Processed cheese spread and preparation method thereof

A processed cheese and spread-type technology, applied in the field of spread-type processed cheese and its preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

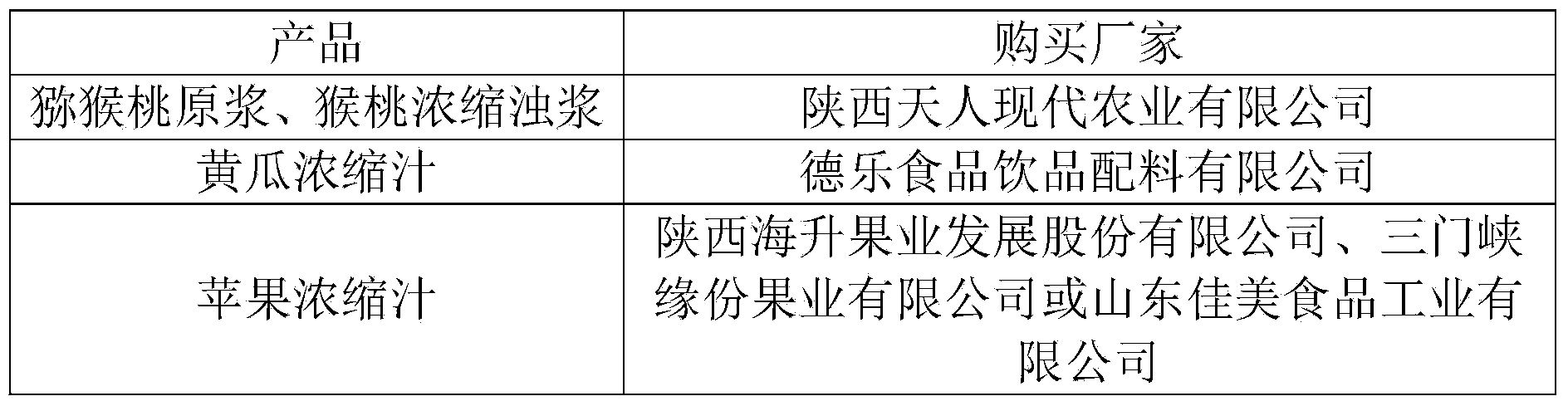

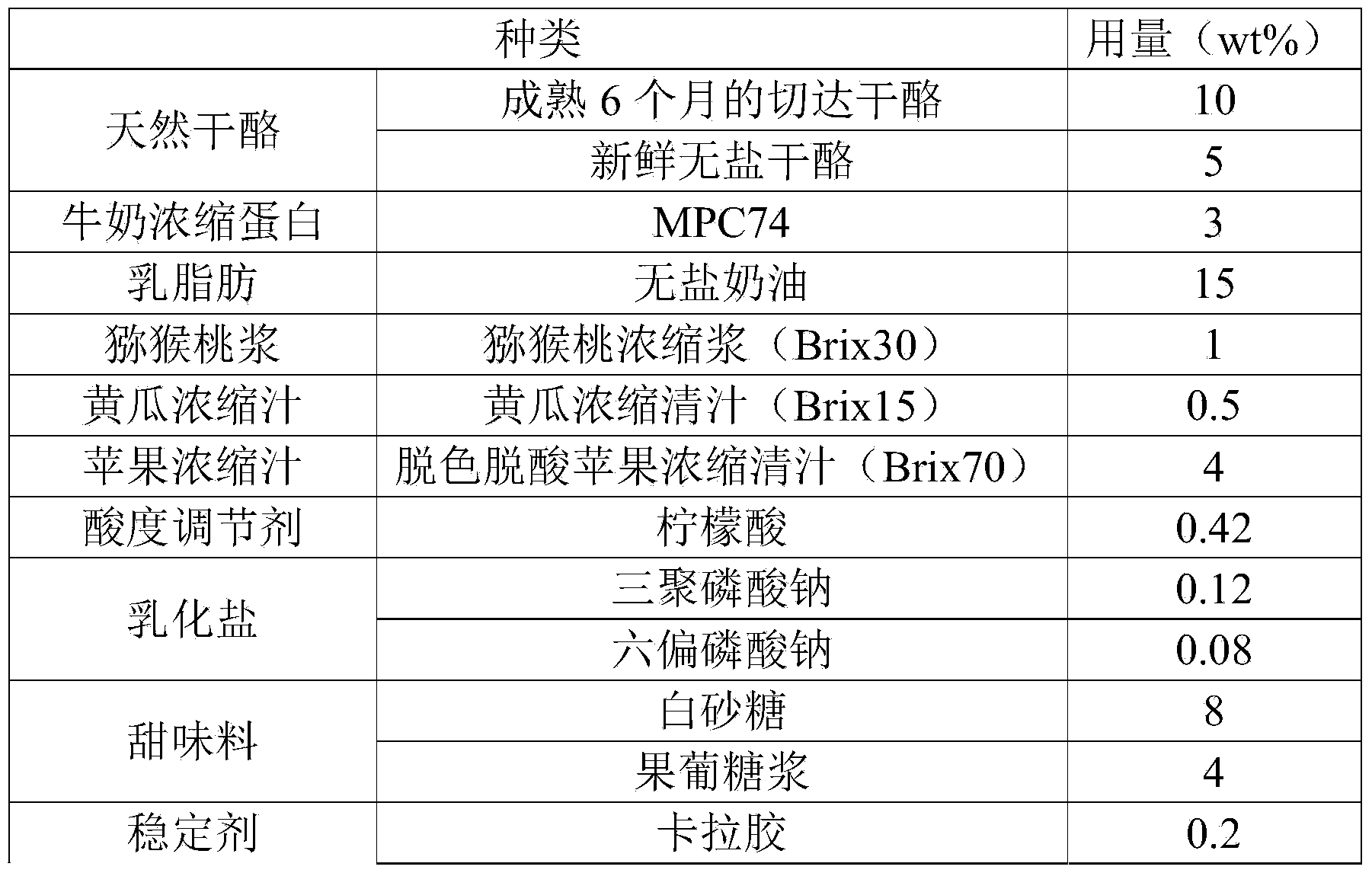

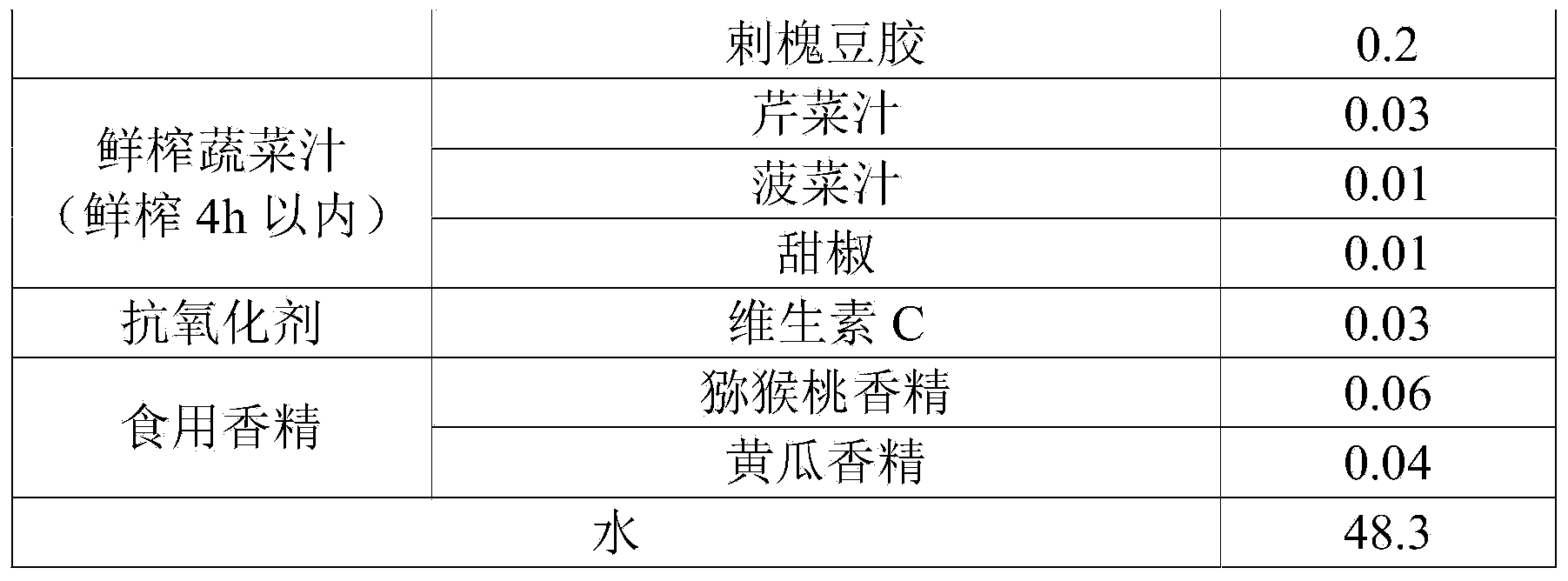

[0052] raw material:

[0053]

[0054]

[0055] Preparation:

[0056] (1) Finely cut natural cheese and milk fat, then stir with emulsifying salt, sweetener, milk protein concentrate, stabilizer and water at a temperature of 65°C and a stirring speed of 3000rpm for 8 minutes, and melt and mix to obtain slurry A;

[0057] (2) At a stirring speed of 900rpm, add kiwi fruit pulp, apple concentrated juice, cucumber concentrated juice, acidity regulator, antioxidant and food flavor to slurry A, and stir evenly to obtain slurry B;

[0058] (3) Homogenize the slurry B and pasteurize it; the homogenization temperature is 90°C, the homogenization pressure is 20MPa, the pasteurization temperature is 88°C, and the pasteurization time is 2min;

