Component-reconstituted thick milk and preparation method thereof

A milk fat and emulsifier technology, applied in dairy products, milk preparations, applications, etc., can solve the problems of single consumption structure, single product structure, few product types, etc., and achieve rich milk aroma, high nutrient density and strong flavor. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] (RO reverse osmosis and NF forward osmosis combination)

[0067] Ingredients list:

[0068] The present embodiment list of ingredients is as shown in table 1:

[0069] Table 1

[0070]

[0071] The protein content of thick milk prepared in this example is 6.24%wt, and the fat is 11.3%wt.

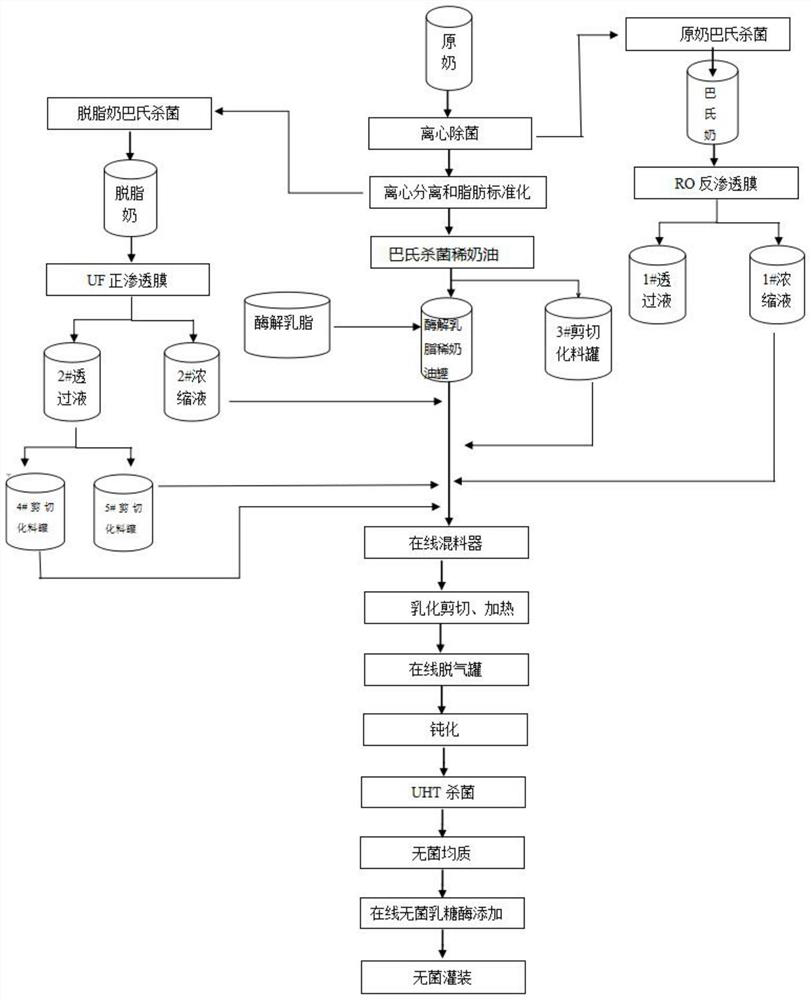

[0072] Preparation method: (see attached figure 1 )

[0073] (1) Raw milk is preheated to 58°C, sterilized by centrifugation at 5800rpm, pasteurized (85°C, 10s), cooled to 2-7°C, sent to RO reverse osmosis membrane equipment, and 2.5 times RO concentrate is obtained after treatment. Temporarily stored in the 1# concentrate tank for later use;

[0074] (2) After the raw milk is preheated to 58°C and sterilized by centrifugation at 5800rpm, it is separated into skimmed milk (fat 0.05%wt) and cream (fat 45%wt) by centrifugal separation and on-line fat standardization equipment (4850rpm) two parts;

[0075] (3) Skim milk is pasteurized (85°C, 10s) and then cooled to 2-7°C into t...

Embodiment 2

[0089] (RO reverse osmosis and NF forward osmosis combination)

[0090] Ingredients list:

[0091] The present embodiment list of ingredients is as shown in table 3:

[0092] table 3

[0093]

[0094] The thick milk prepared in this embodiment has a protein content of 9.12%wt and a fat content of 5.45%wt.

[0095] Preparation:

[0096] The preparation method is the same as in Example 1, except that after RO reverse osmosis membrane treatment, 1.5 times RO concentrated solution is obtained; after UF forward osmosis membrane treatment, 5.0 times concentrated solution is obtained.

