Fruit-vegetable processed cheese spread and preparation method thereof

A processed cheese and spread-type technology, which is applied to the field of fruit and vegetable spread-type processed cheese and its preparation, and can solve the problems of poor taste, color and texture, and low sensory evaluation of products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

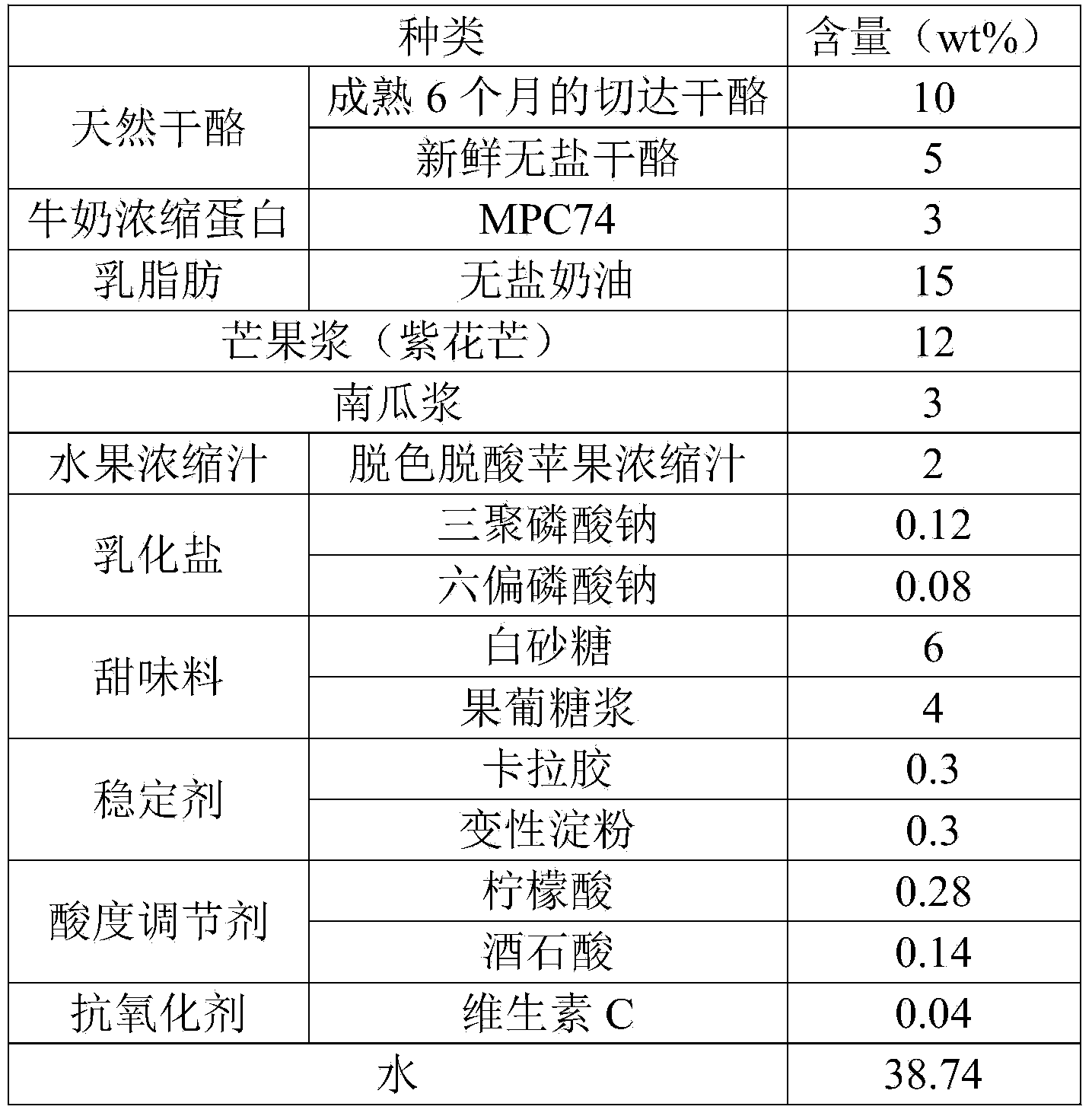

[0043] raw material:

[0044]

[0045] Preparation Process:

[0046] ① Finely cut the natural cheese and butter, then melt and mix with emulsified salt, sweetener, milk protein concentrate, stabilizer and water at 65°C and 3000rpm stirring speed for 8min to obtain slurry A;

[0047] ② Add mango pulp, pumpkin pulp, fruit juice concentrate (Brix ≥ 70, Shandong Jiamei Food Industry Co., Ltd.), acidity regulator and antioxidant under the stirring condition of 900rpm, and then stir evenly to obtain slurry B;

[0048] ③Raise the temperature of slurry B to 90°C, homogenize while it is hot, the homogenization pressure is 20MPa, and then pasteurize at 88°C for 2 minutes;

[0049] ④ Filling while it is hot, three-stage rapid cooling and molding, using 45°C hot water, 20°C room temperature water and ice water for three-stage cooling, the processing time is 25 minutes, the product center temperature is lower than 23°C, and it can be refrigerated.

