Delactose dairy product and its preparing method

A dairy product, lactose-removing technology, applied in dairy products, milk preparations, applications, etc., can solve problems such as unpopularity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] The first example is a continuous process without water addition. It is carried out in accordance with the UF and NF parameters of the system inlet pressure, discharge pressure, supply rate, and temperature shown in Table 1.

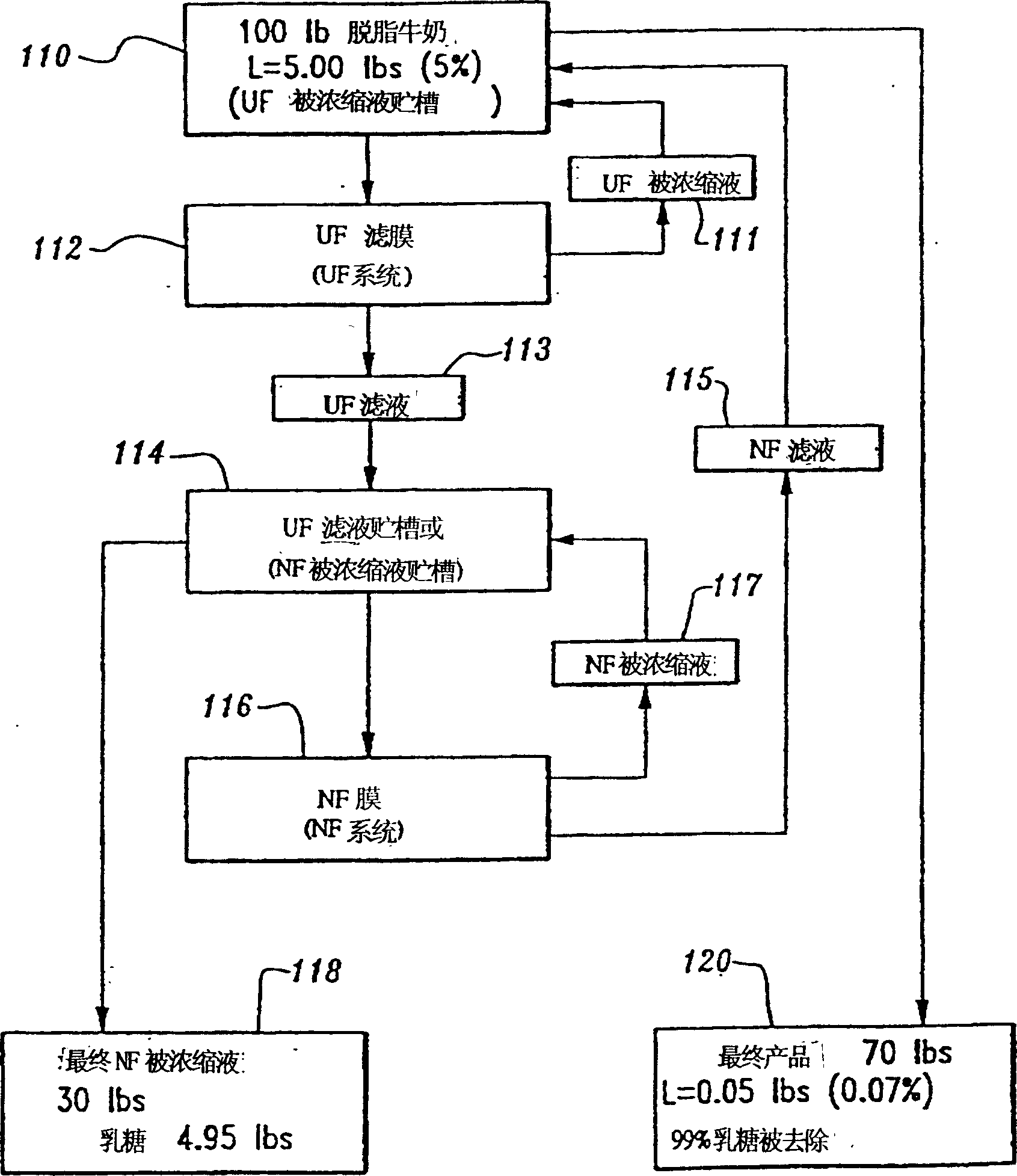

[0063] Such as figure 1 , 100lbs of skimmed milk 110 raw materials are provided to the manufacturing method of the present invention for processing. The original lactose content is 5.0% or 5lbs. The raw material is processed by UF 112 using a 900MWCO membrane to produce UF retentate 111 and UF permeate 113 . The concentrated liquid 111 mainly contains complexes of large molecular weight, for example, fat, casein like protein, whey, some non-protein nitrogen (NPN) substances, various minerals combined with macromolecules. The filtrate 113 contains small molecular weight compounds that can pass through the filter membrane, such as lactose, minerals, some NPN substances, and water. Next, the UF filtrate is collected in the storage tank 114...