[0059] (4) Squeeze fresh vegetables together with sterile water that is less than twice its weight at room temperature to extract juice. After extracting juice, filter it through two layers of gauze to obtain freshly squeezed vegetable juice...

Embodiment 2

[0063] raw material:

[0064]

[0065]

[0066] Preparation:

[0067] (1) Finely cut natural cheese and milk fat, then stir with emulsifying salt, sweetener, milk protein concentrate, stabilizer and water at 70°C and 1500rpm stirring speed for 5 minutes, melt and mix to obtain slurry A;

[0068] (2) At a stirring speed of 1200rpm, add kiwi fruit pulp, apple juice concentrate, cucumber juice concentrate, acidity regulator, antioxidant and food flavor to slurry A, and stir evenly to obtain slurry B;

[0069] (3) Homogenize the slurry B and pasteurize it; the homogenization temperature is 82°C, the homogenization pressure is 18MPa, the pasteurization temperature is 80°C, and the pasteurization time is 10min;

[0070] (4) Squeeze fresh vegetables together with sterile water that is less than twice its weight at room temperature to extract juice. After extracting juice, filter it through two layers of gauze to obtain freshly squeezed vegetable juice. The vegetable juice is s...

Embodiment 3

[0074] raw material:

[0075]

[0076] Preparation:

[0077] (1) Finely cut the natural cheese, then stir it with cream, emulsifying salt, sweetener, milk protein concentrate, stabilizer and water for 6 minutes at a temperature of 68°C and a stirring speed of 1800rpm, and melt and mix to obtain slurry A;

[0078] (2) At a stirring speed of 600rpm, add kiwifruit pulp, apple juice concentrate, cucumber juice concentrate, acidity regulator, antioxidant and food flavor to slurry A, and stir evenly to obtain slurry B;

[0079](3) Homogenize the slurry B and pasteurize it; the homogenization temperature is 87°C, the homogenization pressure is 15MPa, the pasteurization temperature is 85°C, and the pasteurization time is 6 minutes;

[0080] (4) Squeeze fresh vegetables together with sterile water that is less than twice its weight at room temperature to extract juice. After extracting juice, filter it through two layers of gauze to obtain freshly squeezed vegetable juice. The vege...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com