Process and device for producing tetrachloro-2-cyanopyridine with liquid chromatography

A cyanopyridine and a production process technology are applied in the field of liquid-phase chlorination reaction processes and devices to achieve the effects of low energy consumption, improved safety and operability, and reduced processing load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

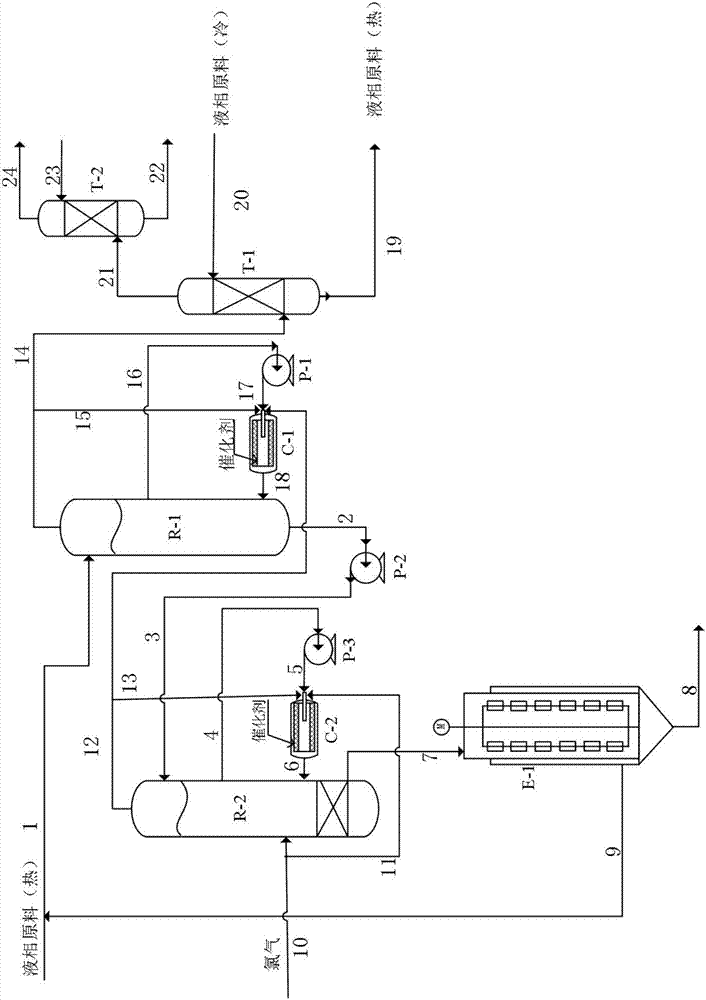

[0037] Fill 20kg of FeCl loaded with 5% (wt) in the first microbubble generator (C-1) and the second microbubble generator (C-2) respectively 3Activated carbon was used as a pre-reaction catalyst and a main reaction catalyst. After the liquid 2-cyanopyridine is preheated to 30°C, it enters the first gas-liquid enhanced reaction tower (R-1) at a rate of 125kg / h through pipeline 1 to fully mix with chlorine gas, and the gas-liquid mixture passes through pipeline 16 and the first cycle The pump (P-1) enters the first microbubble generator (C-1), and the pre-reaction is carried out in the first microbubble generator (C-1), and part of the gas phase material can also enter the first microbubble generator through the pipeline 15 The device (C-1) completes the circulation of the gas phase material. The material from the first microbubble generator (C-1) enters the first gas-liquid intensified reaction tower (R-1) through pipeline 18 and fully mixes with chlorine gas. The first gas-...

Embodiment 2

[0039] In the first microbubble generator (C-1) and the second microbubble generator (C-2), respectively fill 18 kg with 5% (wt) FeCl 3 Activated carbon was used as a pre-reaction catalyst and a main reaction catalyst. After the liquid 2-cyanopyridine is preheated to 70°C, it enters the first gas-liquid enhanced reaction tower (R-1) at a rate of 130kg / h through pipeline 1 to fully mix with chlorine gas, and the gas-liquid mixture passes through pipeline 16 and the first cycle The pump (P-1) enters the first microbubble generator (C-1), and the pre-reaction is carried out in the first microbubble generator (C-1), and part of the gas phase material can also enter the first microbubble generator through the pipeline 15 The device (C-1) completes the circulation of the gas phase material. The material from the first microbubble generator (C-1) enters the first gas-liquid intensified reaction tower (R-1) through pipeline 18 and fully mixes with chlorine gas. The first gas-liquid ...

Embodiment 3

[0041] Fill the first microbubble generator (C-1) and the second microbubble generator (C-2) with 25 kg of FeCl loaded with 5% (wt) 3 Activated carbon was used as a pre-reaction catalyst and a main reaction catalyst. After the liquid 2-cyanopyridine is preheated to 110°C, it enters the first gas-liquid enhanced reaction tower (R-1) at a rate of 130kg / h through pipeline 1 to fully mix with chlorine gas, and the gas-liquid mixture passes through pipeline 16 and the first cycle The pump (P-1) enters the first microbubble generator (C-1), and the pre-reaction is carried out in the first microbubble generator (C-1), and part of the gas phase material can also enter the first microbubble generator through the pipeline 15 The device (C-1) completes the circulation of the gas phase material. The material from the first microbubble generator (C-1) is fully mixed with chlorine gas through the first gas-liquid enhanced reaction tower (R-1) in pipeline 18. The first gas-liquid enhanced ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com