High-protein lactose-free milk and preparation method thereof

A high-protein, lactose-based technology, applied in dairy products, milk preparations, applications, etc., can solve problems such as easy coking, and achieve the effect of assisting blood sugar control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

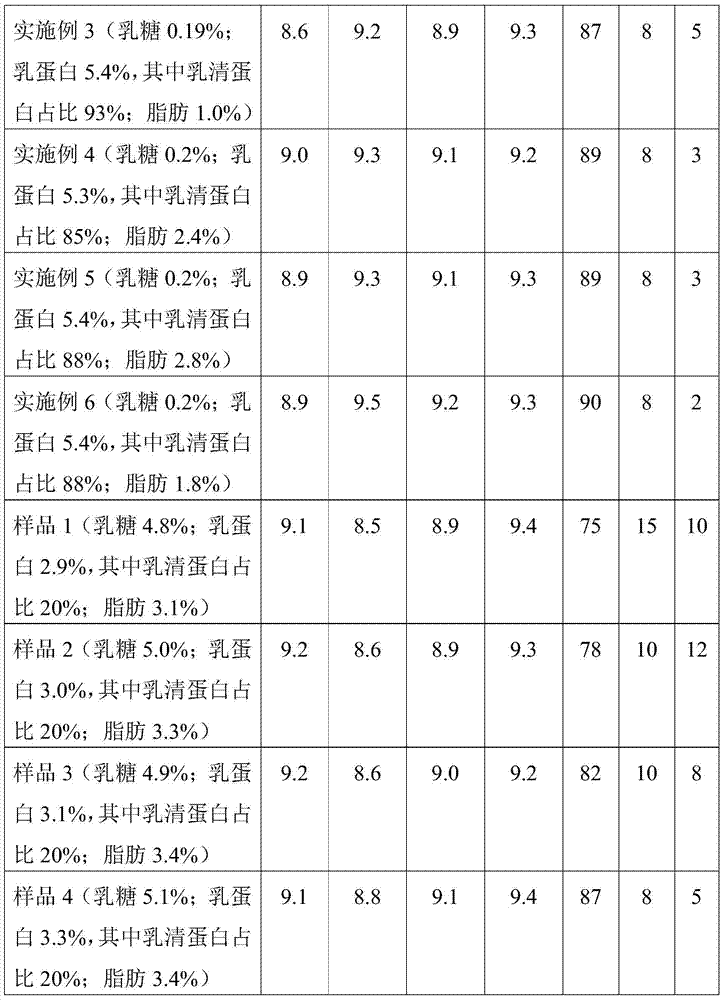

Examples

Embodiment 1

[0026] 1. Raw material formula (see Table 1):

[0027] The raw material formula of table 1 embodiment 1

[0028] raw material

[0029] 2. Preparation method:

[0030] ①Mix the concentrated milk protein, desalted and isolated whey protein and water, the mixing temperature is 45°C, and the mixing time is 10 minutes. 4m / s, the transmembrane pressure is 0.4Bar, and the feed liquid A is filtered;

[0031] ② The cream is pasteurized at 85°C for 15s to obtain feed liquid B;

[0032] ③Stir and mix feed liquid A and feed liquid B in a sterile tank at 45°C for 10 minutes;

[0033] ④55℃, 18MPa sterile homogeneous;

[0034] ⑤Cool to 2°C and fill aseptically.

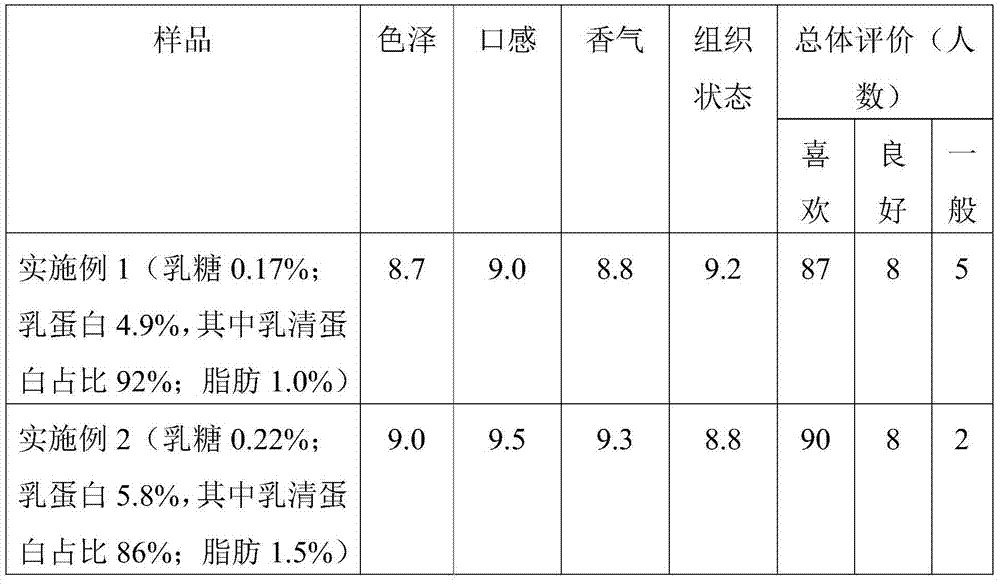

[0035] Protein, fat, lactose content index in the final product of this embodiment:

[0036] project

[0037] The protein content was determined according to the national standard GB 5009.5; the fat content was measured according to the national standard GB 5413.3; the lactose was measured according to the...

Embodiment 2

[0039] 1. Raw material formula (see Table 2):

[0040] The raw material formula of table 2 embodiment 2

[0041] raw material

technical indicators

Amount added (wt%)

concentrated milk protein

Protein content ≥ 80%, lactose content ≤ 5%

1.0

demineralized whey protein

Protein content ≥ 90%, lactose content ≤ 3%

5.5

cream

Fat: 60%

2.5

water

91.0

total

100

[0042] 2. Preparation method:

[0043] ①Mix the concentrated milk protein, desalted whey protein and water, the mixing temperature is 55°C, the time is 20min, the mixed feed liquid is left to stand for 60min and then filtered through a ceramic membrane, the membrane pore size is 1.4μm, the filtration temperature is 50°C, and the flow rate is 6m / s , the transmembrane pressure is 0.6Bar, and the feed solution A is obtained after filtration;

[0044] ② The cream is pasteurized at 85°C for 20s to obtain feed liquid ...

Embodiment 3

[0051] 1. Raw material formula (see Table 3):

[0052] The raw material formula of table 3 embodiment 3

[0053] raw material

technical indicators

Amount added (wt%)

concentrated milk protein

Protein content ≥ 80%, lactose content ≤ 5%

0.5

demineralized whey protein

Protein content ≥ 90%, lactose content ≤ 3%

5.5

cream

Fat: 40%

2.5

water

91.5

[0054] total

100

[0055] 2. Preparation method:

[0056] ①Mix the concentrated milk protein, desalted and isolated whey protein and water, the mixing temperature is 55°C, and the time is 10 minutes. The mixed feed liquid is left to stand for 40 minutes and then filtered through ceramic membrane. , the transmembrane pressure is 0.4Bar, and the feed solution A is obtained after filtration;

[0057] ② The cream is pasteurized at 85°C for 15s to obtain feed liquid B;

[0058] ③Stir and mix material liquid A and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com