Embodiment 2

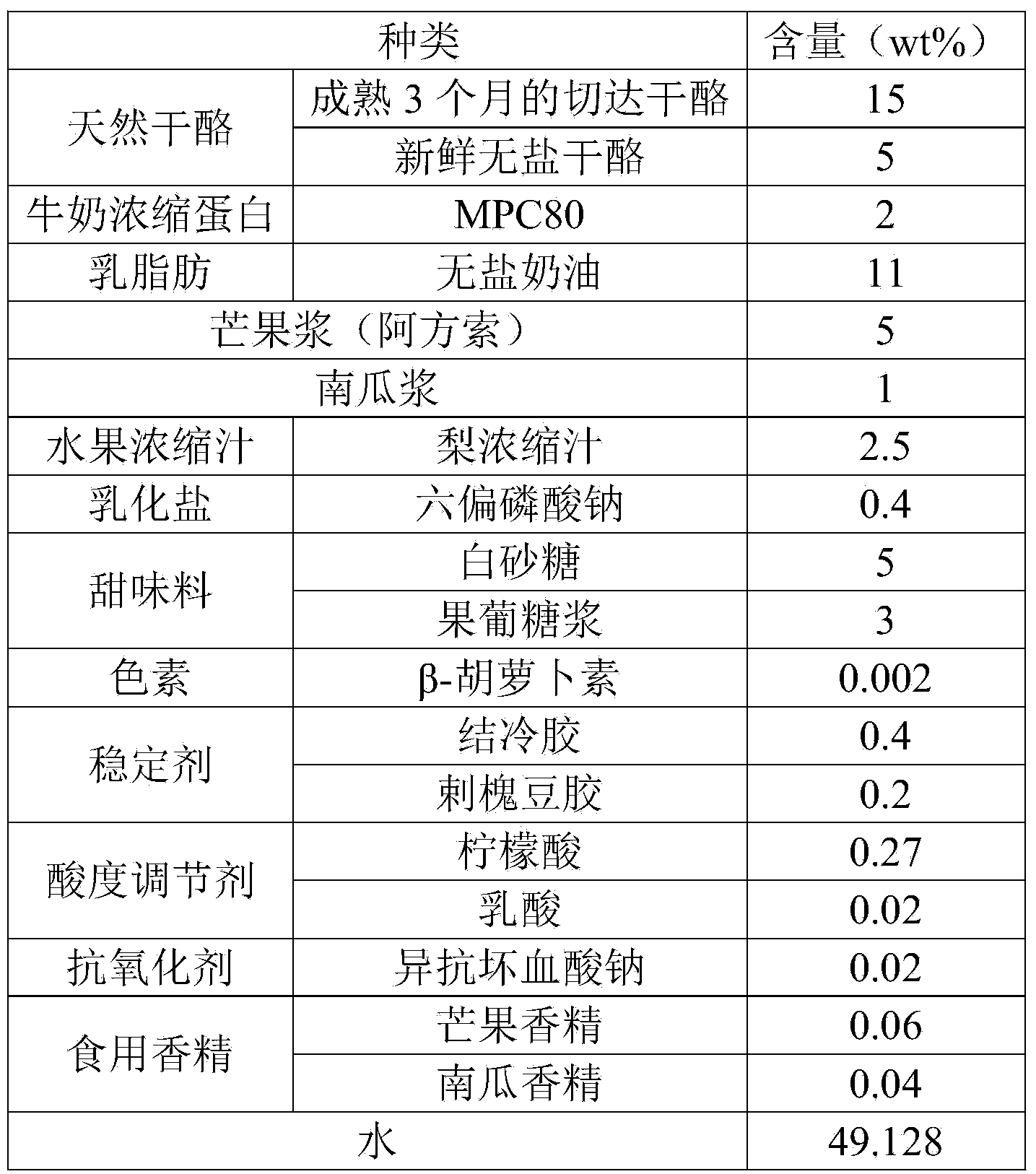

[0051] raw material:

[0052]

[0053] Preparation Process:

[0054] ① Finely cut the natural cheese and butter, then melt and mix with emulsifying salt, sweetener, milk protein concentrate, stabilizer and water at 70°C and 1500rpm stirring speed for 5min to obtain slurry A;

[0055] ② Add mango pulp, pumpkin pulp, fruit juice concentrate (Brix ≥ 70, Delo Food and Beverage Ingredients Co., Ltd.), acidity regulator, antioxidant, food flavor and pigment under the stirring condition of 1200rpm, and stir evenly to obtain slurry B Obtain slurry B;

[0056] ③ Raise the temperature of material B to 82°C, homogenize while it is hot, the homogenization pressure is 18MPa, and then pasteurize at 80°C for 10 minutes;

[0057] ④ Filling while it is hot, three-stage rapid cooling and forming, using 55°C hot water, 10°C room temperature water and ice water for three-stage cooling, the processing time is 30 minutes, the product center temperature is lower than 20°C, and it can be refrige...

