Preparation of instant milk protein gel and application thereof in 3D printing

A 3D printing, milk protein technology, applied in animal protein processing, additive processing, etc., can solve the problem of low nutritional value, achieve high nutritional value, improve adaptability, and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Example 1: The preparation process of 3D printing instant plain milk protein gel food with a protein solid content of about 45%

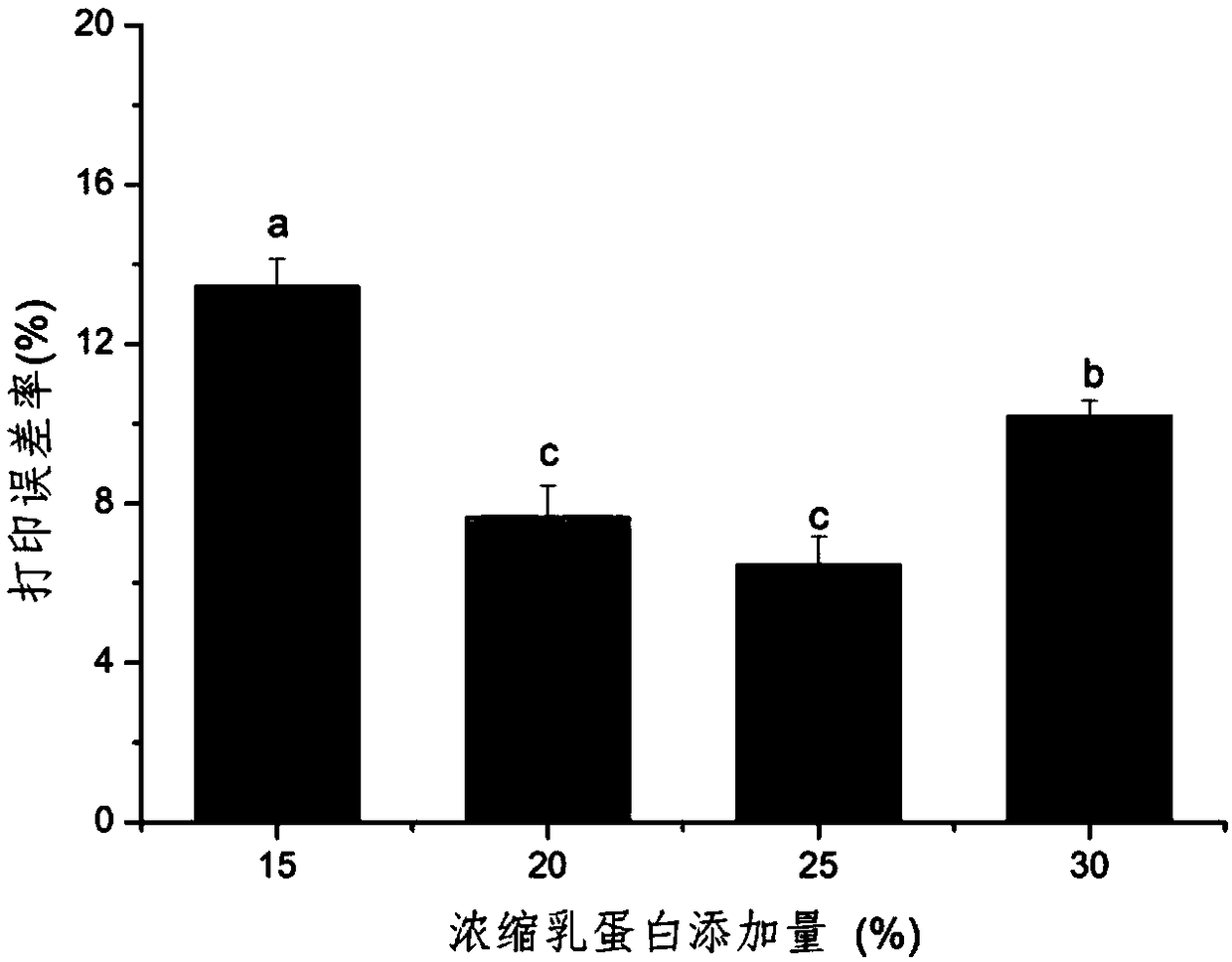

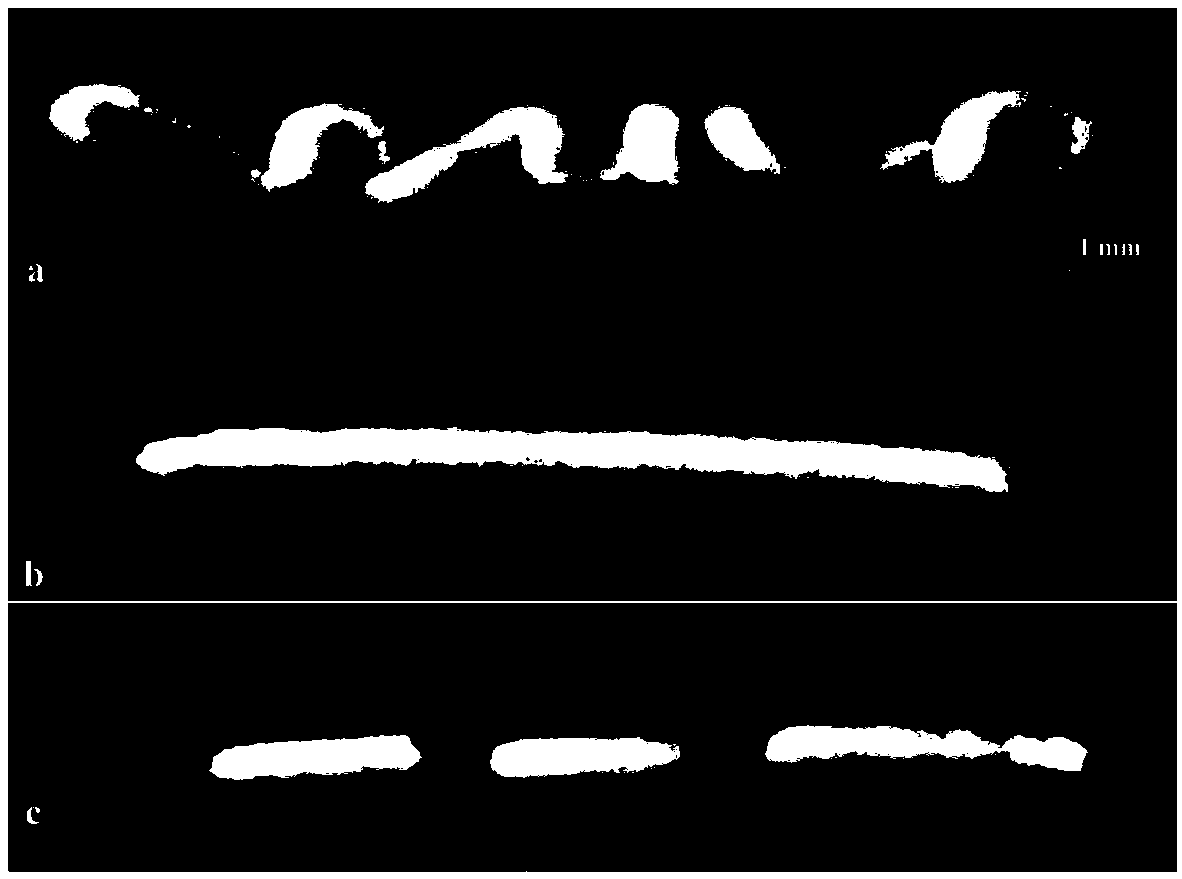

[0046] First, measure 20 mL of honey and dissolve it in 200 mL of deionized water to prepare an aqueous honey solution with a volume fraction of 10%. Weigh 40g of sodium caseinate and add it into the above-mentioned aqueous solution for 3 times, and dissolve overnight under the condition of magnetic stirring (in order to increase the dissolution rate, the water temperature can also be increased to 45-50°C), finally forming a casein with a mass fraction of 20%. Sodium proteinate homogeneous glue. Based on the quality of the sodium caseinate suspension, add 25% concentrated milk protein powder (MPC485) to the sodium caseinate glue, use a small dough mixer for 6 minutes to mix, and finally prepare a certain stretch A semi-solid latex protein glue.

[0047] Weigh about 30g of composite latex protein glue into the barrel of the 3D printer, and s...

Embodiment 2

[0048] Example 2: The preparation process of 3D printed instant cocoa-flavored milk protein gel food with a protein solid content of about 43%