Embodiment 2

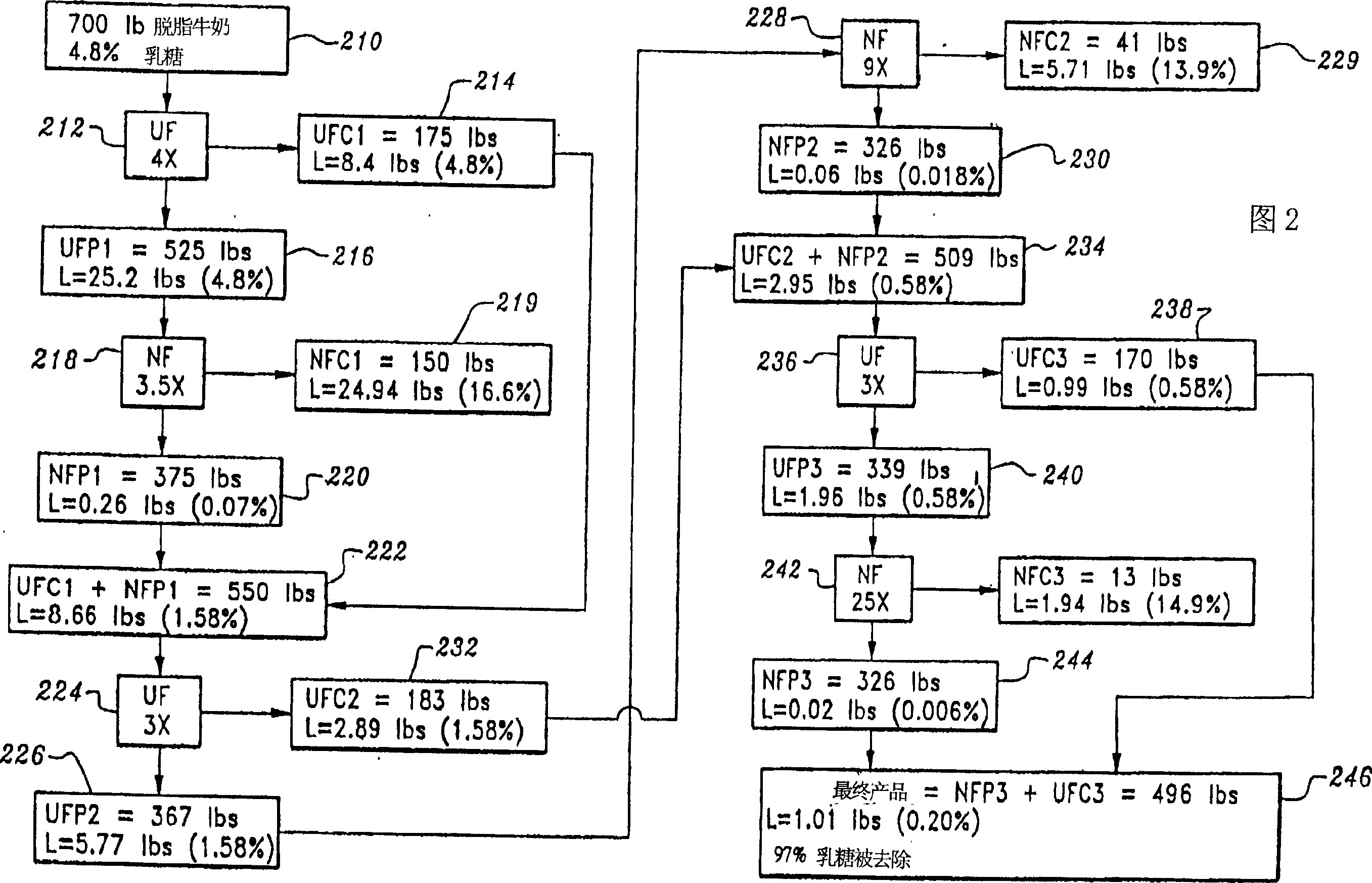

[0074] Example 2 is a batch process without water addition. Referring to FIG. 2, 700 lbs of skim milk 210 is provided to the manufacturing method of the present invention for processing.

[0075] The lactose content of the raw material is 4.8% or 33.6 lbs. The raw material is ultrafiltered 212 until 175 lbs of concentrate (UFC1) 214 is obtained at a concentration factor of 4X. 525 lbs of filtrate (UFP1) 216 was concentrated 3.5X with NF218. 375 lbs of filtrate (NFP1) 220 is combined with UF concentrate (UFC1) 214 to form 550 lbs of liquid 222, which is then ultrafiltered 3X 224.

[0076] 367 lbs of filtrate (UFP2) 226 were nanofiltered 9X 228 to yield 326 lbs of filtrate (NFP2) 230 . This filtrate was combined with UFC232 to form 509 lbs of liquid 234. This liquid was then ultrafiltered 3X 236 to produce 170 lbs of concentrate (UDC3) 238 and 339 lbs of filtrate (UFP3) 240. The filtrate was then nanofiltered 25X 242 and yielded 326 lbs of filtrate (NFP3) 244. This ...

