Accurate 3D printing method for high-protein semifluid instant food

A 3D printing, semi-fluid technology, applied in the field of precise 3D printing of high-protein semi-fluid ready-to-eat food, can solve the problems of insufficient protein intake and unbalanced diet, and achieve the goal of solving insufficient protein intake, easy to swallow and chew, and conducive to chewing. and swallowing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Example 1 Preparation of high-protein semi-fluid ready-to-eat 3D printed food with different amounts of carrageenan added

[0037] First prepare a carrageenan colloid solution with a concentration of 1%-2%, then add 5% fructose syrup type 55 to improve the taste, then add 32% concentrated milk protein to it, and stir evenly to obtain a milk protein paste . Then weigh about 30g of milk protein paste and put it into the barrel of the 3D printer, and select a printing nozzle with a diameter of 0.8mm. Make a 3D model and set parameters such as software slicing. The printing speed is set to 25mm / s, the printing temperature is 25°C, the height of the printing platform is 0.9mm, the filling rate is 40%, and the retraction speed is 50mm / s for 3D printing. . Such as figure 1 As shown, adding 1.5% and 2% carrageenan has a better effect on maintaining the shape of the printed object.

[0038] In order to perform sensory evaluation on the printed food, 10 people were asked to c...

Embodiment 2

[0043] Example 2 Preparation of high-protein semi-fluid ready-to-eat 3D printed food with different pectin concentrations

[0044] First prepare a pectin colloid solution with a concentration of 1%-2.5%, then add 5% fructose syrup type 55 to improve the taste, then add 32% concentrated milk protein to it, and stir evenly to obtain a milk protein paste . Then weigh about 30g of milk protein paste and put it into the barrel of the 3D printer, and select a printing nozzle with a diameter of 0.8mm. Create a 3D model and set parameters such as software slicing. The printing speed is set to 25mm / s, the printing temperature is 25°C, the height of the printing platform is 0.9mm, the filling rate is 40%, and the retraction speed is 50mm / s for 3D printing. .

