed by the invention is greatly increased; and the effect that the meal replacement powder can be instantly dissolved as soon as 250g of 35 DEG C water is poured into 50g of meal replacement powder disclosed by the invention can be achieved.

Owner:东莞市涵养科技有限公司

Nutritional composition

ActiveUS20170013869A1Less developed self-regulationRapid weight gainSugar food ingredientsAcidic food ingredientsBiotechnologyNutrition

A nutritional composition having a total energy content of 67 kcal / 100 ml or lower and including: a protein content which is 1.25 g / 100 ml or lower, an energy content from protein of 7.2-8.4% of the total energy content of the nutritional composition, an energy content from fat which is at least 49% or more of the total energy content of the nutritional composition, a medium chain fatty acid content comprising 8 to 10 carbons which is less than 3 wt % of total amount of fatty acids, a sialic acid content of 10-25 mg / 100 ml, a cholesterol content of 5-10 mg / 100 ml, and a sphingomyelin content of 9-15 mg / 100 ml is disclosed.

Owner:SEMPER

Shelf-stable ice cream and ice cream mix and process for making same with agave nectar

InactiveUS20150342219A1Low in lactoseCrystallization is reduced and eliminatedMilk preparationFrozen sweetsLactaseIce cream

Methods for making an ice cream mix or ice cream-like mix are disclosed, the methods including forming a mixture that includes one or more dairy products wherein at least one of the one or more dairy products comprises lactose, one or more stabilizers, and agave nectar, the method further including pasteurizing the mixture; and contacting at least some of the lactose with an enzyme at a temperature and for a time sufficient to allow the enzyme to reduce the lactose content of the mixture. Ice cream and ice cream-like products are also disclosed. An ice cream that includes one or more dairy products, agave nectar (or derivative thereof), and lactase.

Owner:ZWARG JEAN +1

Lung cancer nutritious food and preparation method thereof

The present invention discloses a lung cancer nutritious food and a preparation method thereof, and belongs to the technical field of nutritious foods. The lung cancer nutritious food contains nutrient components including proteins, fat, carbohydrate, vitamins, minerals, glutamine, arginine, lycopene, melatonin and apple essence. Under the premise of enough heat, the nutritious food in the invention is high in proteins, high in carbohydrate, low in fat and high in content of active functional substances, and targeted vitamins match with mineral element, so that the food can control the pathogenesis of patients from the aspects of oxidative stress and immunity, can improve the immune function of chemotherapy patients with advanced lung cancer, can protect the immune barrier of intestinal mucosa, and can regulate the mood and psychology of patients. Under the premise of effect, the product price is reduced through the element form selection and the simplification of collocation and salemode. The food can meet the nutritional requirements of patients as a single nutrient source, and also can be eaten together with other daily diets, thereby enriching the dietary types and eating modes and stimulating the eating interest of patients.

Owner:SHANDONG UNIV OF TECH +1

Cold-active beta-galactosidase, a method of producing same and use of such enzyme

InactiveUS8288143B2High specific activityLow in lactoseBacteriaCheese manufactureSpecific enzymeLactose

A novel cold-active beta-galactosidase is enzyme specific for lactose. The enzyme is thus useful in e.g. the food industry for catalyzing at low temperatures the hydrolysis of lactose disaccharide into its constituent monosaccharides, glucose and galactose. A method produces the cold-active beta-galactosidase by recombinant DNA technology.

Owner:COLDZYMES APS

Preparation method of galacto-oligosaccharide

ActiveCN108949856AStable physical and chemical propertiesSolve churnFermentationMembrane enzymesPolyvinyl chloride

The invention belongs to the technical field of functional oligosaccharide preparation, and concretely relates to a preparation method of a galacto-oligosaccharide. A novel organic-inorganic compositematerial of a polyvinyl chloride-silicon dioxide film used in the invention has good flexibility. A membrane enzyme reactor formed by immobilizing beta-galactosidase can react in a stirring state orbe rolled up into a column to be packed in a cylindrical container so as to enable substrate lactose to react when passing through the reactor, which effectively solves the problems of loss and reaction column blockage in a recovery process of a small granular immobilization enzyme. According to the preparation method, the content of the galacto-oligosaccharide in primary conversion syrup is morethan 60% which is 24-57% higher than the content of the galacto-oligosaccharide in the primary conversion syrup by a conventional enzyme method. According to the preparation method, the content of thelactose in the primary conversion syrup is less than 15% which is 20-35% much lower than the content of the lactose in the primary conversion syrup by the conventional enzyme method.