[0097] Property analysis:

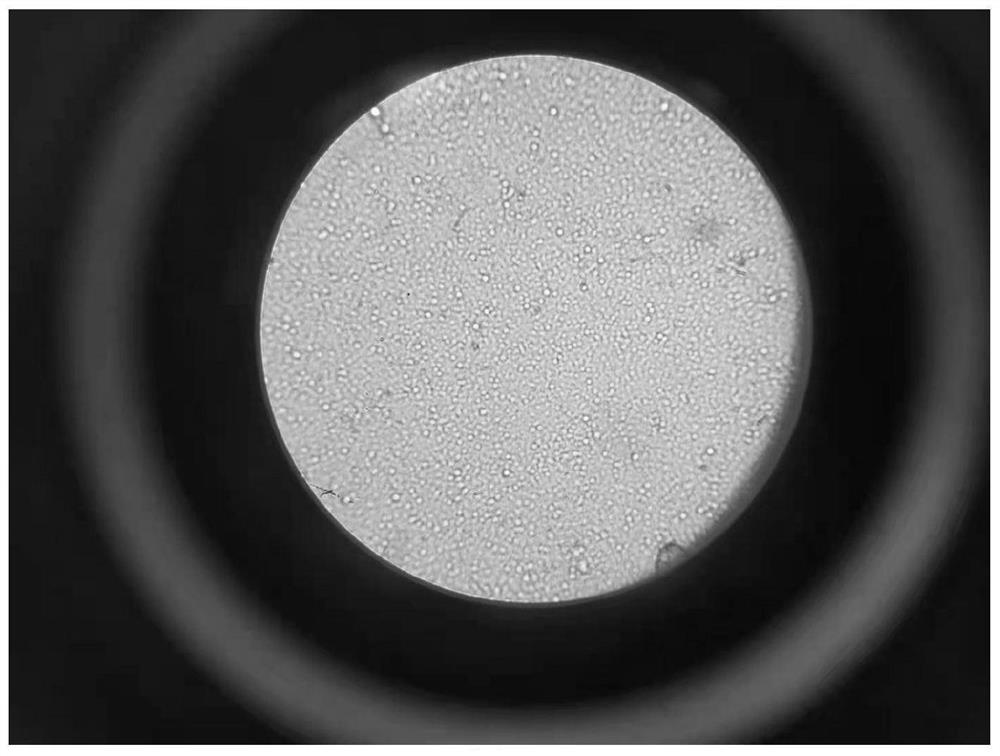

[0098] 1. Microscopic analysis was carried out on the thick milk obtained in this embodiment. The results of microscopic examination under a trinocular microscope (1600×) showed that the fat globules in the thick milk were uniform in size and evenly distributed.

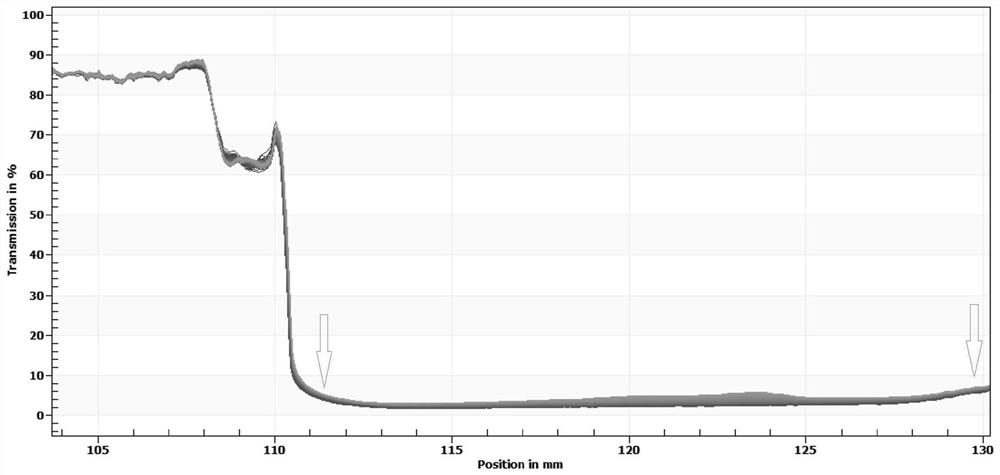

[0099] 2. Use a stability analyzer to analyze the stability of thick milk. The instability index is 0.0...

Embodiment 3

[0104] (combination of evaporator and NF forward osmosis)

[0105] Ingredients list:

[0106] The present embodiment list of ingredients is as shown in table 5:

[0107] table 5

[0108]

[0109]

[0110] The protein content of the thick milk prepared in this example is 7.21%wt, and the fat is 16.2%wt.

[0111] Preparation:

[0112] The preparation method is the same as in Example 1, except that the evaporator is used instead of the RO reverse osmosis membrane to obtain a 4-fold concentrated solution; the NF forward osmosis membrane is used instead of the NF forward osmosis membrane to obtain a 1.5-fold concentrated solution.

[0113] Property analysis:

[0114] 1. Microscopic analysis is carried out to the thick milk obtained in the present embodiment, and the result of the microscopic examination under a trinocular microscope (1600×) shows that the fat globules of the thick milk are evenly distributed (see attached Figure 4 ).

[0115] 2. Use a stability analyze...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com