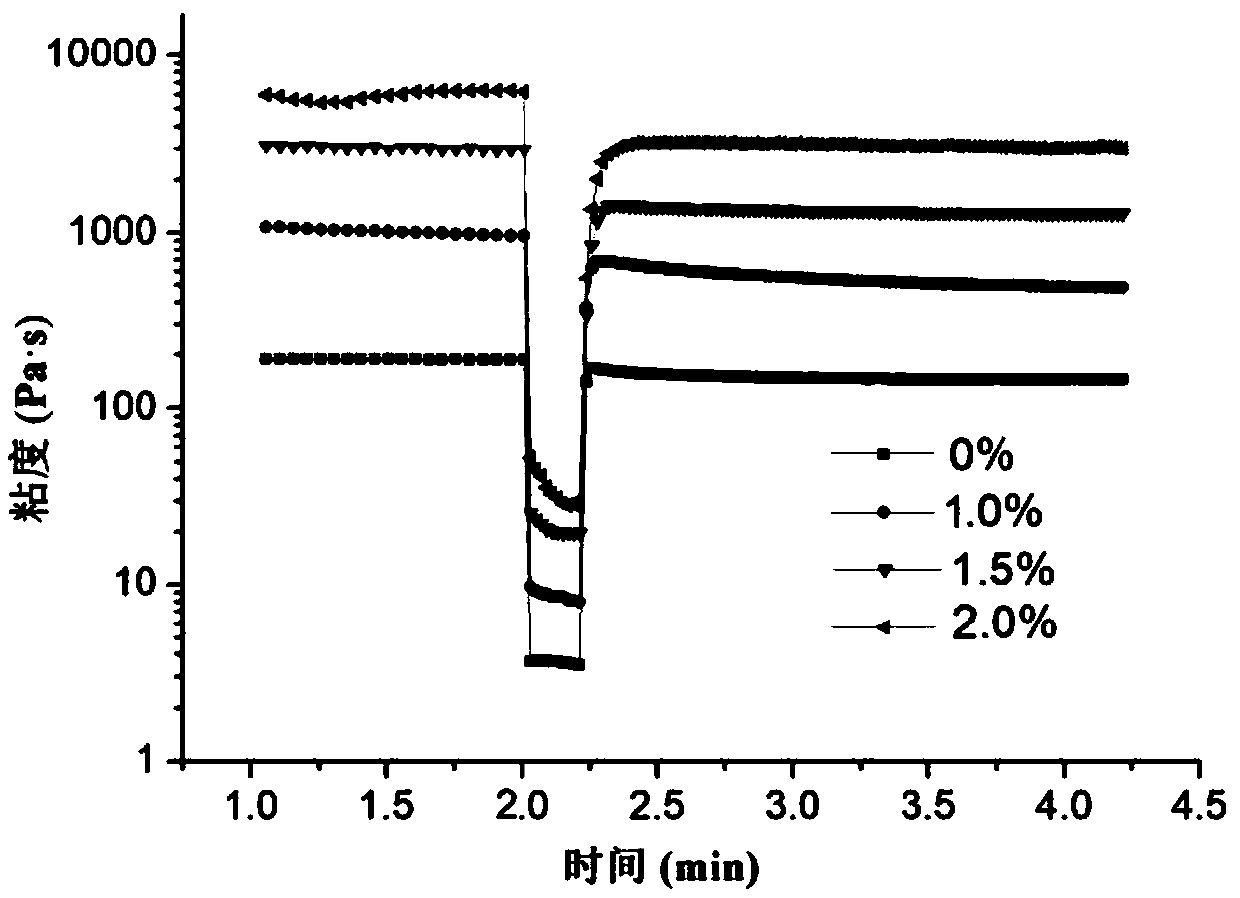

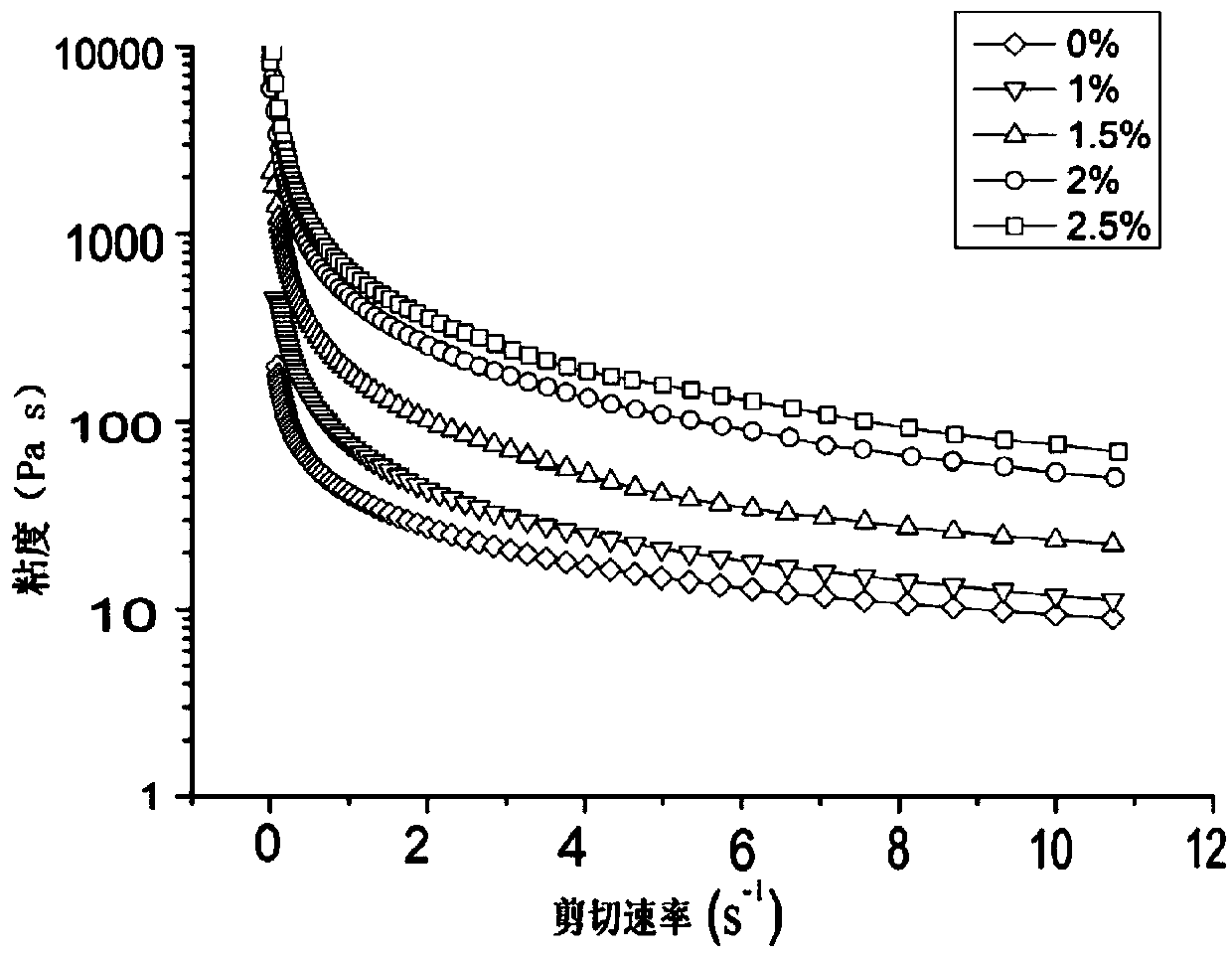

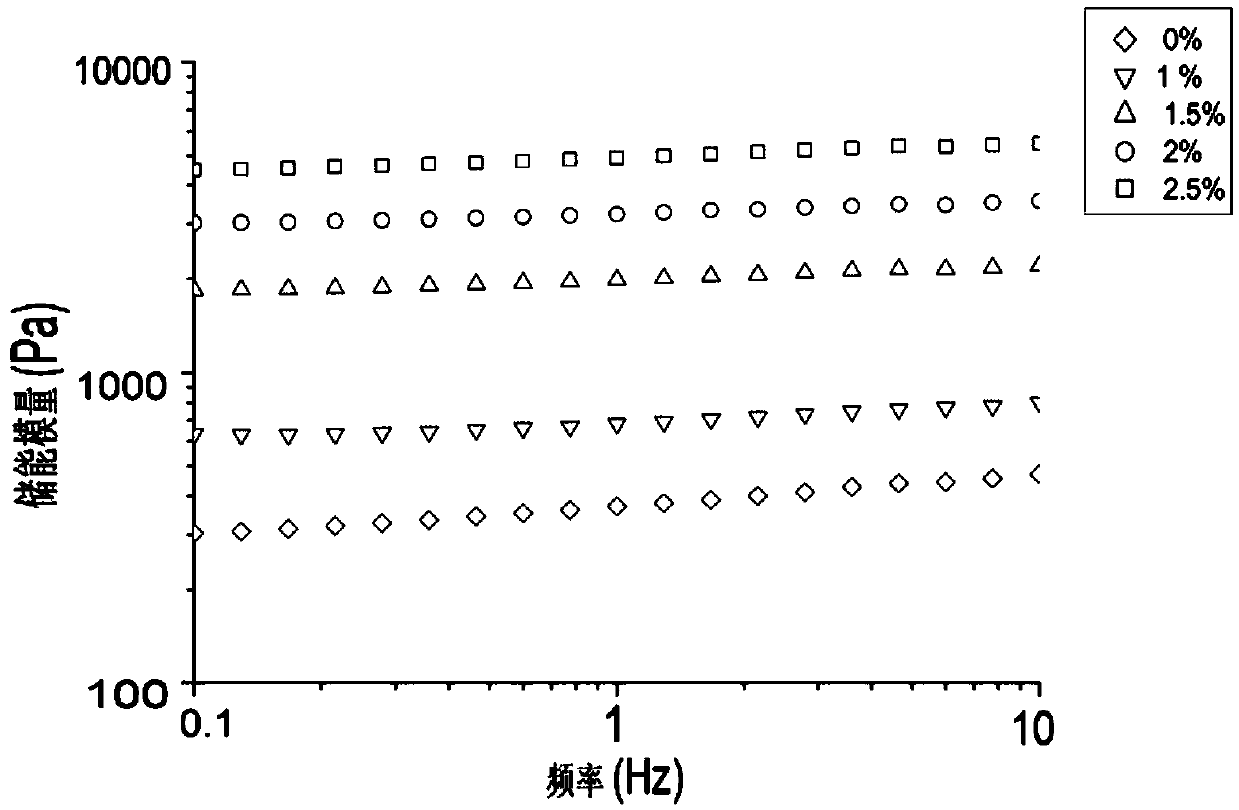

[0045] The protein paste containing different pectin content was subjected to rheological test, and the storage modulus and viscosity were measured, and the results were as follows: figure 2 , image 3 and Figure 4 shown. ...

Embodiment 3

[0046] Embodiment 3 Preparation of high-protein semi-fluid ready-to-eat 3D printed food

[0047] First prepare a pectin colloid solution with a concentration of 2%, then add 5% fructose syrup type 55 to improve the taste, then add 32% concentrated milk protein therein, and stir evenly to obtain a milk protein paste. Then weigh about 30g of milk protein paste and put it into the barrel of the 3D printer, and select a printing nozzle with a diameter of 0.8mm. Make a 3D model and set parameters such as software slicing. The printing speed is set to 25mm / s, the printing temperature is 25°C, the height of the printing platform is 0.9mm, the filling rate is 40%, and the retraction speed is 50mm / s for 3D printing. . get as Figure 5 Printed physical image shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com