Owner:量子高科(广东)生物有限公司

Preparation method of low-lactose dairy product rich in honey pomelo fibers

The invention discloses a preparation method of a low-lactose dairy product rich in honey pomelo fibers. The preparation method comprises the following steps of cleaning peel fibers of honey pomelos, performing dicing, and performing debittering treatment so as to obtain honey pomelo fiber blocks; sterilizing liquid milk, performing cooling, performing inoculation with lactic acid bacteria, performing primary fermentation until the lactose content is not reduced, performing coagulation, performing centrifugation, collecting precipitate, adding water to the precipitate until the pH is greater than 5.0, and performing homogenizing treatment so as to obtain primary fermented milk; mixing the honey pomelo fiber blocks with the primary fermented milk, performing inoculation with lactic acid bacteria, and performing secondary fermentation until the lactose content is lower than 0.04%; or performing inoculation with lactic acid bacteria on the primary fermented milk, performing secondary fermentation until the lactose content is lower than 0.04%, and then mixing the primary fermented milk with the honey pomelo fiber blocks; and pre-freezing the honey pomelo fiber blocks treated in the steps, and performing vacuum freeze drying so as to obtain the low-lactose dairy product rich in honey pomelo fibers. Therefore, the problems that the dairy product is short of high-quality cellulose, high in lactose content and high in storage and transportation cost are solved, and the nutrient requirements of crowds suffering from lactose intolerance can be met.

Owner:JIMEI UNIV

Lactose-free normal-temperature yoghourt and preparation method thereof

The invention provides lactose-free normal-temperature yoghourt and a preparation method thereof. The preparation method comprises the steps of milk pretreatment, burdening, homogenization, primary sterilization, fermentation, secondary sterilization and filling, a leavening agent adopted for fermentation comprises streptococcus thermophilus AiBi S 4.01 SWEET with the addition amount larger than or equal to 100 AU / T, the fermentation temperature ranges from 29 DEG C to 31 DEG C, and the fermentation time ranges from 23 h to 25 h. The invention also provides the lactose-free normal-temperature yoghourt which is prepared by the preparation method, and the lactose content of the lactose-free normal-temperature yoghourt is lower than 0.5 g / 100g. According to the preparation method provided by the invention, lactose in the raw materials can be fully hydrolyzed into glucose and galactose in the fermentation process, and the addition of exogenous lactase and saccharides is reduced, so that the cost is reduced, and product labels are cleaner and accord with low-sugar and low-fat healthy choices.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

Low-sugar drinking type normal-temperature yoghourt and preparation method thereof

The invention discloses low-sugar drinking type normal-temperature yoghourt and a preparation method thereof. The preparation method comprises the following steps: mixing pre-sterilized raw milk withsugar, starch and a food additive to obtain a mixed solution; melting, homogenizing, sterilizing and cooling the obtained mixed solution, adding an edible essence, and inoculating a leavening agent for fermentation to obtain a yoghourt base material; and demulsifying and cooling the obtained yoghourt base material, sterilizing, cooling and filling to obtain the low-sugar drinking type normal-temperature yoghourt. The preparation method is simple in process, easy to operate and convenient for industrial processing and production, the product prepared by the preparation method is refreshing andsmooth in taste and good in flowability, compared with common yoghourt, the use of cane sugar can be reduced, the sweetness and acceptability of yoghourt with normal cane sugar content are maintained,and meanwhile, the prepared yoghourt is low in lactose content and beneficial to people with lactose intolerance.

Owner:BRIGHT DAIRY & FOOD

Genetic engineering Escherichia coli and method for preparing low lactose milk containing oligosaccharide by beta-glycosidase generated by same

InactiveCN101781633AIncrease hydrolysis rateLow in lactoseMilk preparationBacteriaEscherichia coliLactose

The invention relates to a strain, a method for preparing beta-glycosidase TtbetaGLY by the strain and a method for preparing low lactose milk containing oligosaccharide by the beta-glycosidase TtbetaGLY. The invention provides Escherichia coli TTBGLYWT CGMCCNo.3078. The method for preparing the low lactose milk comprises a conventional method for preparing the low lactose mil, i.e. the enzyme is added into raw and fresh milk to carry out hydrolysis; and after sterilized at superhigh temperature, the milk is filled to obtain a finished product. The enzyme is beta-glycosidase TtbetaGLY and is prepared by fermenting and extracting the genetic engineering strain Escherichia coli TTBGLYWT. By adopting the technical scheme, a great deal of galactooligosaccharide can be synthesized when reducing the lactose content in the milk, wherein the hydrolysis ratio of the lactose can reach 95.24 percent at maximum, and the galactooligosaccharide occupies 37.13 percent of sugar in the milk at maximum.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