Embodiment 3

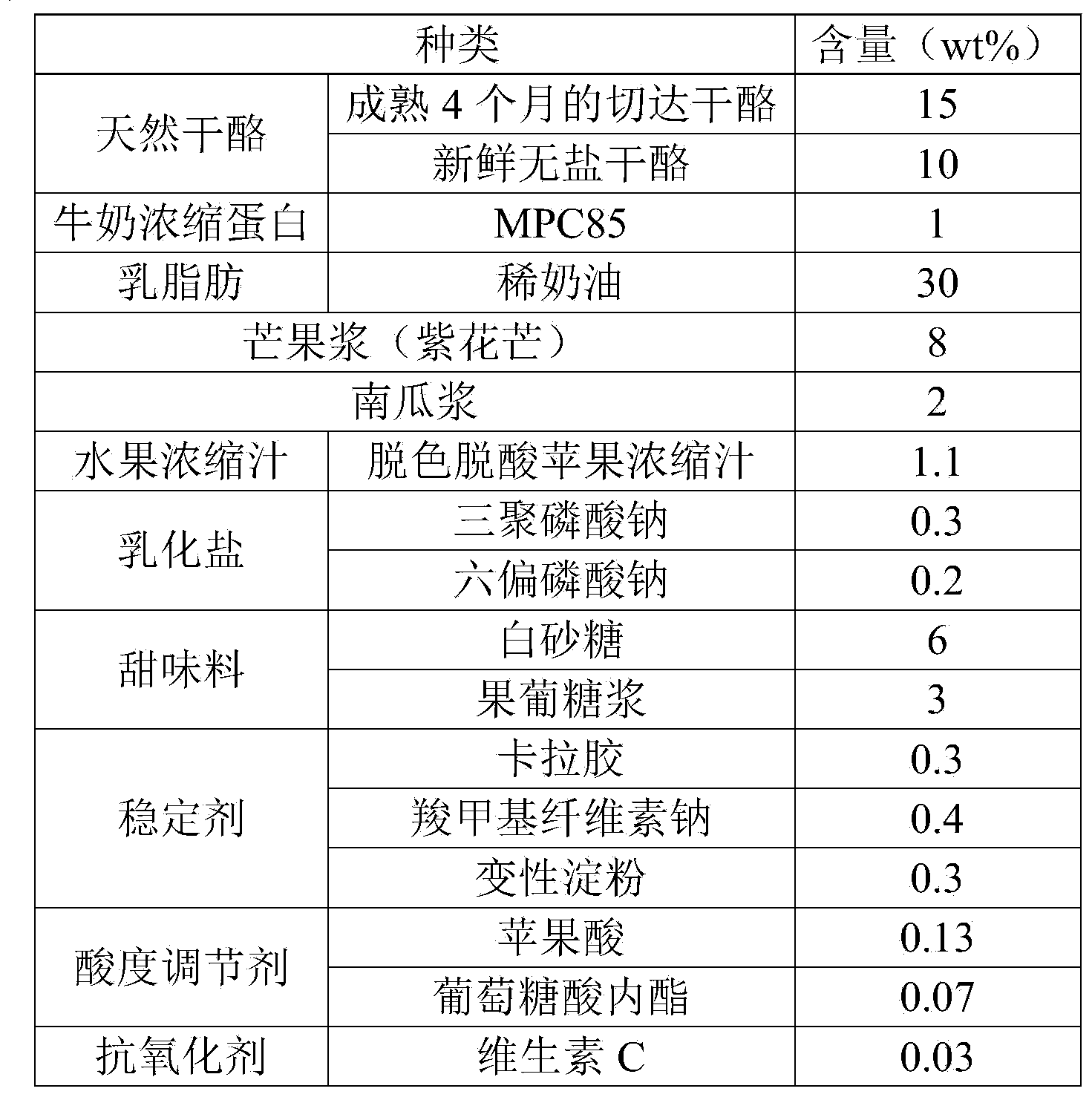

[0059] raw material:

[0060]

[0061]

[0062] Preparation Process:

[0063] ① Subdividing and cutting the natural cheese, then melting and mixing with cream, emulsifying salt, sweetener, milk protein concentrate, stabilizer and water at 68°C and stirring speed of 1800rpm for 6min to obtain slurry A;

[0064] ② Add mango pulp, pumpkin pulp, fruit juice concentrate (Brix70-72 Shaanxi Haisheng Fruit Industry Development Co., Ltd.), acidity regulator, antioxidant and food flavor under the stirring condition of 600 rpm, and stir again to obtain slurry B;

[0065] ③Raise the temperature of material B to 87°C, homogenize while it is hot, the homogenization pressure is 15MPa, and then pasteurize at 85°C for 6 minutes;

[0066] ④ Filling while it is hot, three-stage rapid cooling and forming, using 50°C hot water, 20°C room temperature water and ice water for three-stage cooling, the processing time is 25 minutes, the product center temperature is lower than 24°C, and it can b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com