Lactose-free normal-temperature yoghourt and preparation method thereof

A yogurt and lactose technology, applied in the direction of dairy products, milk preparations, bacteria used in food preparation, etc., can solve the problems of increased product cost, cumbersomeness, and inability to decompose lactose, and achieve the effect of reducing lactose content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

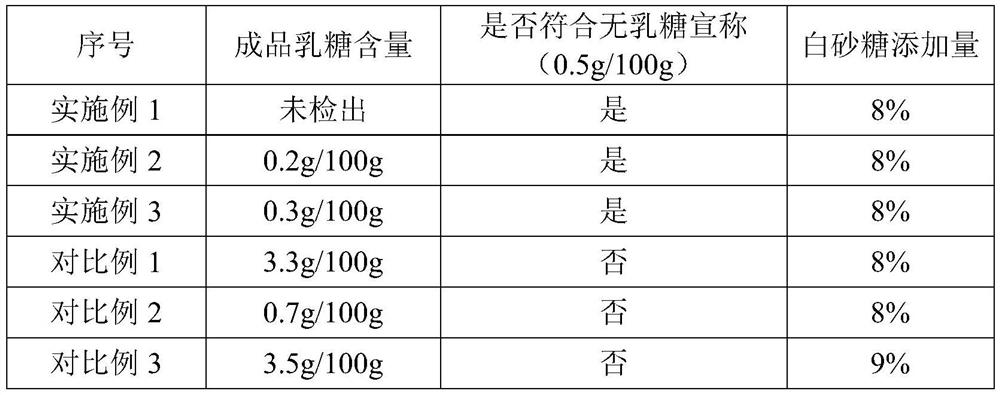

Examples

Embodiment 1

[0034] This embodiment provides a method for preparing lactose-free room temperature yogurt, which specifically includes the following steps:

[0035] 1. Milk pretreatment: pasteurize the milk at 121°C for 4s;

[0036] 2. Ingredients: Based on the total weight of yogurt raw materials as 100%, weigh 89% pretreated milk, 8% white sugar, 1.5% acetylated distarch phosphate, 0.1% pectin, 0.1% agar and the balance Mix the white granulated sugar and other powdery raw material stabilizers evenly and add them into the milk, and use the chemical equipment with mixing, dispersing and shearing effects to process the material. The temperature of the material is 55 ° C, and the time of the material is 20 minutes. Uniform feed liquid;

[0037] 3. Homogenization: Homogenize the feed liquid under the conditions of 30 / 150bar pressure and 62℃ temperature;

[0038] 4. One-time sterilization: pasteurize the homogenized feed liquid at 95°C for 300s;

[0039] 5. Fermentation: Add Streptococcus th...

Embodiment 2

[0044] This example provides a method for preparing lactose-free room temperature yogurt, the specific steps of which are basically the same as in Example 1, the difference is that in the fermentation step, 100AU / T Streptococcus thermophilus AiBi S 4.01SWEET and 50AU / T Bulgaria For Lactobacillus, the fermentation temperature is controlled to be 30° C., and the fermentation time is 24 hours.

[0045] The residual lactose content of the yoghurt product prepared by the above method was detected to be 0.2g / 100g, reaching the limit value (0.5g / 100g) of lactose-free declaration.

Embodiment 3

[0047] This example provides a method for preparing lactose-free room temperature yogurt, the specific steps of which are basically the same as in Example 1, the difference is that in the fermentation step, 100AU / T Streptococcus thermophilus AiBi S 4.01SWEET and 50AU / T Bulgaria For Lactobacillus, the fermentation temperature is controlled to be 31° C., and the fermentation time is 23 hours.

[0048] The residual lactose content of the yoghurt product prepared by the above method was detected to be 0.3g / 100g, reaching the limit value (0.5g / 100g) of lactose-free claims.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com