[0049] First, measure 20mL of honey and dissolve it in 200mL of deionized water to prepare a honey aqueous solution with a volume fraction of 10%, then add 1% (m / v) cocoa powder to the above solution, and stir for 1 hour to completely and evenly disperse the cocoa powder In the water. Weigh 40g of sodium caseinate and divide it into the above-mentioned aqueous solution for 3 times, and dissolve overnight under the condition of magnetic stirring, (in order to improve the dissolution rate, the water temperature can also be increased to 45-50 ° C), and finally form a mass fraction of 20%. Uniform glue of sodium caseinate. Based on the quality of the sodium caseinate suspension, add 23% concentrated milk protein powder (MPC485) to the sodium caseinate glue, use a small dough mixer for 6 minutes to mix, and finally prepare a certain stret...

Embodiment 3

[0051] Example 3: Preparation process of 3D printed instant milk protein composite gel food with a protein solid content of about 40%

[0052] First, measure 20mL of honey and dissolve it in 200mL of deionized water to prepare a honey aqueous solution with a volume fraction of 10%, then add 1% (m / v) carrot powder to the above solution, and stir for 1 hour to completely and evenly disperse the cocoa powder In the water. Weigh 40g of sodium caseinate and divide it into the above-mentioned aqueous solution for 3 times, and dissolve overnight under the condition of magnetic stirring, (in order to improve the dissolution rate, the water temperature can also be increased to 45-50 ° C), and finally form a mass fraction of 20%. Uniform glue of sodium caseinate. Based on the quality of the sodium caseinate suspension, add 20% concentrated milk protein powder (MPC485) to the solution of sodium caseinate, use a small dough mixer for 6min mixing operation, and finally prepare a certain d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com