Embodiment 3

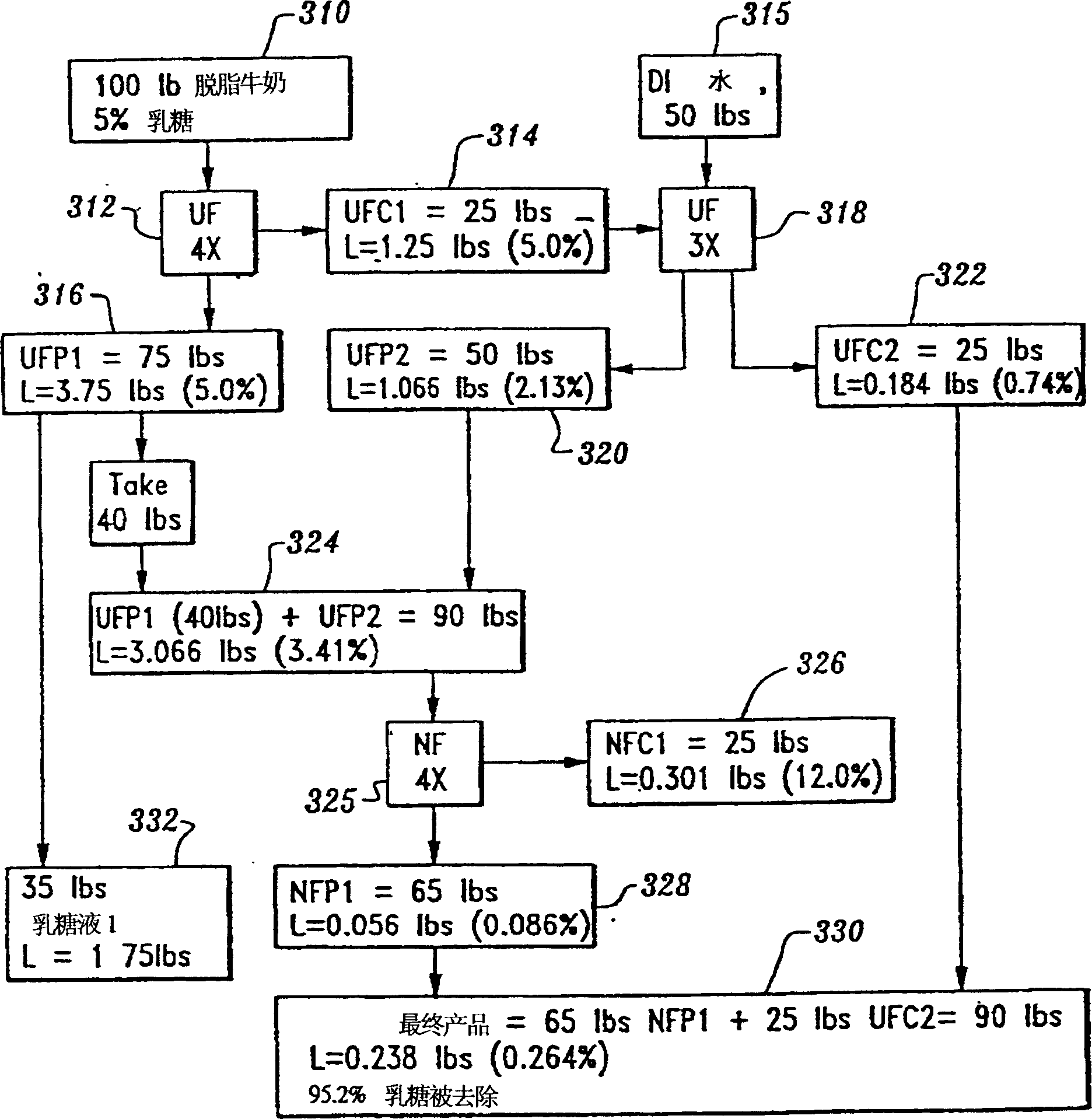

[0082] Example 3 is a water-added UF / NF batch process. refer to image 3 , 100 lbs of skimmed milk raw material 310 is provided to the manufacturing method of the present invention for processing. The lactose content of the raw material is 5% or 5 lbs. Feedstock is ultrafiltered 4X concentration 312 until 25 lbs of liquid to be concentrated (UFC1 ) 314 is obtained. 75 lb of filtrate (UFP1) 316 was obtained. 25 lbs of the concentrate (UFC1 ) 314 was dialyzed by adding 50 lbs of deionized (DI) water at a rate equivalent to that of the UF filtrate (UFP2 ) 220 . After all the water has been used, the concentrate (UFC2) 322 is still 25 lbs and the filtrate (UFP2) 320 is 50 lbs.

[0083] Combine 40lbs of 75lbs UFP1 with 50lbs of UFP 2320 to make 324. The liquid is nanofiltered 325 until 25 lbs of concentrate (NFC1) 326 is obtained. The resulting filtrate (NFP1) 328 was 67.5 lbs. Next, 65 lbs of NFP1 was combined with 25 lbs of NFC2330 to form a 90 lbs dairy product. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com