Method for producing low-lactose or low-sugar yogurt by using milk protein concentrates (MPC)

A milk protein concentrate, low lactose technology, used in applications, dairy products, milk formulations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

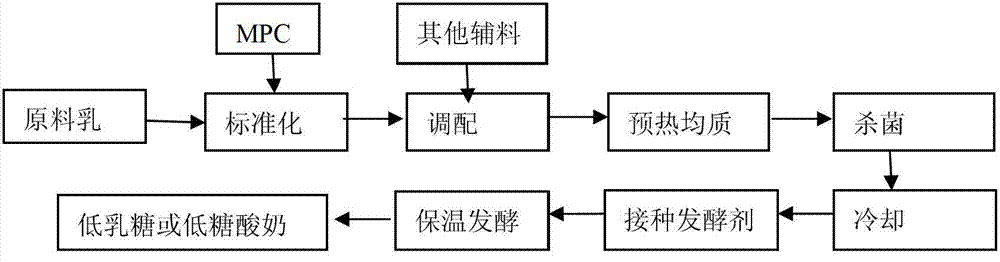

[0015] according to figure 1 As shown in the flowchart, the liquid MPC produced by ultrafiltration is mixed with fresh milk and standardized to lactose 1.5wt%, protein 4.5wt%, fat 1.2wt%, then add gelatin 0.3wt%, modified starch 1wt%, sweetener A Mix 0.03wt% of spartame evenly and heat to 60~65°C. After homogenization, continue to heat up to 90~95°C, keep warm for 5 minutes to sterilize, and then inoculate yogurt starter MY-821 (DSM) and keep it fermented to pH4. 4~4.6, get low-sugar yogurt.

Embodiment 2

[0017] according to figure 1 As shown in the flowchart, MPC powder is mixed with fresh milk and water and standardized to lactose 1.6wt%, protein 5.5wt%, fat 0.5wt%, then add agar 0.2wt%, modified starch 0.5wt%, sweetener cyclamate 0.05wt%, mix evenly and heat to 60~65°C, continue to heat up to 90~95°C after homogenization, keep warm for 5 minutes to sterilize, then inoculate yogurt starter YF-L822 (Ke-Hansen) and keep fermented to pH4.4 ~4.6, to get low-fat low-sugar yogurt.

Embodiment 3

[0019] according to figure 1 As shown in the flow chart, mix MPC powder with fresh milk and water and standardize to lactose 1.6wt%, protein 5.5wt%, fat 0.5wt%, then add compound yogurt thickener 0.5wt%, sucrose 5wt%, after mixing evenly Heat to 60~65°C, continue to heat up to 90~95°C after homogenization, keep warm for 5 minutes to sterilize, then inoculate yogurt starter Yo-Mix-401 (DuPont) and keep it fermented to pH 4.4~4.6 to obtain low-fat and low-lactose yogurt.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com