Stirring-type flavored fermented milk and preparation method thereof

A fermented milk and stirring technology, which is applied in the direction of bacteria and lactobacillus used in dairy products and food preparation, can solve the problem of rough taste and achieve the effect of delicate taste, rich nutrition and stable shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

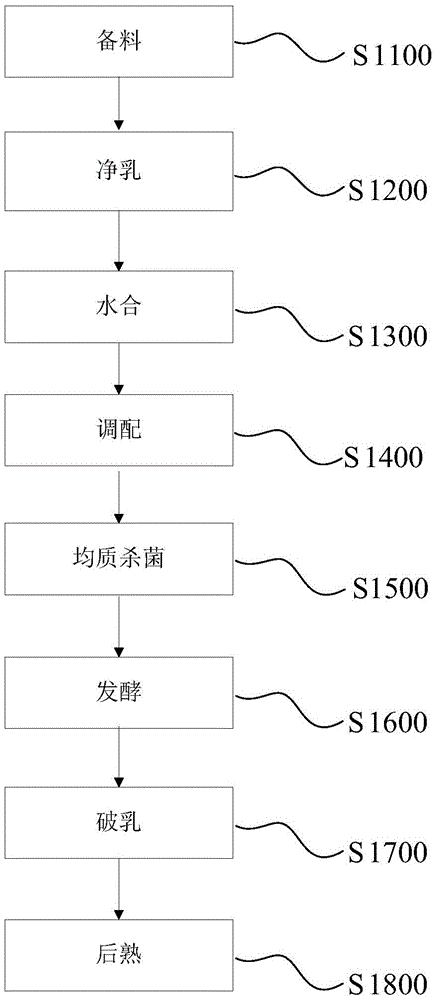

[0037] In addition, the present invention also provides a method for preparing the above-mentioned stirred flavored fermented milk, figure 1 A schematic flow chart of the method for preparing the stirred flavored fermented milk of the present invention is shown. Such as figure 1 As shown, the method includes the following steps:

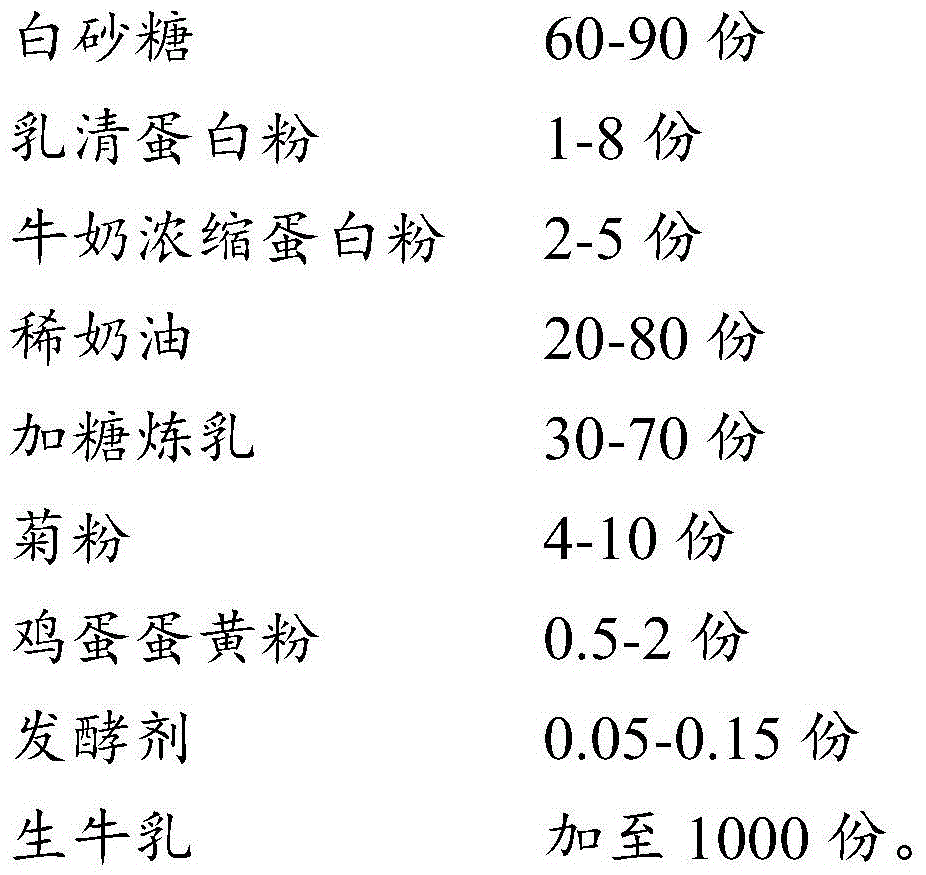

[0038] Material preparation step S1100: Prepare 1000 parts of raw materials according to the following weight ratio: 60-90 parts of white sugar, 1-8 parts of whey protein powder, 2-5 parts of milk protein concentrate powder, 20-80 parts of cream, 30 parts of sweetened condensed milk -70 parts, 4-10 parts of inulin, 0.5-2 parts of egg yolk powder, 0.05-0.15 parts of starter, and the rest is raw milk;

[0039] Milk cleaning step S1200: cooling the raw milk to 2-6°C after removing impurities;

[0040]Hydration step S1300: heat up 30-50% of the total weight of raw milk after removal of impurities to 45-50°C, then add whey protein powder, concentrated ...

Embodiment 1

[0053] In this example, 1000 kg of raw materials are used to prepare stirred flavored fermented milk, and the weight ratio of each raw material is: 80 parts of white granulated sugar, 2 kg of whey protein powder, 4 kg of concentrated milk protein powder, 60 kg of cream, 50 kg of sweetened condensed milk, chrysanthemum Powder 7kg, egg yolk powder 1kg, starter 0.15kg, and the balance is raw milk.

[0054] The preparation method of stirring type flavor fermented milk is:

[0055] Firstly, the qualified raw milk is filtered to remove impurities, and then cooled to 2-6°C.

[0056] Weigh 400kg of raw milk after removing impurities, heat up to 45-50°C, add whey protein powder, concentrated milk protein powder and sweetened condensed milk, stir for 10-15 minutes, then let stand for hydration for 30 minutes to obtain a hydration liquid.

[0057] Then weigh 400kg of raw milk after removing impurities, heat up to 60-65°C, add white sugar, cream, inulin and egg yolk powder, stir for 15-2...

Embodiment 2

[0062] In this example, 1000 kg of raw materials are used to prepare stirred-flavored fermented milk, and the weight ratio of each raw material is: 60 kg of white granulated sugar, 8 kg of whey protein powder, 2 kg of concentrated milk protein powder, 20 kg of cream, 30 kg of sweetened condensed milk, and 30 kg of inulin 4kg, egg yolk powder 2kg, starter 0.1kg, the rest is raw milk.

[0063] The preparation method of stirring type flavor fermented milk is:

[0064] Firstly, the qualified raw milk is filtered to remove impurities, and then cooled to 2-6°C.

[0065] Weigh 300kg of raw milk after removing impurities, heat up to 45-50°C, add whey protein powder, concentrated milk protein powder and sweetened condensed milk, stir for 10-15 minutes, then let stand for hydration for 60 minutes to obtain a hydration liquid.

[0066] Then weigh 400kg of raw milk after removing impurities, heat up to 60-65°C, add white sugar, cream, inulin and egg yolk powder, stir for 15-20 minutes, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com