Puddings and preparation method of puddings

A technology for pudding and stabilizer, applied in the field of pudding and its preparation, can solve the problems of high fat content, obesity, influence on appearance and white effect, etc., and achieve the effects of simple and feasible preparation process, delicate taste, and Q-bounce taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] In a specific embodiment, a method for preparing pudding is provided, comprising the following raw materials in mass percentage: 87.3-94.65% raw milk, 0.2-0.5% lactase; 5-10% sweetener and 0.15-2.2% Stabilizer; The preparation method comprises the following steps:

[0024] (1) The raw milk is defatted, concentrated, pre-pasteurized and cooled, and hydrolyzed by adding lactase,

[0025] get lactose-free milk;

[0026] (2) mixing lactose-free milk, sweetener and stabilizer to obtain feed liquid;

[0027] (3) Homogenize the feed liquid, sterilize, and cool.

[0028] The labels of the above steps (1), (2), and (3) are not used to limit the order of each step in the preparation method, each step in the method, as long as it is logically reasonable, the order of each step can be changed; and, before and after each step Other reasonable steps that do not affect the essence of the present invention may also be included.

[0029] Through the above pudding preparation method,...

Embodiment 1

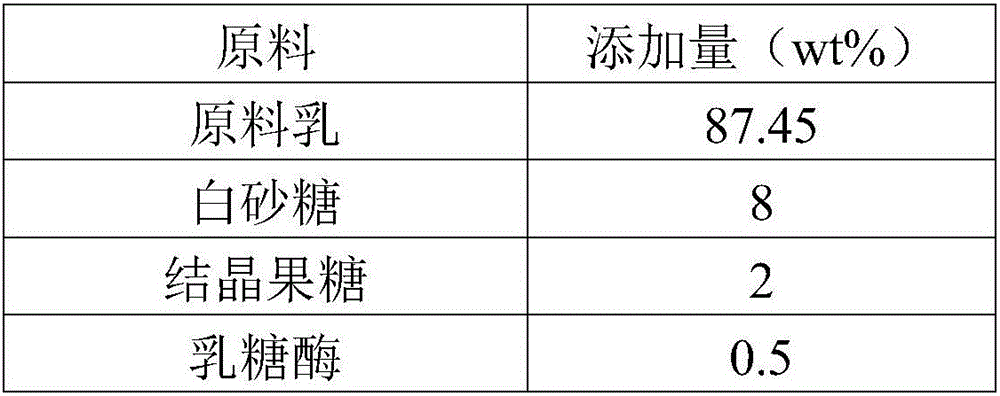

[0070] Raw material formula:

[0071]

[0072]

[0073] Preparation:

[0074] (1) Pre-pasteurize the raw milk that has undergone centrifugal degreasing and falling film concentration (concentration temperature 50°C, concentration pressure 20000Pa, acidity 16), cool it to 40°C, and add lactase to hydrolyze it for 2 hours to obtain lactose-free milk;

[0075] (2) Mix lactose-free milk with sweetener and stabilizer at a mixing temperature of 60°C and a mixing time of 15 minutes to obtain a feed liquid;

[0076] (3) Homogenize the feed liquid, temperature at 65°C, pressure at 20MPa, sterilization at 120°C, 4S, cooling at 50°C for filling, and refrigeration at 2°C;

[0077] The present embodiment obtains the main technical index of pudding:

[0078] project content protein 6.1% Fat 0.3% calcium 160mg / 100g lactose not detected

[0079] The pudding obtained in this example has a good flavor and a delicate Q-bomb taste, and the shelf ...

Embodiment 2

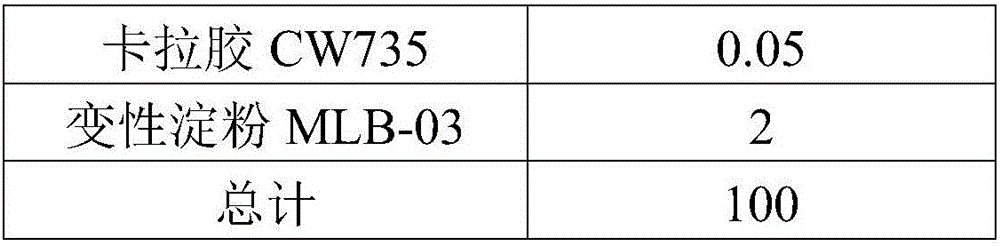

[0081] Raw material formula:

[0082]

[0083]

[0084] Preparation:

[0085] (1) Pre-pasteurize the raw milk that has undergone centrifugal degreasing and falling film concentration (concentration temperature 60°C, concentration pressure 15000Pa, acidity 18), cool it to 4°C, and add lactase to hydrolyze it for 24 hours to obtain lactose-free milk;

[0086] (2) Mix lactose-free milk with sweetener and stabilizer at a mixing temperature of 75°C and a mixing time of 15 minutes to obtain a feed liquid;

[0087] (3) Homogenize the feed liquid at a temperature of 75°C, a pressure of 20MPa, sterilize at 137°C for 2 seconds, cool at 75°C for filling, and refrigerate at 6°C;

[0088] The present embodiment obtains the main technical index of pudding:

[0089] project content protein 6.2% Fat 0.2% calcium 164mg / 100g lactose 0.4g / 100g

[0090] The pudding obtained in this example has a good flavor and a delicate Q-bomb taste, and the sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com