Low-lactose acid goat milk and preparation method thereof

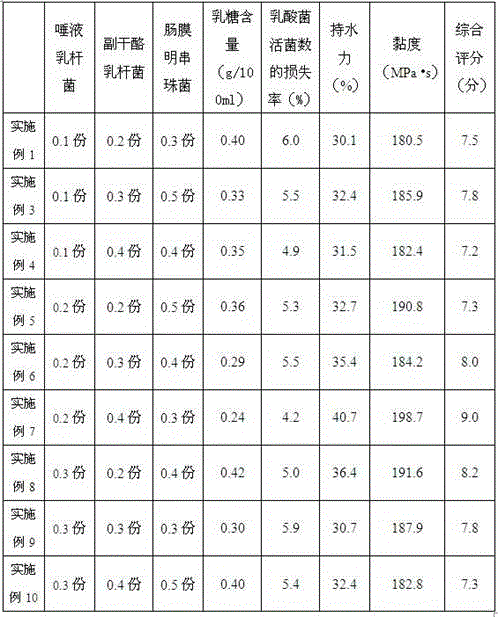

The invention provides low-lactose acid goat milk. The content of lactose in the low-lactose acid goat milk is 0.15-0.43g / 100ml. The invention further provides a preparation method of the low-lactose acid goat milk. The preparation method comprises the following steps of preparing hippophae rhamnoides juice, preparing a semen platycladi extract, preparing a lily bulb extracting solution, performing blending and performing fermentation. The acid goat milk prepared by the preparation method disclosed by the invention is fine and smooth in tissue, uniform, and free from separation of whey, the protein content is 3.0-3.1%, the fat content is 2.8-3.2%, the content of non-grease solid is greater than or equal to 8.1-8.5%, the acidity is 90-93 Thorner degrees, the viable count of lactic acid bacteria is 1.8-2.2*10<8>cfu / g, and the content of lactic acid bacteria is stable. The acid goat milk prepared by the preparation method disclosed by the invention is low in lactose content, the content of the lactose in the acid goat milk is 0.15-0.43g / 100ml, the water-holding capacity of the acid goat milk is 30-43%, the viscosity of the acid goat milk is 180-212 MPa.s, and the comprehensive score of the acid goat milk is 7.2-9.5.

Owner:山东坤泰生物科技有限公司

Low milk-sugar blending milk

InactiveCN1245881CSimple processImprove product qualityMilk preparationWhey proteinAdditive ingredient

Owner:浙江三鹿实业有限公司

Low-lactose dairy product and production method thereof

The present invention relates to a low-lactose dairy product and a production method thereof. The low-lactose dairy product is prepared by the following method: raw milk is sterilized, microalgae cells at the logarithmic growth phase are collected and washed, and the washed microalgae cells are added into a reaction vessel at a certain proportion; and the microalgae cells are cultivated for a certain time at suitable temperature, light and ventilation conditions. The microalgae which is edible and rich in nutrients is used to metabolize and degrade lactose in the raw milk and to solve the problem that part of the population are intolerant with the dairy products rich in lactose. The method is simple and convenient in operation processes, can effectively reduce the cost of degradation of lactose, and has a better degradation effect. The processed milk contains lower lactose content, and the addition of microalgae enables the dairy product to have higher protein content and to be rich in other nutrients and active factors, such as fatty acids, astaxanthin, carotene, etc., and thus the quality of dairy products is further improved.

Owner:YANGZHOU UNIV

Preparation method and application of whole nutrient formula food for cervical cancer

The invention belongs to the technical field of nutritive foods, and particularly relates to a preparation method and application of a whole nutrient formula food for cervical cancer. The nutritive food for colon cancer contains protein, fat, carbohydrate, vitamins, minerals, xanthophyll, soybean isoflavone, lycopene, lycium barbarum polysaccharide and apple essence. According to the nutritive food disclosed by the invention, based on nosogenesis and chemotherapy side effects of cervical cancer patients of 18-64 years old, a formula food is designed in a targeted manner, under the premise thatcalorie is guaranteed, active functional substances high in protein, low in carbohydrate, low in fat and high in content are used, vitamins and mineral elements are matched in a targeted manner, comprehensive synergistic reaction of all elements is utilized, the body and the mind of the patients are regulated from the respects of oxidative stress, immune competence and chemotherapy side effects,nutrient supplement and regulation effects of cervical cancer patients during chemotherapy are exerted, and deterioration or recurrence of diseases of the patients is avoided.

Owner:SHANDONG UNIV OF TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com