Low-sugar brown lactobacillus drink and preparation method thereof

A technology of lactic acid bacteria drinks and sugar brown, which is applied in dairy products, milk preparations, applications, etc., can solve the problems of increased sucrose and high sugar content, and achieve the effect of meeting low sugar, reducing lactose content, and avoiding the use of stabilizers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

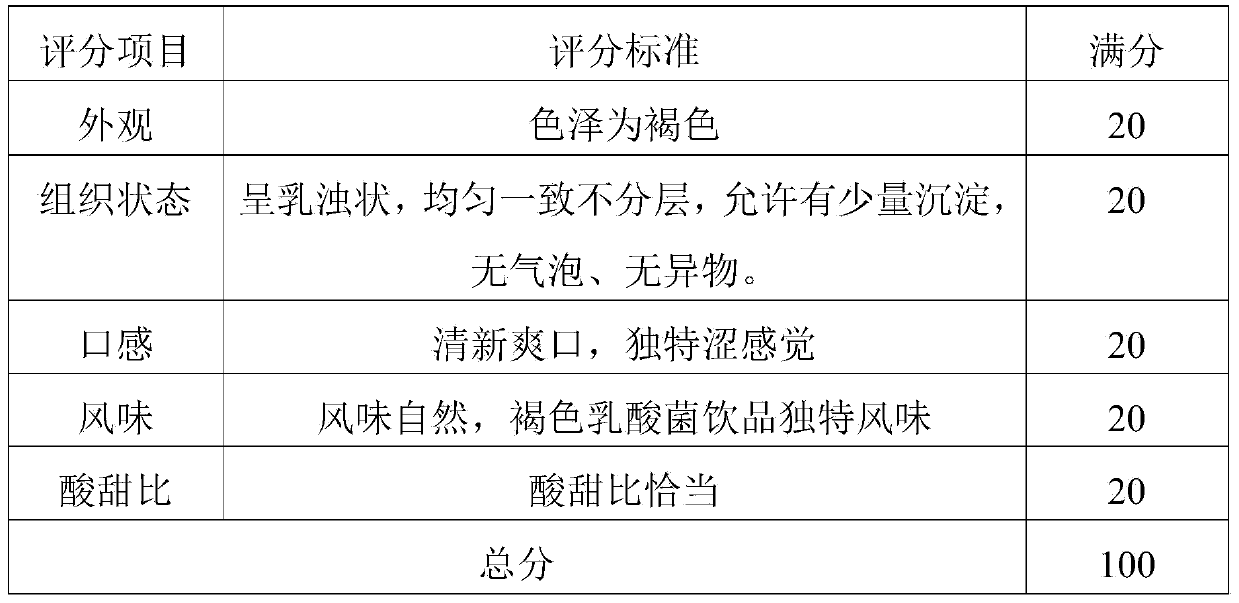

Image

Examples

Embodiment 1

[0029] (1) 99.97% skimmed milk (3.0% protein content, 0.49% fat content, said percentage is the mass percentage of skim milk) and 0.03% lactase were mixed at 35°C for 15min, and stood at 35°C for 4 hours to obtain a mixed solution, Described percentage is the mass percentage that accounts for described mixed solution;

[0030] (2) Keeping the mixed solution at 90° C. for 1.5 hours for natural browning reaction to obtain a browning feed solution;

[0031] (3) Cool the browning feed liquid to 36°C, inoculate L.paracasei LYO-NM starter 1×106cfu / mL for fermentation, ferment at 36°C for 68 hours until the acidity is 180°T, cool to below 20°C , to obtain fermented milk base material;

[0032] (4) Mix the sugar water feed liquid with the fermented milk base material according to the ratio of 3.2:1 (W / W), use citric acid to adjust the acidity and control it at 50 ° T, after a first-level 16Mpa homogenization, homogenization at 20 ° C , filling at the same time according to the addit...

Embodiment 2

[0035] (1) with 9% skimmed milk powder (the described skimmed milk powder comprises 0.5% fat, 32% protein, 54% lactose, described percentage is the mass percent that accounts for skimmed milk powder), 0.05% lactase and 90.95 % water, mixed at 37°C for 20min, and left to stand at 37°C for 3.5 hours to obtain a mixed solution, the percentage being the mass percentage of the mixed solution;

[0036] (2) Keeping the mixed solution at 92° C. for 2 hours for natural browning reaction to obtain a browning feed solution;

[0037] (3) Cool the browning feed liquid to 37°C, inoculate L.casei 01 starter 6×106cfu / mL for fermentation, ferment at 37°C for 80 hours until the acidity is 185°T, cool to below 20°C, and obtain fermented milk base;

[0038] (4) Mix the sugar water feed liquid with the fermented milk base material according to the ratio of 2.3:1 (W / W), use citric acid to adjust the acidity and control it at 56 ° T, after the pressure of the first stage is 15Mpa, the pressure of t...

Embodiment 3

[0041] (1) with 12.2% skimmed milk powder (the described skimmed milk powder comprises 0.7% fat, 33% protein, 55% lactose, described percentage is the mass percent that accounts for skimmed milk powder), 0.08% lactase and 87.72 % water, mixed at 39°C for 25min, left to stand at 39°C for 3 hours to obtain the mixed solution, the percentage is the mass percentage of the mixed solution;

[0042] (2) Keeping the mixed solution at 95° C. for 2 hours for natural browning reaction to obtain a browning feed solution;

[0043] (3) Cool the browning feed liquid to 38° C., inoculate L.paracasei LYO-NM starter 8×10 6 cfu / mL for fermentation, ferment at 38°C for 72 hours until the acidity is 180°T, cool to below 20°C to obtain fermented milk base material;

[0044] (4) Mix the sugar water feed liquid with the fermented milk base material in a ratio of 3:1 (W / W), adjust the acidity with citric acid and control it at 60°T, after the first-stage homogeneous pressure is 17Mpa, the second-stag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com